TKR Group VAS 294 011A Instructions for use

VAS 294 011A

Granule jet blasting device

Translation of original instruction manual

2

3

www.tkr-support.com

1.

2.

3.

4.

5.

This instruction manual is protected by copyright. Any use outside of the boundaries of copyright law without

the consent of the manufacturer is not permitted and is punishable by law. This also applies to the extraction

of individual illustrations and the use of texts in excerpt form.

Chapter Page

1. Information regarding this manual 4

2. Permitted operators 4

3. Explanation of symbols 4

1. Intended use 5

2. Sources of danger 5

3. Safety devices 6

4. Safety measures at the setup location 7

1. Unpacking the device 8

2. Identification and description of the device components 8

3. Device components 9

4. Technical data 10

1. Operating the granule jet blasting device 10

2. Preparing and connecting the granule jet blasting device 11

3. Filling with blast medium 12

4. Connecting the suction hose to the suction unit 13

5. Attaching the blasting probe to the handle 14

6. Starting the cleaning process 15

7. Blasting 15

8. Cleaning the inlet valves and the inlet channel 16

9. Shutting down the device 17

1. Maintenance / cleaning 17

2. Replacement parts and accessories for the

granule jet blasting device 19

3. Warranty 20

4. EU Declaration of Conformity 21

1. Download current instruction manuals

2. Support

4

Note

State-of-the-art

Technical modifications

Reading the

instruction manual

Handling

Faults

Legislation stipulates that users must be trained in the use of manually operated blasting

equipment.

The granule jet blasting device is state of the art. To ensure that the equipment operates safely, it

must be operated in a proper and safe manner.

In the interests of quality assurance, we reserve the unrestricted right to apply technical

modifications arising out of further developments in technology and product improvements

without prior notification.

Read the instruction manual carefully before using the device.

All handling necessary to ensure correct operation is described in the instruction manual.

No working method which is not expressly approved by the manufacturer may be used. If the

device malfunctions during use, only trained technical personnel are permitted to repair it.

1.2 Permitted operators

1.3 Explanation of symbols

Follow the instruction

manual

Observe the general

instructions

Wear face mask

Wear hear protection

Wear gloves

Wear protective clothing

WARNING

Use of this machine with

nut granulates will produce

allergenic dust.

Persons allergic to nuts

should not use this machine

without adequate respiratory

safety equipment.

Several sections of these operating instructions are marked with internationally recognised warning signs, danger notes and general

prohibition signs. Please comply with all notes and safety rules! The individual symbols are explained in the following.

Follow all instructions and safety rules.

The owner/operator of the machine must make the operating instructions available to the operator and ensure

that they have been read and understood. Only then may the operator start up the device.

1.1 Information regarding this manual

5

The granule jet blasting device complies with the machinery directive 2006/42 EC and is used to treat the surface

of metal by means of a jet of granules blasted onto the metal surface. Compressed air is used to propel the blast

medium.

The granule jet blasting device is used to remove carbonized material from the inlet channel and valves of internal

combustion engines.

The jet blasting device may only be operated in combination with the vacuum adapters that are approved for the

particular engine type and a vacuum cleaner with sufficient suction power.

Unauthorised modifications or changes to the device are not permitted for safety reasons.

2.1 Intended use

2.2 Sources of danger

1.3 Explanation of symbols

Warning

General source of danger

Warning

System under pressure

Risk of hearing damage

Warning - noise with high

sound pressure level

Blow out with air

Clean with air/granule

mixture

Audibly engage

Please note the following!

Arrow to clarify

compression

Arrow indicating direction

For further information

see chapter...

The granule jet blasting device is safe if used for its correct purpose.

If it is used incorrectly and/or negligently by untrained personnel, serious injuries could be caused by the granules

emerging from the device.

The blasting probe must never be used without the suction adapter intended for it and a suction device of

sufficient power.

Never direct the blasting probe at persons or look into the opening of the blasting probe. Risk of injury!

6

2.3.1 2.3.2

2.2 Sources of danger

2.3 Safety devices

The device must only be operated using hoses which are approved for the purpose of use and the operating pressure of

the device.

The device may only be used by trained personnel.

• Never throw or drop the granule jet blasting device.

• The granule jet blasting device may only be used at ambient temperatures of between 5 °C and 45 °C.

• The granule jet blasting device must not be used in potentially explosive areas!

• The device must never be operated without suitable protective clothing, such as a safety mask and safety shoes. Risk

of injury!

The compressed air must be disconnected and the device depressurised before maintaining and cleaning or

filling the device with granules.

The granule jet blasting device may only be operated with compressed air.

The granule jet blasting device must always be set up on a level surface or the floor of the workshop. The device

must not be set up on tables, workbenches or other objects. (Tank is under pressure!)

Hoses and supply lines must be routed in such a way that they cannot be damaged or disconnected! The hoses must also

be routed in a way that prevents people from tripping over them.

chap. 5.1

chap. 2.4

Position B:

Operating

Position A:

Depressurise

Fig. 2.3.1

The compressed air must be disconnected

and the device depressurised.

Fig. 2.3.2

In the “Depressurise“ position, the tank and the

control system are switched to depressurise.

7

7

2.4.1

2.3.1

2.3 Safety devices

Fig. 2.4.1

The surface where the device is installed must be level and of

suitable load carrying capacity for the weight of the device and

must be stable.

The device may only be operated in association with the suction

adapters designed for the particular engine type and a vacuum

cleaner of sufficient size and power.

Hoses and feed pipes must be laid so that they cannot be dam-

aged or disconnected! The hoses must also be routed in a way

that prevents people from tripping over them.

2.4 Safety measures at the setup location

If a control function fails, the device must be taken out of service immediately and repaired by a trained technical

personnel!

There is a pressure gauge on the granules tank. The operating pressure of the device must never exceed 8 bar. A

safety valve is installed on the granules tank that controls the maximum operating pressure of the device. The

valve opens at pressure of approx. 8.5 bar.

If the safety setup location malfunction, the device must be taken out of service immediately! The device should

undergo preventive maintenance at least once per annum by a specialist company!

Fig. 2.3.3

There is a 2-way ball valve on the handle of the blasting probe. This can be operated in the event of failure of a control

function. When the ball valve is closed, no air or blasting medium can emerge from the probe.

8

3.1.1

3.2 Identification and description of the device components

3.1 Unpacking the device

Main elements of the granule jet blasting device:

Granule blasting medium tank with 3-way ball valve, granules control valve, compressed air control valve and safety valve.

Hose assembly with granules delivery hose and three colour-coded control hoses.

Handle with 2-way ball valve and connection for the blasting probe. The control function in the handle is activated using two control

valves connected in series. The operating lever is fitted with a safety device to prevent the equipment restarting unintentionally.

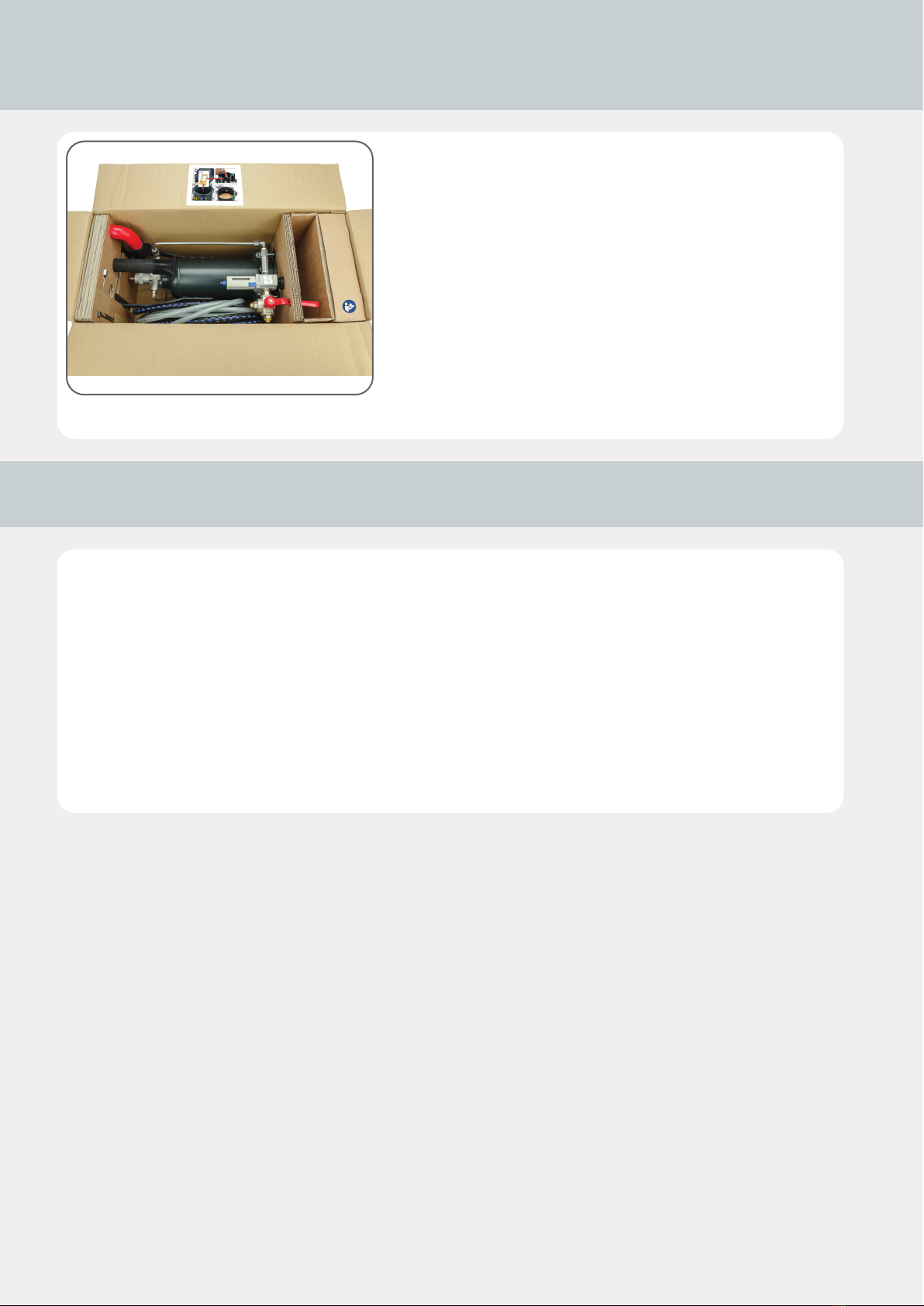

• Place the box on a level surface.

• Open the box and carefully remove the device.

• Check the scope of supply:

