PSI Woodworking Products LCSET10 User manual

#LCSET10 PSI Woodworking Products

© 2021 PSI Woodworking Philadelphia PA 19115 - v06/21

10 pc Super Spindle Lathe Chisel Set user manual

Read instructions before using tools

WARNING:

#LCSET10 PSI Woodworking Products

General & Specic Safety Rules:

1. Keep Work Area Clean –Cluttered areas and benches invite accidents.

2. Do Not Use in a Dangerous Environment –Keep area well lit. Do not use tools in damp or wet locations or expose them to rain.

3. Keep Children Away and Make Sure Workshop is Child Proof –All visitors should be kept a safe distance from work area.

4. Use the Right Tool –Do not attempt to use a tool to do a job for which it was not designed.

5. Maintain Tools –For the best and safest performance, keep tools clean and sharp.

6. Do Not Force Tool –It will do a better and safer job in the manner for which it was designed.

7. Wear Proper Apparel –Do not wear loose clothing, ties, rings, or other jewelry than can get caught in moving parts. Wear non-slip

footwear. Tie back or cover long hair.

8. Use Safety Goggles or a Face Shield –Everyday glasses are NOT safety glasses.

9. Use a Face or Dust Mask for operations that generate particulates.

10. Do Not Over-reach –Keep balance and footing at all times.

11. Check for Damaged Parts –Before use, check for any damage and determine if it will interfere with proper use of the tool. Damaged

tools should be properly replaced.

Description Cutting Tip Page

1. 1” Skew Chisel M2 HSS 4

2. 1” Roughing Gouge M2 HSS 5

3. 3/16” Parting Tool M2 HSS 6

4. 3/4” Spindle Gauge M2 HSS 7-8

5. 5/8” Skew Chisel M2 HSS 4

6. 3/8” LCWIZ Square Cut Chisel Carbide 9

7. 3/8” LCWIZ Super Skew Carbide 9-10

8. 1/4” Mini Spindle Gouge M2 HSS 9

9. 1/4” Mini Skew Chisel M2 HSS 4

10. 1/16” x 1-1/4” Tenon Tool M2 HSS 6

1 2 345 6 7 8 9

10

2

#LCWIZ Key

#LCSET10 PSI Woodworking Products

Your lathe should be mounted on a stable surface. The height of the

centerline should be approximately even with the bend in your elbow. The

tool rest height will ideally be just a little below the lathe centerline.

The distance from the work piece and the tool rest should be just enough

that when the chisel reaches the work piece, it is supported behind the

bevel (Fig.1). This will provide good support as the chisel engages the work

piece. When the stock is reduced, the tool rest should he moved closer to

maintain chisel support. Other adjustments to the tool rest position may be

necessary for certain tools and techniques.

It is a good idea to read up on turning methods or to search for video advice online. The best advice after watching or reading about any aspect

of woodturning is to practice. The easiest and fastest way to gain experience with the chisels is to purchase cheaper lumber and practice using

different motions to see how the chisel works. This will provide practical demonstration without wasting valuable wood.

Do not try to use theses practice sessions to make specic items; they are just to get a feel for how the tool cuts into the material, learn lathe

adjustments such as tool rest position and speed, and to develop techniques for different shapes. Do not be discouraged if practice pieces get

damaged. Try to turn away the damaged section with careful cuts. Once a practice piece is too small to continue, you can always start over with a

new piece. Practice materials can include pine 2x4’s, hardwood dowels, and inexpensive plastics.

The basic hold of turning chisels is that the dominant hand is placed on

the handle while the other hand us used to guide the gouge on the tool rest.

When turning, it is important to have a solid grip on the handle and brace

it with the arm to reduce vibration from the impact of the cuts. The smaller

the work piece is the higher on the handle the hand will be for more delicate

control.

When gripping the chisels on the tool rest, the knuckles of your leading nger should be against the tool rest (Fig.1) to help maintain a steady

guide for the tool.

If learning for the rst time, try to start with smaller stock - around 1”. The smaller pieces will require ne control mostly in the hands and

forearms. Wider pieces will require more work from the arms, body, and legs. Learning from small to large allows the skills to adapt to the larger

movements needed for bigger stock.

Make note that the large the stock is, the lower the speed of the lathe should be. Bigger pieces turn with more force and higher speed on large

stock can be very dangerous.

It is safer to cut from wider spots to narrower spots. Moving a chisel from narrow areas to wider areas increases the chance of the tool catching

on the material. Also, avoid coming into the blank from the very end of the blank towards the center whenever possible to avoid catching the end

grain.

