HG Feeder 900 User manual

1

H E D E N S T E D G R U P P E N A / S

H G F E E D E R

9

90

00

0

-

-

1

12

20

00

0

Vejlevej 15, DK-8722 Hedensted

Tlf. 0045 75891244 Fax 0045 75891180

USERS MANUAL

Read and understand this Users Manual before

operating the machine

2

Feeder 900/1200

The manual covers the models Feeder 900 and 1200

Page

1. Precautions 3 - 5

2. Operation controls 6 - 15

3. Precautions before starting 16-20

4. Driving / Feeding 21-24

5. Maintenance 25-29

6. Trouble shooting 30

7. Hydraulic- and electricity diagrams 31-34

8. Tecnical data 35

10. Guarantee regulations 36

3

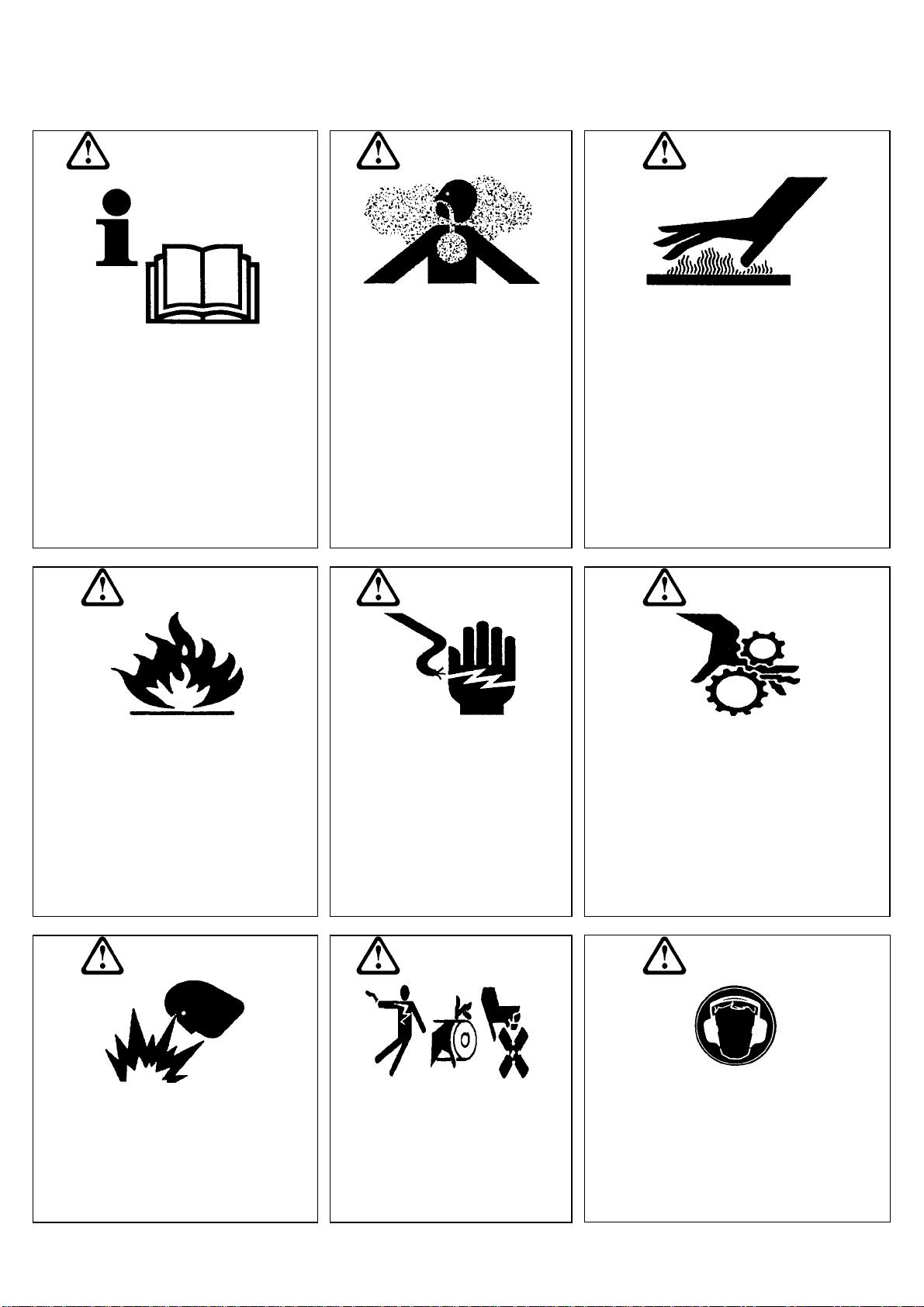

1. Precautions

Instruction in safe use of the feeding machine

IMPORTANT! WARNING! WARNING!

READ THE MANUAL CARBON MONOXID HOT PARTS

It is very important to read this manual in

order to avoid dangerous situations.

Read the manual carefully. If other persons

use the machine let them read the manual

too.

Dangerous carbon monoxide from

the exhaust can cause serious

sickness, faint and death.

Do not use this machine in closed

and limited rooms.

Hot parts can cause serious burns.

Do not touch the engine or the exhaust during

the operation or immediately after stopping the

engine.

WARNING! WARNING! WARNING!

FIRE RISK HIGH VOLTAGE ROTATING PARTS

Explosive fuel can cause fire and serious

burns.

Always switch off the engine and let it cool

before refueling

The engine generates high voltage

which can cause body injuring or

death

Do not touch the wires while the

engine is running

Rotating parts can cause serious damage.

Keep hands, feet, hair and cloths away from

all moveable parts. Never use the machine

without the delivered shields.

WARNING! WARNING! WARNING!

EXPLOSIVE GAS! DANGER! NOISE!

