Titan Implement 7000 Series Guide

Titan Implement, LLC 3 7000 Series Disc Harrows

(423) 334-0012 January 2022

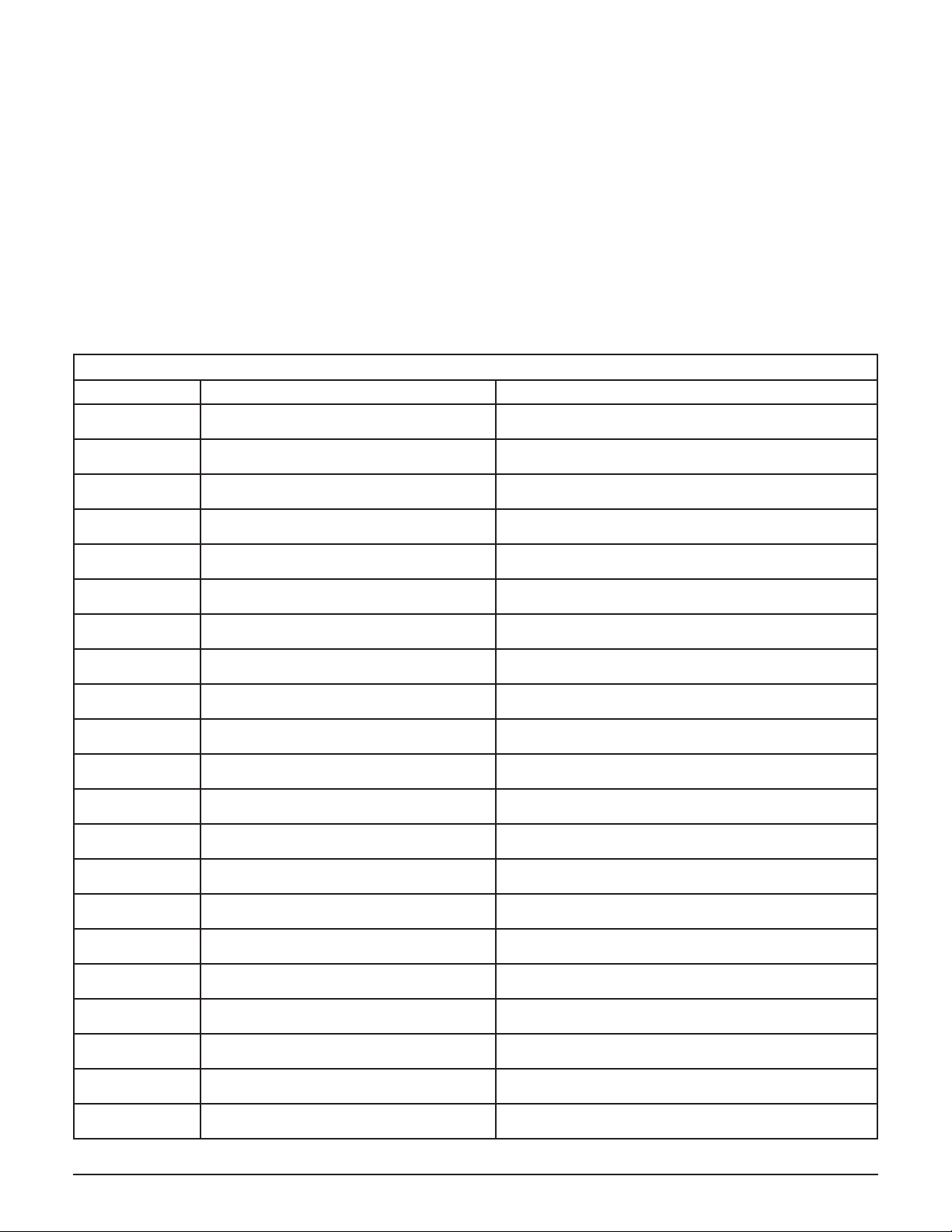

Pre-Delivery Checklist

The Dealer should inform the Purchaser of this product of the Warranty terms, provisions, and procedures that are

applicable. The Dealer and Purchaser should review the contents of the Operation and Parts Manual including

safety equipment, safe operation and maintenance, review the Safety Signs on the implement (and tractor, if

necessary), and the Purchaser’s responsibility to train their operators in correct operating procedures.

• MOUNTED IMPLEMENTS: I have explained that Deectors, Guards, or Shields must be installed and

maintained in good repair, and that the operator is responsible for watching out for persons in the work area.

PRE-DELIVERY SERVICE

CHECK AND ADJUST OR LUBRICATE, AS REQUIRED

See Operation and Parts Manual for Details

Inspection Performed - Warranty and Safety Procedures Explained - Installation Complete

LUBRICATION

Grease All Zerks

IMPLEMENT

Review Procedure to Adjust Disc Harrow

Make Sure that All Hardware is Properly Tightened

ATTACHMENTS & INSTALLATION

Make Sure All Bolts, Pins, and Nuts are Properly

Installed and Tightened

I have thoroughly instructed the purchaser on the above-described equipment. This review included the Operation

and Parts Manual contents, equipment care, adjustments, safe operation, and applicable warranty policy.