Your Lathe:

General Set Up and Usage of #LCSET10 Turning Tools

Holding Chisels - Best Practices:

Practical Learning and Practice:

Fig 1: Holding the Chisel

Keeping Chisels Sharp:

All High Speed Steel chisels in this set will require regular sharpening. A Bench Grinder(C) with an 8” wheel is recommended to maintain the

proper curve on the bevel. In addition to the Grinder, at (A) and curved (B) diamond plates will help in honing the edge of your tools in between

sharpening. A setup such as the PSI 4pc Precision Sharpening System (D), which includes accessories that are very helpful in maintaining the

correct angles on your tools as well as a Fingernail Jig that is indispensable for maintaining the ngernail grind on spindle gouges.

3

A

C

B

D

#LCSET10 PSI Woodworking Products

Skew Chisels –Set includes 1”, 5/8”, and 1/4”

The Skew chisel is one of the most versatile chisels in the wood turner’s arsenal. Unlike gouges, the skew is beveled on

both the top and the bottom of the edge. Notice that the edge of the skew is on an angle to the shaft. Therefore there are

two different points on either side of the edge. The longer point is called the “toe” and the shorter point is called the “heel”.

Skews can do tasks from planing surfaces smooth to cutting angled grooves and ne lines –it can even do curves. Larger

sizes can handle thick spindles and small, thin sizes can be used to add extremely ne details in tight areas. The skew is

one of the hardest tools to learn how to use fully, so it is very important to practice with this tool. Below are the two basic

cuts which will establish skills needed for more advanced techniques.

Using the Skew for a Planing Cut:

This is the basic cut for the skew chisel. It is used to smooth and even out the turning surface after the blank has been

reduced close to its nal shape. The sharp edge slices along the work piece reducing any raised ridges to match the sur-

rounding surface. When done correctly, can leave a surface that does not necessarily need to be sanded.

To plane, the bevel follows the edge riding along the cut surface (Fig. 2). The skew is presented to the work piece at an

approximately 25° angle (Fig. 3). Notice that the toe will be above the material and pointing away from the turner. When

performing a planing cut, it is extremely important that the toe does not touch the turning surface as it will cause a signi-

cant catch. All cutting is done from the middle of the edge down to the heel.

The primary goal is to keep the tool alignment steady and the cut light. The angle is maintained on the handle end and

the hand holding the shaft should help maintain a light touch and to prevent the tool from twisting, which might allow the

toe to catch on the surface. Do not try to force the edge into the surface; simply allow it to cut a small amount of material.

Repeat the pass until the surface is smooth.

Using Skew for Grooves:

This cut uses the toe to cut a v-groove into the material. This will

require practice as the toe cuts are more aggressive. It is important to

maintain a steady hand to keep the tool at the right angle during the

approach and during the cut. Performing this will utilize some of the

skills learned from using the gouges and parting tools. Learning this

cut will open up the potential to do more advanced techniques.

The basic v-groove is done by lining up the toe and the edge in ex-

actly the angle desired for one side of the groove. The toe starts above

the material and the handle is raised up and away from the cut so the

toe slides straight into the stock at the correct angle (Fig. 4). The skew

is then ipped over to the other side of the groove and the toe will

make the exact opposite cut until it meets the end of the previous cut

in the center of the groove. Practice until the cuts match up consis-

tently without needing to even up afterwards.

Fig 2: Planing Cut –top view

Fig 4: Cutting a v-groove

Fig 3: Planing Cut –front view. Note toe is above surface

Direction of cut

4

#LCSET10 PSI Woodworking Products

The Roughing Gouge is one of the primary tools for woodturning. Its main purpose is to remove stock quickly until the surface is a relative even

diameter. The Roughing Gouge can do some decent nal shaping as well with proper handling. The basics of turning, such as stance and chisel

control are easiest to learn with the roughing gouge. Note that Roughing gouges are different from other spindle gouges. The tip is usually at

across, the curve of the gouge is u-shaped, and the thickness will be uniform around the ute.

WARNING: Using a Roughing Gouge for Side Grain Turning can result in a broken gouge and serious injury to the turner. Only use

for between center spindle turning. Under no circumstance should the Roughing Gouge be used for Bowl Turning or any cuts where

the gouge will be cutting into the end grain.

Roughing Gouge –Set includes 7/8”

Using the Roughing Gouge:

The basic hold of the gouge will have the ute facing up while the

bottom of the gouge sits on the tool rest. When roughing, it is impor-

tant to have a solid grip on the handle and brace it with the arm to

reduce vibration from the impact of un-rounded stock.

