Time TH170 User manual

INTEGRATED HARDNESS TESTER

TH170

Instruction Manual

TIME Group Inc.

CONTENTS

1 Introduction…………………………………………………………..…………… 1

1.1 Features……………………………………………….………….……..…..…… 1

1.2 Main application and testing range…………………………….…..………..… 1

1.3 Specification..……………………………………………….……….………...… 2

1.4 Working condition……………………………………………….….…...……… 3

2Structure feature & testing principle………………………..….….……………. 4

2.1 Structure feature…………………………………………………..……..…...… 4

2.2 Testing principle……………………………………………………..…..……… 5

3 Specialties…………………..………………….……………….……..…………… 5

3.1 Specifications………………………………………………….…….……..….… 6

3.2 Dimension and weight……………………………………………..…………..…7

4 Using……………………..………………………………….………..……………. 7

4.1 Preparation before using…………………………………………..…………… 7

4.2 Testing…………………………………………………………………..…..…… 8

5 Special prompt……………………...…………………….……………..……...… 9

6Operation explain in details………………………………….….……..………… 9

6.1 Switch on…………………………………………….………….……..…....…… 9

6.2 Measuring operation……………………………………………..……….…… 10

6.3 Key-press operation……………………………………………….………...… 10

6.4 Switch off……………………………………………….……………...….…… 10

6.5 Menu structure…………………………………………...……..……..……… 10

6.6 Common function………………………………………………..……..……… 12

6.7 Memory manager………………………………………………..……..……… 13

6.8 Test setting…………………………………………………………..…….....… 14

6.9 System setting……………………………………………………………….…. 17

6.10 Software……………………………………………………………..…………18

6.11 Software calibration……………………………………….………..…………18

6.12 Battery replacement…………………………………….….……….…………19

6.13 Backlight………………………………………………………..….…………..20

6.14 Auto Power Off…………………………………………………….………….20

6.15 Connection of data transmission cable……………….………………………20

7Maintenance and repair…………………………….…………………………… 20

7.1 Impact device………………………………………….……………..………… 20

7.2 Repair………………………………………………………....………...……… 20

8Inspection periods………………...…………………..……….………………… 20

9Notice for uses……………………...……………………………..….…..…….… 20

10 Notice of transportation and storage………………………..……………………21

1 Introduction

1.1 Features

zLCD display 128×32 dot matrix;

zUSB communication interface;

zImpact direction automatically identifying;

zMemory 270 average data in 9 files ;

zUpper and lower limit pre-setting;

zBattery capacity display and power off automatically lack of voltage;

zBacklight for convenient use in darkness;

zSoftware calibration;

zAAA 1.5V(7#)battery 2 pc;

zComputer software available.

1.2 Main application and testing range

1.2.1 Main application

zThe installed machinery and permanently assembled parts;

zDie cavity of moulds;

zHeavy and large work piece;

zFailure analysis of pressure vessel, steam turboset and other equipment;

zNarrow space workpiece;

zAxletree and other spare parts;

zMaterial identification of the metal material warehouse;

zQuick inspection for large workpiece;

zOthers.

1.2.2 Testing range

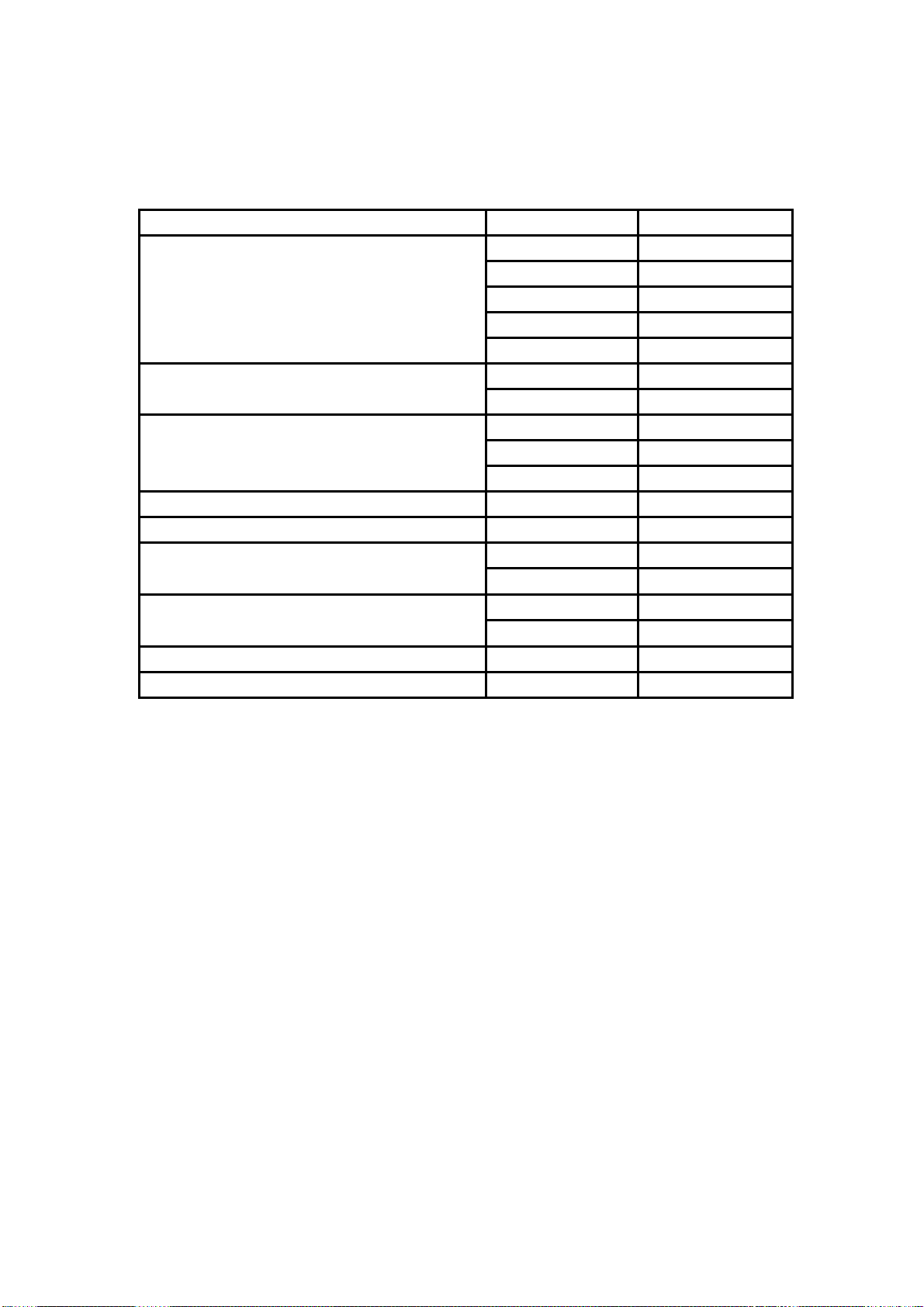

See table 1.

Table 1

Material Hardness scale Application range

HRC 20.0~68.4

HRB 38.4~99.8

HB 81~654

HV 81~955

Steel and Cast Steel

HS 32.5~99.5

HRC 20.4~67.1

Cold Work Tool Steel HV 80~898

HRB 46.5~101.7

HB 85~655

Stainless Steel

HV 85~802

Grey Cast Iron HB 93~334

Nodular Cast Iron HB 131~387

HB 19~164

Cast Aluminum Alloys HRB 23.8~84.6

HB 40~173

Copper-Zinc Alloys HRB 13.5~95.3

Copper-Aluminum Alloys HB 60~290

Wrought Copper HB 45~315

1.3 Specification

1.3.1 Standard delivery

TH170 Main Unit 1

AAA 1.5V(7#) battery 2

Smallsupportingring 1

Cleaning brush 1

Hardness test block(760±30HLD)1

USB communication cable 1

Drivingdiskforcomputer 1

1.3.2 Optional parts

DataView for TH170;

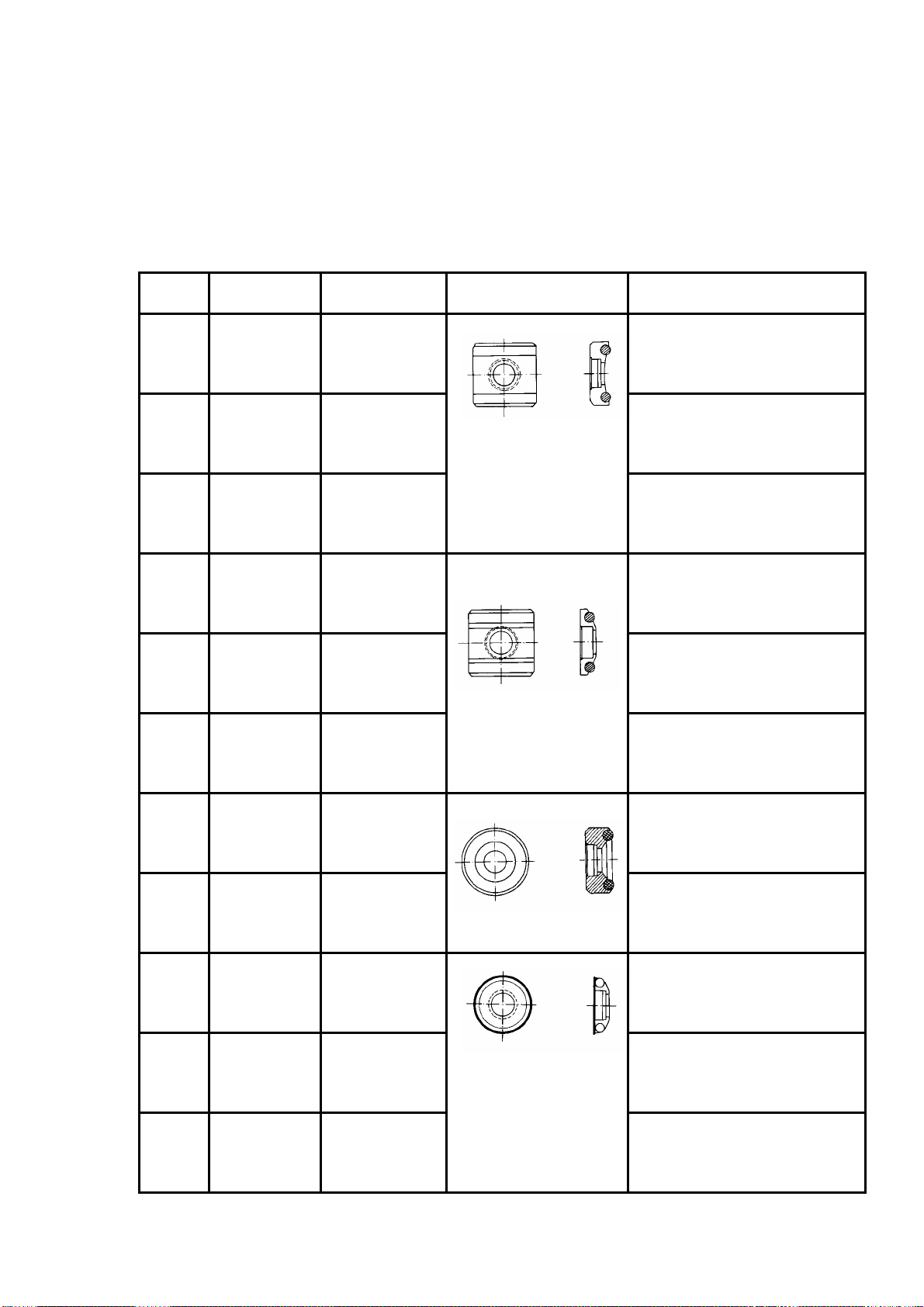

Supporting rings,see table 2.

Table 2

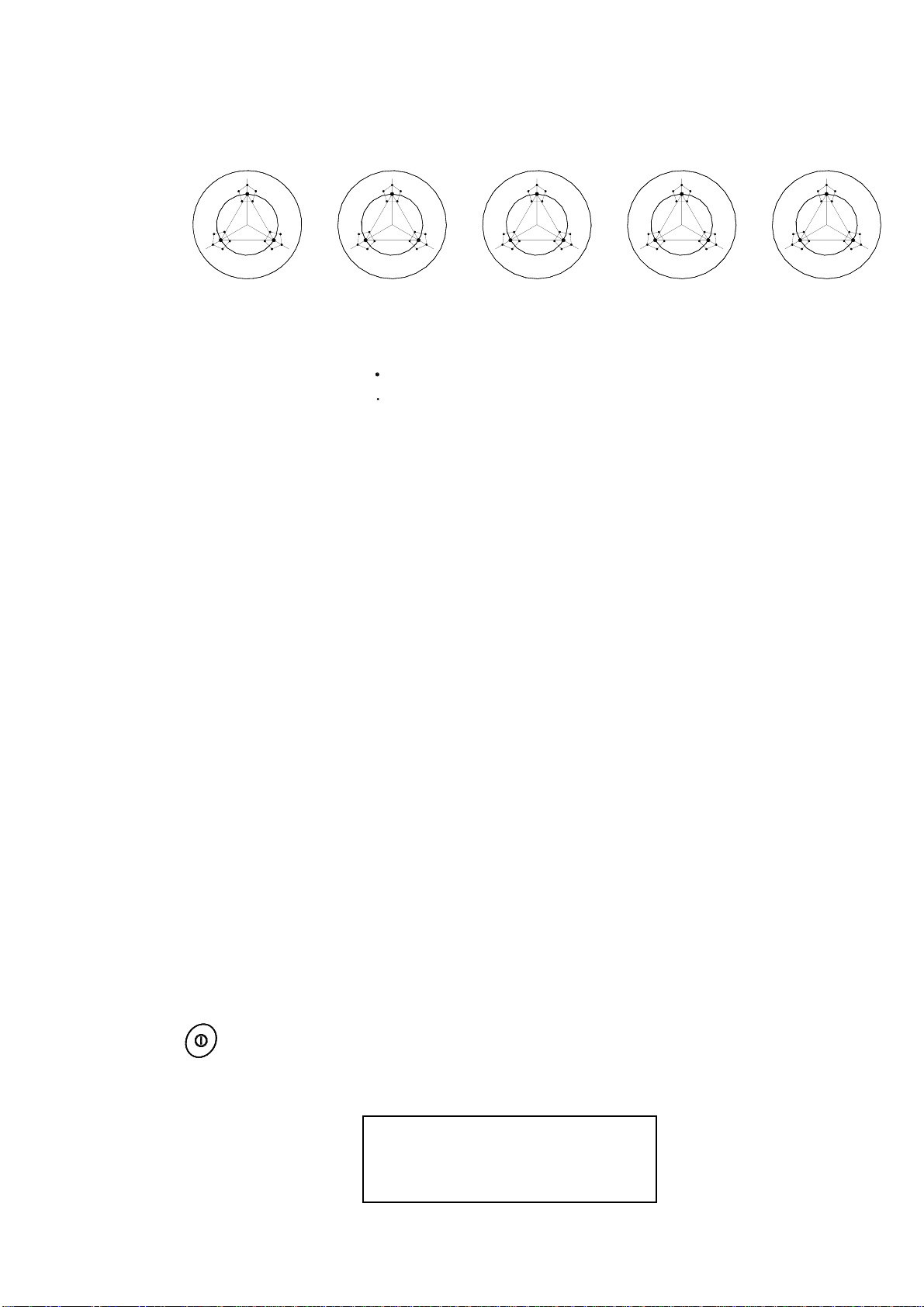

No. Code Model Sketch Remarks

1 03-03.7 Z10-15 For testing cylindrical outside

surface R10-R15

2 03-03.8 Z14.5-30 For testing cylindrical outside

surface R14.5-R30

3 03-03.9 Z25-50

For testing cylindrical outside

surface R25-R50

4 03-03.10 HZ11-13 For testing cylindrical inside

surface R11-R13

5 03-03.11 HZ12.5-17 For testing cylindrical inside

surface R12.5-R17

6 03-03.12 HZ16.5-30

For testing cylindrical inside

surface R16.5-R30

7 03-03.13 K10-15

For testing spherical outside

surface SR10-SR15

8 03-03.14 K14.5-30

For testing spherical outside

surface SR14.5-SR30

9 03-03.15 HK11-13 For testing spherical inside

surface SR11-SR13

10 03-03.16 HK12.5-17 For testing spherical inside

surface SR12.5-SR17

11 03-03.17 HK16.5-30

For testing spherical inside

surface SR16.5-SR30

12

03-03.18 UN

For testing cylindrical outside

Surface , radius adjustable

R10~∞

1.4 Working condition

Environmental temperature:0℃~40℃;

Relative humidity: ≤90 %;

The surrounding environment should be no vibration, strong magnetic field, corrosive

medium and heavy dust.