Date__________________ Dealer Rep. Signature_________________________________________

The above equipment and Operation and Parts Manual have been received by me, and I have been thoroughly

instructed as to equipment care, adjustments, safe operation, and applicable warranty policy.

Date__________________ Purchaser’s Signature_________________________________________

IMPLEMENT TO TRACTOR CONNECTIONS

Make Sure A-Frame Pivot and Links are Properly

Installed

Make Sure Lift Arms are Adjusted Equally

Complete All Pre-Operation Checks

SAFETY ITEMS

Make Sure Protective Shields are Properly Installed

Review Operation and Parts Manual (Supplied)

Make Sure Tractor PTO Shield is Installed

Make Sure S.M.V. Sign is Installed, if Needed

(Customer Supplied)

Cut Here to Remove Page or Make Copies of This Page

Titan Implement, LLC 5 7000 Series Disc Harrows

(423) 334-0012 January 2022

Table of Contents

1. INTRODUCTION ........................6

1.1 Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Safe Operation .........................6

1.3 Specications ..........................7

1.4 Intended Usage .........................7

1.5 Operator Orientation .....................7

1.6 Serial Number Location (Typical) ...........7

1.7 Product Improvements ...................8

1.8 Disposal of Equipment at End of Useful Life ...8

1.9 Unanswered Questions ...................8

2. SAFETY................................9

2.1 General ...............................9

2.2 Safety Alert Symbols .....................9

2.3 Safety Icon Nomenclature ................10

2.3.1 Personal Protection/Important

Information ......................10

2.3.2 Prohibited Actions ................10

2.3.3 Hazard Avoidance ................10

2.4 General Safety Instructions ...............11

2.5 Training ..............................12

2.6 OSHA Training Requirements .............12

2.7 Federal Laws and Regulations ............13

2.8 Sign-Off Form .........................14

2.9 Operation Safety .......................15

2.10 Transporting Safety .....................15

2.11 Storage Safety.........................15

2.12 Maintenance Safety.....................15

3. NOMENCLATURE ......................16

4. ASSEMBLY ............................17

4.1 Assembly Procedure ....................17

5. OPERATION ...........................18

5.1 Operating Safety .......................18

5.2 Tractor Requirements ...................19

5.2.1 Tractor Safety Devices.............19

5.2.2 ROPS and Seat Belt ..............19

5.2.3 3-Point Hitch ....................20

5.3 Attaching to Tractor ....................20

5.4 Setting the Disc Harrow..................21

5.4.1 Leveling the Frame ...............21

5.4.2 Setting the Disc Angle .............21

5.4.3 Adjusting the Width ...............21

5.5 Initial Setup Checklist ...................22

5.6 Implement Break-In ....................22

5.7 General Operating Instructions ............22

5.8 Detaching From Tractor .................23

6. TRANSPORTING .......................24

6.1 Transporting Safety (Road) ...............24

7. STORAGE .............................25

7.1 Storage Safety.........................25

7.2 Placing In Storage ......................25

7.3 Removing From Storage ................25

8. SERVICE AND MAINTENANCE ...........26

8.1 Maintenance Safety.....................26

8.2 Greasing .............................26

8.3 Disc Blade Replacement .................27

8.3.1 7100 Series Disc Blade Replacement 27

8.3.2 7300, 7400 Series Disc Blade

Replacement ....................27

8.4 Bearing Replacement ...................28

8.4.1 7100 Series Bearing Cap

Replacement ....................28

8.4.2 7300, 7400 Series Bearing

Replacement ....................28

8.5 Welding Repairs .......................28

8.6 Bolt Torque Requirements................29

8.7 Service Record ........................30

9. TROUBLESHOOTING ...................31

10. WARRANTY ...........................32

11. PARTS INFORMATION ...................35

7000 Series Disc Harrows 6 Titan Implement, LLC

January 2022 (423) 334-0012

1. INTRODUCTION

1.1 Welcome

7316 Disc Harrow

Congratulations on your choice of a Titan Implement

disc harrow. This equipment has been designed and

manufactured to meet the needs of discerning users.

The Titan Implement disc harrow is designed to break

up the soil surface in preparation for planting.

Many features incorporated into this disc harrow are

the result of suggestions made by customers like you.

Read this manual carefully to learn how to operate

the disc harrow safely and how to adjust it to provide

maximum plowing efciency.

By following the operating instructions, in conjunction

with a good maintenance program, your Titan

Implement disc harrow will provide many years of

trouble-free service.

This manual covers Titan Implement Disc Harrow

models:

Model Description

7112 12 blade, 16”

7116 16 blade, 16”

7316 16 blade, 18”

7320 20 blade, 18”

7324 24 blade, 18”

7416 16 blade, 20”

7420 20 blade, 20”

7424 24 blade, 20”

1.2 Safe Operation

Safe, efcient, and trouble-free operation of your disc

harrow requires that you, and anyone else who will be

using or maintaining the unit, read and understand the

information contained within the Operation and Parts

Manual.

Use this manual for reference and for new operators or

owners.

WARNING

Read And Understand Manual

To prevent personal injury or even death, be

sure you read and understand all of the

instructions in this manual and other related OEM

equipment manuals! The disc harrow, if not used

and maintained properly, can be dangerous to users

unfamiliar with its operation. Do not allow operating,

maintaining, adjusting, or cleaning of this disc

harrow until the user has read this manual and has

developed a thorough understanding of the safety

precautions and functions of the unit.

