TKS 6150 User manual

I6100_01

I6150_01

Tks Operator’s manual

1

UH124470

Operator’s manual Round Bale Wrapper 6150 / 6100 / 6110 EN, issue 1 2011-04

Operator’s manual

Round Bale Wrapper

6150 / 6100 / 6110

Tks Operator’s manual

2

Tks Operator’s manual

3

CE certificate of conformity

We,

TKS Mekaniske AS,

Torlandsvegen 3

N-4365 Nærbø

Norge

declare under our sole responsibility that the product:

Bale Wrappers 6150 / 6100 / 6110

to which this declaration relates corresponds to the relevant basic safety and health

requirements of the Directives 2006/42/EC

Nærbø, 27 april 2011

Henning Thunheim

Managing Director

Enter the serial number

of the machine here

TKS Mekaniske AS, manufacturer of farm machinery, reserve the right to change

designs and/or specifications without notice. This does not include an obligation to

make changes to machines previously supplied.

Tks Operator’s manual

4

Guarantee

TKS products carry warranty for a period of one year from the date of delivery, against defects in

material and workmanship.

Components not manufactured by TKS. electrical and hydraulic, PTO shafts and tyres are

guaranteed according to the original manufacturer’s recommendation.

The components listed below have a limited warranty due to their function:

• Tyres

• Pre-stretcher rollers

• Fuses

• Hydraulic seals of motors, valves and cylinders

• Oil filter

• Chain

• Sprocket

• Web

Weakening due to wear and tear is considered to be normal for these parts. The product

guarantees for these components are limited to manufacturing defects, breakage, poor

workmanship, transport damage etc on new machines.

Any damage to bearings that are fitted with grease nipples is not covered under the standard

product guarantee, if the damage is shown to be caused by rust or due to the ingress of liquids.

Such damage is caused by insufficient lubrication or the use of low quality lubricants.

Any damage caused by the use of corrosive additives in or nearby the machine is also not

covered.

If a failure is expected to be covered under the guarantee, the owner or its representative should

inform the dealer when parts and/or repair work is required. Any guarantee claim should be applied

for within the period of guarantee.

The dealer should fill in one guarantee claim form for each matter and forward it to the TKS

representative before the 10th of the following month after the claim was raised.

The damaged parts should be marked with the number of the corresponding warranty claim and

should be stored for 6 months by the dealer, available for inspection by the TKS representative if

required.

Due to the operation of the TKS products being out of the manufacturer’s control, the guarantee

covers the product quality only. Performance or any consequential losses are not covered.

The guarantee may be invalid if:

a) spurious spare parts are used or the product is repaired or modified without the

TKS authorisation.

b) operator’s and service instructions given by the manufacturer are not complied with.

c) the machine is used for other purposes than those designed for.

d) The damage occurs as a result of external faces such as high voltage fluctuations due

to a low supply voltage, lightening or other electrical phenomena.

The guarantee does not cover damage caused by normal wear.

Public safety regulations require from the manufacturer of this machine that all safety aspects

regarding the use of the machine is thoroughly evaluated. As a result of these obligations TKS and

its representative are not responsible for the function of components not shown in the spare parts

catalogue covering this product.

TKS reserve the right to change the product with no obligation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product’s serial number; see page 7

Machine identification.

Tks Operator’s manual

5

Content

CE - Certificate of conformity . . . . 3

Guarantee. . . . . . . . . . . . . . . . . . . 4

Introduction. . . . . . . . . . . . . . . . . . 6

Machine identification. . . . . . . . . . 7

Main dimensions - 6150 . . . . . . . . 8

Technical specifications . . . . . . . . 9

Main dimensions - 6100 / 6110. . 10

Technical specifications . . . . . . . 11

Model description . . . . . . . . . . . . 12

Safety . . . . . . . . . . . . . . . . . . . . . 13

1 Preparing a new machine. . . . . . . . . . 20

1.1 Packing. . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Adjustment of turn table . . . . . . . . . . 20

1.3 Belts . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.4 Bale drive . . . . . . . . . . . . . . . . . . . . . 21

1.5 Hydraulic brake on the table. . . . . . . 21

1.6 Adjustment of applicutter . . . . . . . . . 21

1.7 The film prestretcher. . . . . . . . . . . . . 22

1.8 Height adjustment of pre-stretcher. . 22

1.9 Film overlap . . . . . . . . . . . . . . . . . . . 23

1.10 Film collector . . . . . . . . . . . . . . . . . . 23

1.11 Applicutter knife . . . . . . . . . . . . . . . . 23

1.12 Round bale wrapper. . . . . . . . . . . . . 24

1.13 Preparing el./computerised control. . 25

1.14 Position of sensors. . . . . . . . . . . . . . 26

2 Tractor requirements. . . . . . . . . . . . . . 27

3 Stretch film requirements. . . . . . . . . . 27

4 Operating the machine . . . . . . . . . . . . 28

4.1 Open/closed centre system. . . . . . . . 28

4.2 Integrated oil filter . . . . . . . . . . . . . . . 28

4.3 Hydraulic Load Sensing system. . . . 29

4.4 Use clean hydraulic oil. . . . . . . . . . . . 30

4.5 Operating the wrapper. . . . . . . . . . . . 30

4.6 Working speed. . . . . . . . . . . . . . . . . . 30

4.7 Wrapping procedure . . . . . . . . . . . . . 31

4.8 How to use the Round Bale Wrapper 32

5 Bale wrapper computer control . . . . . 34

5.1 Command panel . . . . . . . . . . . . . . . . 35

5.2 Symbols. . . . . . . . . . . . . . . . . . . . . . . 36

6 Control system . . . . . . . . . . . . . . . . . . 37

7 Error messages . . . . . . . . . . . . . . . . . . 38

8 Change the wrap parameter. . . . . . . . 39

9 Maintenance. . . . . . . . . . . . . . . . . . . . . 42

9.1 Lubrication shart . . . . . . . . . . . . . . . . 44

Recycling - waste to resource - . . . . . . . . . 46

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Tks Operator’s manual

6

Introduction

We congratulate you on the purchase of your new TKS product. You have chosen a product which

will give you satisfaction through a network of efficient dealers where function, finish, after sales

service and spare parts are always at hand.

All TKS products are designed and tested in close co-operation with farmers and contractors to

ensure optimal function and reliability.

Please read this manual carefully and thoroughly looked into the machine’s operation before it is

used.

Good effort and the right approach to current conditions ensuring the best possible results.

Good luck!!

Yours faithfully

TKS Mekaniske AS

TKS Mekaniske AS,

Torlandsvegen 3

N-4365 Nærbø

Norway

Phone : + 47 51 43 63 00

Fax : + 47 51 43 48 62

Tks Operator’s manual

7

Machine identification

The machine’s serial number and the manufacturer’s address are found on the number plate of the

machine. See illustration below.

The serial number and year of manufacture for this machine is given below. This number is

important with regard to service and the correct supply of spare parts.

The machine is CE-marked. This marking with appurtenant EU statement of agreement means that

the machine complies with substantial health and security demands, and that it in accordance with

the directives 2006/42/EC.