- Operating instructions

- Granules tank with hose assembly

attached and handle

- Straight blasting probe

- Angled blasting probe

- 2x seals

- Suction hose 90°

- Suction hose 250 mm

- Container with nutshell granules

9

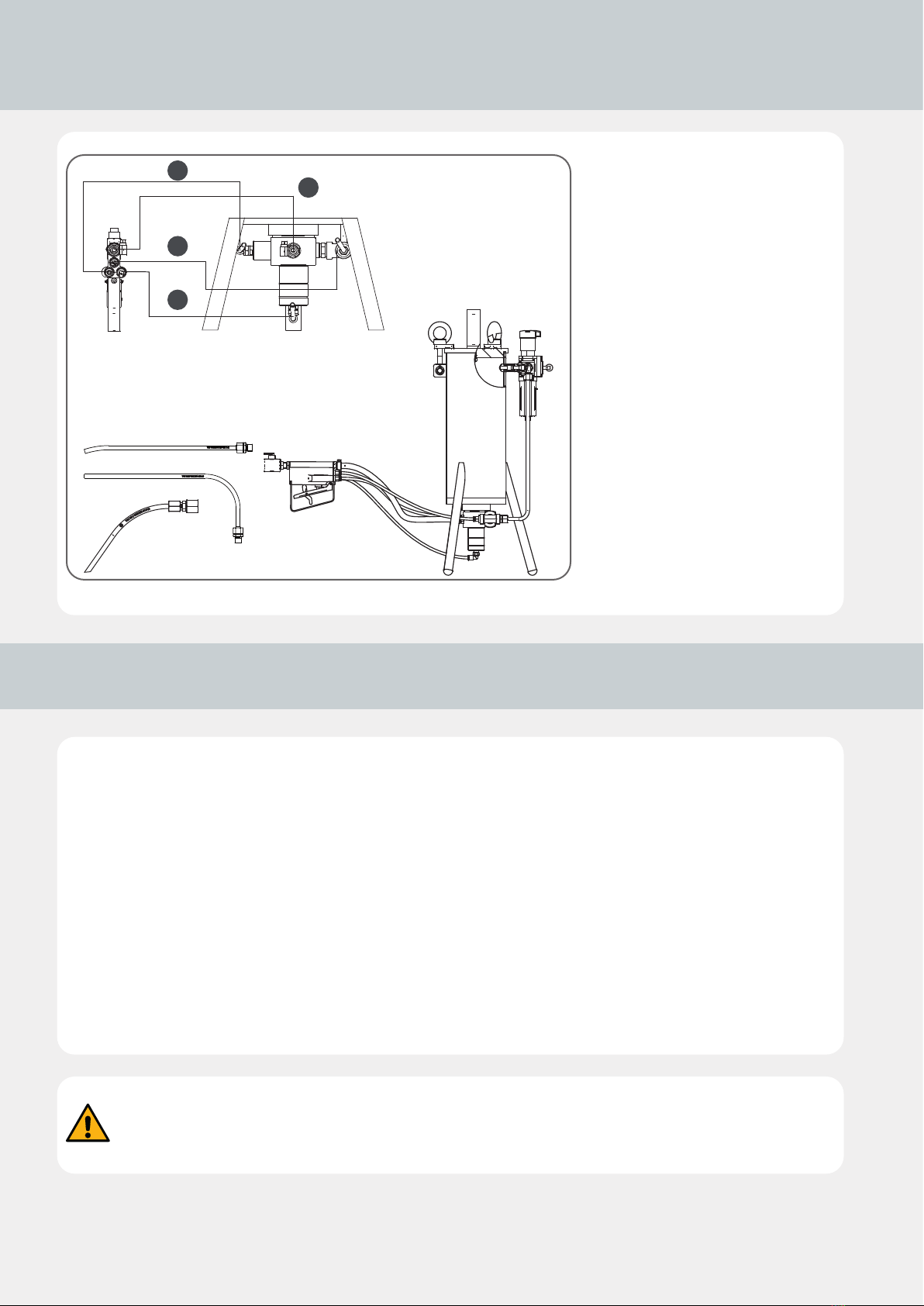

3.3.1

2

3

4

7

7

8

1

5

6

9

3.3 Device components

No. Title Quantity

1 Granule blasting device 1

2Straight blasting probe 1

3 Angled blasting probe 1

4Blasting probe 1

5 Suction hose 90° 1

6 Suction hose 250 mm 1

7Seal 2

8 Cleaning granulate –

9Instruction manual, complete 2

10

3.4.1

1

2

3

4

3.4 Technical Data

Length approx 290 mm

Width approx 280 mm

Height 610 mm

Max. operating pressure 8 bar

Container volume 5 l

Weight 16 kg

Hose package working length 4 m

Length and weight without hoses

4.1 Operation of the granule jet blasting device

• Fill with blasting granules.

• Connect the suction hose to the suction unit.

• Connect the seal and suction hose together.

• Attach the blasting probe to the handle.

• Attach the granule jet blasting device to the compressed air supply.

• Connect the suction hose to the opening on the engine and push the seal on the engine.

• Plug the blasting probe into the opening of the suction hose.

• Start the cleaning process.

• Clean the inlet valves and the inlet channel.

• Blow out: blast with air.

• Stop the compressed air supply.

• Shut down the device.

• Maintain the granule jet blasting device.

Always check the condition of the hoses before starting up the device!

Stop using defective hoses immediately. Risk of injury!

1 = Control air, black hose

2 = Main air, transparent hose

3 = Granules supply, blue hose

4 = Blasting medium hose, Ø14 mm

Straight blasting probe 3/3-way

control valve

Angled blasting probe

Blasting probe

11

4.2.14.2.1 4.2.2

4.2.4

4.2.3

4.2.5 4.2.6

4.2.84.2.7

G1/4G1/4“

R1/4“R1/4“

• Fill with blasting granules.

• Connect the suction hose to the suction unit.

• Connect the seal and suction hose together.

• Attach the blasting probe to the handle.

• Attach the granule jet blasting device to the compressed air supply.

• Connect the suction hose to the opening on the engine and push the seal on the engine.

• Plug the blasting probe into the opening of the suction hose.

• Start the cleaning process.

• Clean the inlet valves and the inlet channel.

• Blow out: blast with air.

• Stop the compressed air supply.

• Shut down the device.

• Maintain the granule jet blasting device.