This disc harrow is designed for the specic

purpose of breaking up the soil surface in

preparation for planting. DO NOT modify

or use this disc harrow for any application

other than that for which it was designed.

Disc harrows maintained or operated improperly,

or by untrained personnel, can be dangerous;

exposing the user and/or bystanders to possible

serious injury or death.

Titan Implement, LLC 7 7000 Series Disc Harrows

(423) 334-0012 January 2022

1.3 Specifications

Model 7112 7116

Horsepower Required 20-30 25-35

Working Width 48” 60”

Weight (Lbs.) 391 502

Number of Disc Blades 12 16

Disc Blade Diameter 16”

Disc Blade Spacing 7-1/2”

Bearings Cast

Hitch CAT I

Quick Hitch Compatible Yes

Model 7316 7320 7324

Horsepower Required 30-45 35-50 40-60

Working Width 60” 72” 84”

Weight (Lbs.) 650 700 750

Number of Disc Blades 16 20 24

Disc Blade Diameter 18”

Disc Blade Spacing 7-1/2”

Bearings Sealed

Hitch CAT I

Quick Hitch Compatible Yes

Model 7416 7420 7424

Horsepower Required 35-60 50-70 60-80

Working Width 72” 92” 108”

Weight (Lbs.) 872 1019 1250

Number of Disc Blades 16 20 24

Disc Blade Diameter 20”

Disc Blade Spacing 9”

Bearings Sealed

Hitch CAT l CAT I CAT l & ll

Quick Hitch Compatible Yes

Specications subject to change without notice.

1.4 Intended Usage

Do not use this disc harrow for any other purpose

than its intended use of breaking up the soil surface in

preparation for planting.

1.5 Operator Orientation

The directions left, right, front, and rear, as mentioned

throughout this manual, are as seen from the tractor

operator’s seat and facing in the direction of travel.

1.6 Serial Number Location (Typical)

The serial number decal is located on the front of the

frame.

Model Number ______________________________

Serial Number ______________________________

7000 Series Disc Harrows 8 Titan Implement, LLC

January 2022 (423) 334-0012

1.7 Product Improvements

Because Titan Implement, LLC maintains an ongoing

program of product improvement, we reserve the

right to make improvements in design or changes in

specications without incurring any obligation to install

them on units previously sold.

1.8 Disposal of Equipment at End of Useful

Life

The Titan Implement, LLC disc harrow has been

designed for the specic purpose of breaking up the

soil surface in preparation for planting. When this unit

is no longer capable of doing its designed purpose, it

should be dismantled and scrapped. Do not use any

materials or components from this unit for any other

purpose.

1.9 Unanswered Questions

If you have any questions not answered in this manual,

require additional copies, or the manual is damaged,

please contact your dealer or:

Titan Implement, LLC

P.O. Box 649

232 Industrial Lane

Decatur, TN 37322

Phone: (423) 334-0012

Fax: (423) 334-0023

The manual is also available for download at:

www.titanimplement.com

1. Select “Products”.

2. Select “Disc Harrows”.

3. Click the “Specs., Manuals, Warranty” tab.

4. Click “Download Manual”.

Titan Implement, LLC 9 7000 Series Disc Harrows

(423) 334-0012 January 2022

2. Safety

2.1 General

Safety of the operator and bystanders is one of the

main concerns in designing and developing a new

piece of equipment. Designers and manufacturers

build in as many safety features as possible. However,

every year many accidents occur which could have

been avoided by a few seconds of thought and a more

careful approach to handling the equipment.

Most work-related accidents are caused by failure to

observe basic safety rules or precautions. An accident

can often be avoided by recognizing potentially

hazardous situations before an accident occurs. As

you assemble, operate, or maintain the disc harrow

(unit), you must be alert to potential hazards. You

should also have the necessary training, skills,

and tools to perform any assembly or maintenance

procedures.

Improper operation and maintenance of this unit could

result in a dangerous situation that could cause injury

or death.

If you have any questions not answered in this manual,

require additional copies, or the manual is damaged,

please contact your dealer or:

Titan Implement, LLC

P.O. Box 649

232 Industrial Lane

Decatur, TN 37322

Phone: (423) 334-0012

Fax: (423) 334-0023

WARNING

Do not assemble, operate, or maintain the

unit until you read and understand the

information contained in this manual.

Safety precautions and warnings are provided

in this manual. If these hazard warnings are

not heeded, bodily injury or death could occur

to you or to other persons.

Titan Implement, LLC cannot anticipate every possible

circumstance that might involve a potential hazard.

The warnings in this manual are, therefore, not all-

inclusive. If a method of assembly, operation, or

maintenance not specically recommended by us is

used, you must satisfy yourself that it is safe for you

and for others. You should also ensure that the unit will

not be damaged or be made unsafe by the methods

that you choose.

The information, specications, and illustrations in this

manual are based on the information that was available

at the time this material was written and can change at

any time without notice.