Serial number

3710

2280

2920

2400

517

2280

4320

Tks Operator’s manual

8

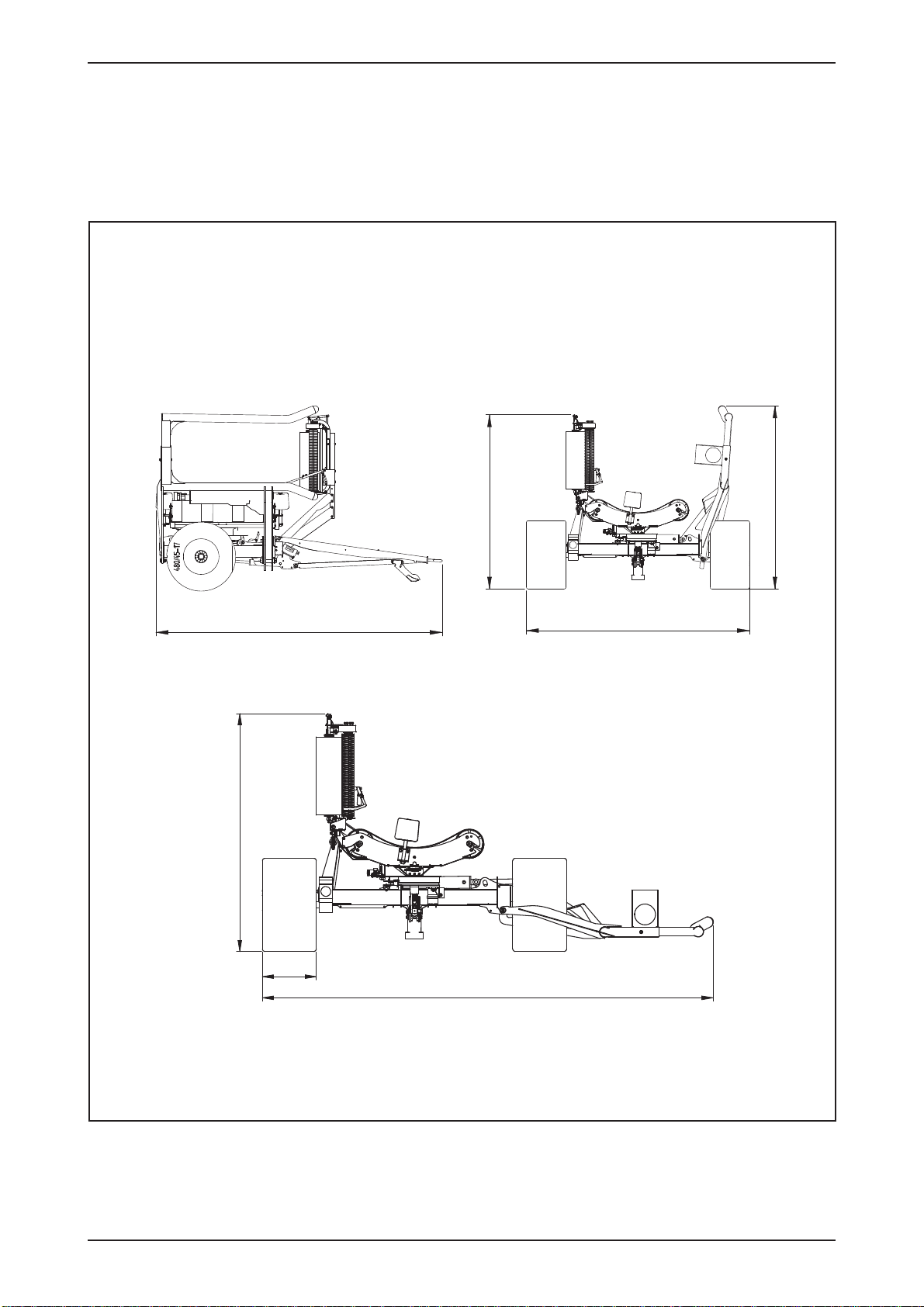

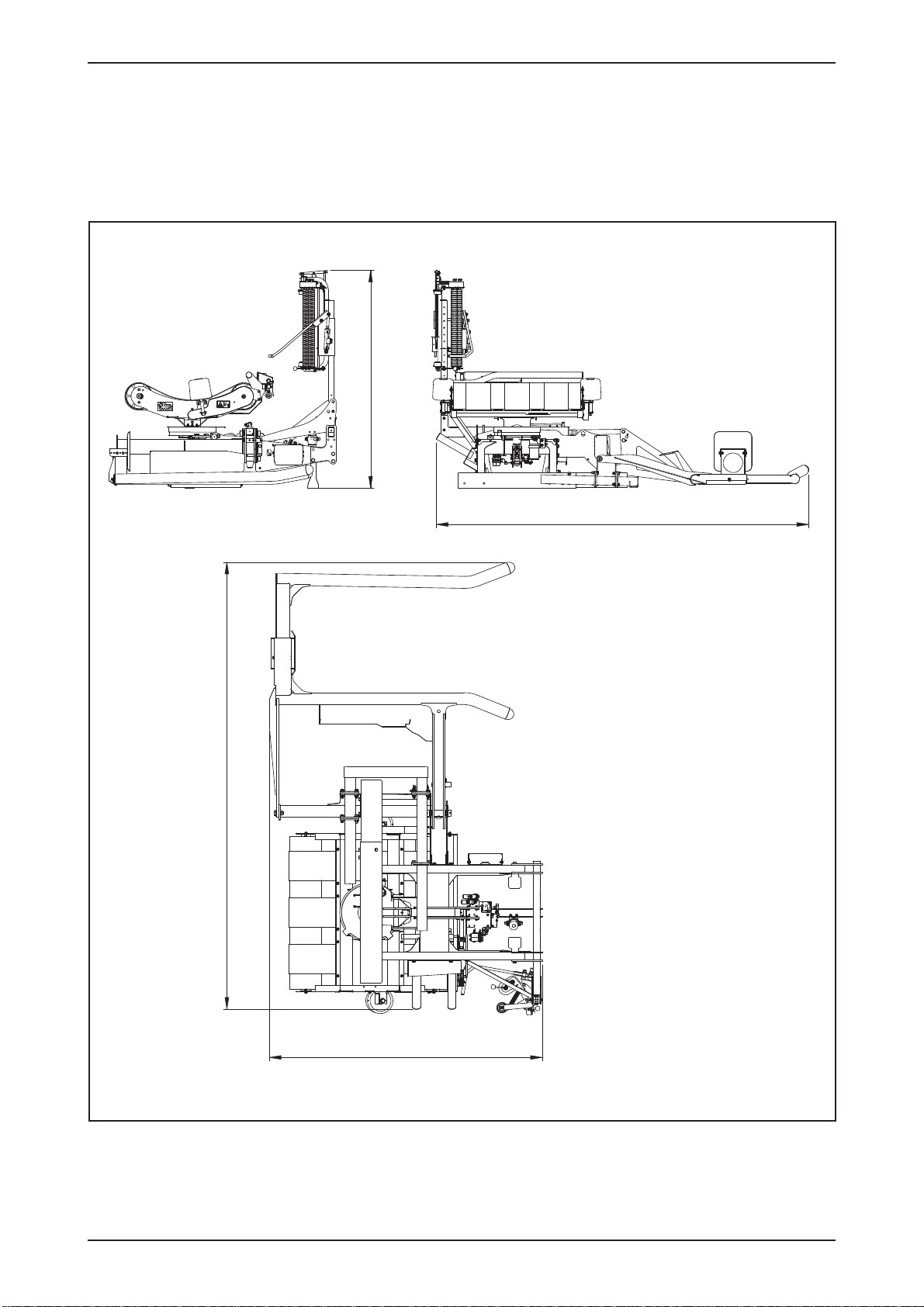

Main dimensions - 6150 Trailed wrapper

All dimensions are in mm

I6150_14

Tks Operator’s manual

9

Technical specifications

Trailed bale wrapper 6150

Weight machine 1505 Kg

Weight machine with counterweights 1825 Kg

Oil flow requirements Approx. 35 l/min (150bar)

Power supply 12V

Maximum turn table speed Approx. 30 rpm

Drawbar Std

Film pre-stretcher, standard width 750mm

Nominel film pre-stretch 60 %

Number of film layers 2+2+.....