Explosive gas from the battery can cause

fire and serious corrosive damages.

Only charge the battery in a ventilated

place. Keep away all sources of open fire.

Sudden start can cause serious

damage and death

By servicing the machine or by par-

king, the machine has to be switched

off and the ignition key removed

Long stay in noise damages the hearing.

Always use ear protection…

4

1.1. Education

• Read the instructions carefully. You ought to have knowledge to operation grips and correct use of the

equipment.

• Do not let children or persons, who have no knowledge of the instructions, use the feeding machine.

The law can state an age limit for persons, who can use the feeding machine.

• Remember that the driver is responsible for accidents or situations of danger that can happen toward

human beings or their property.

• The driver must be instructed carefully in using the feeding machine. These instructions should put

emphases on following:

- The need of being carefully and concentrated by operating automotive machines.

- Have a comprehensive view of what happens in front and behind the vehicle, especially during

feeding, where other people can appear.

The most important causes to accidents are:

1. Driving too fast, especially with a filled up feed tank.

2. Swinging in high speed, especially with feed in the tank.

3. Lack of comprehensive view.

4. The knowledge of the driver of the vehicle is insufficient.

5. The ground conditions are to steep.

1.2. Preparation

• By driving make sure not to wear clothes, that are too loose, it can be caught on nest boxes or

doorways. You ought to use nonslip shoes in order to operate the pedals safe.

- Keep the fuel in cans approved to the purpose and out of reach of children and unauthorized persons.

- Only refuel outdoors. Smoking by refuel is forbidden.

- Refuel before starting the engine. Never take off the filler cap or refuel, while the

engine is running or hot.

- If you waste fuel do not try starting the engine, instead move the machine away from the spot, where

the fuel were wasted in order to avoid ignition of the fuel.

. If you waste fuel on the exhaust or on the engine, wait until it is evaporated, or else a fire could arise.

- If you get gasoline, diesel or engine oil on your skin, wash your skin thoroughly with soap.

- Inhaling of gasoline, steam or oil mist are damaging to your health.

- Consuming fuel or oil is highly dangerous.

5

1.3. Operation

• Do not let the engine run in small closed rooms, where dangerous carbon monoxide can mount up.

• WARNING: Inhaling carbon monoxide can cause poisoning and possible death.

• Do not use the machine in places with inflammable dust or explosive gases or where the exhaust can get

in touch with flammable material.

• If it is possible only use the feeding machine in daylight or a good artificial lightning.

• When you start the engine your feet must not rest on the pedal, they have to be placed on the running

board.

• Do not drive on slopes that surpass 15 degrees.

• Be aware that the driving quality of the machine is changed considerable from empty to full tank,

because a filled tank moves up the center of gravity.

• With a full tank pay attention to the fact that the machine can tip over, if you drive too fast in curves,

or on slopes with more than 15 degrees tilt.

• You can achieve pleasant driving by operating the driving pedal with soft movements with the food.

Remember that the driving speed increases proportional with the movement of the driving pedal. This is

valid both forward and backwards.

• When you leave the machine, the ignition key has to be removed from the dashboard.

The ground must not slope more than 15o

1.4. Maintenance

• By visual control the following has to be checked after every fill up:

- That there are no leaks in the hydraulic system at the hoses, the tank and so on.

- That there are no leaks in the fuel system at the hoses, filters, the tank and so on.

- That all bolts and nuts are securely tightened.

- Check that the silencer is dense.

- That the admission of air under the seat and the rotating flywheel are free of wool.

- That there is no wasted engine oil around the filler cap.

- Check the air pressure in the tires once a week.

- That the driving pedal easily goes to center position in slow speed (that the machine stands still, when

you let go of the driving pedal).

