TKS FeedBelt User manual

1

TKS Operator's manual

988862FeedBelt AUTO EN, issue 3 2019-12

Operator's manual

FeedBelt - AUTO

2

TKS Operator's manual

Content

1 GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 USING THE SCREEN AND PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 EXAMPLE OF GROUP ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 MAINTENANCE / CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 ALARMS AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 CE - Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Technical data - FeedBelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.1 Model description and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.2 Machine identifi cation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.3 Main dimension - FeedBelt with 1 center-section. . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.2 Additional safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.3 Overview of safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.4 Lifting FeedBelt during installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.5 New machine - caution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.6 Installation and commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.6 Recycling - waste to resource - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Using the screen and PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Numeric keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3

TKS Operator's manual

2.3 Alphabetic keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Selecting values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.5 On/off button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Menu Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Menu Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Menu Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 Menu Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6 Menu Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Example of group adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 Maintenance / care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1 Important before maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2 Commissioning and inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3 Weekly inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.4 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.5 Oil change gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

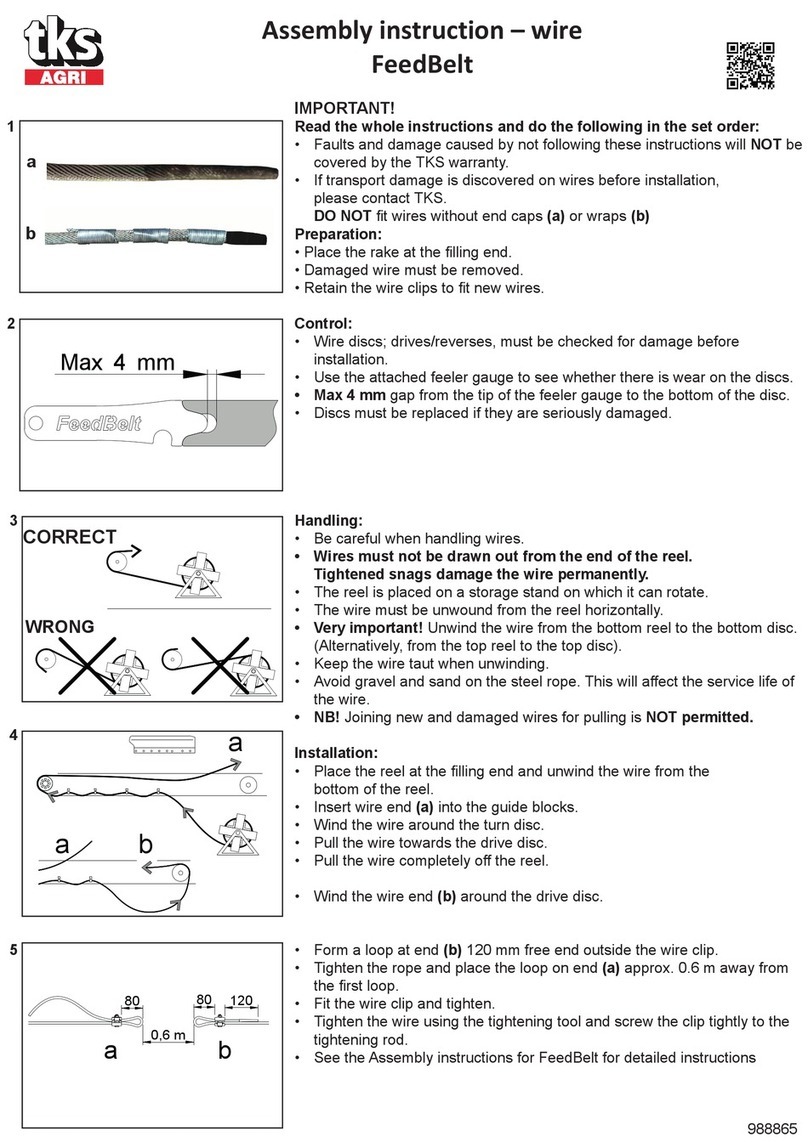

5.6 Wire maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.7 Belt tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.8 Wire tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.9 Scrape reverser adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.10 Tightening torque for screws and bolts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.11 Cleaning the FeedBelt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.12 Fault symptoms on the wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 Alarms and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4

TKS Operator's manual

1 General safety instruction

1.1 CE – Declaration of conformity

We,

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norge

declare that the product:

TKS - FeedBelt

has been built in conformity with the Machine Directive and meets the relevant

fundamental health and safety requirements

Kverneland, 16 October 2019

Atle Sjølyst - Kverneland

General Manager

Enter the serial number

on the machine:

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specifi cations of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

5

TKS Operator's manual

1.2 Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to

TKS or TKS’s distributor/importer within the 10th of the month following the one in which the defect

was reported. The defective parts shall be marked with the claim number and be kept for up to 6

months so that TKS or TKS’s distributor/importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any resulting damage.

The guarantee is not valid if:

a) third party spare parts are used, or the product is repaired or altered without the

approval of TKS.

b) the operating and servicing instructions have not been followed.

c) the machine has been used for other purposes than those for which it is designed

d) control box opens.

The guarantee does not cover damage due to normal wear and tear

Offi cial safety regulations specify requirements that apply to the manufacturers of this machine

relating to the careful review of safety hazards that may arise when this type of machine is used

correctly. Therefore, TKS and our importer/distributor are not responsible for the functioning of

components that are not shown in the spare-parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number; see page 12 on Machine identifi cation See chapter. 1.4.2

Other manuals for FeedBelt

1

Table of contents

Other TKS Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions