TitanTec TT-BC620T User manual

TT-BC620T

1

ORIGINAL INSTRUCTION

Symbols and warning labels on the machine.

16

15

13

12

10

09

05

04

03

02

8

9

6

12

这2

5

14

3

GB02

Recommended

cutting attachment

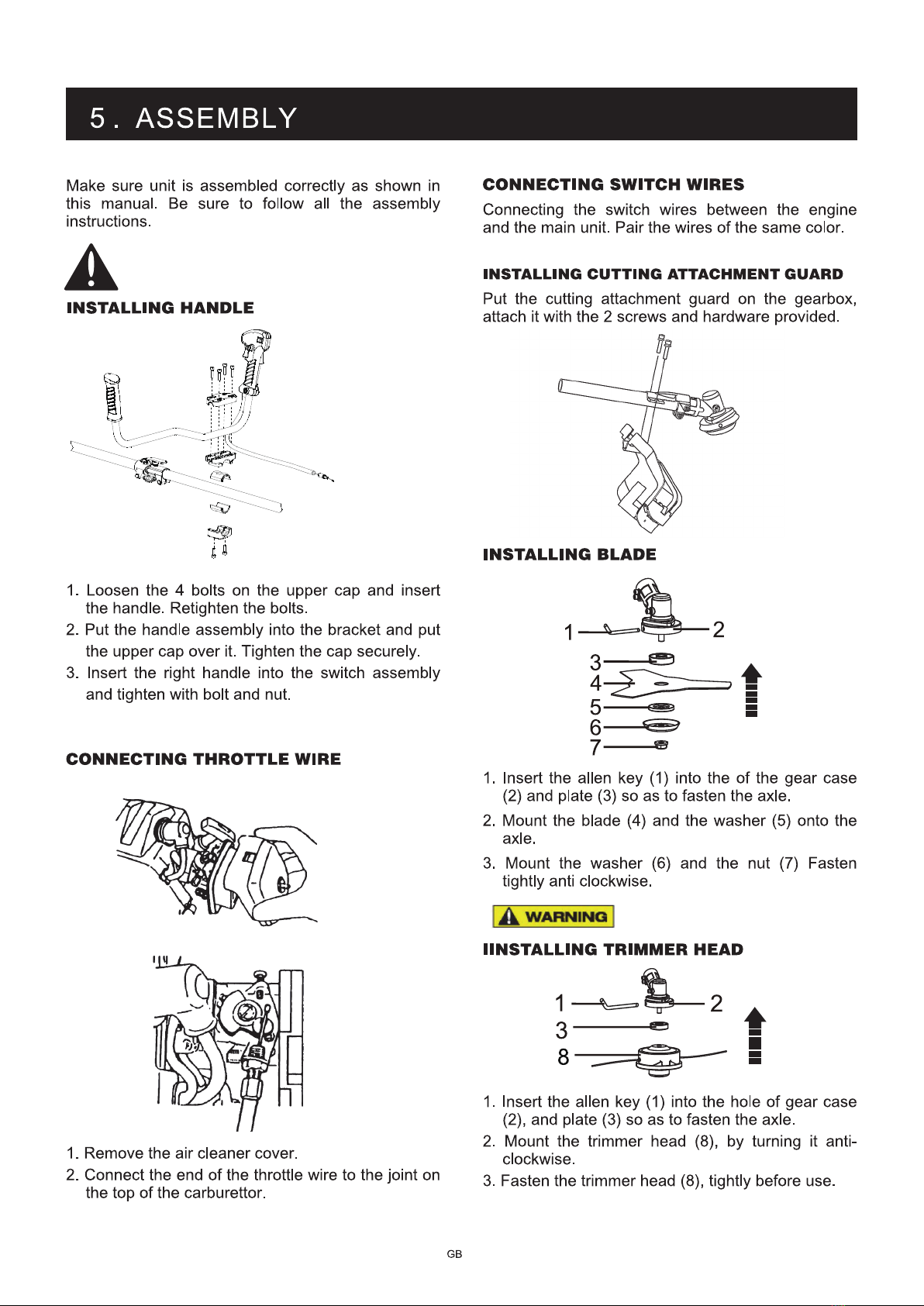

1.Only use accessories recommended by the manufacturer.

2.Never replace the nylon line with a metal wire. RISK OF INJURIES.

