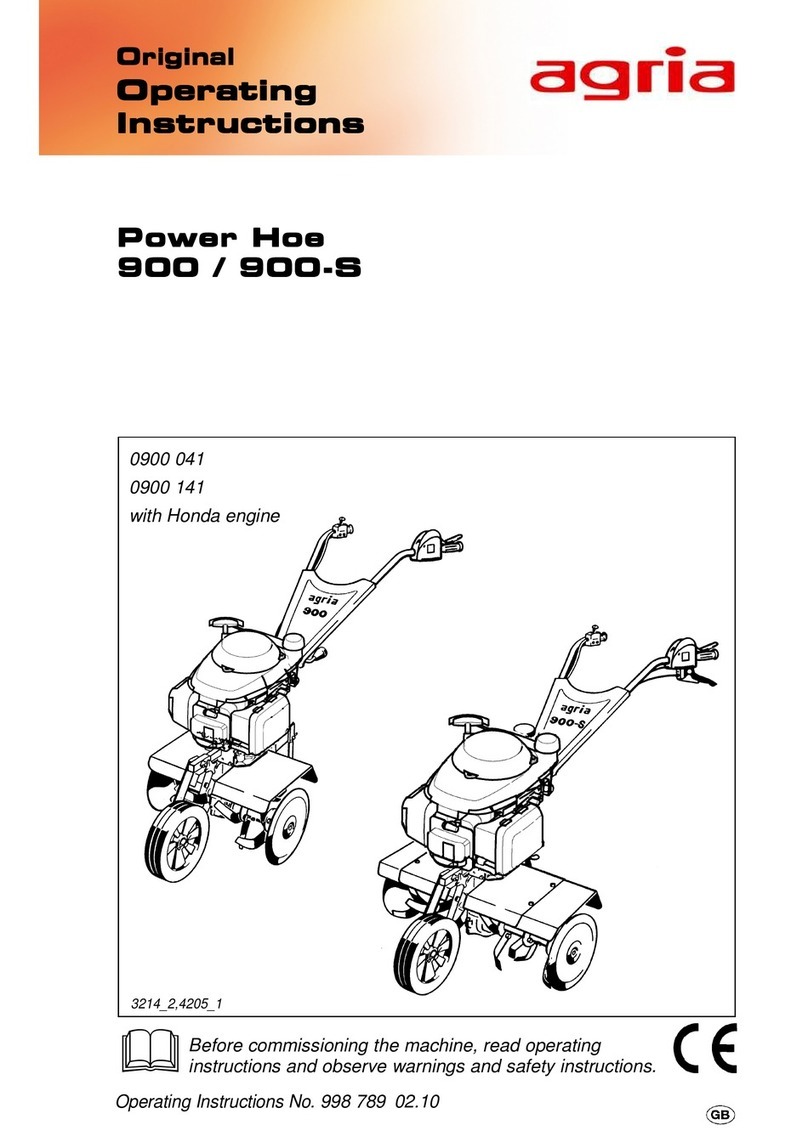

TKS 3742 User manual

TKS Operator’s manual

1

Operator’s manual 3742 Potato planter EN, issue 2007-12

Operator’s manual

Mounted 4-row

potato planter

3742 UH124411

TKS Operator’s manual

2

TKS Operator’s manual

3

CE certificate of conformity

We,

TKS Mekaniske

Torlandsvegen 3,

N-4365 Nærbø

Norway

declare under our sole responsibility that the product:

4-row potato planter 3742

has been built in conformity with the Machine Directive 2006/42/EC and meets the

relevant fundamental health and safety requirements.

Kverneland, 13 December 2007

Henning Thunheim

Managing Director

Enter here the serial

number of your machine:

TKS, manufacturers of farm machinery reserve the right to change designs and/or

specifications without notice. This does not include an obligation to make changes to

machines previously supplied.

TKS Operator’s manual

4

Guarantee

TKS products are guaranteed for a period of one year from the date of delivery, against defects in

material and workmanship.

Components not manufactured by TKS, i.e. electrics and hydraulics, PTO shafts and tyres are

guaranteed according to the original manufacturer’s recommendation.

The components listed below have limited guarantee due to their function:

Tyres

Share and share points

Pins

Fuses

Hydraulic seals of motors, valves and cylinders.

Oil filter

Weakening due to wear and tear is considered to be normal for these parts. The product

guarantees for these components are limited to manufacturing defects, breakage, poor

workmanship, transport damage etc on new machines.

Any damage to bearings that are fitted with grease nipples is not covered under the standard

product guarantee, if the damage is shown to be caused by rust or due to the ingress of liquids.

Such damage is caused by insufficient lubrication or the use of low quality lubricants.

Any damage caused by the use of corrosive additives in or nearby the machine is also not

covered.

If a failure is expected to be covered under the guarantee, the owner or its representative should

inform the dealer when parts and/or repair work is required. Any guaranty claim should be applied

for within the period of guarantee.

The dealer should fill in one guarantee claim form for each matter and forward it to the TKS

representative before the 10th of the following month after the claim was raised.

The damaged parts should be marked with the number of the corresponding warranty claim and

should be stored for 6 months by the dealer, available for inspection by the TKS representative if

required.

Due to the operation of the TKS products being out of the manufacturer’s control, the guarantee

covers the product quality only. Performance or any consequential losses are not covered.

The guarantee may be invalid if:

a) spurious spare parts are used or the product is repaired or modified without the TKS

authorisation.

b) operator’s and service instructions given by the manufacturer are not complied with.

c) The machine is used for other purposes than those designed for.

The guarantee does not cover damage caused by normal wear.

Public safety regulations require from the manufacturer of this machine that all safety aspects

regarding the use of the machine is thoroughly evaluated. As a result of these obligations TKS and

its representative are not responsible for the function of components not shown in the spare parts

catalogue covering this product.

TKS reserve the right to change the product with no obligation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product’s serial number; see

page 7 Machine identification.