4.2 Preparing and connecting the granule

jet blasting device

Fig. 4.2.1

The device is supplied from the factory

without a compressed air coupling. The

ball valve has a ¼ inch female threaded

connection. The thread is fitted with a

seal cap.

Fig. 4.2.2

Remove the sealing cap.

Fig. 4.2.3

Insert a suitable compressed air connec-

tor with seal into the thread.

Fig. 4.2.4

Tighten the compressed air connector

using a suitable tool.

The device must only be operated

using dry, oil-free compressed air!

Fig. 4.2.6

The granule jet blasting device has an in-

tegrated supply unit which enables you

to adjust the operating pressure.

Fig. 4.2.7 / 4.2.8

The operating pressure of the device

should be between 6 and 8 bar, and must

never exceed an operating pressure of

8 bar!

6 - 8 barmax. 8 bar

Ø 6 mm

≥ Ø 6 mm

12

4.3.24.3.1

4.3.3

4.3.64.3.6

4.3.4 4.3.5

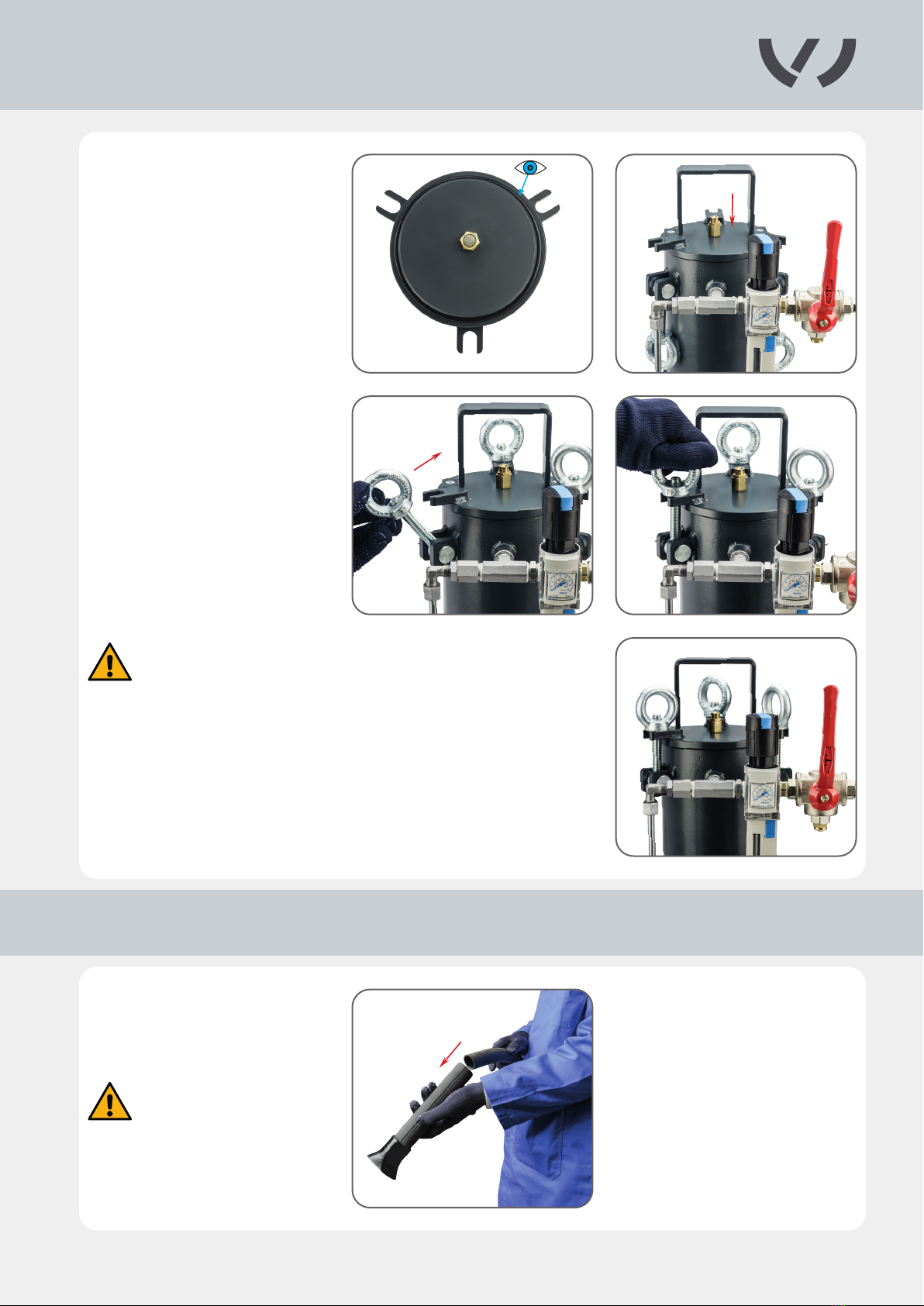

4.3 Filling with blasting medium

Warning! You must only fill the device when the tank is depressurised

anddisconnected from the supply line.

Only use a blasting medium which is approved by the manufacturer.

The blasting medium must be free of impurities.

Never re-use blasting medium.

Fig. 4.3.1

3-way ball valve in "Depressurise" posi-

tion (red lever).

Fig. 4.3.2

Pressure gauge must zero pressure.

Fig. 4.3.3

Undo eye bolts and swivel out swivelling

screw fitting.

Fig. 4.3.4

Remove the cover from the tank.

Fig. 4.3.5

Fill with granules.

Fig. 4.3.6

Max. filling level 20–30 mm below air inlet

connection.

20–30 mm

13

4.3.84.3.7

4.3.104.3.9

4.3.11

4.4.1

4.3 Filling with blasting medium

Fig. 4.3.7

Check sealing cap. The seal must be clean

and must not show any signs of damage.

Fig. 4.3.8

Place the cover on the tank.

Fig. 4.3.9

Engage the swivelling screw fitting.

Fig. 4.3.10

Tighten eye bolts by hand.

Fig. 4. 3.11

3-way ball valve in “Depressurise” position.

Fig. 4.4.1

Connect the suction hose to an industrial

vacuum cleaner.

Make sure that the suction hose is

firmly and securely connected to the

vacuum cleaner.

Check device for leaks!

If compressed air is leaking from the device, you must stop work and

eliminate the cause!

4.4 Connecting the suction hose to the suction unit

14

4.4.2

4.5.1 4.5.2

4.5.44.5.3

7

4.4 Connecting the suction hose to the suction unit

Fig. 4.4.2

Fix the suction hose in the inlet channel of the cylinder head.

Then, push the seal onto the engine block.

Fig. 4.5.1

Screw the correct blasting probe on to

the 2-way ball valve.

Fig. 4.5.2

Turn the 2-way ball valve to the open

position.

Fig. 4.5.3

Slowly turn 3-way ball valve to the oper-

ating position.

Fig. 4.5.4

No air must come out of the blasting

probe unless the hand lever is operated.

The device is now ready for operation!

Use the 90° suction hose (red) for transverse engines!

Use the 250 mm suction hose (black) for longitudinal engines!

Close or cover all openings except the one which is being worked on.

4.5 Attaching blasting probe to handle

15

4.6.24.6.1

4.7.1 4.7.2

2

1

2

1

4.6 Starting the cleaning process

4.7 Blasting

Before the cleaning process is started,

the operator must put on the prescribed

protective clothing!

Fig. 4.7.1

Blasting with air / blowing out

When the trigger is moved to position 1

(half-way position) only air comes out of

the blasting probe.

This operating position is used to blow

out the area to be cleaned.

Fig. 4.7.2

Blasting with air/granules mixture /

cleaning

When the trigger is moved to position 2

(pushed all the way) air and granules flow

out of the blasting probe with considera-

ble power.

This operating position is used to clean

the coked areas).

This device must only be used by trained and instructed technical

personnel!

Never pull the blasting probe out of the suction adapter during

the cleaning process!

Risk of injury!

16

4.8.1 4.8.2

4.8.3 4.8.4

4.8.5

4.8.6

7

3

4.8 Cleaning the inlet valves and the inlet channel

Fig. 4.8.1 – 4.8.4

The blasting probe must be positioned

close to the surfaces being cleaned. The

cleaning phases should last no more than

2-3 seconds. Then the area being cleaned

should be blown out again with air.

Alternate between cleaning and blowing

out several times. Each time the blast-

ing probe must be moved to a different

position so that the entire coked area is

cleaned.

