Titus TA1 User manual

Installation Manual ANA-IOM-1.0 3-10-20

TA1/TA2 Controller, CTE-5202 Thermostat

Installation, Operation, and Maintenance Manual

General Information

Power Requirements

TITUS TA1/TA2 controllers operate on 24 VAC power. Power

required to operate the controller and actuator is 7 VA plus any output

loads for fan relays, heating contactors, and control valves (assume

10 VA each). Always switch control voltage off prior to disconnecting

any wires from the controller to prevent possible damage to control

components.

Damper Control

TITUS TA1/TA2 controllers provide pressure independent VAV control

for terminal primary air valves. Primary airflow volume is monitored by

means of a multipoint center-averaging velocity sensor located in the

inlet duct. Differential pressure is measured by an on-board platinum

ceramic transducer. Dampers are always shipped full open and move

counter-clockwise (CCW) to close. The primary damper opens and

closes to vary air volume to match cooling demand. Changes in static

pressure will result in damper position changes for a given flow

volume. In automatic changeover (ACO) sequences, the primary

damper also moves to match heating demand. If the primary fan

system is off and the terminal is calibrated to control a minimum flow

limit other than 0 cfm, the damper will drive full open. Flow limit

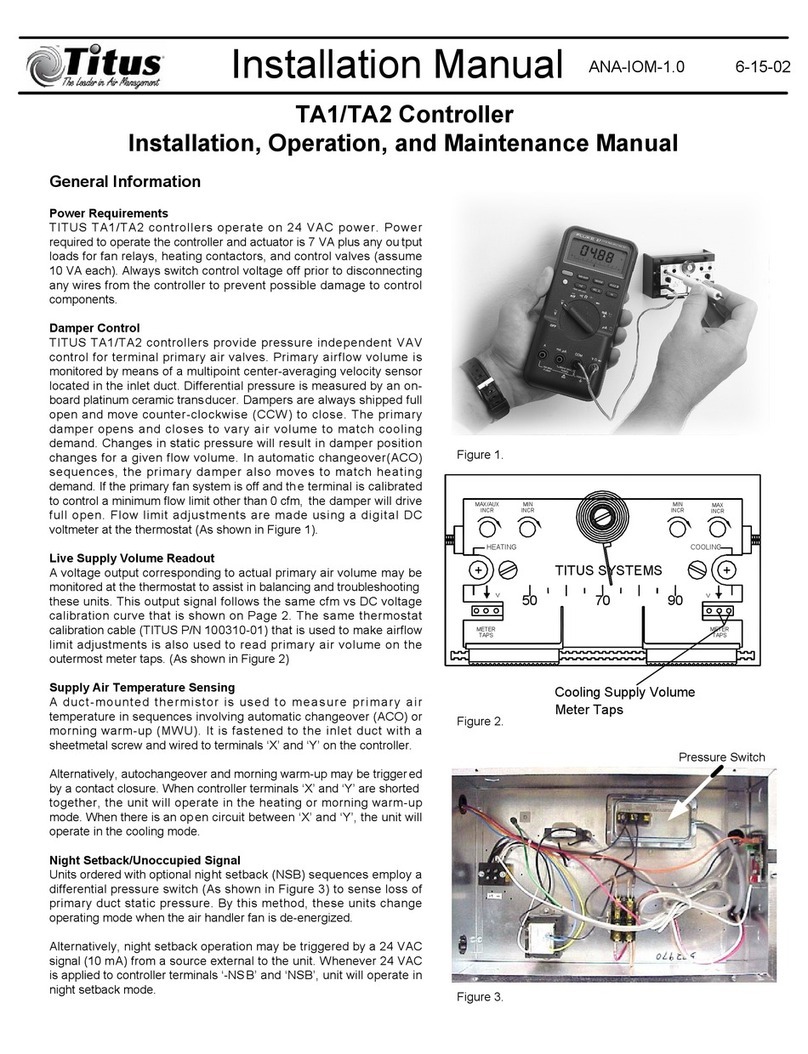

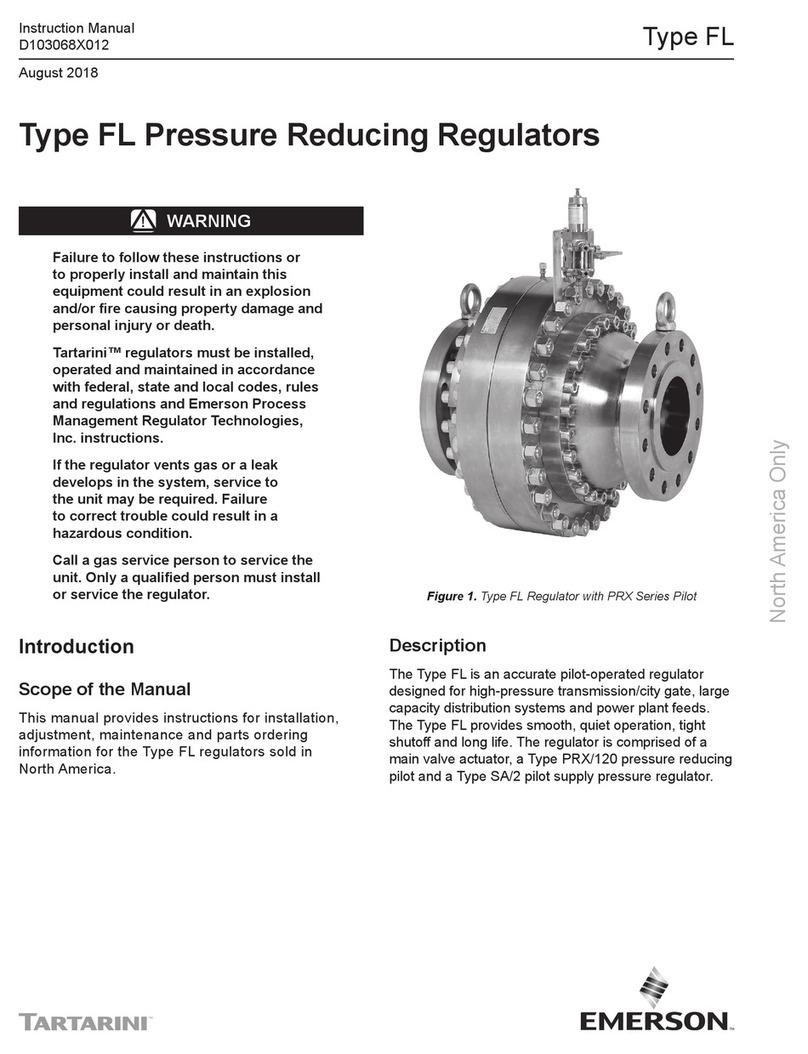

adjustments are at the thermostat (As shown in Figure 1).

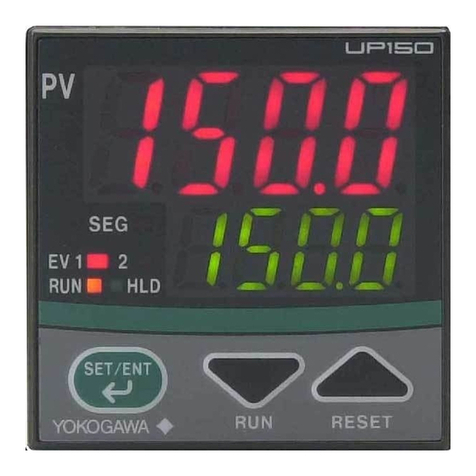

Live Supply Volume Readout

A voltage output corresponding to actual primary air volume may be

monitored at the thermostat to assist in balancing and troubleshooting

these units. This output signal follows the same cfm vs DC voltage

calibration curve that is shown on Figures 4 and 5.

Supply Air Temperature Sensing

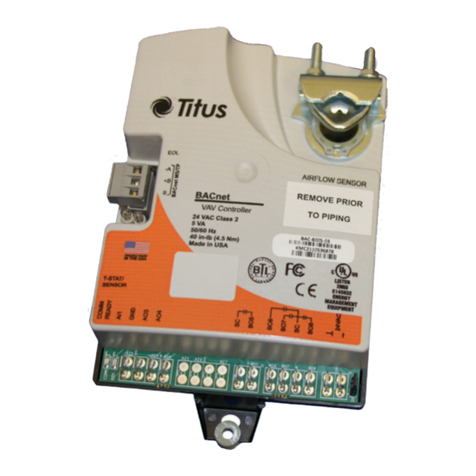

A duct-mounted thermistor is used to measure primary air

temperature in sequences involving automatic changeover (ACO) or

morning warm-up (MWU). It is fastened to the inlet duct with a

sheetmetal screw and wired to terminals ‘AI1’ and ‘┴’ on the

thermostat (As shown in Figure 2).

Alternatively, autochangeover and morning warm-up may be triggered

by a contact closure. When controller terminals ‘X’ and ‘Y’ are shorted

together, the unit will operate in the heating or morning warm-up

mode. When there is an open circuit between ‘X’ and ‘Y’, the unit will

operate in the cooling mode.

Night Setback/Unoccupied Signal

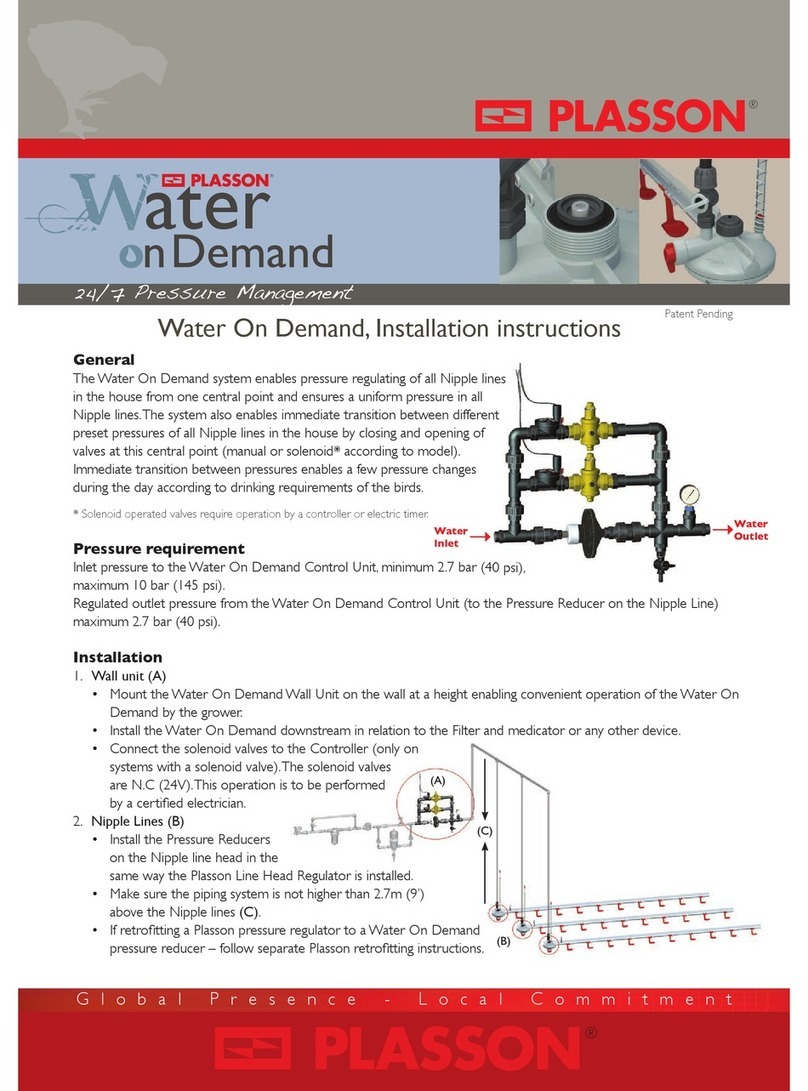

Units ordered with optional night setback (NSB) sequences employ a

differential pressure switch (As shown in Figure 3) to sense loss of

primary duct static pressure. By this method, these units change

operating mode when the air handler fan is de-energized.

Alternatively, night setback operation may be triggered by a 24 VAC

signal (10 mA) from a source external to the unit. Whenever 24 VAC

is applied to controller terminals ‘-NSB’ and ‘NSB’, unit will operate in

night setback mode.

Figure 1.

Figure 2.

Figure 3.