The best approach is to allow the least amount of resistance when

cutting the wood. The edge should be in line with the surface you are

turning, and to do this you want to “ride the bevel”. This means the

bevel should have as much contact with the material as possible. With

this method, the edge is only deep enough to make small cuts and the

bevel is resting along the freshly cut surface. This helps support and

steady the edge and provides the least amount of drag as the material

is cut.

Before the rst cut, the gouge should be placed on the tool rest with

handle low and the edge pointing above the spindle - the stock should

not be in contact with the tool. To begin the cut, slowly raise the butt

end of the handle to pivot the edge down towards the center of the

stock. The stock will rst start to hit the heel of the bevel (Fig. 5) and

then the edge as the handle continues to rise. Raising the handle like

this is how you can adjust the depth and aggressiveness of the cut.

It also helps make sure the bevel remains in contact with the surface

(Fig. 6).

Start with light cuts, moving along the stock to make the surface

even (Fig. 7). Rapid sideways movement will cause ridges, slower

movement will allow a more even surface. Continue to raise the

handle to increase the depth of the cut as the stock is reduced to

round. It may be necessary to move the tool rest closer to the material

as the diameter is reduced to aid in supporting the tool.

As the stock becomes round, you will be able to feel the difference in

vibration as the tool transitions from rounded to uncut stock. Stop the

lathe to check how close to fully rounded the stock is. You may wish to

gently touch the top of the stock to feel for any remaining at sections.

It is important not to touch anywhere that is near the tool rest when

the stock is spinning; it can lead to injury.

Once stock is ready, you can may general shapes quickly with the

roughing gouge. With some practice, many work pieces can come

close to nal shape using the roughing gouge only.

Fig 5: Initial contact with the heel of the bevel

Fig 7: Reducing to round

Fig 6: Bevel remains in contact with cut material

5

#LCSET10 PSI Woodworking Products

Using the 3/16” Parting Tool:

Parting Tools

Parting and Tenon Tools are similar types of chisel. The difference between the parting and the tenon tools is the width of

the cutting surface and the leverage for the cut. Parting tools are generally wider and so will cover longer sections quickly.

The Tenon tool excels at making narrow, scraping cuts such as the narrow tenons on pen kits. The Tenon Tool can also be

used to cut deep, straight grooves, such as those on a honey dipper.

They are also used to part off support pieces when they are no longer needed. Another handy use is reducing the edges

of sections to be turned or to reduce small sections next to beads or bevels prior to cutting those shapes -clearing space

for the cuts.

The primary cutting edge of the Parting tool is the narrow side. The tool

is held so the wide edge is perpendicular to the oor.

To make a shear cut, the parting tool is held with the handle low and

the point above the center line over the surface of the stock. To begin

the cut, the handle is raised, which lowers the edge into the stock and

controls the depth of the cut (Fig. 8). To reduce friction, a slight twisting

of the handle will help to widen the sides of the cut.

Long sections can be made moving the tool halfway to the side, so it

overlaps the cut and the uncut sections and making additional cuts to

the same depth (Fig. 9).

To part off the supporting sections a work piece, use the parting tool

to narrow the connection point. All sanding and polishing should be

nished before the nal separation cut. Be sure to lightly hold the work

piece so that it does not fall and get damaged once the support piece is

removed.

Using the 1/16” x 1-1/4”Tenon Tool:

The narrow cutting surface and large blade depth of the

tenon tool helps to make clean straight corner cuts. The tenon

tool will work better with a scraping cut. To do a scraping

cut, the edge will be below the centerline and the handle will

be angled up (Fig. 11). Cut is made raising the edge into the

stock.

The wideness of the at helps in creating leverage and

ne control during the cut.

The scraping cut will create a cleaner edge than one

made above the centerline (Fig11).

Fig8: Single cut

Fig 9: Overlapping cuts for long sections

Fig 10: Scraping cut below centerline

Fig 11

Cut below centerline

Cut above centerline

6

#LCSET10 PSI Woodworking Products

Spindle Gouges are meant to do ne shaping. They can do Beads and Coves, as well as straight cuts and gradual sloping. The tip

shape is referred to as a ngernail grind and the bevels that sweep back from the tip are referred to as “wings”. The ngernail tip al-

lows for a more focused cut than the roughing gouge allowing dynamic control of shapes through the position of the ute and handle.

