VaritrakT.G. Schmeiser Co., Inc.

Ph. (559) 268-8128

Fax (559) 268-3279

www.tgschmeiser.com

3

Adjust Wing Turnbuckle............................20

Calibrate Wing Linkage.............................20

Initial Setup Checklist.........................................21

Implement Break-In............................................21

Connecting to Tractor.........................................21

Detaching from Tractor.......................................21

Field Operation...................................................22

Operation with a Laser System.................22

When Transporting Varitrak on the Road...........23

MAINTENANCE.......................................................23

Lubrication Points...............................................23

Wheel Hub Bearings.................................23

Wing Linkage.............................................23

Service Items......................................................24

Hydraulic Cylinders...................................24

Hydraulic Hoses........................................24

Front 3-Pt. Linkage....................................24

Tires...........................................................24

Ground Engaging Components..........................24

Bucket Blade.............................................24

S-Tines......................................................24

Maintenance Schedule.......................................25

STORAGE................................................................26

Storage Preparation...........................................26

Placing in storage...............................................26

Removing From Storage....................................26

PARTS SECTION.....................................................27

Component Nomenclature..................................27

Ordering Parts....................................................28

Parts Drawings...............................................28

Self-Leveling 3-Pt. Hitch Assembly...........28

3-Pt. Hitch Laser Option Assembly............29

Wing Linkage and Turnbuckle Assembly...30

Sliding Plates Assembly............................31

Dual Tire Frame Assembly........................32

Single Tire/Steel Wheel Frame Assembly..33

Wing Bucket Assembly..............................34

Rear Braces Assembly..............................35

S-Tine Attachment Assembly (Optional)...36

S-Tine Attachment Links Assembly (Opt.).37

S-Tine Assembly (Optional)......................38

S-Tine Layouts (Optional)..........................39

HYDRAULIC DIAGRAMS.........................................40

LIMITED WARRANTY STATEMENT.......................43

CONTENTS

INTRODUCTION........................................................4

Engineered for Long Life...................................4

Serial Number Information....................................4

Replacement Parts................................................4

Warranty Information............................................4

Serial Number Location.........................................4

Factory Contact Information..................................4

Dealer Contact Information....................................4

SPECIFICATIONS......................................................5

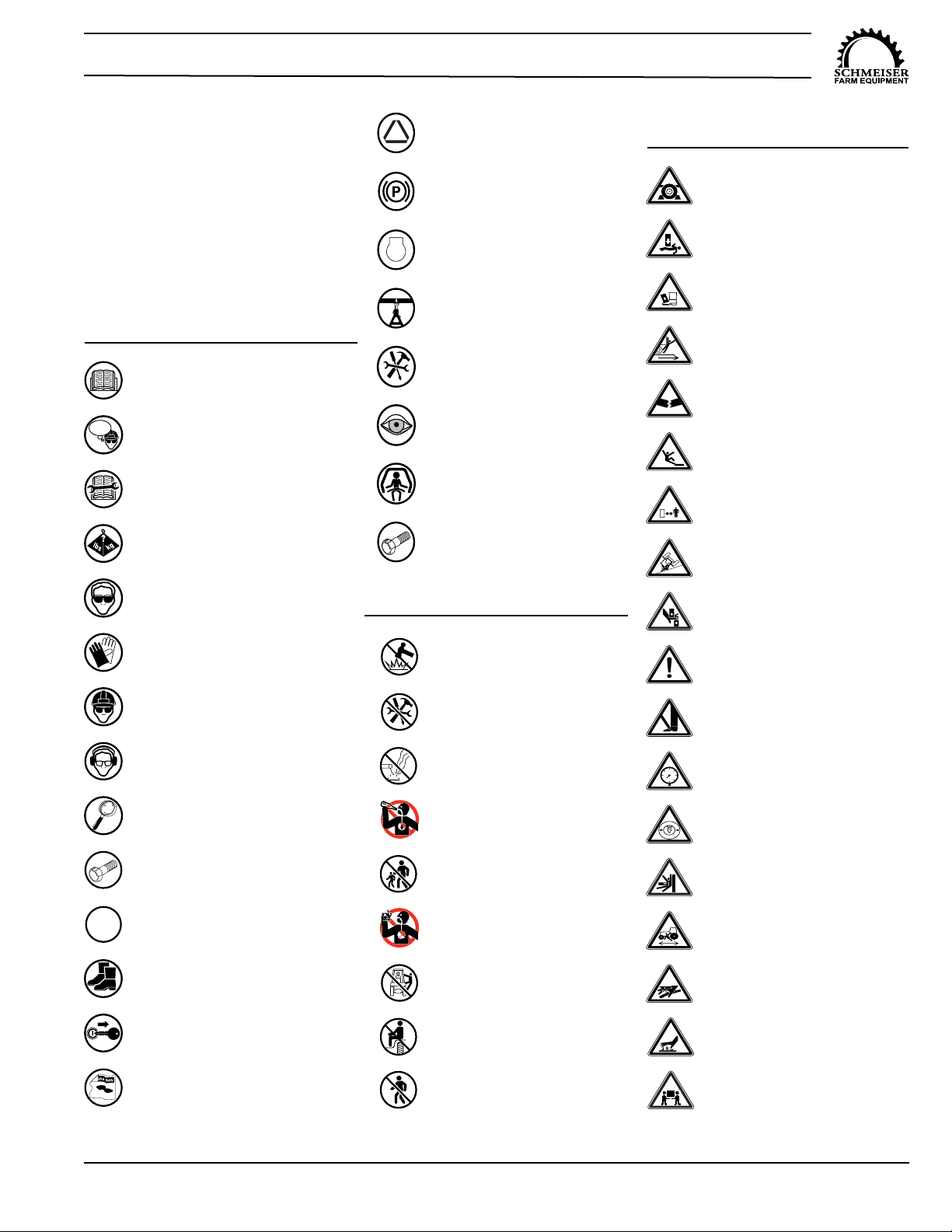

SAFETY......................................................................6

Safety Alert Symbols............................................6

Safety Icons Nomenclature..................................7

Personal Protection/Important Information..7

Prohibited Actions........................................7

Hazard Avoidance.......................................7

General Safety......................................................8

Assembly Safety...................................................8

Towing Safety.......................................................9

Highway and Transport Operations..........10

Operation Safety.................................................10

Tractor Requirements................................10

Tractor Safety Devices..............................11

ROPS and Seat Belt..................................11

Attaching to Tractor............................................11

Prior to Connecting Unit ............................11

Connecting to the Tractor..........................11

Hydraulic Component Safety..............................12

Maintenance Safety............................................12

Tires Safety...............................................13

Tire and Lug Torque Specifications...........13

Bolt Torque Requirements.........................13

Welding Repairs........................................14

Storage Safety...................................................14

Disposal of Equipment at End of Useful Life......14

Safety Marking and Lighting...............................15

SAFETY SIGNS AND DECALS...............................16

Safety Sign Placement....................................16

Safety Signs and Decals.....................................17

ASSEMBLY AND OPERATION...............................18

Assembly Procedure...........................................18

Self-Leveling Hitch.................................18

Laser Control Kit (Optional)..................19

S-Tine Assembly (Optional)..................19

Adjustment Procedure.......................................20

Level Wings..............................................20