TKS Operator’s manual

5

Content

CE-Certificate of conformity. . . 3

Guarantee. . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . 6

Machine identification. . . . . . . . . . 7

Technical specifications. . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . 9

Model descriptions . . . . . . . . . . . . 10

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1 Preparing a new machine. . . . . . . 19

1.1 Packing . . . . . . . . . . . . . . . . . . . . . 19

1.2 Row width control . . . . . . . . . . . . . 19

1.3 Assembling the coverers . . . . . . . 20

2 Tractor requirements. . . . . . . . . . . 21

3 Tractor connections. . . . . . . . . . . . 22

3.1 Threepoint linkage . . . . . . . . . . . . 22

3.2 Clamp . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Hydraulic drive . . . . . . . . . . . . . . . 24

4 Mechanical drive. . . . . . . . . . . . . . 28

4.1 Sticker planting spacing 3742. . . . . .

Mechanic models. . . . . . . . . . . . . 30

4.2 Sticker planting spacing . . . . . . . . . .

extra short 3742 . . . . . . . . . . . . . . 31

5 Operating the machine . . . . . . . . . 32

5.1 Seed potato size. . . . . . . . . . . . . . 32

5.2 Altering the row width . . . . . . . . . . 32

5.3 Planting spacing adjustment. . . . . 32

5.4 Depth adjustment . . . . . . . . . . . . . 32

5.5 Covering up. . . . . . . . . . . . . . . . . . 33

5.6 Working speed . . . . . . . . . . . . . . . 33

5.7 Belt agitation. . . . . . . . . . . . . . . . . 34

5.8 Regulation of potato flow . . . . . . . . .

from hopper to planting units . . . . 35

5.9 Emtying the potato hopper. . . . . . 35

5.10 Markers. . . . . . . . . . . . . . . . . . . . 36

6 Electronic control panel . . . . . . . . 38

6.1 The keys of the control panel . . . . 38

6.2 Connecting the tractor . . . . . . . . . . .

power supply. . . . . . . . . . . . . . . . . 38

6.3 Panel display. . . . . . . . . . . . . . . . . 40

7 Maintenance . . . . . . . . . . . . . . . . . 50

7.1 Maintenance of mechanic. . . . . . . . .

components . . . . . . . . . . . . . . . . . 50

7.2 Maintenance hydraulics . . . . . . . . 51

7.3 Maintenance electrics/electronics. . .

equipment. . . . . . . . . . . . . . . . . . . 51

8 Trouble shooting . . . . . . . . . . . . . . 52

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . 53

TKS Operator’s manual

6

Introduction

We congratulate you on the purchase of your new TKS product. You have chosen a product which

will give you satisfaction through a network of efficient dealers where function, finish, after sales

service and spare parts are always at hand.

All TKS products are designed and tested in close co-operation with farmers and contractors to

ensure optimal function and reliability.

Please read this manual before using your new machine.

We wish you all the best with your TKS product.

Yours faithfully

TKS Mekaniske AS

TKS Mekaniske

Torlandsvegen 3,

N-4365 Nærbø

Norway

Phone : + 47 51 43 63 00

Fax : + 47 51 43 48 62

TKS Operator’s manual

7

Machine identification

The machine’s serial number and the manufacturer’s address are found on the number plate of the

machine. See illustration below.

The serial number and year of manufacture for this machine is given below. This number is

important with regard to service and the correct supply of spare parts.

The machine is marked CE. This marking with appurtenant EU statement of agreement means that

the machine complies with substantial health and security demands, and that it is accordance with

the Machine Directive 2006/42/EC

I3742_08

TKS Operator’s manual

8

Technical specifications

Model 3742

Number of rows 4

Connection to tractor Kat. 2 and 3

Row width (intervals of 5 cm) 75 cm - 90cm

Planting intevals (electro-hydraulic model) infinite variable 10 - 80

cms

Planting intevals (mech. model) std. 14-69cm,

extra 10-49 cm

Hopper capacity

potatoes 2000 kg

Minimum filling height, potatoes 118 cm

Wheel dimension 7.50-16 4 PLY lugged

Monitor

Track width 150 - 180 cm

Weight empty machine 1800 kg

Working speed 4-10km/t

Extra equipment

(Wheel dimension)

Marker arms

Floating opening shoe (delivered instead of standard).

Floating opening shoe (delivered as kit)