The two sizes of Spindle gouges included with the set will perform the same type of cuts. However, there will be a difference in the

size of the shapes than can be made. The 1/4” gouge will be capable of making smaller coves and beads with a tight radius, while the

3/4” will create larger shapes.

Spindle Gouge –Set includes 3/4” and 1/4”

Using Spindle Gouges:

The main advantage of a spindle gouge is in making curved patterns. The ngernail prole brings an added dimension to chisel posi-

tion. With the at tip of the roughing gouge, the handle can be rotated without changing the cutting edge. The ngernail grind on the

spindle gouges, however, means that twisting the handle will alter the cut.

A bead is a reasonably easy shape to make with the spindle gouge. Using the following technique, the bead will practi-

cally cut itself.

Initially the ute will face upwards at the center of where the bead will be (Fig. 12). To form the bead, you will rotate the

handle so the gouge rolls towards the edge of the bead while increasing pressure (Fig. 13). You can also swing the back

end of handle out so that it angles away from the center.

Once the bead has been cut to one edge, re-center the gouge and perform the opposite action towards the other edge of

the bead (Fig. 14). You can alter the depth and the curve by changing the angle of the handle and the rate of handle rotation

in addition to how quickly you move along the work piece. Repeat on each side to deepen and rene the curve (Fig15).

Cutting a Bead:

Fig 12: Start cut with ute facing up Fig 13: Twist tool so ute rolls towards the cut

Fig 14: Do the same action in the opposite direction Fig 15: Repeat and rene

7

#LCSET10 PSI Woodworking Products

A cove is a rounded groove, and it is the opposite of a bead. Coves therefore require almost the opposite motions. It may

help to imagine scooping ice cream using the side of the scoop. Try to do shallow coves to start; you want to avoid having

the end of the wings catch on the material. Again, marking the center and edges of the cove will help.

Initially, the gouge will be held with the ute facing towards where the center of the cove will be. Start cutting at the de-

sired edge of the cove (Fig. 16). While increasing pressure, twist the handle so the ute starts to rotate upwards and move

the tip towards the center of the cove (Fig. 17). There will be slight resistance as the tool rotating away from the center

while you are moving towards it.

Once the ute is facing directly upwards, reverse the ute direction and repeat the scoop from the opposite edge of the

cove (Fig. 18). Join and smooth the two curves at the center with the ute facing up (Fig. 19). You can alter the depth and

the curve of the cove by changing the angle of the handle and the rate of handle rotation in addition to how quickly you

move the tip along the work piece.

Cutting a Cove:

Fig 16: Start with ute facing center of intended cove Fig 17: Make cut with a sideways scooping action

Fig 18: Make a second cut from the other side Fig 19: Both cuts meet in the middle with ute facing up

Spindle Gouge (continued)

8

#LCSET10 PSI Woodworking Products

Carbide Tools

Carbide tools offer an advantage over traditional high speed steel tools in that a carbide will last several times longer than

a steel edge. The replaceable blades have several faces so that as one edge gets dull, the blade can be loosened using the

included star key and rotated to present a fresh edge. When turning materials such as TruStone, a carbide tool is essential

to resist dulling from the stone content in the material.

The 3/8” #LCWIZ Square Cutter:

The Square Scraper is used for making roughing and shaping cuts. The blade has a 2”radius edge so that light cuts can

be made away from the corners of the blade. As a scraper, the tool is presented at or below the centerline of the work

piece. Generally, the tool is held parallel to the oor and the depth is controlled by moving the tool. It is important to make

light cuts with this tool.

With all carbide blades, remember that the blade is very

sharp and will stay sharp for a considerable length of time.

This will make it more aggressive and can cause it to be too

aggressive with certain delicate materials such as Acryles-

ter. Too much pressure on delicate material can cause

vibration and blowout. This aggression can be minimized

by angling the tool downward so that the blade is below the

center line and the handle is pointing up (Fig. 20).

This creates a negative rake, reducing the stress on the

material and helping to reduce tearing and chipping of the

material surface.

The #LCWIZ Super Skew:

The Super Skew is meant to shine as a shearing tool

similar to the HSS Skew with the handle designed to hold

the blade at an angle (Fig. 21). It promotes using the blade

to slices the material rather than scraping which results in

a cleaner and smoother cut.

The tool can sit on the tool rest on either of the angled

sides to make passes in each direction. The Super Skew is

presented to the material either along the tip edge or at the

lower corner and side for roughing.

The handle should be pointing out from the lathe, close to

90°. Make light passes to take down the corners, always

move towards the cutting direction. Deeper passes can be

used as the material becomes round (Fig. 22).