2 Structure feature & testing principle

2.1 Structure feature

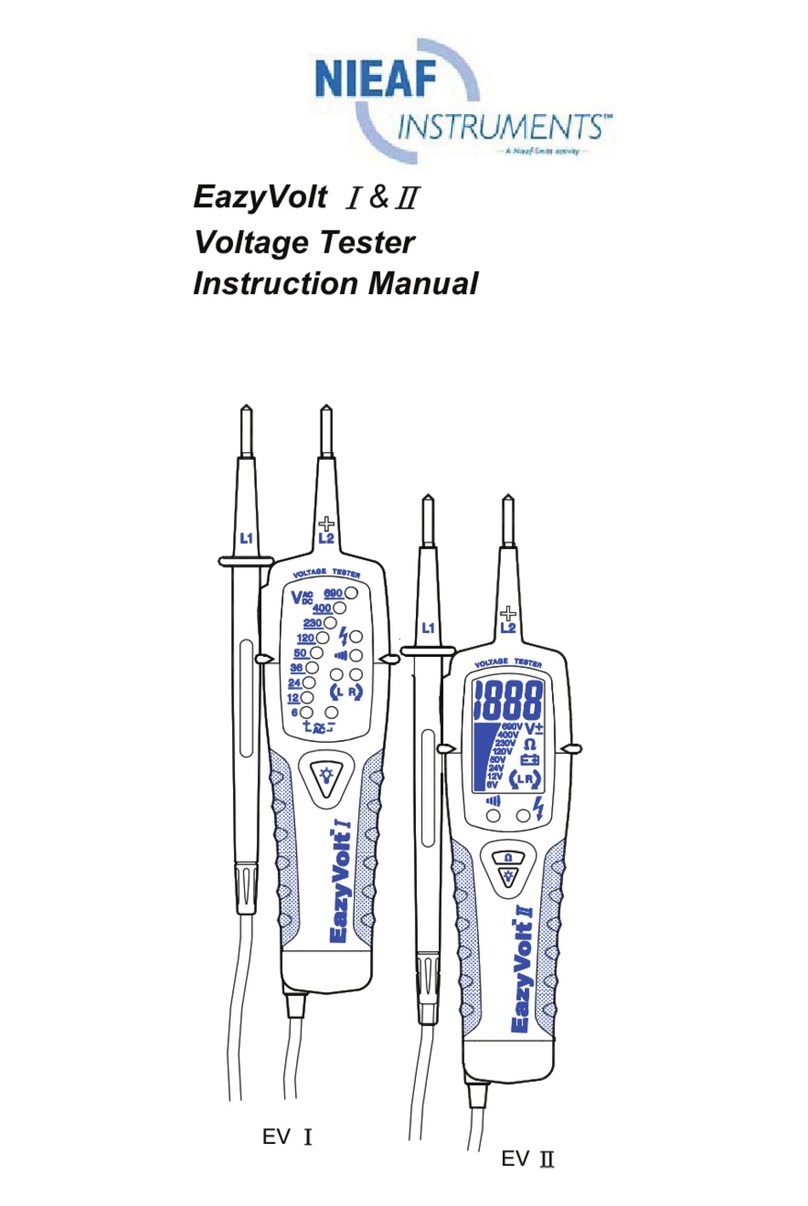

Structure feature see figure 1.

TIME Group Inc.

Hardness Tester TH170

MODLE

HARDNESS TESTER

BATTERY

GROUP INC.

AAA 1.5V X 2

TH170

USB

HARDNESS TESTER

TH170MODLE

BATTERY

AAA 1.5V X 2

GROUP INC.

Figure 1

2.2 Working principle

The basic principle is: The impact object of certain weight pounds at the testing surface under

certain test force. Measure the impacting velocity and the rebounding velocity of the impact object

respectively when it is 1mm above the testing surface. The calculation formula is as followed:

HL=1000×VB/ VA

Where, HL--Leeb hardness value

VB-- Rebounding velocity of the impact object

VA --Impacting velocity of the impact object

3 Specialties

3.1 Specifications

3.1.1Impact Device:D;

3.1.2 Features of Impact Device and testing demand see table 3,indentation dimension of test tip

see table 4;

Table 3

Parameter Value

Impact energy 11mJ

Impact object weight 5.5g

Hardness of test tip ≥1600HV

Diameter of test tip 3mm

Material of test tip Tungsten Carbide

Max. hardness of workpiece 940HV

Roughness of workpiece Ra ≤1.6μm

Min. weight of workpiece

Test directly >5kg

Need stable support 2~5kg

Need couplant 0.05~2kg

Min thickness of workpiece

Test directly >5mm

Need couplant ≤5mm

Min. depth of harden surface 0.8mm

Table 4

Hardness

(HV)

Parameter Value(mm)

Indentation diameter 0.54

300 Indentation depth 0.024

Indentation diameter 0.54

600 Indentation depth 0.017

Indentation diameter 0.35

800 Indentation depth 0.010

3.1.3 Accuracy and repeatability of displayed value see table 5.

Table 5

Hardness value of Leeb

standard test block

Error of

displayed value

Repeatability of

displayed value

760±30HLD ±6 HLD 10 HLD

530±40HLD ±10 HLD 10 HLD

3.1.4 Measuring range:170~960HLD;

3.1.5 Measuring direction:360°;

3.1.6 Scales:HL、HB、HRB、HRC、HV、HS;

3.1.7 Display:128×32 dot matrix LCD;

3.1.8 Data memory:270 average data in 9 files;

3.1.9 Upper and lower limit setting:same to measuring range;

3.1.10 Power:AAA(7#)1.5V 2pc;

3.1.11 Continual working time :about 150 hours(without backlight);

3.1.12 Communication interface:USB2.0.

3.2 Dimension and weight

3.2.1 Dimension:155mm×55mm×25mm

3.2.2 Weight: about 166g.

4 Using

4.1 Preparation before using

4.1.1Preparation for sample surface

Preparation for sample surface should conform to the relative requirement in figure 3.

●In the preparation process for sample surface, the hardness effect of being heated or cold

processing on the surface of sample should be avoided;

●Too big roughness of the measured surface could cause measure error. So, the measured surface

must be metallic luster, smoothing and polish, without oil stain;