Electric cup belt agitators

Insert cups - small

Insert cups - medium

Automatic depth control

Adjusting kit from 75-80 til 85-90 cm row width

Adjusting kit from 85-90 til 75-80 cm row width

Hopper sensor

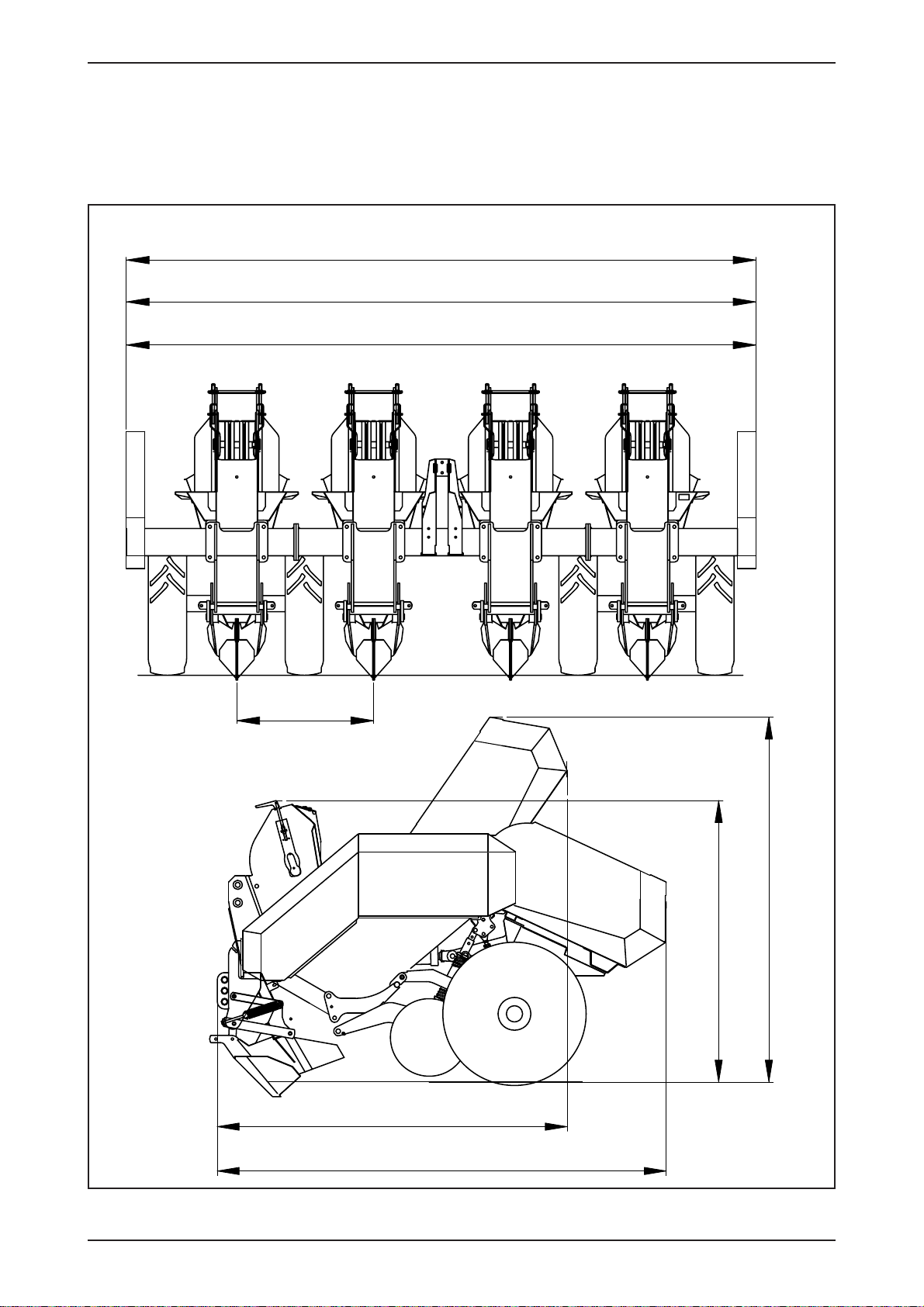

1917

2460

1999

1542

3450 (R = 75 cm)

3600 (R = 80 cm)

3900 (R = 85 - 90 cm)

R

TKS Operator’s manual

9

IK1_05

I3742_09

Dimensions

Valid for machine with wheel size 7.50-16 4 PLY lugged left and right.

All dimensions are in mm (1” = 25.4mm)