2.2 Safety Alert Symbols

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

This manual contains DANGERS, SAFETY

INSTRUCTIONS, CAUTIONS, IMPORTANT NOTICES,

and NOTES which must be followed to prevent

the possibility of improper service, damage to the

equipment, personal injury, or death. The following key

words call the readers’ attention to potential hazards.

Hazards are identied by the “Safety Alert Symbol”

and followed by a signal word such as “DANGER”,

“WARNING”, or “CAUTION”.

DANGER

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme

situations.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE

Indicates that equipment or property damage can result

if instructions are not followed.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent) signs indicate

specic safety-related instructions or procedures.

Note: Contains additional information important to a

procedure.

7000 Series Disc Harrows 10 Titan Implement, LLC

January 2022 (423) 334-0012

2.3 Safety Icon

Nomenclature

Pictorial icons signal a type of

hazard and warn of personal

protection issues, prohibited

actions, and hazard avoidance.

2.3.1 Personal Protection/

Important Information

Read the manual

Maintenance procedure

N

I

NG

AR

Damaged hazard label

Eye protection

Fire extinguisher

First aid kit

Hand protection

Head protection

Hearing protection

Inspect equipment

OEM

OEM

OEM parts only

Protective shoes

Remove key

Set parking brake

STOP Stop engine

THINK

SAFETY! Think safety

Transmission in park

Use proper support

Use proper tools

Use two people when

lifting heavy objects

Visibility

Rollover protection

Wear seat belt

Weight rating

2.3.2 Prohibited Actions

Do not alter or modify

Use proper tools

Do not weld

No alcohol

No drugs

No smoking

No young children

No riders

2.3.3 Hazard Avoidance

Crush

hazard

Crush hazard (chock

wheels)

Crush hazard (foot)

Defective or broken part

Fall hazard

Fire hazard

Disc blade contact

hazard (hand)

Disc blade contact

hazard (foot)

Lifting hazard

Cutting hazard

Pinch point hazard

Rollover protection

Safety alert symbol

Sharp object hazard

Slipping injury

Tripping injury

Titan Implement, LLC 11 7000 Series Disc Harrows

(423) 334-0012 January 2022

2.4 General Safety Instructions

The owner/operator is responsible for the SAFE use

and maintenance of the disc harrow. Make sure

anyone who is operating, maintaining, or working

around the disc harrow is familiar with the operating

and maintenance procedures and related SAFETY

information contained in this manual. This manual will

take you step-by-step through your working day and

alerts you to all good safety practices that should be

used while using the disc harrow.

In addition to the design features of the disc harrow,

including safety signs, accident prevention is

dependent upon the awareness, concern, prudence,

and proper training of the people involved in the

operation, maintenance, and storage of the disc

harrow.

In addition to this safety section, refer also to safety

messages and instructions in each of the appropriate

sections of the disc harrow manual.

These general safety instructions apply to the overall

use and maintenance of the disc harrow.

More specic instructions on safety are found in the

operation, maintenance, and storage sections of this

manual. Refer to these sections before performing any

of these tasks.

WARNING

Failure to comply with the following safety

instructions can and will result in serious injury and

possibly even death if they are not understood and

followed.

Stay Clear

Clear the area of people, especially small

children, before using the disc harrow. Under

no circumstances should young children be allowed

to work with or around the disc harrow.

Impaired User Hazard

Do not attempt to assemble, operate, or

maintain this disc harrow under the

inuence of drugs or alcohol. Consult your doctor

before using this disc harrow while taking

prescription medications.

Crush Hazard

Do not allow anyone to ride on the

tractor or the disc harrow. Falling or

crushing hazards can result in severe injuries or

death.

Falling Hazard

Do not allow riders on the hitch,

tractor, or disc harrow at any time.

Falling can result in severe injuries or death.

WARNING

Provide User with Literature

Titan Implement, LLC disc harrow owners

must provide operator instructions to anyone

using the disc harrow before use, and at least

annually thereafter. Refer to “2.6 OSHA Training

Requirements” on page 12.

Damaged Parts Hazard

Do not use the disc harrow if any parts are

damaged. If the disc harrow has a defect,

immediately stop using it and remedy the problem

before continuing.

7000 Series Disc Harrows 12 Titan Implement, LLC

January 2022 (423) 334-0012

CAUTION

The following safety instructions are provided to

help prevent potential injury. Not following these

instructions may result in minor to moderate injury.

Personal Protection Equipment

When using this disc harrow, wear appropriate

personal protective equipment. This list may

include, but is not limited to:

• Protective shoes with slip resistant soles

• Protective goggles, glasses, or face shield

• Protective clothing and gloves

• Safety vest (when operating near roads)

• Hearing protection

Hearing Loss

Prolonged Exposure To Loud Noise May

Cause Permanent Hearing Loss!

Working environments with noise-producing

equipment can cause partial to permanent hearing

loss. We recommend using hearing protection any

time noise levels exceed 80 decibels (dB). Noise

levels over 85 dB, on a long-term basis, can cause

severe hearing loss. Noise levels over 90 dB over a

period of time can cause permanent and even total

hearing loss.

Hearing loss from loud noise is cumulative over a

lifetime without hope of natural recovery.