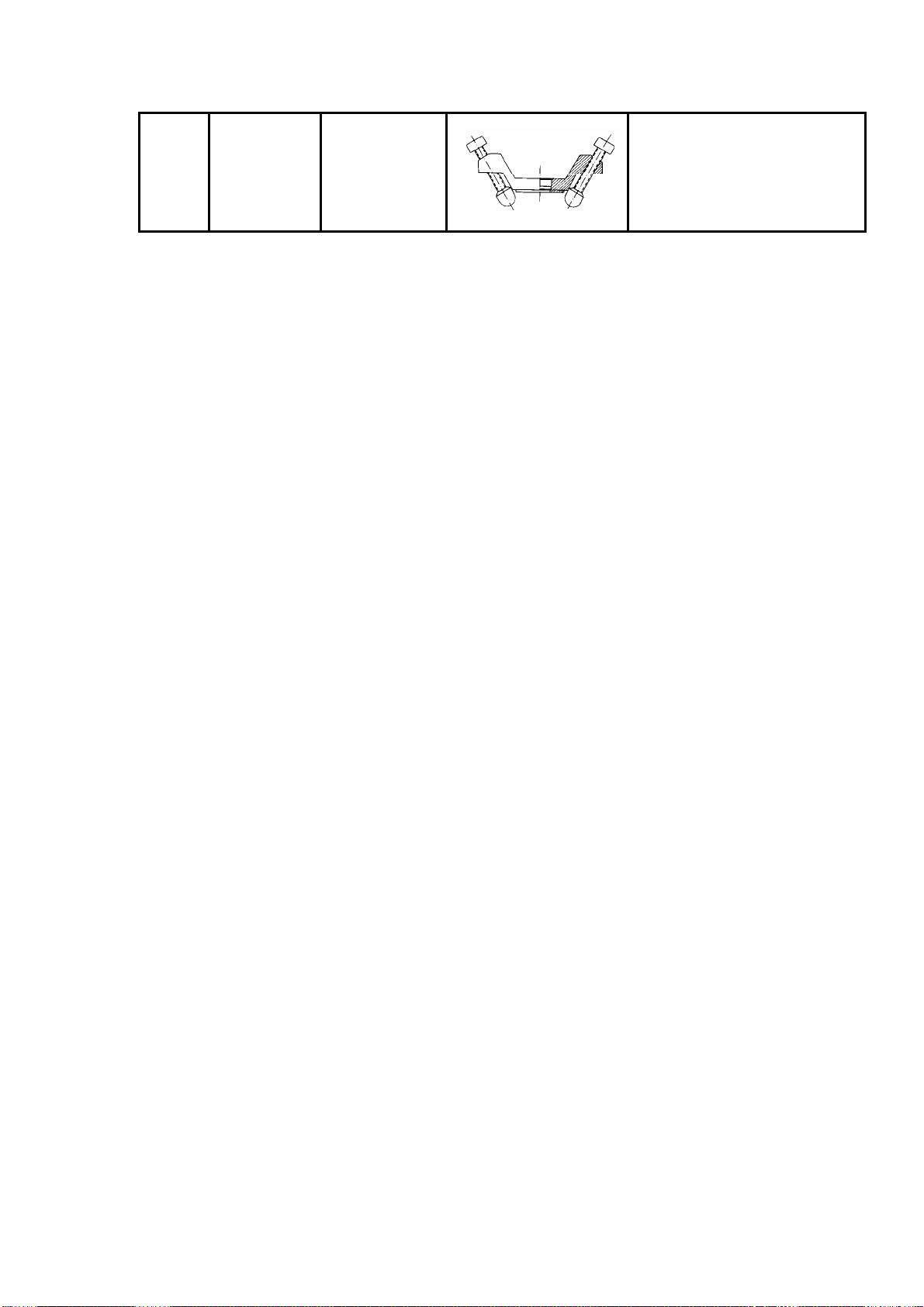

●Curved surface: The best testing surface of sample is flat. When the curvature radius R of the

surface to be tested is smaller than 30mm,the small support ring or the shaped support rings

should be chosen, see figure 2.

Figure 2

●Support of test sample

Support is not necessary for heavy sample.

Medium-weight parts must be set on the smoothing and stable plane. The sample must set

absolutely equability and without any wobble.

●The sample should have enough thickness, minimum thickness of sample should conform to

table 3.

●For the sample with hardened layer on surface, the depth of hardened layer should conform to

table 3.

●Coupling

Light-weight sample must be firmly coupled with a heavy base plate. Both coupled surfaces must

be flat and smooth. And there should be no redundant coupling agent exists. The impact direction

must be vertical to the coupled surface.

●When the sample is a big plate, long rod or bending piece, it can be deformed and become

unstable, even though its weight and thickness is big enough, and accordingly, the test value may

not be accurate. So should be reinforced or supported at its back.

●Magnetism of the sample itself should be avoided.

4.1.2 Preset test parameters

See 6.8.

4.2 Testing

zThe instrument can be calibrated with standard test block, the accuracy and repeatability

displayed should be within the regulation of table 5.

4.2.1 Loading

zPut the supporting ring onto the surface of workpiece,hold the concave area by left

hand,and press down the body by right hand while holding the loading key;

zImpact direction should be vertical to tested surface.

4.2.2 Testing

zPress release button at top of the main unit to test. The sample and the main unit as well

as the operator are all required being stable;

zUsually, test 5 times on each measure area of sample. The data dispersion should not be

more than mean value±15HL;

zThe distance between any two indentations or from the center of any indentation to the

edge of tested sample should conform to the regulation of table 6;

Table 6

Distance between any two indentations

(mm)Indentation to the edge of tested sample

(mm)