TKS Operator’s manual

10

Model descriptions

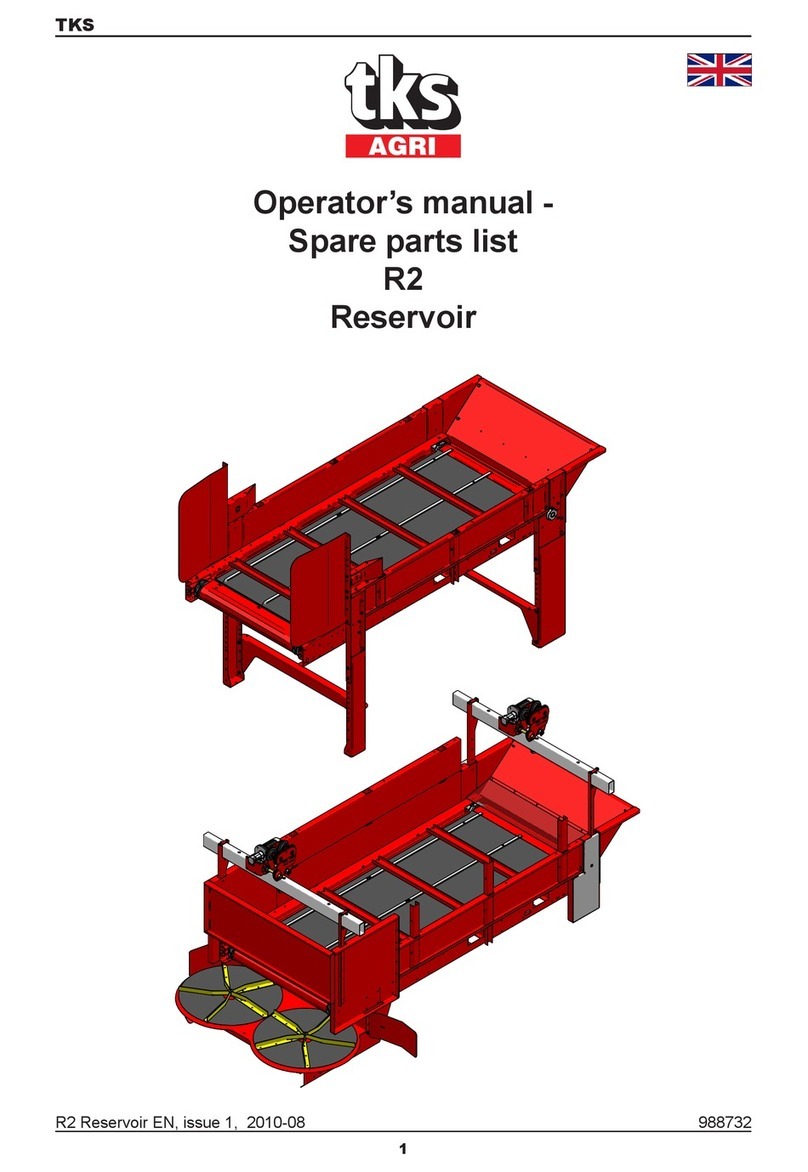

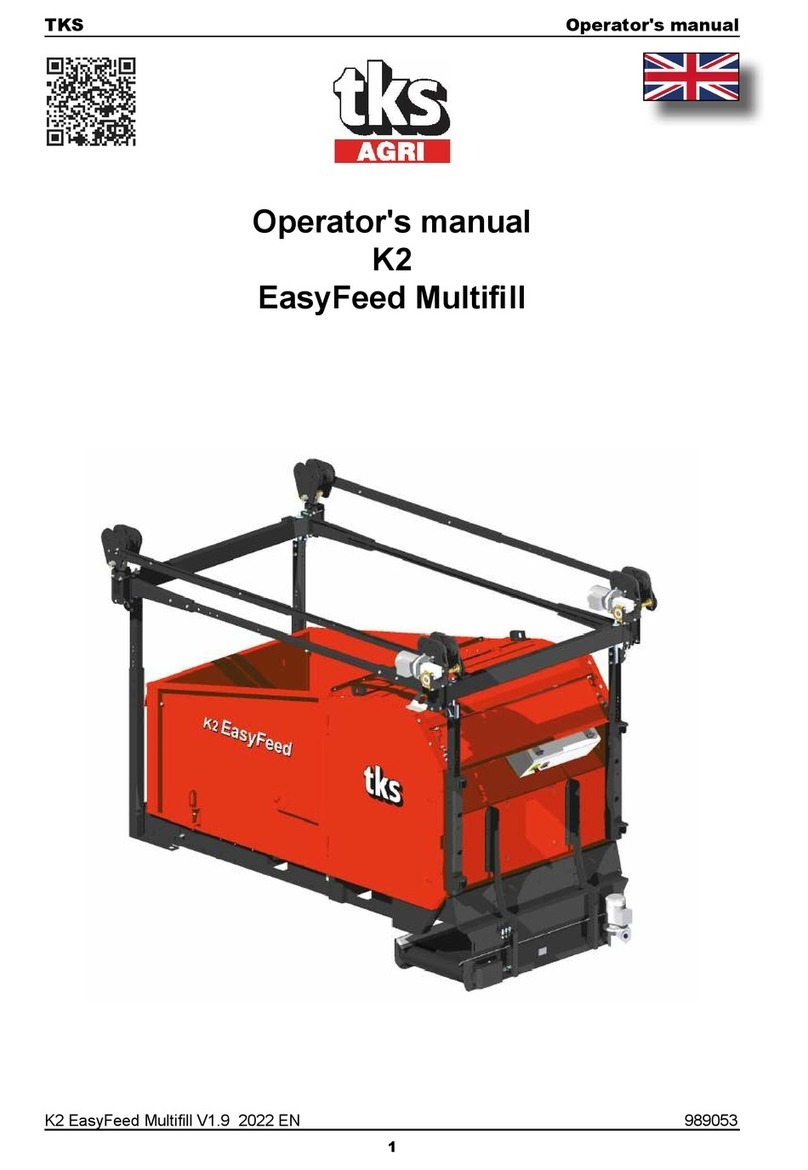

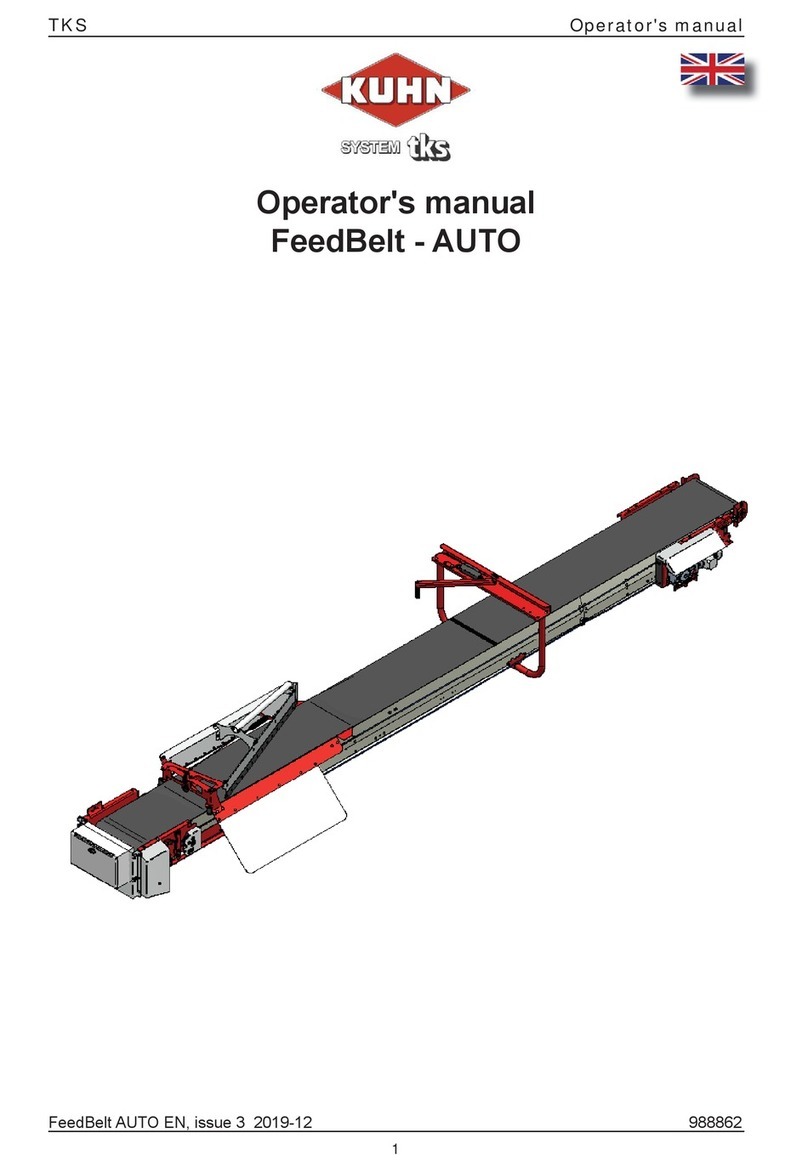

The 3742 automatic potato planter from TKS is a four row mounted machine. The planting units

include double cup belts, adjustable gate between hopper and planting unit, adjustable row width,

choice between mechanicall and electronic/hydraulic drive systems, infinite planting distance

adjustment, rigid furrow openers and manually or automaticcally controlled planting depth.

The machine is available as follows:

• 4-row- basic machine, row width 75cm

• 4-row- basic machine, row width 80cm

• 4-row- basic machine, row width 85cm

• 4-row- basic machine, row width 90cm

The machine is equipped with hydraulic hopper 2000kg

The machine is equipped with double cup belt.

Choose between following cup types:

• Planting cup Ø66mm (steel inserts for reducing to Ø55 available)

• Planting cup Ø74mm (steel inserts for reducing to Ø65 available)

• Planting cup large (white plastic inserts for reduction to medium size available)

(green plastic inserts for reduction to small size available)

The machine is delivered with disc roller 450mm for covering up each row.