Pressure Switch

TA1 Controller Voltage vs. Airflow Curves

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

0 200 400 600 800 1000 1200 1400

Airflow (CFM)

Output Voltage (DC Volts)

4

5

6

7

8

9

TA1 Controller Voltage vs. Airflow Curves

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500 8000

Airflow (CFM)

Output Voltage (DC Volts)

10

12

14

16

8x14

8x18

16x24

ANA-IOM-2.0 3-10-20

Figure 4.

Figure 5.

Table 1. AeroCrossTM K-Factors

Terminal

Size

04

05

06

07

08

09

10

12

14

16

8x14

8x18

40(16x24)

K-Factor

(CFM)

273

360

448

667

904

1167

1436

1891

3015

3839

2106

2498

7176

ANA-IOM-3.0 3-10-20

Night Setback Temperature Adjustment

Adjustment of setback temperature is made by means of a plug-in resistor

(As shown in Figure 6). All TA1 controls provide a 47k ohm resistor that

provides an approximate 10° F setback in heating. Other 1/4 watt resistors

may be substituted in the field to achieve various setback temperatures

(see Table 2).

Fan Control

The TITUS TA1 provides sequencing for continuous and intermittent unit

fan operation. Fan relays with 24 VAC coils (10 VA max) are wired to

terminal ‘FAN/1’. Fan will run intermittently for parallel fan sequences if

jumper ‘J1’ on board is intact. Cutting jumper ‘J1’ will result in continuous

operation during occupied mode suitable for series fan sequences. Fan

volume adjustments are made with a screwdriver by means of a silicon-

controlled rectifier (SCR) or ECM Speed Controller located on the side of

the hi voltage control box. (As shown in Figure 7 and Figure 8)

On/Off Reheat Control

The TITUS TA1 provides sequencing for up to three stages of on/off heat.

Heat contactors with 24 VAC coils (10 VA max each) are wired to

terminals ‘Fan/1’, ‘1/2’, and ‘2/3’. Fan-powered sequences are limited to

two stages of heat. Two position, normally closed hot water valves (10 VA

max) are wired to ‘FAN/1’ for single duct sequences and ‘1/2’ for fan-

powered sequences. Jumper ‘J1’ must be intact to properly operate reheat

for single duct sequences.

Proportional Reheat Control

The TITUS TA1 provides sequencing for one stage of proportional heat.

Hot water valves with 0-10 VDC control signals (10 mA max) are wired

with (+) to terminal ‘T2’ on the thermostat and (-) to terminal ‘–’ on the

controller. (See Figure 6)

Thermostat Calibration

Thermostats are factory calibrated to specified flow limits. If field

adjustments are necessary, desired limit control can be calculated using

Table 1 and the following formulas, or Figures 4 and 5.

CFM = K[(0.1171 VDC) - 0.016]

VDC = {[CFM + (K x 0.016)]/(K x 0.1171)}

Voltage can be adjusted under ‘LIMITS’ menu in the thermostat (As

Shown on Figure 1). Always set minimum flow limits before setting

maximum flow limits. Voltages corresponding to desired flow limits are

modified using ‘UP’ and ‘Down’ arrows on thermostat under ‘LIMITS’ menu

(As Shown on Figure 1).

Table 2.

Figure 6.

Figure 7.

Figure 8.

Setback (oF) Resistance (K Ohm)

Setback Resistor Values

4.5

5.0

5.5

6.5

7.0

8.0

9.0

10.0

11.0

12.5

14.0

15.5

17.0

19.0

22.0

25.0

27.0

100

91

82

75

68

62

56

51

47

43

39

36

33

30

27

24

22

ANA-IOM-4.0 3-10-20

Single Duct Terminal Units Without Reheat

Thermostat Calibration Procedure

Press and hold both Up and Down arrows buttons for about 10

seconds until the display starts flashing “LIMITS”. Use Up or

Down arrow to display a flashing “SYSTEM”. Press “Set Point”

button. Select Sequence 01, SE01 and press “Set Point”

button, press Up or Down arrow to flashing “Exit”. Use Up or

Down arrows to navigate to “LIMITS” and press “Set Point”

Button. Set cooling minimum by adjusting voltage for A01 MIN

corresponding to desired minimum flow volume from Figures 4

and 5. Set cooling maximum by adjusting voltage for A01 Max

corresponding to desired maximum flow volume from Figures 4

and 5.