Max..15°

6

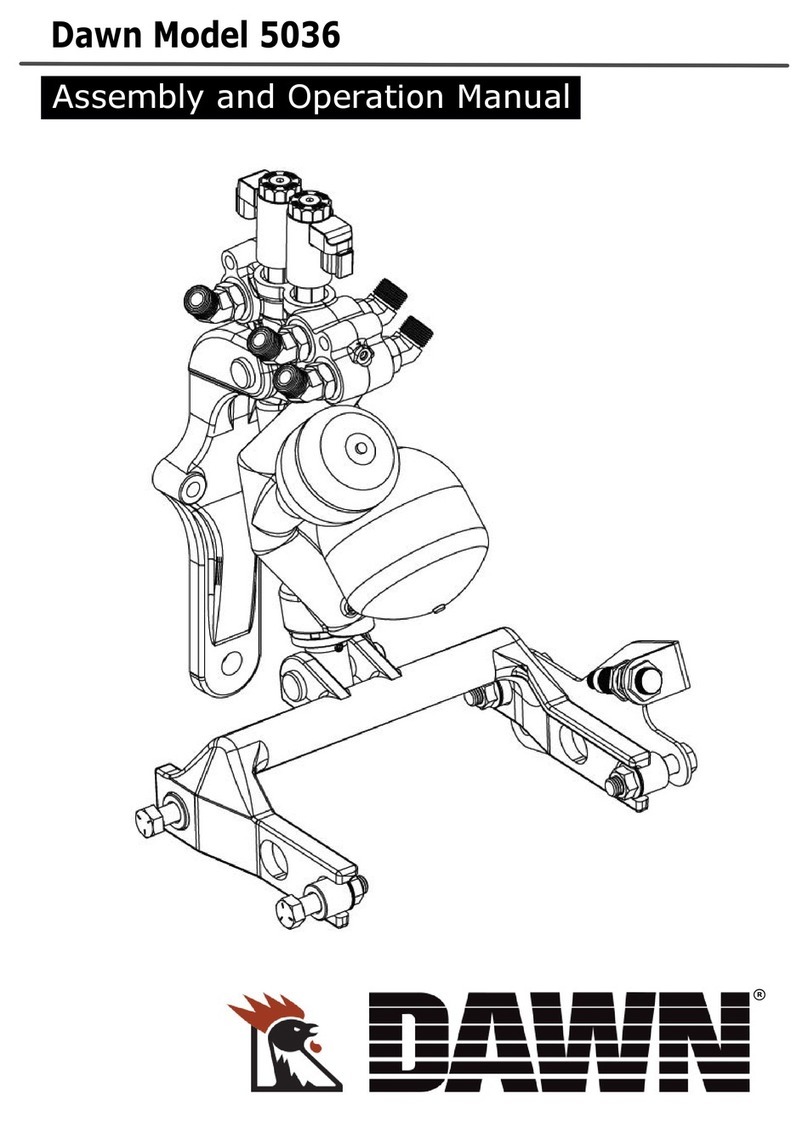

2. Operation controls

The position of the operation parts Feeder 900/1200

1. Feeding pedal.

2. Revcounter and hour meter.

3. Speeder (hand).

4. Speeder (food) pedal.

5. Ignition switch.

6. Regulation of water.

7. Regulation af speed for feed pump.

8. Handle for setting of seat.

9. Inspection glass for water tank.

10. Water refill.

11. Driving pedal.

12. Hydraulic filter and oil level gauge.

13. Feeding computer, extra equipment, look section 9.

14. On and off contact for screw.

15. Temperature meter.

16. Refuel/Tank meter

17. Speed and direction selector.

18. Main switch.

19. Refill cooling water / expansion tank

20. Air filter.

21. Light indicators.

22. Water pump contact.

23. Fuse box (not illustrated)

24. Filter manometer (not illustrated)

3

13

15

4

1

7

12

11

10

9

3

5

19

16

22

20

18

2

14

6

8

1

7

21

7

2.1. Feed pedal

Feeding pedal is placed outer right on the

machine.

The pedal must be activated every time you pump

out feed.

Feeding pedal

2.2. Hour meter and revolution counter.

The hour meter indicates how many hours the

machine has operated.

If this instrument stops working, repair it

immediately, or else there is no indication of time

for changing oil and so on.

Notice that this instrument counts as long as

the machine runs, so remember to switch off

the ignition and remove the key, when you

leave the machine.

Hour meter and revolution counter

2.3. Speed (hand)

Handle for speed (hand) is placed on the left side

of the steering column

Speed (hand)

8

2.4. Speed (food) pedal.

Speed (food) pedal is placed on the right side,

between the feed pedal and the central bracket.

Speed (food) pedal

2.5. Ignition switch.

The key activates the ignition switch.

The ignition switch has 3 steps

1. Ignition

2. Preheating

3. Start

Ignition switch

2.6. Regulation of water.

With the water regulation you can decide the

amount of water that is mixed in the feed, when

you activate the feed pump.

Placed at the left side by the back of the seat.

Adjust the amount of water by turning the tap:

Clockwise less water.

Anticlockwise more water.

Regulation of water.

9

2.7. Regulation of speed on feed pump.

The feed pump regulator adjusts the circulation

speed for the feed pump, so that more or less feed

can be pumped out at regular intervals.

You will find the indication for adjustment under

the regulators.

Regulation of water pump

2.8. Seat adjustments.

1 Longitudinal adjustment of seat.

2 Weight/hardness adjustments.

3 Seat adjustments.

4 Backrest adjustments

Adjustment handle for seat

2.9. Inspection glass for water tank.

2.10. Water filling up/Emptying.

Inspection glass / Water filling up. Drainplug watertank. Water dosing pump.

1

2

3

4

10

2.11. Driving pedal.

The driving pedal is placed on the left outer side

of the machine.

Notice: The pedal must be activated carefully,

since the speed of the machine is proportional

with the effect on the pedal. Furthermore the

driving will be more pleasant, when you operate

the pedal with gentle movements.

Driving pedal.