Operation

Control system Electronic control system

Control panel Boks med display og joystick

Bale size

Round bale diameter 1,0 - 1,6 m

Bale length Max. 1,2 m

Bale weight on:

Standard machine 800 Kg

Machine with counter weight on hub 1000 Kg

Machine with counter weight on frame 1200 Kg

Machine w/ counter weight on hub and frame Max.1400 Kg

Wheel dimensions

Alt 1 300/80-15.3”

Alt 2 400/60-15.5”

Alt 3 500/45-17”

Available equipment

2 film holders (5+2)

Road lights and road light brackets

Counter weight 230 Kg - mounted on frame

Counter weight 90 Kg - mounted on hub

Alternative pre-stretch 55% or 65%

2227

3804

2324

3807

Tks Operator’s manual

10

Main dimensions - 6100 / 6110 Mounted

All dimensions are in mm

I6150_25

Tks Operator’s manual

11

Technical specifications

Mounted wrapper 6100 / 6110

Weight machine 6100 / 6110 1000 Kg / 700 Kg

Oil flow requirements Approx. 35 l/min (150bar)

Power supply 12V

Maximum turn table speed Approx. 30 rpm

Film pre-stretcher, standard width 750mm

Nominel film pre-stretch Approx. 60%

Number of film layers 2+2+.....

Operation

Control system Electronic control system

Control panel Box with display and joystick

Bale size

Round bale diameter 1,0 - 1,6 m

Bale length Max. 1,2 m

Bale weight Max. 1400 Kg

Available equipment

1 film holder with 2-rollers

Road lights and road light brackets

Remote control

Alternative pre-stretch 55% or 65%

Tks Operator’s manual

12

Model description

TKS Round Bale Wrapper is designed for stretch film wrapping straw/hay or dried grass in the form

of round bales for silage.

The wrappers are hydraulic driven. A rotating table rotates the bale as the film is applied onto the

bale. The prestrecher ensures a correct prestrech of the film. The applicutter cuts and holds the

film prior to unloading of the wrapped bale.

The machine is powered by the tractor’s oil pump.

The Round Bale Wrappers 6150 /6100 /6110 are operated by a computerized control system.

ATTENTION!

This machine is designed to carry a bale with a maximum weight of 1400 Kg.

Operation with a weight in excess of this could damage the machine and be dangerous.