Crush Hazard

The tractor should be equipped with

a Roll Over Protective Structure

(ROPS) and a seat belt. A crushing hazard can occur

if the driver is ejected from the seat while the tractor

is in motion. Fasten the seat belt whenever the

tractor is moving.

SAFETY

INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

First Aid Kit

Have a rst aid kit available for use should

the need arise and know how to use it.

Fire Extinguisher

Have a re extinguisher available for use

should the need arise and know how to use it.

THINK

SAFETY! Think SAFETY!

Work SAFELY!

2.5 Training

Anyone who will be using and/or maintaining the disc

harrow must read, clearly understand, and follow

ALL safety, operation, and maintenance information

presented in this manual and other related OEM

manuals.

If you do not understand any information in this

manual, see your dealer or contact Titan Implement

before proceeding.

Do not use or allow anyone else to use this disc harrow

until all information has been reviewed. Annually

review this manual before the season start-up.

Make periodic reviews of SAFETY and OPERATION

of the disc harrow a standard practice. An untrained

operator is not qualied to use this disc harrow.

2.6 OSHA Training Requirements

The following training requirements have been taken

from Title 29, Code of Federal Regulations Part

1928.57 (a) (6). www.osha.gov.

Operator instructions. At the time of initial assignment

and at least annually thereafter, the employer shall

instruct every employee who operates an agricultural

tractor and implements in the safe operating practices

and servicing of equipment with which they are or will

be involved, and of any other practices dictated by the

work environment.

Titan Implement, LLC 13 7000 Series Disc Harrows

(423) 334-0012 January 2022

2.7 Federal Laws and Regulations

IMPORTANT FEDERAL LAWS AND REGULATIONS

CONCERNING EMPLOYERS, EMPLOYEES AND OPERATORS

This section is intended to explain in broad terms the concept and effect of the following federal laws and

regulations. It is not intended as a legal interpretation of the laws and should not be considered as such.

U.S. PUBLIC LAW 91-596 (The Williams-Steiger Occupational Safety and Health Act of 1970) OSHA

This Act Seeks:

“ ... to assure so far as possible every working man and woman in the nation safe and healthful working conditions and to

preserve our human resources ... “

DUTIES

Sec. 5(a) Each Employer -

(1) shall furnish to each of its employees employment and a place of employment which are free from

recognized hazards that are causing or are likely to cause death or serious physical harm to its

employees.

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards

and all rules, regulations, and orders issued pursuant to this Act which are

applicable to his or her own actions and conduct.

OSHA Regulations

Current OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the

employer shall instruct every employee in the safe operation and servicing of all equipment with which the

employee is, or will be involved.” These will include (but are not limited to) instructions to:

Keep all guards in place when the machine is in operation;

Permit no riders on equipment;

Stop engine, disconnect the power source, and wait for all machine movement to stop before servicing,

adjusting, cleaning, or unclogging the equipment, except where the machine must be running to be

properly serviced or maintained, in which case the employer shall instruct employees as to all steps and

procedures which are necessary to safely service or maintain equipment.

Make sure no one is within 300 feet of machinery before starting the engine, engaging power,

or operating the machine.

EMPLOYEE TRACTOR OPERATING INSTRUCTIONS:

1. Securely fasten your seat belt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going, especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by tractor manufacturers.

9. When tractor is stopped, set brakes securely and use park lock if available.

Child Labor Under 16 Years Old

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to

know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard

Administration, Wage & Home Division, Child Labor Bulletin #102).

7000 Series Disc Harrows 14 Titan Implement, LLC

January 2022 (423) 334-0012

2.8 Sign-Off Form

Titan Implement, LLC follows the general Safety

Standards specied by the Farm Equipment

Manufacturers Association (FEMA), and the American

National Standards Institute (ANSI). Anyone who

will be using and/or maintaining the disc harrow must

read and clearly understand ALL safety, operation and

maintenance information presented in this manual.

Do not use or allow anyone else to use this disc harrow

until all information has been reviewed. Annually

review this manual before the season start-up.

Make periodic reviews of SAFETY and OPERATION

of the disc harrow a standard practice. An untrained

operator is not qualied to use this disc harrow.

Sign-Off Form

Date User’s Signature Owner’s Signature

This sign-off sheet is provided for your records to

show that all personnel who will be working with the

equipment have read and understand the information

in this Operation and Parts Manual and have been

instructed in the operation of the equipment.

Titan Implement, LLC 15 7000 Series Disc Harrows

(423) 334-0012 January 2022

2.9 Operation Safety

Refer to “5.1 Operating Safety” on page 18 for safety

recommendations related to using the disc harrow. All

applicable safety recommendations in other sections

should also be followed.

2.10 Transporting Safety

Refer to “6.1 Transporting Safety (Road)” on page 24

for safety recommendations related to transporting the

disc harrow. All applicable safety recommendations in

other sections should also be followed.

2.11 Storage Safety

Refer to “7.1 Storage Safety” on page 25 for safety

recommendations related to storing the disc harrow.

All applicable safety recommendations in other

sections should also be followed.

2.12 Maintenance Safety

Refer to “8.1 Maintenance Safety” on page 26 for

safety recommendations related to maintaining the disc

harrow. All applicable safety recommendations in other

sections should also be followed.