TKS Operator’s manual

11

TKS Operator’s manual

12

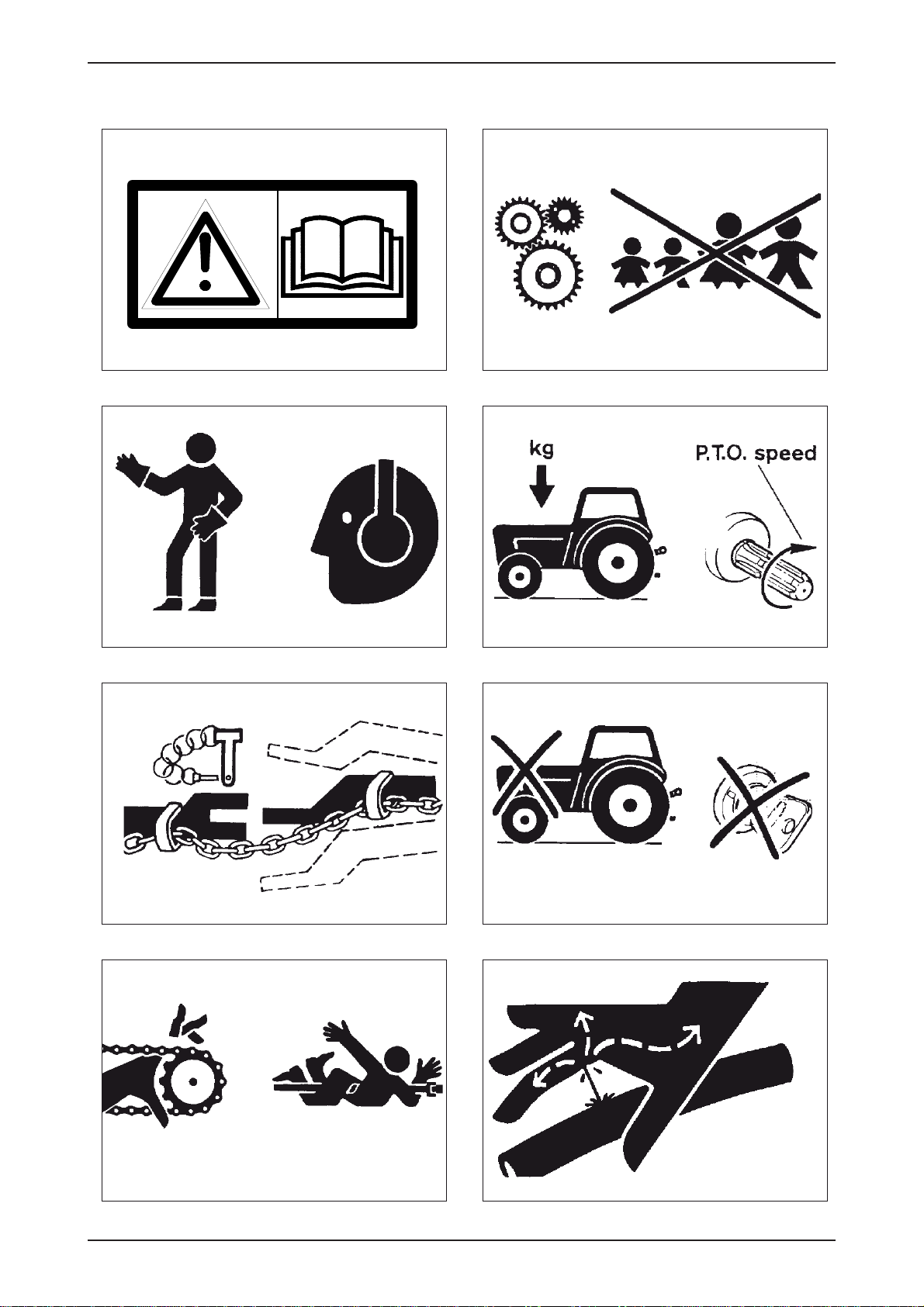

Safety

Before operating, adjusting or servicing the

machine it is important that the safety instructions

in this manual are carefully read and understood

by those, which are directly concerned. (Fig. 1)

Whilst all care and attention has been taken in the

design and production of this machine, as with

all machinery there remains a certain amount of

risk to personnel whilst the machine is in use. It is

strongly recommended that users and operators

take all possible precautions to ensure both their

own safety and that of the others that may be in

the vicinity.

Read and observe the safety instructions in this

manual.

Safety is your responsibility!

Pay particular attention to this symbol. It

means that there could be a serious hazard. It

emphasises precautions, which have to be

complied with in order to prevent accidents.

This symbol can be found throughout this manual

and on the warning signs of the machine. They

are for your safety and should be observed at all

time.

Be careful when other people or animals are

close by!

Never start the machine when people or animals

are close by tractor or machine. Never stand

between the tractor wheels and machine. (Fig. 2)

Bear in mind regulations regarding the lower age

of operators of this kind of machines.

Use of the machine

The machine should be used only for the purpose

it has been designed for.

Use personal protection devices

Do not wear loose clothing, which might catch in

any of the moving parts. In dusty conditions an

approved mask must be used. (Fig. 3)

Take care of excessive noise level. Some tractor/

implement combinations, depending on

conditions, may cause noise level beyond 85dB

at the operator’s ears, even in a “Q” cab. In these

conditions ear defenders must be worn. Keep cab

windows and doors closed to reduce noise level.

The machine must be connected to a correctly

sized tractor

The weight of the tractor must correspond to the

maximum weight of the machine when operated.

Follow domestic law and regulations. (Fig. 4)

Make sure that the tractor has the correct PTO

gear engaged. A machine designed for an input

speed of 540 rpm. should never be connected to

a tractor with 1000 rpm. output speed engaged.

The normal PTO speed is given on a label close

to the PTO input shaft.

Connecting machine to tractor

must always be carried out as described in this

manual. If connection should be carried out with

drawbar, one of the parts (tractor or machine’s

drawbar) must have a clevis. The drawbar pin

must be secured with a lock pin. (Fig. 5)

Observe national regulations regarding road

transport. Some countries require the use of

safety chain when a trailed machine is towed

along public roads.

Think of safety while operating the machine

Stop the tractor engine and remove the ignition

key prior to carrying out repairs, cleaning,

lubrication or maintaining the machine. (Fig. 6)

Safety guards

Make sure all guards are in good order and fitted

correctly. Do not attempt to start the machine

before ensuring this. (Fig. 7)

Pay particular attention to the plastic guards of

the PTO shaft. If damaged they must be replaced.

The chain locks of the guards must always be

fitted on a suitable place on the tractor and the

machine to prevent the outer plastic guards

turning.

Hydraulics

Be very careful when dealing with hydraulics. Use

eye protection and gloves. Escaping hydraulic oil

under pressure might penetrate into the skin and

cause serious infection. See a doctor if you have

been exposed to injury. (Fig. 8)

Take care that nobody is close to the machine

when the hydraulic functions are being operated.

Fig. 2Fig. 1

Fig. 3 Fig. 4

Fig. 6Fig. 5

Fig. 7 Fig. 8

TKS Operator’s manual

13

TKS Operator’s manual

14

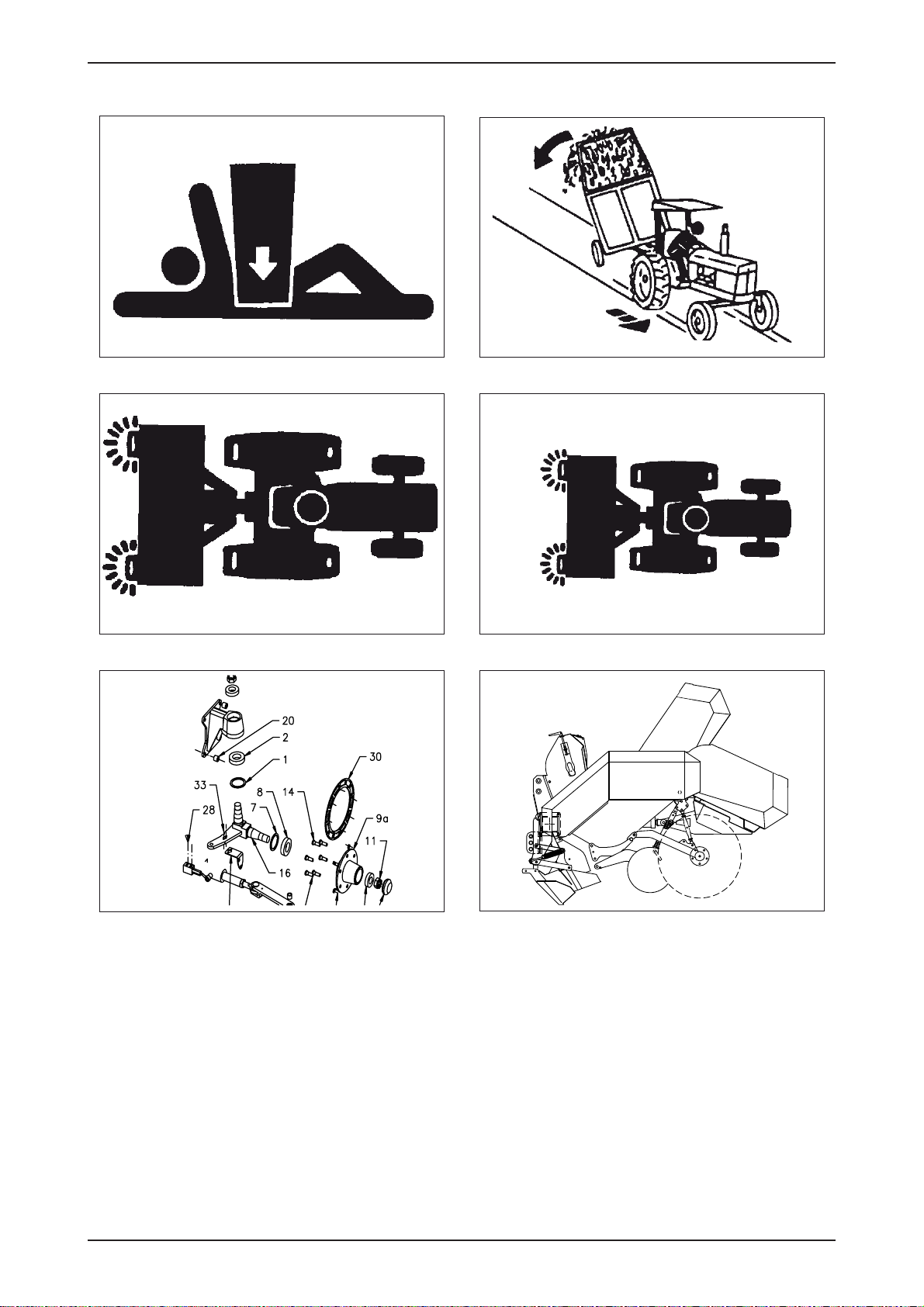

When disconnecting machine and when

leaving tractor/machine

When disconnecting, all hydraulic functions must

be in neutral position. The machine must be

lowered to the ground and be safely secured. If

the machine has parking chocks they should be

used at the wheels. Never allow children to play or

stay near agricultural machinery. (Fig. 9)

Drive safely

Beware of your responsibility, - carelessness or

negligence may cause serious injury or even

death. (Fig. 10)

Prior to transporting the machine along public

roads, check wheel bolts and couplings.

Disconnect or lock the hydraulic system.

Drive carefully. Reduce speed when turning and

driving on uneven ground. Take care that trailed

machine does not start swinging or become

unstable.

Please be aware of the danger of overturning

when working on slopes and in soft ground.

Reduce load.

Lights

The owner and operator is responsible of

providing correct lamps and reflectors on the

machine when transported on public roads.

Comply with public regulations. (Fig. 11)

Safety equipment

Always carry first aid equipment on the tractor.

Also observe the regulations concerning fire

extinguisher. When working with burning

materials like hay and straw a fire extinguisher

must be available at all times. (Fig. 12)

Spare parts

For safety reasons use only original spare parts.

The use of spurious spare parts will cause the

product guarantee to be invalid. (Fig. 13)

Maintenance

Take care that the machine is properly maintained

and kept in good safe working condition.

Never change the basic technical construction of

the machine.

Fig. 10Fig. 9

Fig. 11 Fig. 12

Fig. 13 Fig.14

TKS Operator’s manual

15

TKS Operator’s manual

16

Supplementary safety instructions

for the 3742 potato planter

This machine is designed and built for planting

potatoes or similar root crops.

The machine is equipped with warning

signs.

If any of the decals are damaged, they must be

replaced. Ordering numbers are shown on the

illustrations in this paragraph.

Warning sign UH220532

Be careful! Read and understand the

instructions in the manual before the machine is

put into service and before attempting

adjustment/maintenance.

Warning sign UH220525

Warning sign UH220525. Be careful when

machine is lowered! Keep feet away from

furrow openers, ridgers and wheels. When

operations are to be performed underneath a

raised machine, a support should be placed

under the main frame.

Warning sign 220526

Risk of cutting fingers if catched between roller

chain and sprocket.

Warning sign 220536

Keep distance to the movable hydraulic

operated potato hopper.

Warning sign UH220534

Disconnect all electronics before welding

commences.

Lifting machine with

crane

Only use approved lifting device. The weight of

the machine is given in paragraph “Technical

specifications”.

Be careful! Make sure that nobody stands

under or near the machine when it is being

lifted.

Attach the lifting straps by the “sling here”

signs. Make sure that straps are securely

fastened before lifting.

Use a guide wire to keep machine in position.

Hazard at use of

chemicals

The chemical manufacturer’s

prescriptions regarding handling of pesticides,

insecticides and fertilizer should be noticed.

UH220532 UH220525

UH220526 UH220536

TKS Operator’s manual

17

UH220534

TKS Operator’s manual

18

New machine - be careful

Read the operator’s manual. Great care must

be taken when starting a brand new machine

for the first time. Incorrect assembly, faulty

operations etc. may cause expensive repairs

and loss of profit. The Underhaug product

guarantee does not cover damage occurring

when the instructions given in this book are not

followed.

Pay particular attention to this symbol, - it

emphasises operations where great care must

be taken in order to avoid incorrect assembly,

faulty operations etc.

Carefully do as described below when starting a

new machine.

Check that the machine is mounted correctly

and that it is not damaged. Assure that

electric wirings have length and position that

allow machine to move without causing any

damage to the wirings.

Check the connections between tractor and

machine.