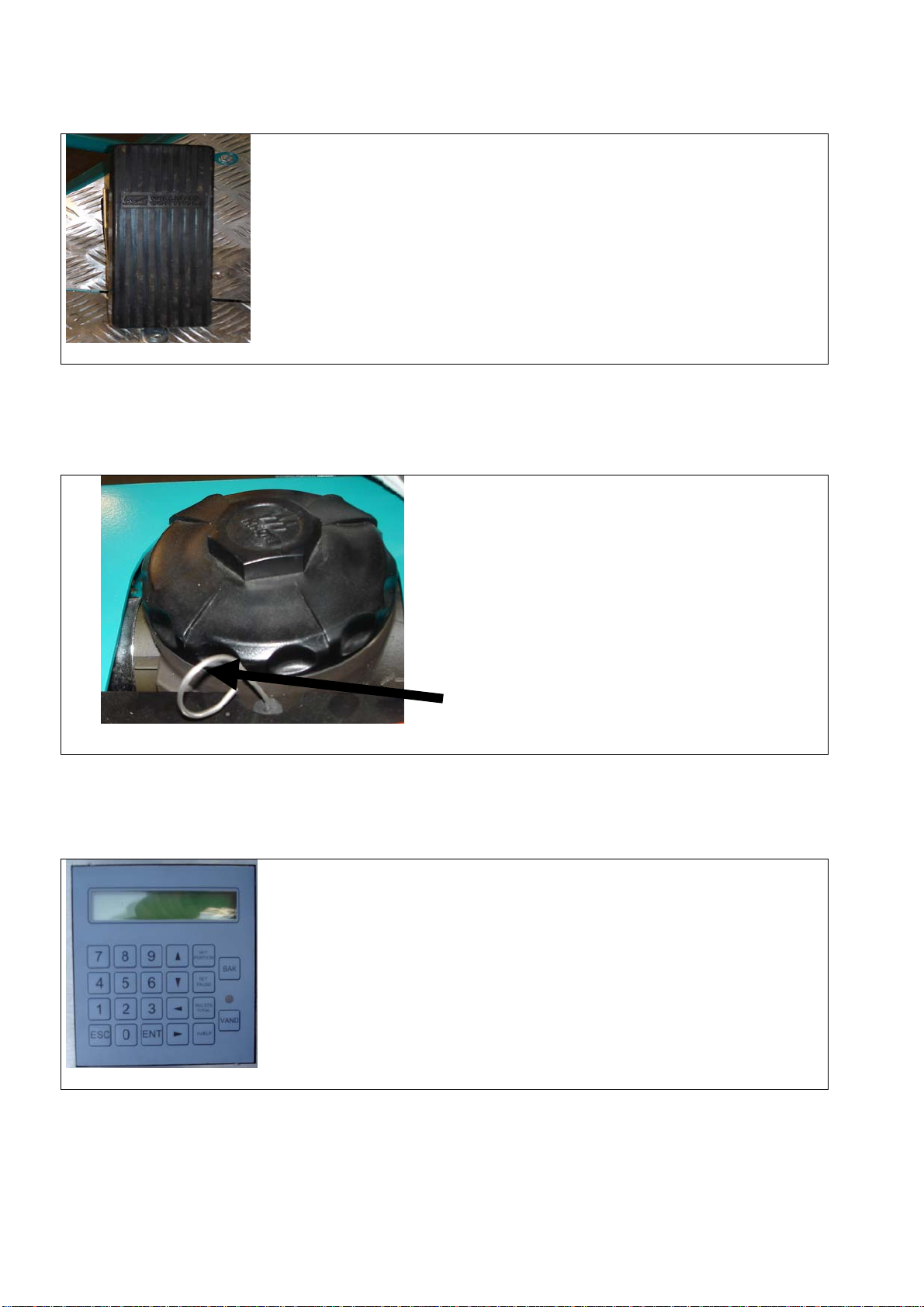

2.12. Hydraulic filter and oil level.

You refill hydraulic oil by removing the big

screw cap.

Dipstick for hydraulic oil.

Hydraulic filter and oil level dipstick.

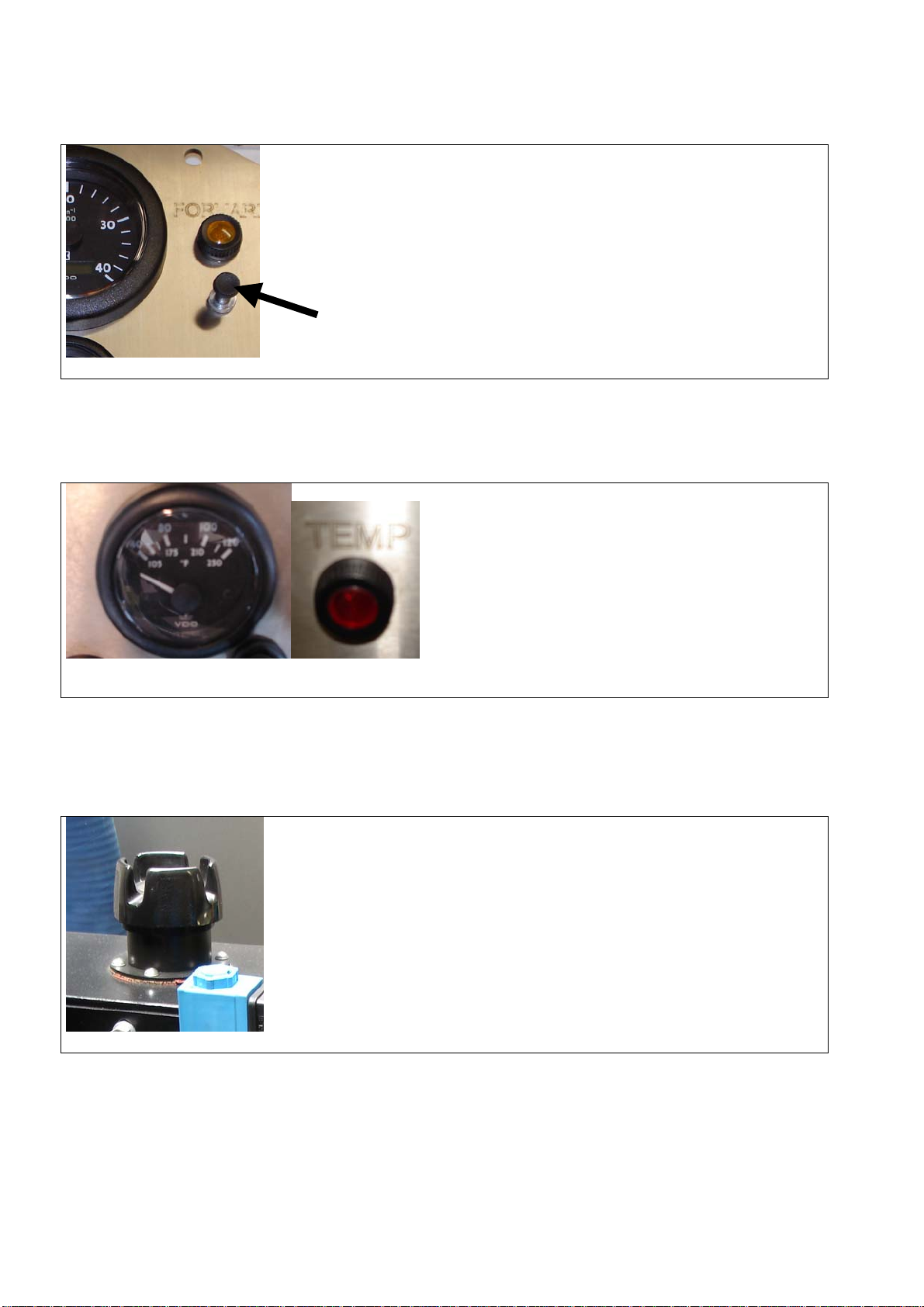

2.13. Feed computer (EXTRA EQUIPMENT).

Feed computer controls that the amount of feed

gets regular.