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/ EC.

Reported sound power level for the machine has been measured with the original cutting attachment that gives the highest

level. The difference between guaranteed and measured sound power is that the guaranteed sound power also includes

dispersion in the measurement result and the variations between different machines of the same model according to

Directive 2000/14/EC.

Model

Engine Displacement

Max. Engine power

Max. Engine speed

Recommend idling speed

Type of carburetor Diaphragm type

Fuel tank capacity 900 ml

Fuel mixture Ratio

Noise emmissiona (see note 1) Sound power level, measured dB(A):

Equipped with trimmer head: 107,7 K=3

Equipped with blade: 105,4 K=3

Sound power level, guaranteed LwA dB(A): 113

Noise levels

Vibration levels

Type

Blade

Non-metallic Flexible

cutting line

centre hole diameter

(mm)

Thickness of blade/

diameter of cutting line (mm)

Cutting width

(mm)

Trimmer head 440 2.4

255 1.6 25.4

Equivalent vibration levels (ahv,eq) at handles,

measured according to EN ISO 11806 and ISO 22867,

m/s2

Equivalent sound pressure level at the operator’s

ear, measured according to EN ISO 11806 and ISO

22868, dB(A):

Equipped with trimmer head: 99,5 K=3

Equipped with blade: 98,4 K=3

Sound pressure level, guaranteed LpA dB(A): 102

Equipped with trimmer head:

Left Handle: 5,259 K=1,5

Right Handle: 4,938 K=1,5

Equipped with blade:

Left Handle: 6,566 K=1,5

Right Handle: 9,661 K=1,5

Petrol 25 : Oil 1

Weight without fuel, harness, cutting attachment and guard 7.8kg

9000/min

3000/min

3teeth, single piece, metal

62cm3(air-cooled,2-stroke)

2.6 KW/8500/min

TT-BC620T

SYMBOLS AND WARRNING LABELS ON THE MACHINE

2. Cleaning and maintenance machine

before storage.

3. Use of a transport cover for metal blades

during transport and storage.

4

GENERAL WORKING INSTRUCTION AVOID KICKBACK

The best protection is to avoid situations that lead to setback s.

1.Keep the position of the upper guide rail always in mind.

2.Be especially careful when cutting in affected areas.

3.Cut only one branch at a time.