≥3 ≥5

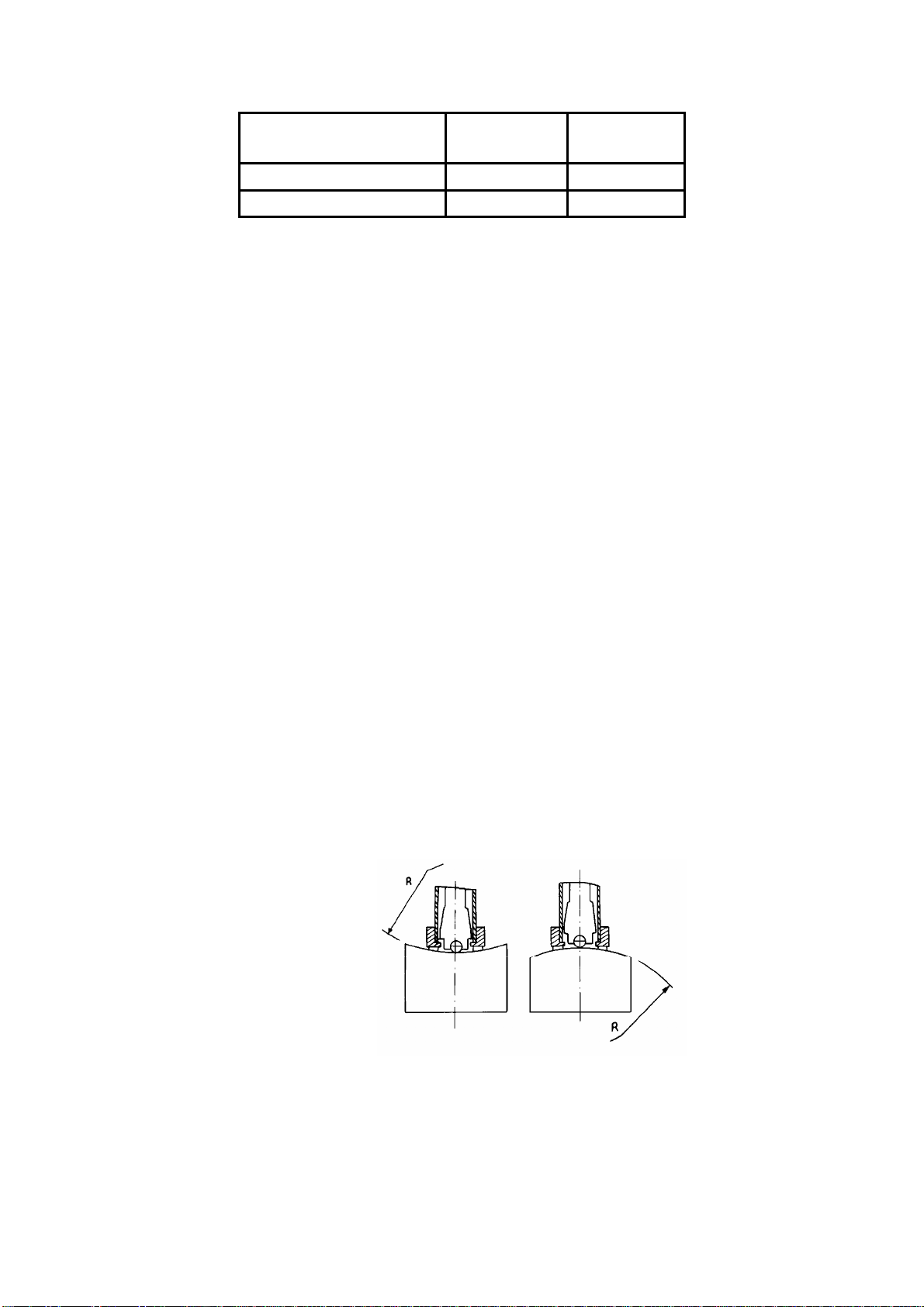

zFor special material, if accurate conversion from the Leeb hardness into other

hardness method is wanted, contrastive test must be done to get conversion relations. Use

inspected qualified Leeb hardness tester and corresponding other hardness tester to test at

same sample respectively. For each hardness value, measure 5 Leeb hardness values. using

Leeb hardness arithmetic average value and corresponding hardness method average value

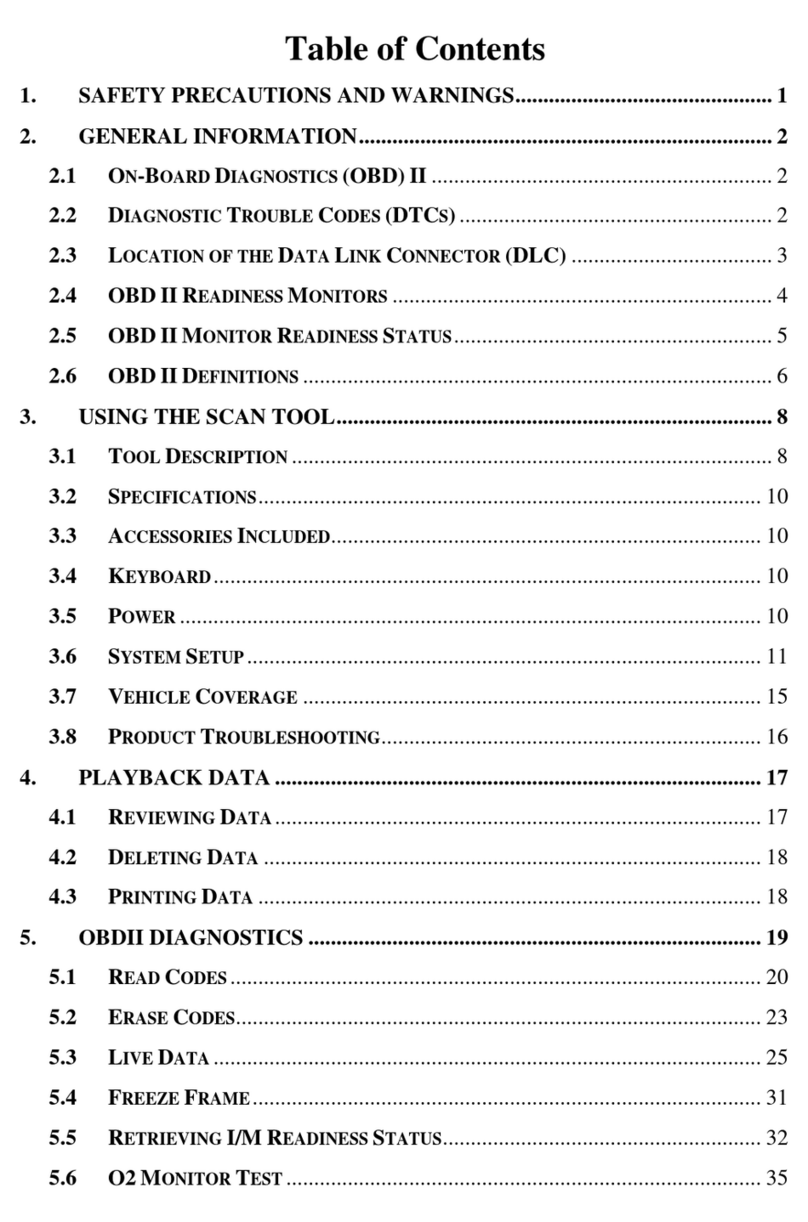

as correlative value to make individual hardness contrastive curve,see figure 3.

A1 A2 A3 A4 A5

A1-A5: Hardness samples

“ ”: Impress of hardness scales to be converted

“ ”: Impress of HL hardness scales

Figure 3

4.2.3 Testing result

zIn front of Leeb hardness symbol HL, expresses the hardness value; behind HL

expresses type of impact device. For example: 700HLD expresses using D type of impact device

measured Leeb hardness value is 700;

zFor other hardness method converted from Leeb hardness, put the symbol of

corresponding hardness method in front of Leeb hardness symbol. For example: 400HVHLD

expresses using D type of impact device measured Leeb hardness value converted Vickers

hardness value is 400.