Tks Operator’s manual

13

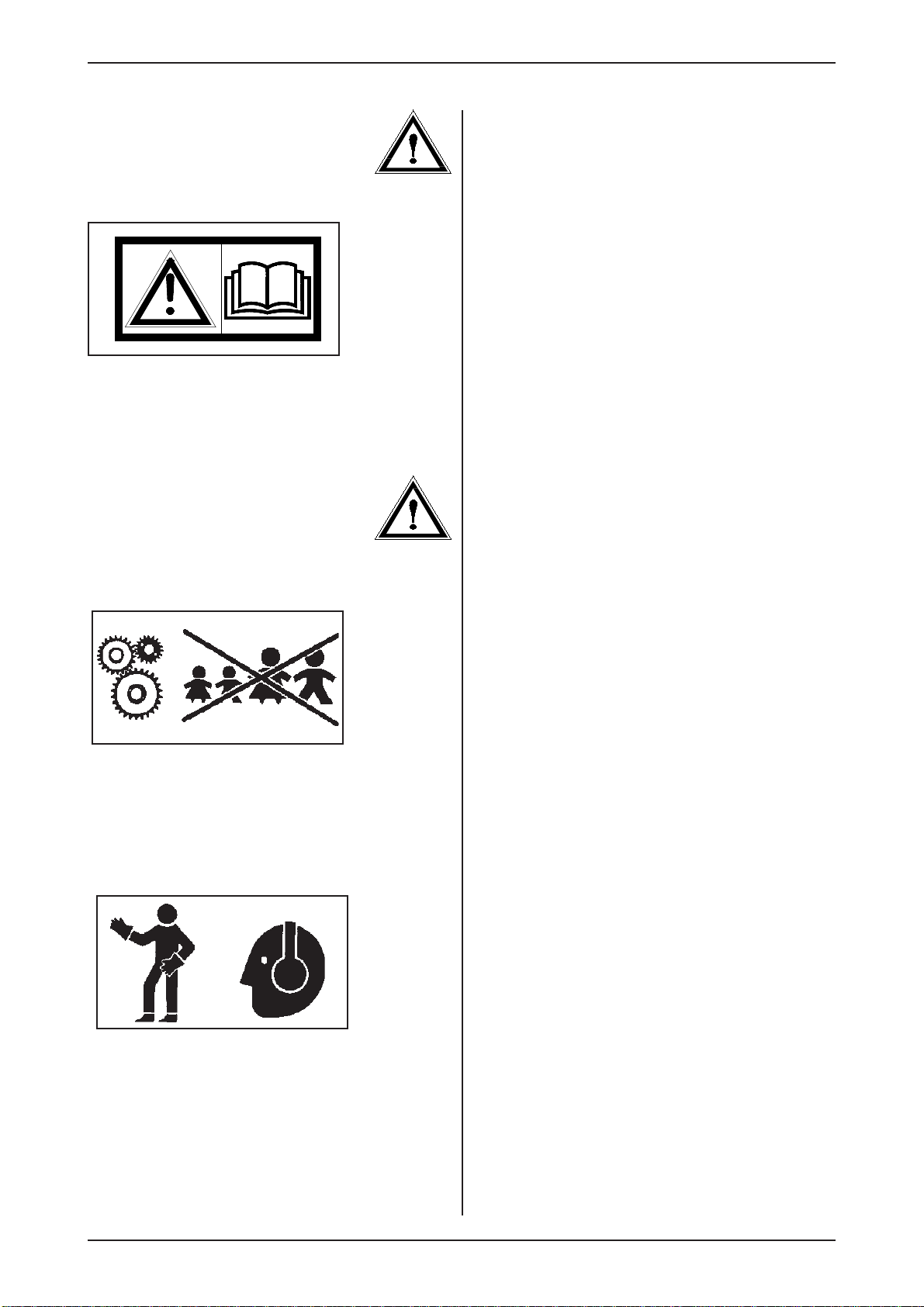

Safety Please pay particular attention to this symbol.

It means that there is a safety risk, and de-

scribes precautions that should be taken in

order to avoid accidents

Before operating, adjusting or servicing the

machine it is important that the safety

instructions in this manual are carefully read

and understood. See Fig. 1

Pay attention and be careful when handling

agricultural machinery. Read and take note of

the safety instructions in this manual.

NB!

Safety at work is your responsibility!

General

safety

instructions Please read and understand these general

safety instructions.

Pay particular attention to this symbol. It

means that there could be a serious hazard.

It emphasises precautions, which have to be

complied with in order to prevent accidents.

Be careful when other people or animals are

close by!

Never start the machine when people or

animals are close by tractor or machine. Never

stand between the tractor wheels and machine.

See Fig. 2

NB!

Bear in mind regulations regarding the lower

age of operators of this kind of machines.

Use of the machine

The machine should be used only for the

purpose it has been designed for.

Use personal protection devices

Do not wear loose clothing, which might catch

in any of the moving parts. In dusty conditions

an approved mask must be used. See Fig. 3

Take care of excessive noise level. Some

tractor/implement combinations, depending on

conditions, may cause noise level beyond 85dB

at the operator’s ears, even in a “Q” cab. In

these conditions ear defenders must be worn.