A deep cut using the tip and side is very effective in rapid

material removal but can also be very aggressive. Avoid

allowing the top corner to contact the material (similar to

regular skew). This cut can also be used lightly to do small,

smooth cuts on highly brittle material because the smaller

surface area will help reduce resistance. Increasing lathe

speed and slower movement of the tool will also help limit

catches and chips.

Fig 20: Holding #LCWIZ Square Cutter below

center to create negative rake angle

Fig 22: Top of Super Skew facing into the cut

Fig 21: #LCWiZ Super Skew’s shape

provides a stable shearing angle

9

#LCSET10 PSI Woodworking Products

© 2021 PSI Woodworking Philadelphia PA 19115 - v06/21

Planing Cut with the Super Skew:

The shaft sits on the tool rest on one of the angled sides. The top of the blade should face towards the direction of the

cut with handle angled away from it (Fig. 23). Skim along the surface with the edge touching the wood and the tip of the

tool holder lifted slightly away (Fig. 24). As you make your pass, you should see the material coming off in thin ribbons or

threads.

The Super Skew can also be used to make grooves in a similar manner to the HSS Skew. By turning the Super Skew to

the side so the blade is vertical, thin lines can be cut with the corner.

Fig 23: Top of blade towards direction of cut Fig 24: Holder tip slightly away from surface

#LCWIZ Super Skew (continued):

10

WARRANTY

This chisel set is engineered and manufactured to the highest standards of quality. You will nd this product an essential acces-

sory to your workshop. This chisel set is warranted against defects in material and workmanship for a period of two years for all

components. This warranty applies to the original purchaser of the product and is limited to the repair and/or replacement of the

product, or its parts at the discretion of PSI Woodworking Products. Excluded are use of the tools for purposes other than wood

turning or use with materials other than those appropriate for turning on a wood lathe. Also excluded are direct or consequential

damages to persons, properties, or materials. Your invoice serves as proof of purchase and must be referenced to authorize any

warranty repair.

Call your PSI dealer for proper authorization.

Table of contents

Other PSI Woodworking Products Tools manuals

Popular Tools manuals by other brands

Würth

Würth FP 12-A Translation of the original operating instructions

Alemlube

Alemlube 600A Owner technical manual

SW-Stahl

SW-Stahl 10587L instruction manual

Woodstar

Woodstar bs 52 Series Original instruction manual

TKR Group

TKR Group 83 30 5 A40 812 Translation of the original manual

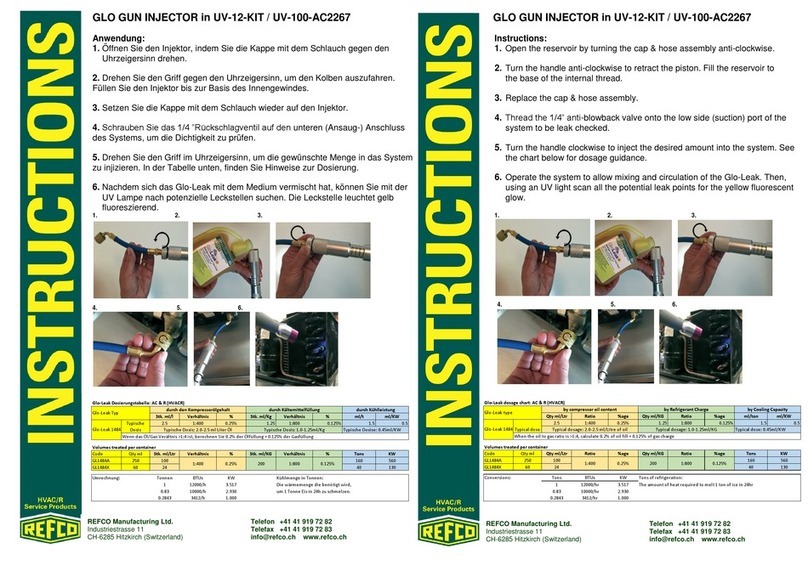

Refco

Refco UV-12-KIT instructions

Jobsite

Jobsite CT4343 Original instructions

claber

claber Rotoroll EVOLUTION 20 instructions

Rothenberger Industrial

Rothenberger Industrial 072990E Instructions for use

SKF

SKF Lincoln PowerLuber B Series Installation and maintenance guide

Kreg

Kreg Jig NK7520 Assembly And Instructions

Benchmark

Benchmark 1280-002 manual