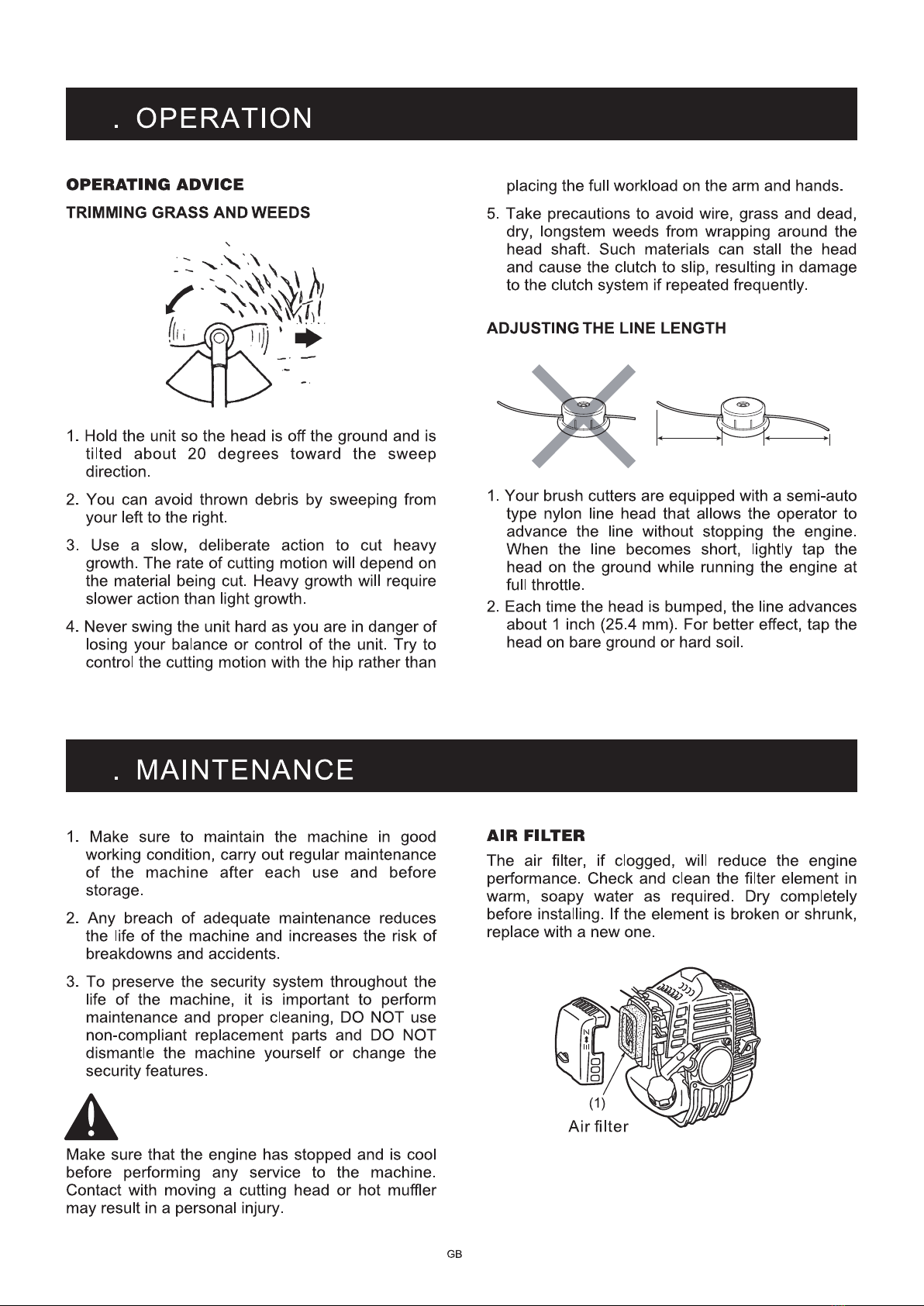

WARNING ABOUT SOUND AND VIBRATION

1.Wear ear-muffs

The impact of noise can cause damage to

hearing.

2.Reduce noise generation and vibration to a minimum!

OTHER BASIC SAFTY RULES

5. FOR SAFE OPERATION

QUICK RELEASE

CUTTING ATTACHMENT GUARD

data. If an incorrect or faulty guard is fitted this

can cause serious personal injury.

Use only equipment that is in perfect condition.

Maintain and clean the equipment

regulary.

Adopt your way of working to the equipment.

Do not overload the equipment.

Have the equipment checked if necessary.

Switch off the equipment when not in use.

Wear gloves.

There is an easily accessible, quic release fitted

at the front as a safety precaution in case the

engine catches fire, or in any other situation that

requires you to free yourself from the machine

and harness. See instructions under the heading

Adjusting the harness and brush cutter.

Check that the harness straps are correctly

positioned. Once the harness and machine have

been adjusted, check that the harness quick

release works correctly.

This guard is intended to prevent loose objects

from being thrown towards the operator. The

guard also protects the operator from accidental

contact with the cutting attachment.

Check that the guard is undamaged and not

cracked. Replace the guard if it has been exposed

to impact or is cracked.

Always use the recommended guard for the cutting

attachment you are using. See chapter on

Technical data.

Never use a cutting attachment without an approved

guard. See the chapter on Technical

1.Please note that some national regulations may

restrict the use of the machine.

2.Subject the brush cutter/grass trimmer to a visual

inspection before each use.

Before starting work, after tank filling, after impact or

dropping:

Check the cutting tools for secure seating,

general visual check for cracks and damage.

Immediately replace damaged or blunt cutting

tools, even in the event of minor hairline cracks.

Sharpen cutting tools (also when required)

3. Parts replacement

Never use without properly mounted blade

guard!

Only use original parts for accessories as well

as for wearing and spare parts. Spare parts are

available from your specialized dealer.

Have your brush cutter/grass trimmer serviced

only by qualified personnel and by use of

original spare parts only. This ensures that the

machine will work safety in the future.

Replace damaged or worn parts with match

ing spare parts they are in the shape and size

of the original parts as necessary.

08

Beware of blade thrust!

09

10

5

6

25

11

6

12

7

7

8

13

14

8

15

8

9

16

10

Table of contents