Check that the roller chains are tensionned and

correctly positioned on the sprockets.

Check that the drive rollers on top of both

planting tubes are equally adjusted in order to

assure cup belts run straight.

Lubricate the machine according to lubrication

instructions.

Check wheel bolts torque setting.

Cleaning

General

We recommend the use of pressured air when

cleaning the machine. Thus there is less risk of

damaging the bearings of the machine. If high

pressure water is used, keep clear of bearings

and electric components.

Cylinders

Assure that piston rods are kept free from

aggressive chemicals in order to avoid

corrosion.

TKS Operator’s manual

19

1. Preparing a new machine

1.1 Packing

Remove all kind of packing material. Any equipment stored in the machine should be

removed.

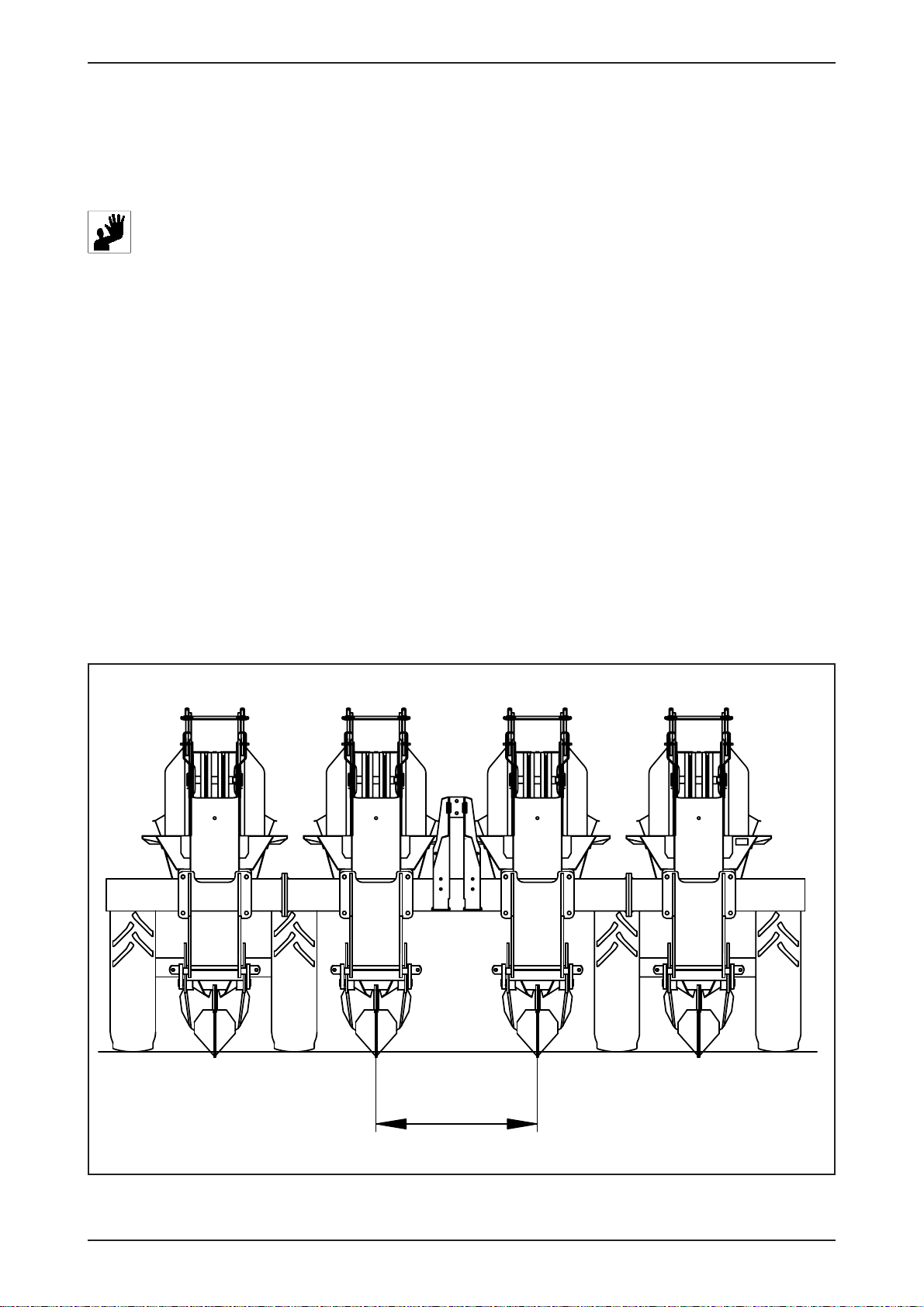

1.2 Row width control

Check that row width is in accordance with customer’s specifications.

The row width could preferential be ordered directly from the factory, since it is quite labour

damanding to change the row width.