Optional Morning Warm-Up (MWU) Operation

If this option has been ordered, the unit damper will drive full

open regardless of flow limit settings whenever supply air

temperature is above 80° F.

Check-Out Procedure

Push the Setpoint button (or either Up/Down button) to display

the current setpoint value. Use the Up/Down buttons to change

the value below room temp. Press the Setpoint button again,

and the thermostat will control at the new setpoint. Observe

damper movement. After a few minutes check to see that the

unit has reached maximum flow limit.

Single Duct Terminal Units with Reheat

Thermostat Calibration Procedure

Press and hold both Up and Down arrows buttons for about 10

seconds until the display starts flashing “LIMITS”. Use Up or

Down arrow to display a flashing “SYSTEM”. Press “Set Point”

button. Select Sequence 02 SE02 and press “Set Point” button,

press Up or Down arrow to flashing “Exit”. Use Up or Down

arrows to navigate to “LIMITS” and press “Set Point” Button.

Set cooling minimum by adjusting voltage for A01 MIN

corresponding to desired minimum flow volume from Figures 4

and 5. Set cooling maximum by adjusting voltage for A01 Max

corresponding to desired maximum flow volume from Figures 4

and 5. Set heating minimum by adjusting voltage for A02 MIN

corresponding to desired minimum flow volume from Figures 4

and 5. Set heating maximum by adjusting voltage for A02 Max

corresponding to desired maximum flow volume from Figures 4

and 5. If no Auxiliary Flow is desired, set A01 Aux to 0.

Check-Out Procedure

Push the Setpoint button (or either Up/Down button) to display

the current setpoint value. Use the Up/Down buttons to change

the snowflake/cool value above room temp. Press the Setpoint

button again, and the thermostat will control at the new

setpoint. Observe damper movement. After a few minutes

check to see that the unit has reached maximum flow limit.

Push the Setpoint button (or either Up/Down button) to display

the current setpoint value. Use the Up/Down buttons to change

the fire/heat value above room temp. Press the Setpoint button

again, and the thermostat will control at the new setpoint.

Observe damper movement. After a few minutes check to see

that the unit has reached minimum flow limit.

Single Duct Terminal Units with Heating/

Cooling Autochangeover(ACO)

Thermostat Calibration Procedure

Snowflake/cool is the cooling setpoint used to control damper

operation when supply air is below 70° F. Fire/heat is the

heating setpoint used to control operation when supply air is

above 80° F.Press and hold both Up and Down arrows buttons

for about 10 seconds until the display starts flashing “LIMITS”.

Use Up or Down arrow to display a flashing “SYSTEM”.

Press “Set Point” button. Select Sequence 02 SE02 and press

“Set Point” button, press Up or Down arrow to flashing “Exit”.

Use Up or Down arrows to navigate to “LIMITS” and press “Set

Point” Button. Set cooling minimum by adjusting voltage for

A01 MIN corresponding to desired minimum flow volume from

Figures 4 and 5. Set cooling maximum by adjusting voltage for

A01 Max corresponding to desired maximum flow volume from

Figures 4 and 5. Set heating minimum by adjusting voltage for

A02 MIN corresponding to desired minimum flow volume from

Figures 4 and 5. Set heating maximum by adjusting voltage for

A02 Max corresponding to desired maximum flow volume from

Figures 4 and 5. If no Auxiliary Flow is desired, set A01 Aux to

0.

Check-Out Procedure

With primary fan system supplying cold air (below 70°F), Push

the Setpoint button (or either Up/Down button) to display the

current setpoint value. Use the Up/Down buttons to change the

snowflake/cool value above room temp. Press the Setpoint

button again, and the thermostat will control at the new

setpoint. Observe damper movement. After a few minutes

check to see that the unit has reached maximum flow limit.

With primary fan system supplying hot air (above 80°F), Push

the Setpoint button (or either Up/Down button) to display the

current setpoint value. Use the Up/Down buttons to change the

fire/heat value above room temp. Press the Setpoint button

again, and the thermostat will control at the new setpoint.

Observe damper movement. After a few minutes check to see

that the unit has reached minimum flow limit.

Fan Powered Terminal Units without Heat

Thermostat Calibration Procedure

Press and hold both Up and Down arrows buttons for about 10

seconds until the display starts flashing “LIMITS”. Use Up or

Down arrow to display a flashing “SYSTEM”. Press “Set Point”

button. Select Sequence 01, SE01 and press “Set Point”

button, press Up or Down arrow to flashing “Exit”. Use Up or

Down arrows to navigate to “LIMITS” and press “Set Point”

Button. Set cooling minimum by adjusting voltage for A01 MIN

corresponding to desired minimum flow volume from Figures 4

and 5.

Optional Morning Warm-Up (MWU) Operation

If this option has been ordered, the unit damper will drive full

open regardless of flow limit settings whenever supply air

temperature is above 80° F.

Optional Night Shutdown (NSD) Operation

Units ordered with optional night shutdown (NSD) sequences

employ a differential pressure switch to sense loss of supply

duct static pressure. By this method, these units change

operating mode when the air handler fan is de-energized. If this

option has been ordered, the unit fan will de-energize

whenever the air handler unit (AHU) is off. If a minimum flow

limit has been set at the thermostat, the unit damper will drive

full open.

Optional Night Setback (NSB) Operation

Units ordered with optional night setback (NSB) sequences

employ a differential pressure switch to sense loss of supply

duct static pressure.

By this method, these units change operating mode when the

air handler fan is de-energized. If this option has been ordered,

the unit fan will operate intermittently to maintain a temperature

setpoint approximately 10° F below the thermostat setting

whenever the air handler unit (AHU) is off. If a minimum flow

limit has been set at the thermostat, the unit damper will drive

full open.

Check-Out Procedure

Fan should be energized regardless of mode on series fan-

powered units (ATQS/ATFS/AFLS). Push the Setpoint button

(or either Up/Down button) to display the current setpoint value.

Use the Up/Down buttons to change the value above room

temp to energize fan on parallel fan-powered units (ATQP/

AFLP). Press the Setpoint button again, and the thermostat will

control at the new setpoint. Observe damper movement. After

a few minutes check to see that the unit has reached minimum

flow limit.

Check-Out Procedure (Night/Unoccupied Mode)

Push the Setpoint button (or either Up/Down button) to display

the current setpoint value. Use the Up/Down buttons to change

the value above room temp to energize fan. Press the Setpoint

button again, and the thermostat will control at the new

setpoint.

Fan Powered Terminal Units with Heat

Thermostat Calibration Procedure

Press and hold both Up and Down arrows buttons for about 10

seconds until the display starts flashing “LIMITS”. Use Up or

Down arrow to display a flashing “SYSTEM”. Press “Set Point”

button. Select Sequence 02 SE02 and press “Set Point” button,

press Up or Down arrow to flashing “Exit”. Use Up or Down

arrows to navigate to “LIMITS” and press “Set Point” Button.

Set cooling minimum by adjusting voltage for A01 MIN

corresponding to desired minimum flow volume from Figures 4

and 5. Set cooling maximum by adjusting voltage for A01 Max

corresponding to desired maximum flow volume from Figures 4

and 5. Set heating minimum by adjusting voltage for A02 MIN

corresponding to desired minimum flow volume from Figures 4

and 5. Set heating maximum by adjusting voltage for A02 Max

corresponding to desired maximum flow volume from Figures 4

and 5. If no Auxiliary Flow is desired, set A01 Aux to 0.

Optional Night Shutdown (NSD) Operation

Units ordered with optional night shutdown (NSD) sequences

employ a differential pressure switch to sense loss of supply

duct static pressure. By this method, these units change

operating mode when the air handler fan is de-energized. If this

option has been ordered, the unit fan will de-energize

whenever the air handler unit (AHU) if off. This will effectively

lock-out all heat operation. If a minimum flow limit has been set

at the thermostat, the unit damper will drive full open.

Optional Night Setback (NSB) Operation

Units ordered with optional night setback (NSB)

sequences employ a differential pressure switch to sense loss

of supply duct static pressure. By this method, these units

change operating mode when the air handler fan is de-

energized. If this option has been ordered, the unit fan and

heat will operate intermittently to maintain a temperature

setpoint approximately 10°F below the thermostat heating

setpoint whenever the air handler unit (AHU) is off. If a

minimum flow limit has been set at the thermostat, the unit

damper will drive full open.