Keep cab windows and doors closed to reduce

noise level

Fig. 1

Fig. 2

Fig. 3

Tks Operator’s manual

14

The machine must be connected to a

correctly sized tractor

The weight of the tractor must correspond to

the maximum weight of the machine when op-

erated. Follow domestic law and regulations.

See Fig. 4

Make sure that the tractor has the correct PTO

gear engaged. A machine designed for an input

speed of 540 rpm. should never be connected

to a tractor with 1000 rpm. output speed

engaged. The normal PTO speed is given on a

label close to the PTO input shaft.

Connecting machine to tractor

must always be carried out as described in

this manual. If connection is carried out with a

drawbar, one of the parts (tractor or machine’s

drawbar) must have a clevis. The drawbar pin

must be secured with a lock pin.

See Fig. 5

Observe national regulations regarding road

transport. Some countries require the use of

safety chain when a trailed machine is towed

along public roads.

Think of safety while operating the machine

Stop the tractor engine and remove the ignition

key prior to carrying out repairs, cleaning,

lubrication or maintaining the machine.

See Fig. 6

Safety guards

Make sure all guards are in good order and

fitted correctly. Do not attempt to start the

machine before ensuring this. Se Fig. 7

Pay particular attention to the plastic guards

of the PTO shaft. If damaged they must be

replaced. The chain locks of the guards must

always be fitted on a suitable place on the

tractor and the machine to prevent the outer

plastic guards turning.

Hydraulics

Be very careful when dealing with hydraulics.

Use eye protection and gloves. Escaping

hydraulic oil under pressure might penetrate the

skin and cause serious infection.

Consult a doctor if you have been exposed to

injury. See Fig. 8

Take care that nobody is close to the machine

when the hydraulic functions are being

operated.

Fig.4

Fig. 5

Fig. 6

Fig. 7

Fig.8

11

20

13

14

21

17

16

12

23 10 15

19

26

22

25

10

28

24

28

10

16

20 27

18

30

10

25

Tks Operator’s manual

15

When uncoupling machine and when

leaving tractor/machine

When uncoupling, all hydraulic functions must

be in neutral position. The machine must be

lowered to the ground and be safely secured. If

the machine has parking chocks they should be

used at the wheels. Never allow children to play

or stay near agricultural machinery. See Fig. 9

Drive safely

Beware of your responsibility, - carelessness or

negligence may cause serious injury or even

death.

See Fig. 10

Prior to transporting the machine along public

roads, check wheel bolts and couplings.

Disconnect or lock the hydraulic system.

Drive carefully. Reduce speed when turning and

driving on uneven ground. Take care that trailed

machine does not start swinging or become

unstable.

Please be aware of the danger of overturning

when working on slopes and in soft ground.

Reduce load.

Lights

The owner and operator is responsible of

providing correct lamps and reflectors on the

machine when transported on public roads.

Comply with public regulations.

See Fig. 11

Safety equipment

Always carry first aid equipment on the tractor.

Also observe the regulations concerning fire

extinguisher. When working with burning mate-

rials like hay and straw a fire extinguisher must

be available at all times.

See Fig. 12

Spare parts

For safety reasons use only original spare

parts. The use of spurious spare parts will

cause the TKS product guarantee to be invalid.

Se Fig. 13

Maintenance

Take care that the machine is properly main-

tained and kept in good safe working condition.

Never change the basic technical construction

of the machine.

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Tks Operator’s manual

16

Supplementary safety

instructions The machine is equipped with warning

signs. If any of the decals are damaged, they

must be replaced. Ordering numbers are shown

on the illustration in the paragraph.

Warning sign UH220532

Be careful! Read and understand the instruc-

tions in the manual before the machine is put

into service and before attempting adjustment/

maintenance.

See Fig. 14

Warning sign UH220520

Danger of trapping if the hand is pulled in

between the pre-stretch roller and the roll of

plastic film.