4-row basic machine, row width 75cm

4-row basic machine, row width 80cm

4-row basic machine, row width 85cm

4-row basic machine, row width 90cm

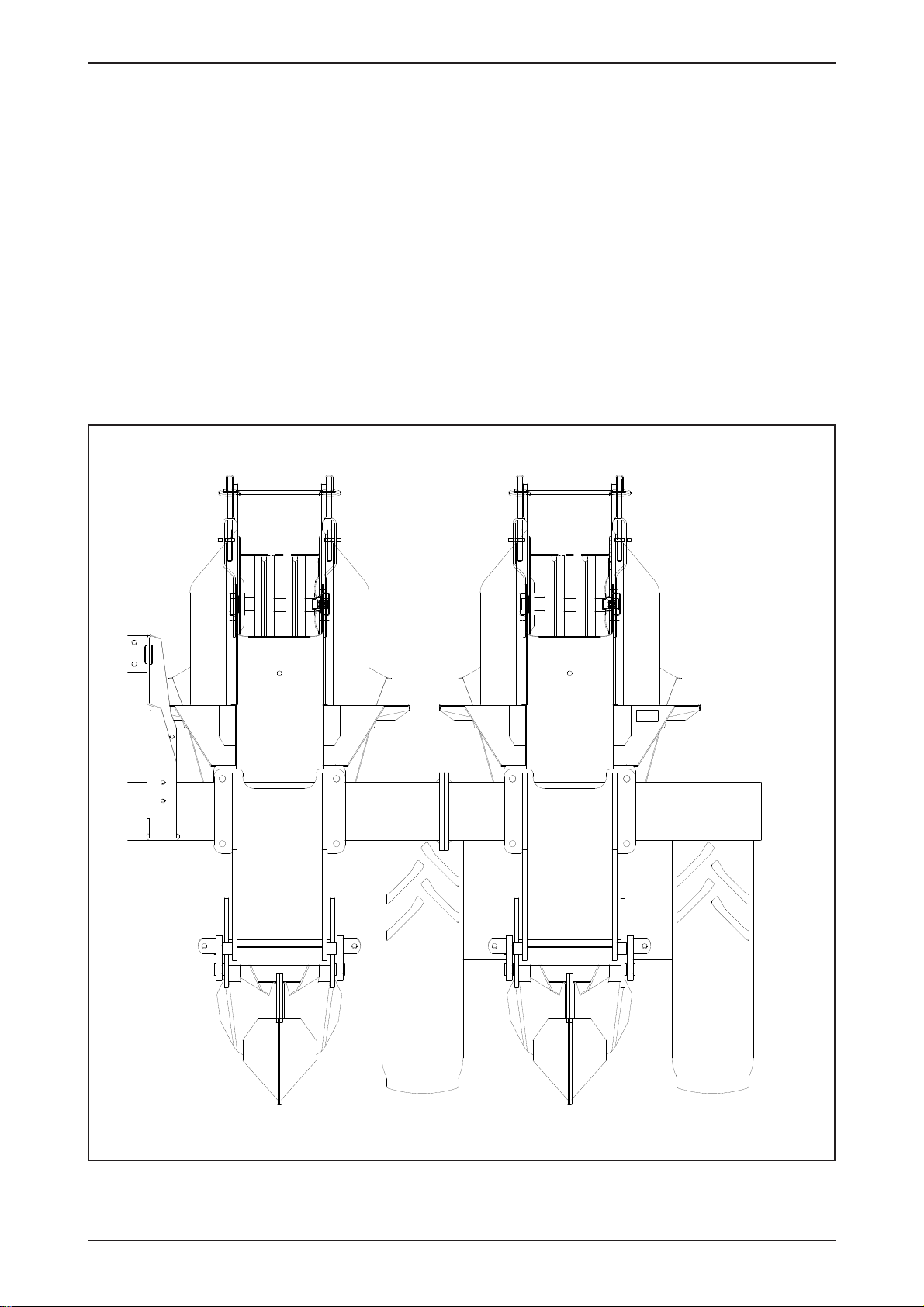

I3742_07

Fig. 20

A

A

B

D

C

TKS Operator’s manual

20

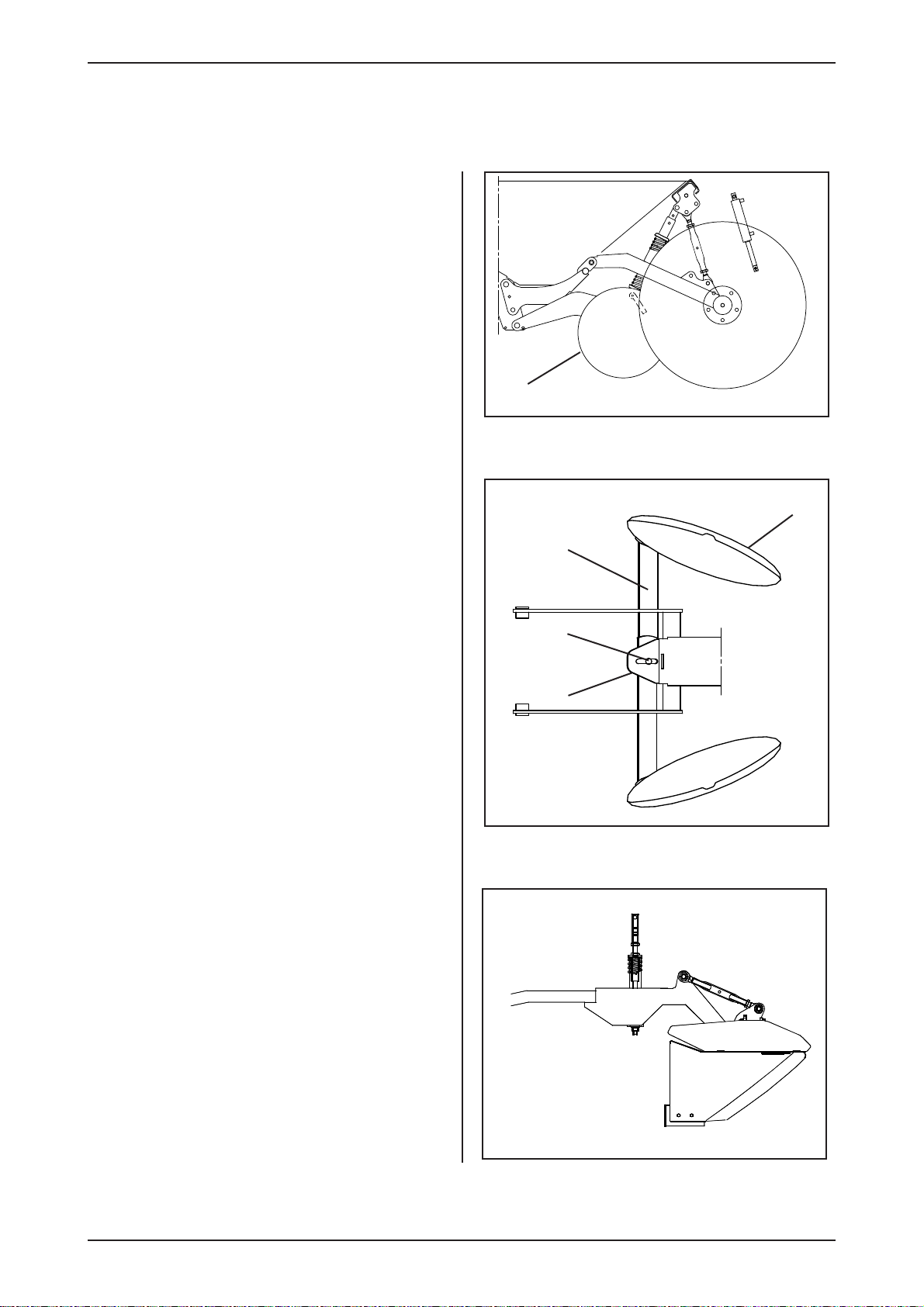

1.3 Assembling the coverers

Disc coverer Ais attatched to the arm B, and

right and left coverer is attatched to the center

of the frame plate C. Adjust the angle of the disc

rollers by moving the fixing point Dfor the disc

arms forward and backward on the frame plate.

Ridging hood (fig. 25):

Is ready for use when factory fitted.

Fig. 23

Fig. 24

Fig. 25

I3742_01

I3742_02

Table of contents

Other TKS Farm Equipment manuals