7000 Series Disc Harrows 16 Titan Implement, LLC

January 2022 (423) 334-0012

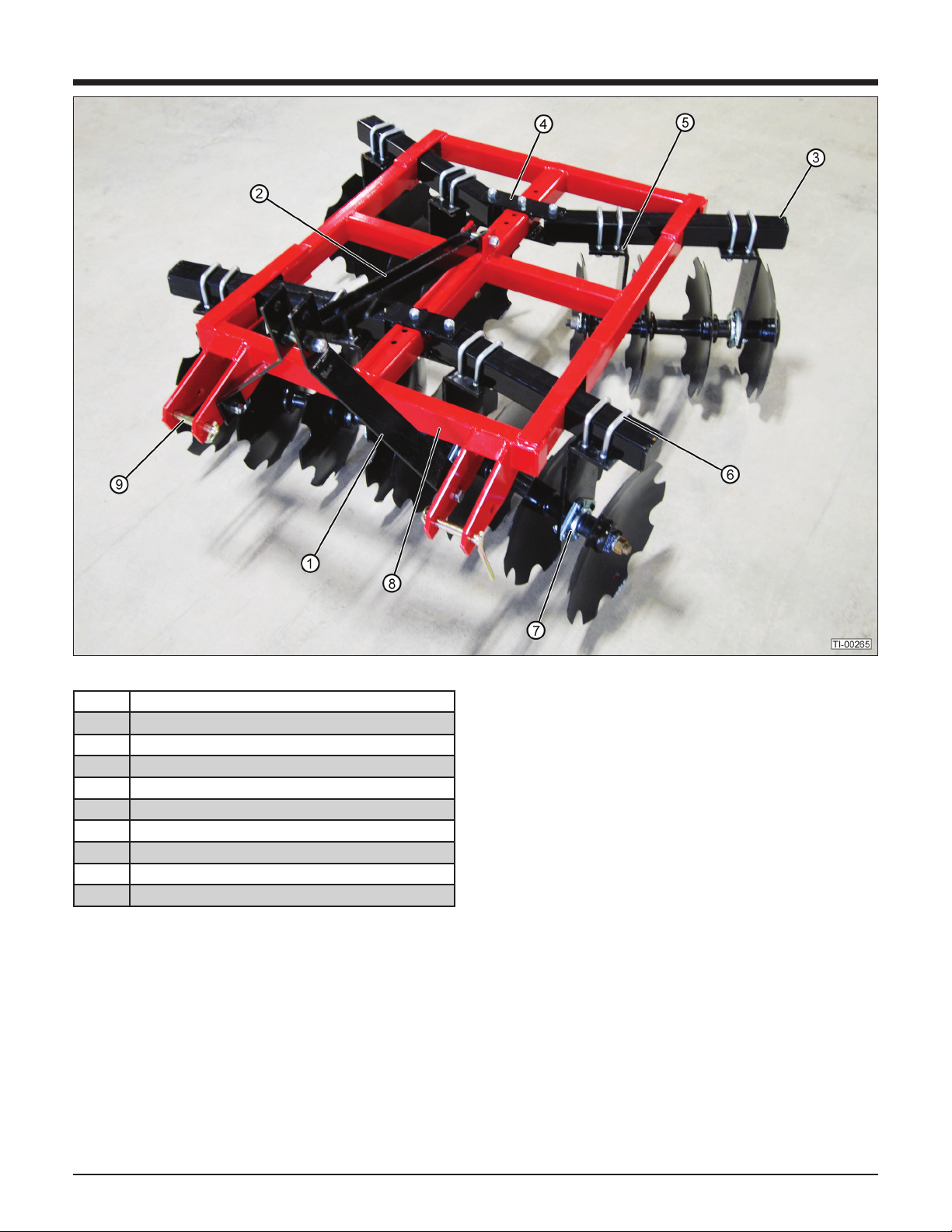

3. Nomenclature

Item Description

1 A-Frame

2 Back Brace

3Disc Gang Tube

4 Pivot Plate

5 Bearing Hanger

6 Hanger U-Bolt

7 Bearing

8 Frame

9 CAT l 3-point Hitch Pin and Retainer Clip

Titan Implement, LLC 17 7000 Series Disc Harrows

(423) 334-0012 January 2022

4. Assembly

4.1 Assembly Procedure

The disc harrow ships with the A-frame folded down for

shipping purposes. It must be erected before use.

1. Cut the wires holding the back brace and A-frame to

the disc harrow frame. Remove the hitch pins from

the frame.

2. Using a 1-1/8” wrench, loosen rear back brace bolt

(1) and lower A-frame bolts (2). Remove front bolt

(3) and spacer (4) from the back brace.

3. Rotate the A-frame halves to an upright position.

Assemble the back brace, bolt, and spacer on the

inside of the A-frame. Make sure to install the bolt

in the lower A-frame holes.

4. Tighten the A-frame and back brace bolts securely.

Reinstall the hitch pins.

7000 Series Disc Harrows 18 Titan Implement, LLC

January 2022 (423) 334-0012

5. Operation

5.1 Operating Safety

Refer to “2.4 General Safety Instructions” on page

11 for general user safety training requirements.