Feed computer.

11

2.14. Switch for screw in feed container.

Start of feed screw pull the knob up.

Stop of feed screw press the knob down.

Switch screw.

2.15. Water temperature. Light indicator.

Temperature meter

IMPORTANT!!

Keep an eye on the temperature.

If the indicator lights STOP the

machine IMMEDIATELY.

Water temperature /Light indicator.

2.16. Filling up fuel and amount of fuel.

Unscrew the filler cap and refuel with diesel oil.

The amount of fuel can be read by looking down

into filler cap.

Filling up fuel.

12

2.17. Speed and direction selector.

Change of running direction:

Forward push the handle forward.

Reverse pull the handle back.

Change of speed:

Low speed pull the handle against the wheel.

High speed push the handle away from the

wheel.

Speed and direction selector.

2.18. Main switch.

The main switch is placed at the back of the fore

carriage.

Main switch

2.19. Filling up cooling water / expansion tank

Refill cooling water.

IMPORTANT

Do not take of the cap before the engine is

cold.

Risk for scalding.

Refill cooling water / expansion tank.

13

2.20. Air filter.

Air filter

Change of filter insert.

Remove end cover and pull out insert.

Air filter.

2.21. Light indicator.

Light indicators.

Light indicators

1. Oil lamp (must switch off after app.

2 seconds – if not turn off the

engine immediately)

2. Temperature light indicator

switches on when the engine is

overheated(if the lamp turns on –

switch off the engine immediately)

3. Charging lamp ( If lamp turns on

while engine runs, the machine do

not charge)

2.22. Switching contact feed computer.

Contact is placed outer at left on the

dashboard.

M: Manual

A: Automatic

K: Constant

Water pump contact.

14

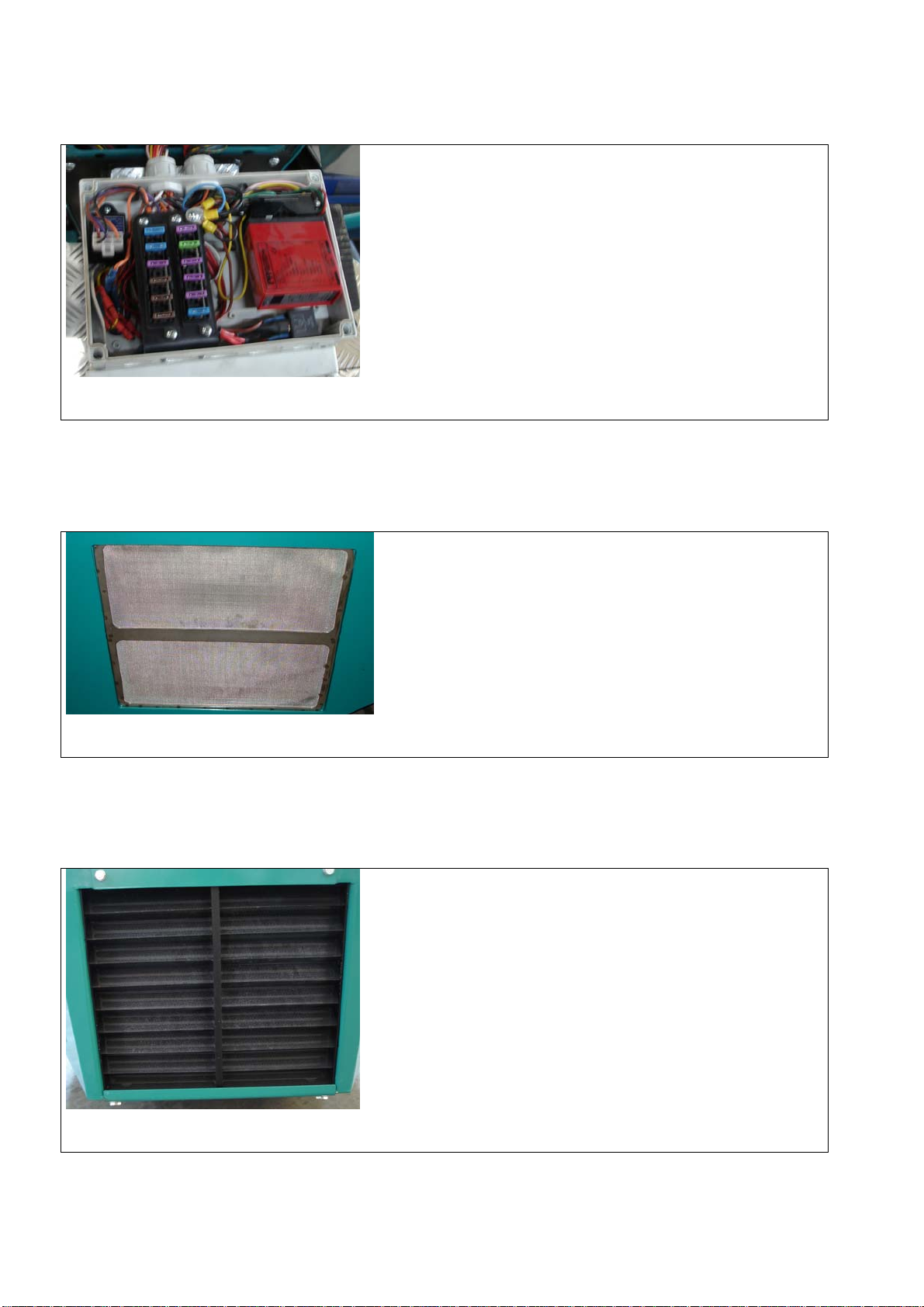

2.23. Fuse box.

The fuse box is placed behind a plate under

the wheel.