Check-Out Procedure (Day/Occupied Mode)

Fan should be energized regardless of mode on series fan-

powered units (ATQS/ATFS/AFLS). Push the Setpoint button

(or either Up/Down button) to display the current setpoint value.

Use the Up/Down buttons to change the value above room

temp to energize fan on parallel fan-powered units (ATQP/

AFLP). Press the Setpoint button again, and the thermostat will

control at the new setpoint. Observe damper movement. After

a few minutes check to see that the unit has reached minimum

flow limit.

Check-Out Procedure (Night/Unoccupied Mode)

Push the Setpoint button (or either Up/Down button) to display

the current setpoint value. Use the Up/Down buttons to change

the value above room temp to energize fan. Press the Setpoint

button again, and the thermostat will control at the new

setpoint.

NOTE: LETTING THE MENU TIME-OUT (ABOUT 30

SECONDS) WILL NOT PREMANENTLY SAVE CHANGES.

Troubleshooting Procedures

Note: TURN OFF POWER BEFORE MAKING ANY WIRING

CHANGES TO THE UNIT FOR TROUBLESHOOTING.

To Check Operation of Controller’s Damper Output Circuit

and Actuator

Disconnect wire from terminal ‘T1’ on controller and put a wire

nut on it. If unit is equipped with morning warm-up or

autochangeover, disconnect wire from terminal ‘Y’ on controller

and put a wire nut on it. Connect a jumper wire between

terminals ‘16VDC’ and ‘T1”, and observe actuator driving full

open. Move jumper wire to connect terminals ‘-‘ and ‘T1’, and

observe actuator driving damper full closed. Remove jumper

wire and reconnect wires to terminals ‘T1’ and ‘Y’.

If Actuator Appears to be Inoperative

Check to see if the damper blade is free to move and that the

actuator gears are engaged. Press in the red linkage release

button on the actuator. It should be possible to turn the actuator

collar whenever this button is held down. After releasing the

button always check to make sure the collar is properly

engaged by attempting to turn it by hand. No movement should

be possible when the button is released.

To Check Operation of Controller’s On/Off Reheat Output

Circuit

Disconnect wire from terminal ‘TX REHEAT’ and put a wire nut

on it. Connect a jumper wire between terminals ‘16VDC’ and

‘TX REHEAT’ and observe that all the heat stages are

energized.

If Desired Thermostat Voltage Settings Cannot be

Achieved

Make sure that minimum flow limit setting is made prior to

setting maximum flow limit setting. If procedure are followed

correctly and problem persists, thermostat will need to be

replaced.

ANA-IOM-5.0 3-10-20

ANA-IOM-6.0 3-10-20

If Voltage Reading Float or Appears to be Unstable during

Thermostat Calibration

Check to make sure that the wire connecting ‘-‘ on the

controller to ‘┴’ on the thermostat is tight and properly

connected. This is the reference ground wire for the regulated

16VDC thermostat supply output. A loose connection will result

in unstable readings due in part to atmospheric static

electricity.

If Unit Fan Runs Intermittently During Day/Occupied

Operation on a Series Fan Powered Terminal

Check the ‘J1’ jumper on controller to see if it has been cut.

When this jumper is cut and removed, fan will run continuously

for Day/Occupied mode. This jumper should be left intact for all

applications other than series fan powered terminals.

Important Operational Note

To guarantee proper autochangeover operation, it is

recommended that minimum flow limits are used for both

heating and cooling modes. This allows airflow to constantly

pass through the unit for accurate supply air temperature

measurement.

This manual suits for next models

1

Table of contents

Other Titus Controllers manuals

Popular Controllers manuals by other brands

Thermo Scientific

Thermo Scientific Uniry Lab Services UP150 Operation

Argus

Argus E25 MOD II instructions

RIB

RIB DUKE 24V manual

EuroLite

EuroLite DMX LED Operator 2 user manual

Lorenz

Lorenz MAGNUM Pro HD WARNING AND INSTALLATION MANUAL

Emerson

Emerson Bettis XTE3000 Installation, operation and maintenance manual