5 Special prompt

zIn normal condition, it could not memory present testing value while not reaching

impact times which has been set. If want to memory, press 【Cal. Average】at the main display

interface to end the testing in advance and then memory;

zWhen using the function of 【Cal. Average】to end the testing in advance, the function

of 【Auto Save】、【Auto Trans.】etc. will not work;

zNot all hardness methods can be converted to each other for all materials(See table 1).

The setting of hardness scale will recover to HL automatically after material setting is changed. So

select 【Material】first then select 【Hardness Scale】when setting measure condition.

6 Operation explain in details

6.1 Switch on

Press to switch on,the screen will show as follows in 2 seconds:

TH170

TIME Group Inc.

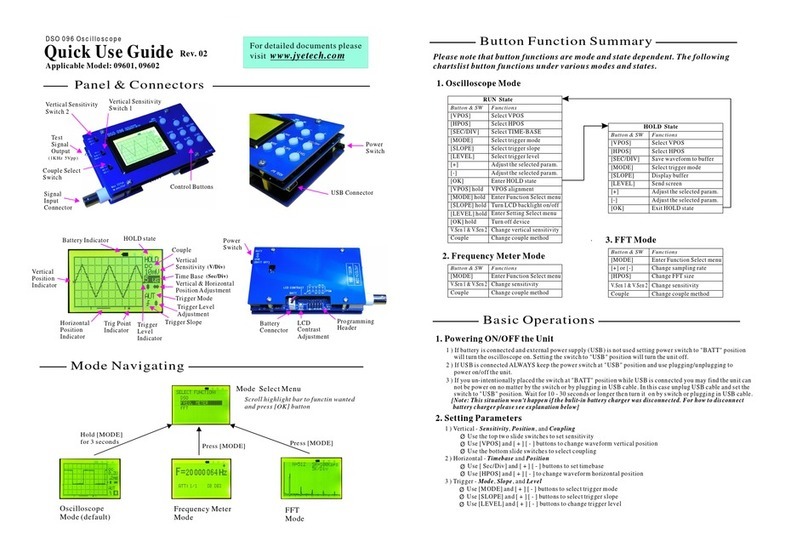

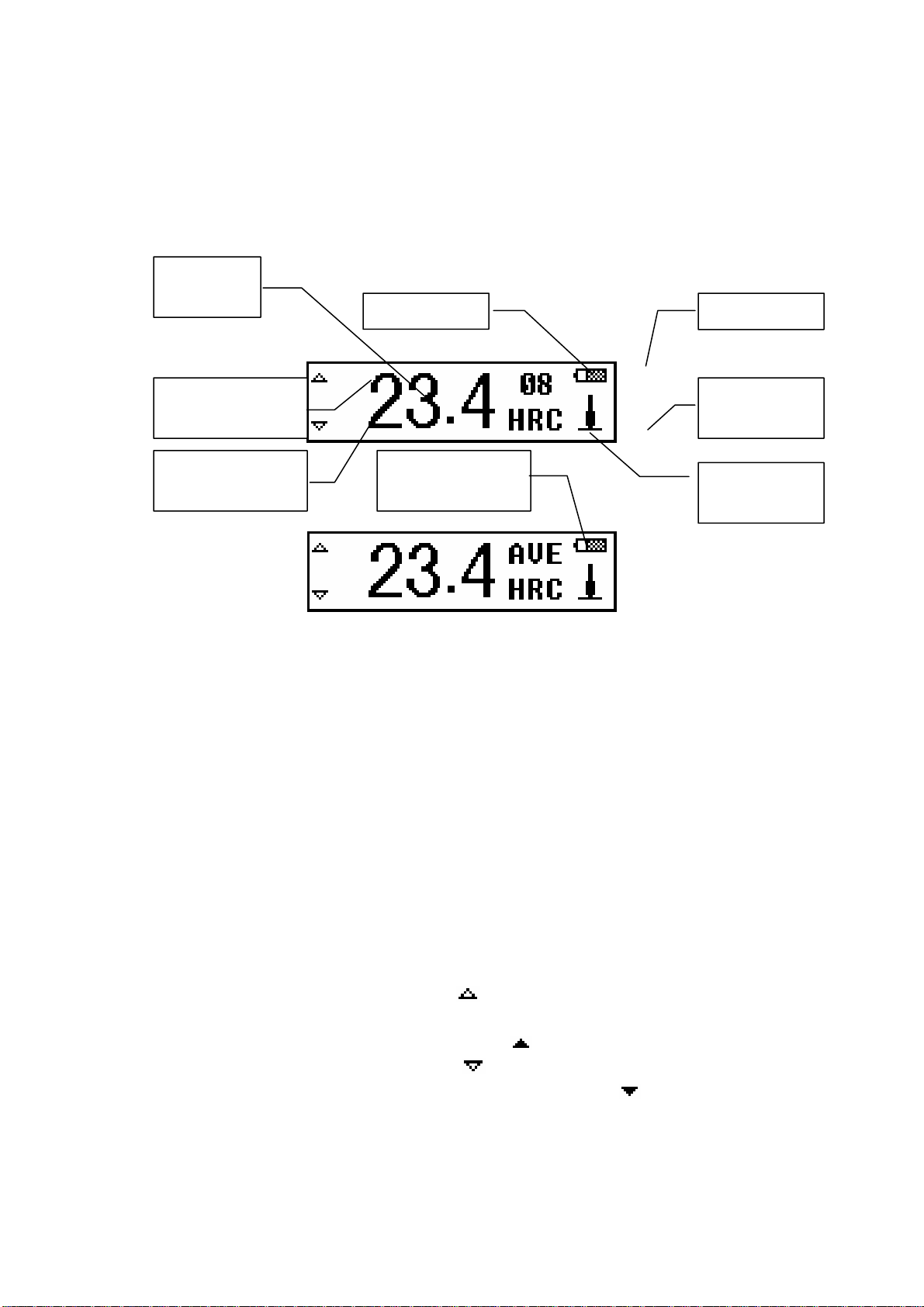

Then it enters the main display interface,see figure 4.

Figure 4

Instruction of the main display interface:

Measured value

:

Display present single time measured value (without average value indicator),

or display the present average value (with average value indicator).