By changing fuses (Never replace the

earlier fuse with a bigger fuse).

Fuse box.

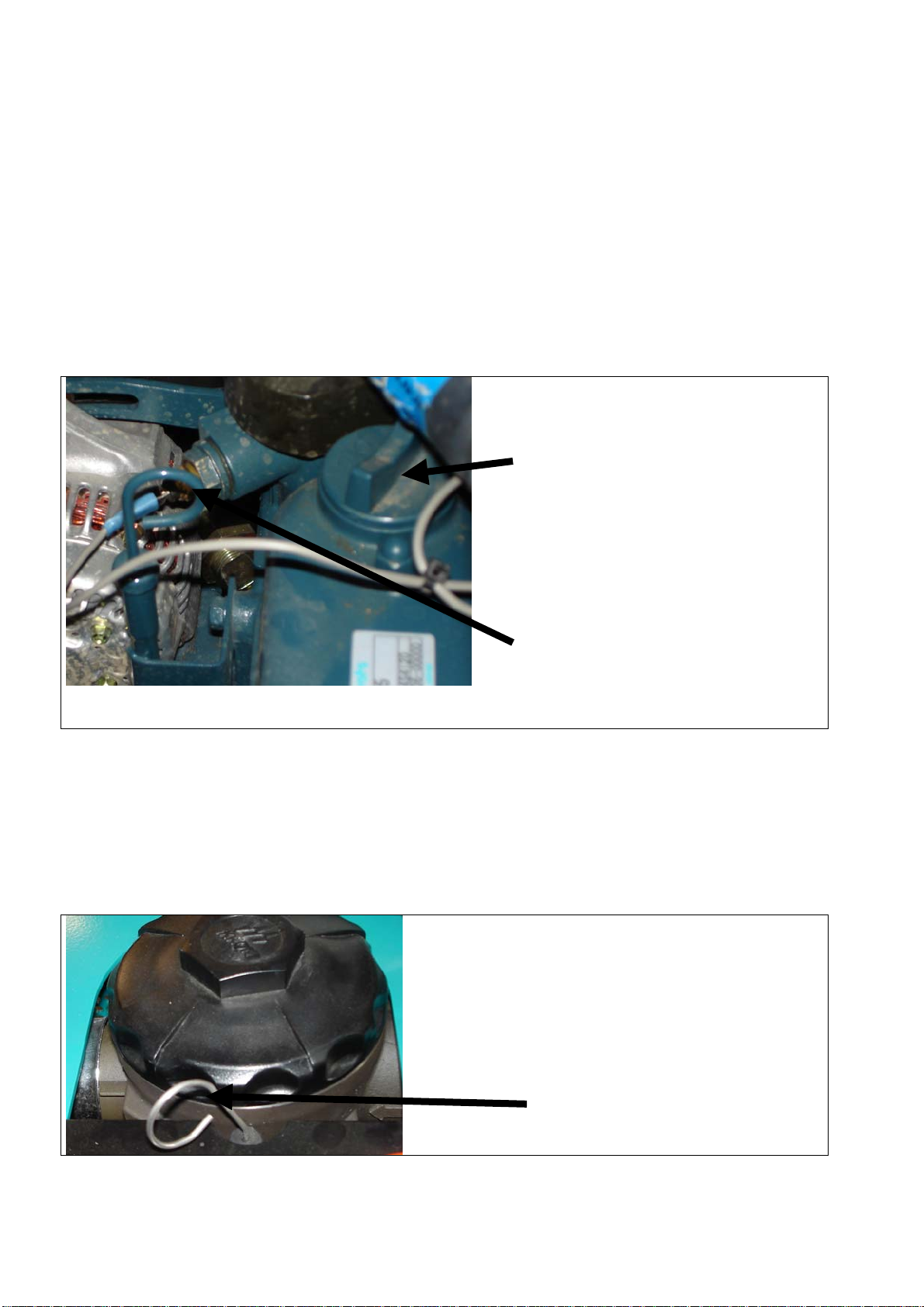

2.24. Particle filter for oil cooler.

Placed on the right side of the machine over

wheel.