Fig. 4.8.5

After all cleaning positions have been

blasted once, the cleaning result must

be visually inspected. If the result is un-

satisfactory, the process must be repeat-

ed and/or the operating pressure of the

device increased. Max. 8 bar!

Fig. 4.8.6

The inlet valves and the inlet channel

area should be bare and free of carbon-

isation.

When cleaning and blowing out, blast-

ing medium must not escape from the

suction adapter! If blasting medium is

escaping, the power of the suction unit

is not sufficient.

17

4.9.1

4.9.3

4.9.2

5.1.1 5.1.25.1.2

5.1.35.1.3

4.9 Shutting down the device

Fig. 4.9.1

After each operation the 3-way ball valve

must be moved to the "Depressurise"

position.

Fig. 4.9.2

The compressed air supply line can be dis-

connected when zero pressure is indicated

on the pressure control valve.

Fig. 4.9.3

Remove cover of blasting device and re-

move any remaining granules.

The granules must always be stored in

a dry place!

Never re-use granules!

Warning! The blasting medium hose is

also subject to wear during operation,

and must be checked for damage at

least every two months.

The blasting material hose should be

replaced once per annum if the device

is used regularly!

Fig. 5.1.1

Remove hose with protective braiding

from hose package.

Fig. 5.1.2, 5.1.3

Undo the hose clamps from the nozzle on

the control valve and on the handle.

5.1 Maintenance / cleaning

18

5.1.6

5.1.45.1.4 5.1.5

5.1.7

1 2 3

5.1.8

2

5.1.95.1.9

3

1

5.1.10

Fig. 5.1.4, 5.1.5

Removing and replacing the hose with a

new one.

Fig. 5.1.6

Use this occasion to examine all the hose

nozzles and connection nipples on the

control valve and on the handle.

If the size of the hole has been in-

creased significantly by the flow of

blasting material, it must be replaced!

Original diameter 6 mm

Wear limit diameter 7 mm

Fig. 5.1.7 – 5.1.9

Clean the filter inserts in the blasting

medium tank and the cover of the device

at regular intervals - after the tank has

been filled 10-15 times at most!

Fig. 5.1.10

Unscrew all filter inserts and blow them

out with a compressed air blow-out

gun from threaded side until all gran-

ule or dust residue has been removed.

After cleaning, the filter inserts must be

screwed back into the relevant positions.

Independently of the normal cleaning and maintenance work, the device must be checked and maintained at

least once per annum by a specialist company!

5.1 Maintenance / cleaning

6–7 mm

19

8

9

7

6

5

4

32

1

5.2.1

5.2 Spare parts and accessories for the

granule jet blasting device

Item No. Article Number Title

1 VAS 294 011/1A Granule blasting device

2 VAS 294 011/2 Straight blasting probe

3 VAS 294 011/3 Angled blasting probe

4 VAS 294 011/4 Suction hose 90°

5 VAS 294 011/5 Suction hose 250 mm

6 VAS 294 011/7 Seal

7 VAS 294 011/8 Cleaning granulate

8 VAS 294 011/9 O-ring

9 VAS 294 011/10 Blasting probe

20

5.3 Warranty conditions

Warranty restrictions

1. The warranty is invalidated if repairs are made to the device by anyone other than

a specialist company or the manufacturer.

2. The warranty is invalidated if the device is used for any other than its intended

purpose.

3. The warranty is invalidated if the operating instructions are not followed and the

maintenance work has not be carried out as stipulated.

4. The warranty is invalidated if the device is used incorrectly and/or the permitted

operating parameters are exceeded.

5. The warranty is invalidated in the event of external effects such as transport damage

and damage caused by impacts or collisions.

6. Repairs which have been carried out by unauthorised third parties.

7. Normal wear to the blasting probes, blasting hoses including handle and the granule

control valve is not covered by the warranty.

Service address

TKR Spezialwerkzeuge GmbH

Am Waldesrand 9–11

D-58285 Gevelsberg (Germany)

Phone +49 2332 66607-0

Fax +49 2332 66607-941

E-mail info@tkrgroup.com

Internet www.tkrgroup.com

This device complies with the current safety regulations and was tested before leaving the factory. We provide

a 24 month warranty and are obliged to carry out all repairs caused by material and/or manufacturing faults

that become necessary during this time.

Table of contents

Other TKR Group Industrial Equipment manuals