WARNING

STOP

Roll Away Hazard

Before leaving the

tractor seat, make sure

the engine is stopped, the transmission is placed in

park, the key is removed, and the parking brake is

set.

The weight of the tractor, plus the disc

harrow if it rolls onto a person, can cause

serious crushing injury or death.

Crush Hazard

The tractor should be equipped with

a Roll Over Protective Structure

(ROPS) and a seat belt. A crushing hazard can occur

if the driver is ejected from the seat while the tractor

is in motion. Fasten the seat belt whenever the

tractor is moving.

Stay Clear

Clear the work area of all unnecessary

people and obstructions to prevent

personal injury.

Disc Blade Contact Hazard (hand)

To avoid serious injury or death, keep away

from ground-engaging components. Do

not put hands under disc harrow.

Disc Blade Contact Hazard (foot)

To avoid serious injury or death, keep away

from ground-engaging components. Do

not put feet under disc harrow.

SAFETY

INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

THINK

SAFETY! Train Unfamiliar Users

It is the disc harrow owner’s

responsibility to make sure any person

using the disc harrow, especially if it is loaned or

rented, has been thoroughly trained on its proper

and safe use.

Be certain only physically-able persons will use the

disc harrow.

Untrained users expose themselves and bystanders

to possible serious injury or death.

If the elderly are assisting with the work, their

physical limitations need to be recognized and

accommodated.

Never allow children to operate equipment.

Do not operate the disc harrow, or drive the tractor

into material that is burning, or areas that recently

burnt and may contain hot spots. Tire damage can

occur when driving over hot material. Oil and grease

on the tractor and disc harrow could ignite, resulting

in equipment destruction.

Titan Implement, LLC 19 7000 Series Disc Harrows

(423) 334-0012 January 2022

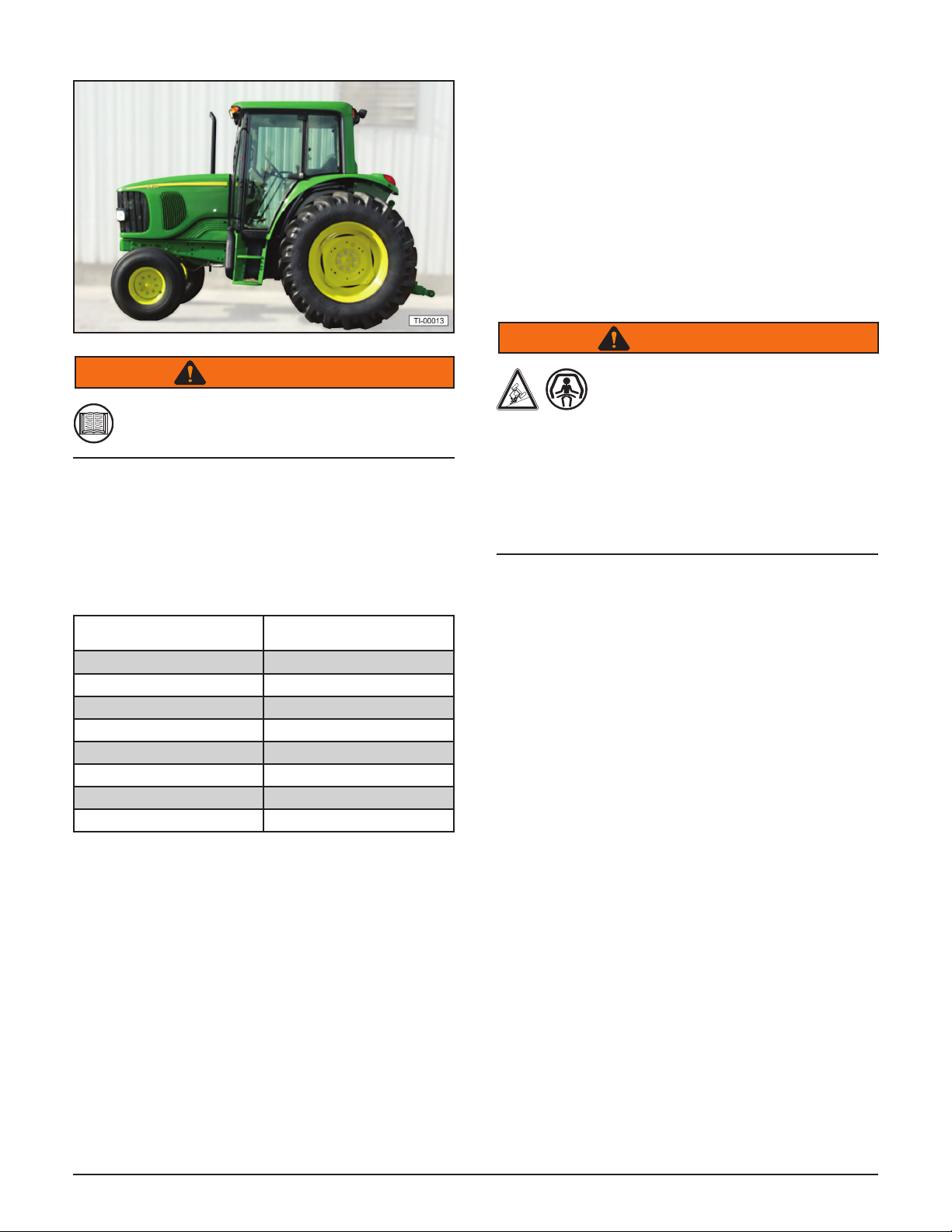

5.2 Tractor Requirements

WARNING

Tractor Owner/Operator Manual

Always refer to the tractor Operator’s Manual

to ensure compatibility and maximum safety.