Lift up and pull out, the bottom first

Particle filter oil cooler

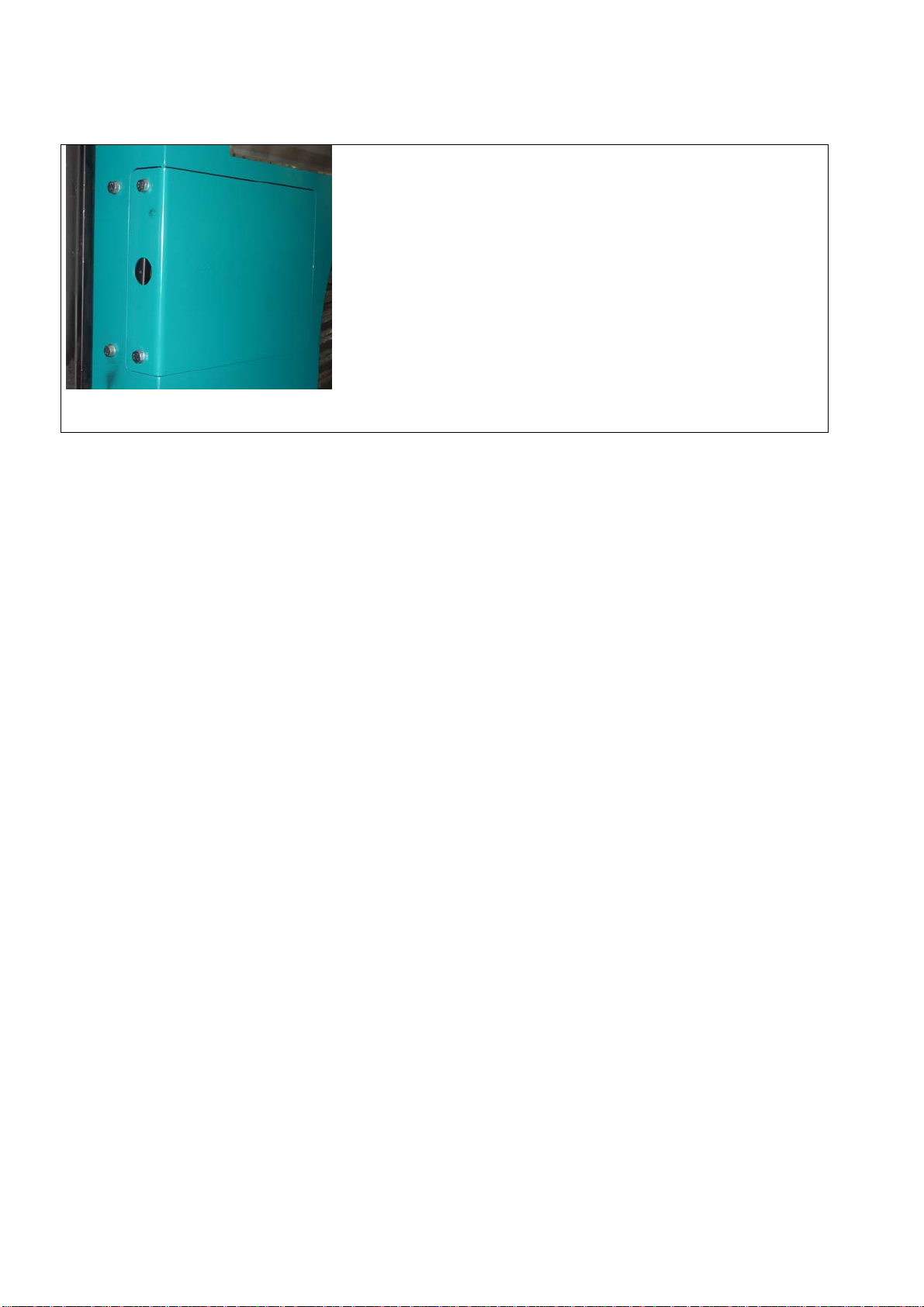

2.25. Particle filter for water cooler.

Placed in front of the feed machine.

Lift up and pull out, the bottom first

Particle filter water cooler.