See Fig. 15

Fig. 14

Fig. 17

Fig. 18

Fig. 15

Fig. 16

Warning sign UH220548

Danger of trapping.

Stop tractor before servicing.

See Fig. 16

Warning sign UH220524

Danger of trapping when tipping turntable /un-

loading a bale. Keep onlookers at a distance

See Fig. 17

Warning sign UH220527

Fingers could be seriously injured. Keep away

from the film applicutter (knife) when it is

activated.

Se Fig. 18

Tks Operator’s manual

17

Fig. 19

Fig. 20

Fig. 22

Fig. 21

Warning sign UH220528

Keep onlookers away from the working range of

the machine. Safe distance 5 meters.

(Do not walk under a raised machine).

See Fig. 19

Warning sign UH220529

The bale may drop off. Do not exeed

recommended turntabel speed 30 rpm.

Uneven or misshappen bales combined with

too high turntable speed may be dangerous.

See Fig. 20

Warning sign UH220535

Danger of trapping.

Place the safety stay under the raised turntable

before working is this area.

See Fig. 21

Warning sign UH220530

Noise hazard.

Noise level near the pre-stretcher may exceed

90 dbA. In such cases, ear defenders must be

used.

See Fig. 22

220532

220548

220528

220529

220530

220520

220524

220535

220527

220548

220532

220528

220529

220524

220520

220530

220535

I6150_30

I6100_31

Tks Operator’s manual

18

Overwiew of safety risk

Fig. 23

I6150_30

I6100_31

Tks Operator’s manual

19

Lifting the machine NB! Only use approved lifting device.

The weight of the machine is given in section

“Technical Specifications”.

Caution!

Keep distance when lifting the machine!

Use a guide strap to keep machine in position

New machine –

caution Read the operator’s manual

Great care must be taken when starting a brand

new machine for the first time. Incorrect

assembly, faulty operations etc. may cause

expensive repairs and loss of profit.

The TKS product guarantee does not cover

damage occurred when the instructions given in

this book are not followed.

Pay particular attention to this symbol, -

it emphasises operations where great care

must be taken in order to avoid incorrect

assembly, faulty operations etc.

Carefully do as described below when

starting a new machine:

• Make sure the bale wrapper is correctly

mounted, and free from damage.

• Assure the electric cables and hydraulic

hoses have length and position that allow

machine to move without causing any

damage to the wirings.

12

Tks Operator’s manual

20

1 Preparing a new machine

Assure that the machine is stable when it is

assembled.1.1 Packing

Remove all kind of packing. Any equipment

stored in the machine should be removed.

1.2 Adjustment of

turn table to fit bale

diameter

The two rollers on the turntable are factory fitted

for bale diameter 1,2m.

If the bale diameter varies from this, the

beltdriven rollers must be moved to obtain

maximum contact between bale and belt.

See Fig. 24

I6150_02

Fig. 24

I6150_03

Fig. 25

1.3 Belts

Three belts are factory standard.

This is sufficient for a 1,2m bale length.

See Fig. 25

This manual suits for next models

2

Table of contents

Other TKS Farm Equipment manuals

Popular Farm Equipment manuals by other brands

LELY

LELY Splendimo 240 MCR Operator's manual

Harvest TEC

Harvest TEC 442C Operation manual

etol

etol blu'mobil easy roll Original user manual

Major

Major MJ30-560HD Operator's manual & parts list

New Holland

New Holland Guardian SP.240F Service manual

Titan Attachments

Titan Attachments HRWDRAWBAR8 owner's manual

American Eagle

American Eagle AE-T12HS operating instructions

Quadivator

Quadivator UTV Harrow Assembly/operators/parts manual

Turf Tick Products

Turf Tick Products Turf Tick Original instructions

Goldacres

Goldacres Batchmate Operator's & parts manual

Bigham Brothers

Bigham Brothers Hipper Chopper HC40FX owner's manual

AMBIC

AMBIC EasiDoser operating instructions