Display ↑means over conversion or measured range, ↓means lower than conversion or measured

range.

Impact times

:

Display the times that have been impacted, the according times will be

displayed in reverse video when browsing single measured value.

Average value indicator

:

After reaching the preset impact times, It appears to show the mean

value.

Hardness scale

:

Show the present hardness scale that has been selected.

Impact direction

:

Show the present impact direction that has been selected.

Battery info

:

Show the rest capacity of battery.

Over tolerance alarm

:

It will display as

when the present measured single value or

average value is

within the tolerance range,otherwise it will display as .

Lower tolerance alarm

:

It will display as when the present measured single value or

average value is within the tolerance range,otherwise it will display as .

6.2 Measuring operation

The screen will display each measured value during each measurement under the measuring

Hardness

scale

Average value

indicator

Impact

direction

Battery info.Impact times

Measured

value

Lower tolerance

alarm

Over tolerance

alarm

display interface, and the impact times add 1 accordingly;if the measured value is beyond

tolerance range,the according mark will change to solid mark;the average value will be

displayed in 2 seconds when reaching the impact times.

6.3 Key-press operation

zPress or to browse singe measured value,the impact times will be

displayed in reverse video;

zPress to enter the menu.

6.4 Switch off

Press to switch off.

6.5 Menu structure

Preset tester parameters and the additional functions can be performed by the menu operation. At

the main display interface, press toenterthemainmenu.

zFor convenient operation, the common function such as “Save Average”、“Delete

Single”、“Cal. Average”、“Backlight On(Off)”,have been put into main display interface;

zThe main display interface have the key 【Exit】,it is convenient to return to measuring

display interface;

zPress 【Exit】key will return to measuring display interface after using common

function and setting function;

Main display

interface

Save Average

Delete Single

Cal. Average

Memory Manager

Backlight On(Off)

Test Set

System Set

About Software

Exit

Auto Save On(Off)

Auto Delete On(Off)

Auto Trans. Off

LCD Brightness

Exit

Impact Direc.

Average

Material

Hardness Scale

Tolerance Limit

Exit

View File

Delete File

Select Save File

Transfer

Exit

zPress or can choose all function and sub-menu circularly ,

press to choose the underside function or sub-menu and then press , the cursor

will skip to the topside function or sub-menu,press to choose the topside function or

sub-menu and then press , the cursor will skip to the underside function or sub-menu.

6.6 Common function

Press to enter the main menu under measuring display interface.

Press or to move the cursor to

demanded function and press to confirm.

Note

:

Press or to see pale

letter

。

Save Average:Memory the present average value.

Delete Single

Cal. Average

Memory Manager

Backlight On

Test Set

System Set

About Software

Exit

Save Avera

g

e

Note

:

The memory can not be processed under the both position of not

reaching preset impact times and not choosing

“

Cal.

Average

”

.

Delete Single:Delete the last measured value;Delete the certain measured value when

browsing the single measured value;Delete the last single measured value when displaying

average value.

Note

:

Please move the cursor to

“

YES

”

or

“

NO

”

and press to

confirm when delete.

Cal. Average:Display the average measured value when impact times have not reached

preset times.

Backlight On(Off):“Backlight On”will be displayed when choosing the backlight;

“Backlight Off”will be displayed when not choosing the backlight.

Note

:

Press any one of the keys 、、when switch on

the backlight will be chose.

6.7 Memory manager

The instrument includes 9 files and each one can memory 30 measured average value. You

can choose another file to memory when 30 measured average value is stored,

Press to enter the main menu when on measuring display interface.

Press 、to move the cursor to

【Memory Manager 】, press enter

【Memory Manager】.

Note

:

The pale letter can be seen by

pressing 、.

Save Average

Delete Single

Cal. Average

Backlight On

Test Set

System Set

About Software

Exit

Memor

y

Mana

g

e

r

Press 、to move the cursor to

certain function key and press .

Note

:

The pale letter can be seen by

pressing 、.

6.7.1 Browsing file

Firstly please choose the file number to be browsed.

Press 、to choose the file

number.

Press to confirm.

Press 、to turn the page.

Press return to【Memory Manager】.

6.7.2 Delete file

Firstly please choose the file number to be deleted.

Press 、to choose the file

number.

Press enter confirm delete interface.

Press 、to choose.

Delete File

Select Save File

Transfer

Exit

View File

File No.: 1

No.01 789HL

No.02 517HL

No.03 788HL

No.04 522HL

File No.: 1

Confirm Delete

NO

YES

Press to confirm and return to【Memory

Manager】.

6.7.3 Memory file choosing

Choose the file number for memory.

Press 、to choose the file

number.

Press to confirm and return to measuring

display interface.

6.7.4 Data communication

The memory value can be transmitted out via USB interface,see 6.15.

6.8 Test setting

Press to enter the main menu under measuring display interface.

Press 、to move the cursor

to 【Test Set】and press .

Note

:

The pale letter can be seen by

pressing

、.

Press 、to move the cursor

to certain function and press .

Avera

g

e

Material

Hardness Scale

Tolerance Limit

File No.: 1

Save Average

Delete Single

Cal. Average

Memory Manager

Backlight On

System Set

About Software

Exit

Test Set

Im

p

act Direc.

Note

:

The pale letter can be seen by

pressing

、

.

6.8.1 Impact direction setting

Press 、to move the

cursor to certain direction to be set.

Press to finish the set and return to

measuring display interface.

If preset impact direction to ,the instrument can identify the impact direction and correct

the wrong direction automatically. Both directions of and are different and need to be

confirmed by hand.

Press 、to move the cursor

to correct impact direction.

Press to confirm.

The indication of different direction displays

is caused of shaking of impact device.

6.8.2 Mean times setting

The mean times can be modified from 1 to

10.

Press 、to modify.

Press to finish set and return to

measuring display interface.

6.8.3 Material setting

Press 、to move the cursor

to certain material to be set.

Press to finish set and return to

measuring display interface.

Note 1.The hardness scale will come

CWT. Steel

STAIN. Steel

GC. Iron

N

c.Iron

Cast Alumin

Copper-Zinc

Copper-Alumin

Mean Times:

10

(

Cast

)

Steel

Confirm Direc.

Table of contents