15

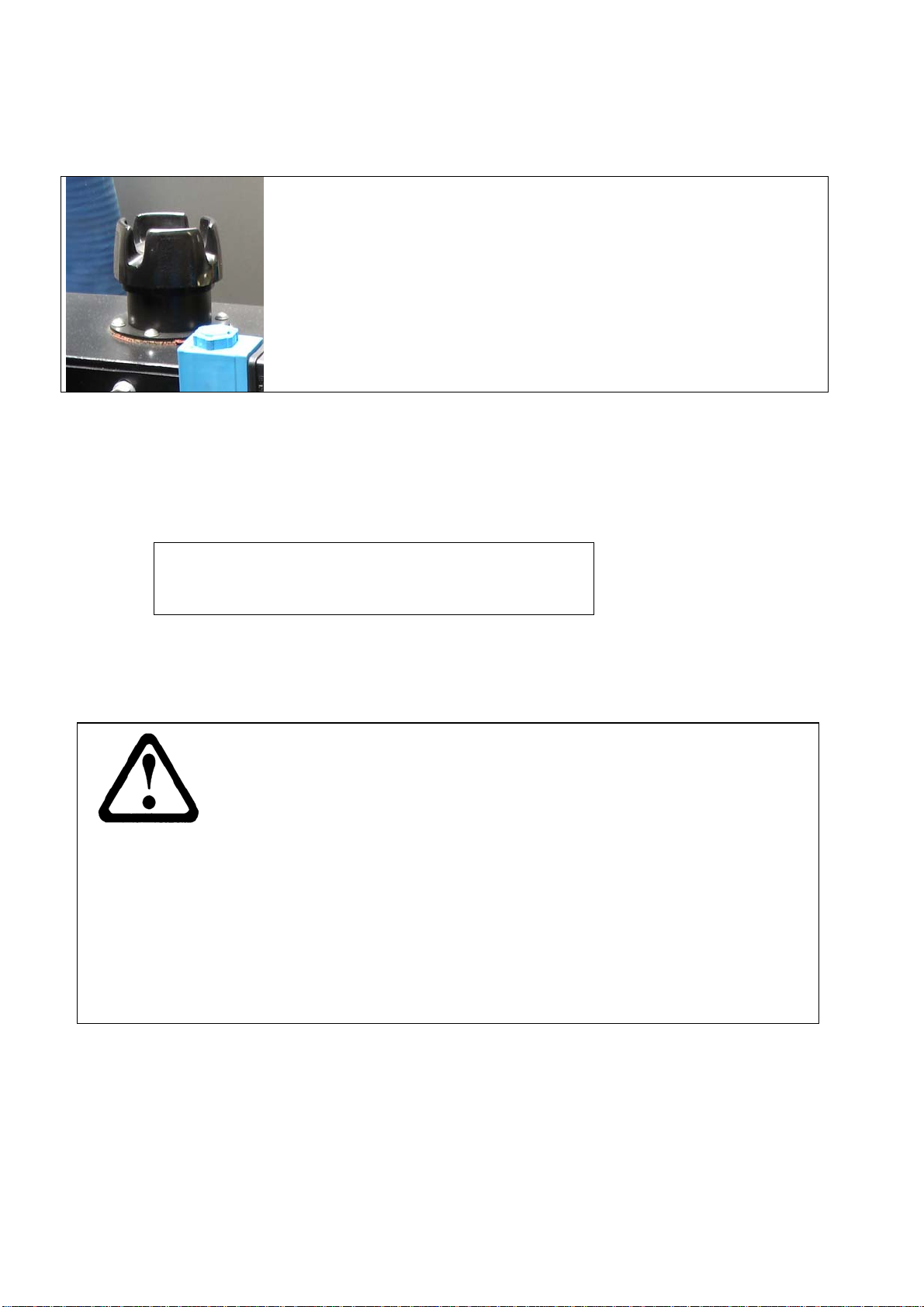

2.26. Accumulator.

The accumulator is placed behind the right

for wheel.

Always keep the accumulator clean on top,

otherwise a discharge of the accumulator

can happen.

Accumulator

16

3. Precautions before start.

3.1. Oil level engine.

The oil level ought to be checked before start, every time you use the machine. The machine has to be

placed horizontal, when you check the oil. Pull out the oil dipstick, wipe it off with a cloth, put it back,

redraw the oil dipstick and read the oil level. If the oil level is under level or right over you have to refill

to max.

Refill oil

Oil dipstick

Oil dip stick / Oil fill up.

3.2. Oil level hydraulic.

You can read the level of hydraulic oil by pulling up the oil dipstick, if the oil level stands by the minimum

mark you have to refill.

Oil dipstick

17

3.3. Refuel.

Unscrew the filler cap and refuel with diesel oil.

You can read the amount of fuel by looking down

into the filler cap.

Feeder 900/1200 engines use ordinary diesel oil.

Normally diesel oil is frost-proofed to about – 21° C, but during strong frost, paraffin is made in diesel oil.

To avoid this you can add petroleum after following table:

At temperaturs under -10° C add 10 % petroleum

At temperaturs under -20° C add 25 % petroleum

At temperaturs under -30° C add 40 % petroleum

At temperaturs under -40° C add 55 % petroleum

To be sure of how frost-proofed your diesel oil is, ask your diesel supplier about the specifications of your

diesel oil.

WARNING

Fuel is very flammable. Display great caution, and always refuel in the

open.

Never smoke during refuel.

Never refuel with a hot engine! Wait minimum 10 minutes.

Do not overfill the fuel tank, fuel can expand and ran over.

Make sure that the tank cap is firmly screwed after refueling.

Keep the gasoline on a cool place in a container, which is made for the

purpose.

The gasoline tank and hoses have to be checked often for leaks.

18

3.4. Air filter.

Keep the air filter clean. A dirty and clogged air filter lowers the effect of the engine and increases the fuel

consumption and the wear on the engine.

Cleaning/change of air filer.

Remove the wingnut in the end of the air filter

house, and pull out the filter.

3.5. Admission of air for engine cooling.

Admission of air cooling water.

Admission of air is placed in front of the

machine.

Important:

You MUST keep the radiator grille clean.

You can take of the filter, lift up the filter and

pull out the bottom.

3.6. Admission of air for cooling the hydraulic oil.

Admission of air is placed on the right side of

the machine.

Important:

You must keep the radiator grille clean.

You can take of the filter, lift up the filter and

pull out the bottom.

19

3.7. Accumulator.

•Check that the acid level is about 10 mm over the plates. Refill with distilled water if the acid level

is too low.

Too high acid level can cause that the acid runs over and causes corrode damages on the machine.

.

WARNING

SMOKING FORBIDDEN!

The accumulator gives off explosive gas. Keep sparks, flames or

cigarettes away. By ignition an explosion, fire and a spread of dangerous

acid over a large area.

Notice that the concentration of explosive gas is extra large by charging.

At starting help with another accumulator, connect the negative pole at

last. Connect the negative pole from the jumb lead to the frame on the

engine, never on the accumulator! When you remove the jump lead

again, remove the negative pole from the engine first.

Never charge on a frozen accumulator!

•Notice: if you use ordinary water for refilling of acid level, then you shorten the lifetime of the

accumulator.

Accumulator.

WARNING

IN CASE OF CONTACT WITH ACID!

-If the acid gets on your skin (External) you have to rinse thoroughly wit

water.

-If the acid is consumed (Internal) you have to drink a huge amount of

water or milk, then more milk with mixed egg or vegetable oil and call

for a doctor immediately.

-If the acid gets into your eyes, then rinse thoroughly with water,

minimum 15 minutes, and visit a doctor as soon as possible.

20

3.8. Tyre pressure.

•Check that the tyre pressure is correct, an incorrect tyre pressure can make the machine

unstable and the maneuver quality will be unpredictable.

Max.

65 PSI

Lawn tyre (std.) nr.:474765. Wheel complete 7,00x12

This manual suits for next models

1

Table of contents

Other HG Farm Equipment manuals

Popular Farm Equipment manuals by other brands

M K Martin Enterprise

M K Martin Enterprise PULSAR 120 Operator and parts manual

Buhler

Buhler 360 user manual

AKO-Agrartechnik

AKO-Agrartechnik Easy Gate 446517 user guide

Toro

Toro 31526 installation instructions

MacDon

MacDon M155 Unloading and assembly instructions

HighLine

HighLine NT Series Operator's manual