The tractor used to operate the disc harrow must have

the power capacity to lift and pull the disc harrow at a

ground speed between 2 and 5 MPH.

Use the chart to select the tractor horsepower

appropriate for your disc harrow. Do not use a

tractor of more than the recommended HP to prevent

overloading frame components.

Model Recommended

HP

7112 20-30

7116 25-40

7316 30-45

7320 35-45

7324 40-50

7416 35-60

7420 50-70

7424 60-80

The tractor must be matched to the weight of the disc

harrow. A minimum of 20% of the combined tractor

and equipment weight should be on the front wheels.

This will ensure adequate stability during transport and

operation.

Always review the “controls” section of the tractor

Operator’s Manual to be familiar with the location,

settings, and function of the tractor controls. Be

familiar with all controls before using this equipment.

5.2.1 Tractor Safety Devices

If transporting or operating the tractor and implement

near a public roadway, the tractor must be equipped

with proper warning lighting and a Slow Moving Vehicle

(SMV) emblem, which are clearly visible from the

rear of the unit. Lights and a SMV emblem must be

attached directly to the implement if the visibility of the

tractor warning signals are obscured.

Never operate the tractor PTO with the PTO master

shield missing or in the raised position.

5.2.2 ROPS and Seat Belt

WARNING

Rollover Hazard

To avoid serious injury or death from

falling off tractor, equipment runover,

rollover, or crushing:

1) Use ROPS equipped tractor.

2) Keep ROPS locked in the UP position.

3) Only operate the equipment when seated in the

tractor seat.

4) Always fasten seat belt when operating the tractor

and disc harrow.

The tractor must be equipped with a Roll Over

Protective Structure (ROPS) (tractor cab or roll-bar)

and seat belt to protect the operator from falling off the

tractor, especially during a roll-over where the driver

could be crushed and killed. Only operate the tractor

with the ROPS in the raised position and seat belt

fastened.

7000 Series Disc Harrows 20 Titan Implement, LLC

January 2022 (423) 334-0012

5.2.3 3-Point Hitch

These disc harrows are designed to be mounted on a

tractor CAT I 3-Point or Quick Hitch. The 7400 models

are equipped with stepped pins to accommodate CAT l

or CAT ll hitches.

Refer to the tractor Operator’s Manual for the category

of the tractor being used. If the hitch does not conform

to ASABE CAT I dimensions, the disc harrow may

not t or raise properly. Consult an authorized dealer

for possible modication procedures to mount non-

conforming hitches. Depending on the hitch category,

certain size pins are used to attach the implement to

the tractor. CAT I hitches require 7/8” lower and 3/4”

upper diameter hitch pins.

Always set the 3-point hitch in the “oat” mode to allow

the disc harrow to follow the contour of the ground.

Many newer tractors are equipped with “load sensing”

hydraulics. It is the responsibility of the operator to set

the tractor hydraulic system to provide ‘’oat” on the

3-point hitch. Refer to the tractor manual for details.

Install the lift arm stabilizer or shorten the stop chains

to place the arms into the non-sway con guration.

Refer to the tractor manual for details.

Always install weights on the front of the tractor to

provide extra stability and traction. This is particularly

important if your tractor is equipped with a front wheel

assist option.

5.3 Attaching to Tractor

Use caution when connecting the disc harrow to the

tractor. The disc harrow should be securely resting at

ground level or setting on blocks. Keep hands and feet

from under the plow and clear of pinch points between

the tractor hitch arms and disc harrow hitch pins.

WARNING

Crush Hazard

Crush hazard between hitch and implement.

Do not allow anyone to stand between the hitch

and implement during hook-up operations.

Never operate the hydraulic 3-point lift controls

while someone is directly behind the tractor.

1. Shorten or remove the tractor drawbar to avoid

interference when raising and lowering the disc

harrow.

2. Board the tractor and start the engine. Position the

tractor with the 3-point lift arms positioned at the

same height and to the outside of the disc harrow

hitch pins.

Note: Set the 3-point lift control to “Position Control”

so that the lift arms maintain a constant height

when attaching the disc harrow. See the tractor

Operator’s Manual for correct settings when

attaching 3-point equipment.

3. Turn off the tractor engine and dismount.

4. One lift arm at a time, insert hitch pin through the lift

arm holes and install retaining pin.

5. Walk around to the opposite side and repeat the

procedure for the remaining lift arm and hitch pin.

6. Extend or retract the 3-point top link to align its end

hole with the hole of the disc harrow’s top link. Insert

the top link hitch pin and insert the retaining pin into

the hitch pin.

7. Adjust any lower link check chains, guide blocks,

or sway blocks to prevent the disc harrow from

swaying side-to-side and possible contact with the

tractor rear tires.

This manual suits for next models

8

Table of contents

Other Titan Implement Farm Equipment manuals