TKS K2 CombiCutter User manual

TKS Operator's manual

1

K2 EasyFeed Multifi ll V1.9 2022 EN 989053

Operator's manual

K2

EasyFeed Multifi ll

TKS Operator's manual

2

Content

1 GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 USING THE CONTROL BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 ALARM AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5 RECYCLING - WASTE TO RESOURCE -. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 CE - Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Garantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.2 Additional safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.3 Overview of safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.4 Lifting the machine with a crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.5 New machine caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Using the control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Constituent parts – radiocontrolled remote operation . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Location and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.7 Numeric keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.8 Alphabetic keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TKS Operator's manual

3

2.9 Selecting values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.10 On/Off button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11 Close windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.12 Manual button on cabinet or panel control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Set the clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3 Single sequence settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.1 Sequence/group without weight, without "Grain" and without "Multifi ll". . . . . . . 21

3.3.2 Sequence with weight, with grain without "Multifi ll". . . . . . . . . . . . . . . . . . . . . . 22

3.3.3 Sequence with weight, with grain with "Multifi ll". . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.4 Sequence Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.4.1 Command "Fill" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.3.4.2 Command "Deliver feed" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.4.3 Command "Feeding grain 1" and "Feeding grain 2" . . . . . . . . . . . . . . . . 28

3.3.4.4 Command "Go to" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.4.5 Command "Pause" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.3.4.6 Command "Run sequence" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.4.7 Delete command line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.4.8 Floating command line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.4.9 Generally about sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.5 Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.4 Feed now function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4.1 EasyFeed - Press once for the feeding of several groups . . . . . . . . . . . . . . . . 35

3.4.2 Changing and starting EasyFeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

TKS Operator's manual

4

3.5 Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.5.1 Defi ne groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.5.2 Forage settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5.2.1 Manual fi lling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.5.2.2 Filling from the top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5.2.3 Filling from Magazine side 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.5.2.4 Forage settings MULTIFILL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.5.3 Grain settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.5.4 Cutter settings Side 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5.5 System menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5.5.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.5.5.2 Reduced speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.5.5.3 Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.5.5.4 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.5.5.5 Brush settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.5.5.6 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.6 Language settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.7 Time counter / Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.8 Alarms log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.9 Multi-fi lling settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.9.1 Filling point settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.9.2 Conveyor settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.9.3 PLC inputs / outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.9.4 Filling point settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.10 Manual Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.11 Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

TKS Operator's manual

5

4 Alarms and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.1 Alarms and controlbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5 Recycling - waste to resource - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

TKS Operator's manual

6

1 General safety instructions

Wi,

TKS Agri AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

declare that the product:

TKS - K2 EasyFeed Multifi ll

has been built in conformity with the Machine Directive and meets the relevant fundamental health

and safety requirements.

Kverneland, 15 September 2022

Atle Sjølyst - Kverneland

General Manager

Enter the serial number

on the machine:

TKS Agri AS, manufacturer of agricultural products, reserves the right to change the design and/ or

specifi cations of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

1.1 CE - Declaration of conformity

TKS Operator's manual

7

1.2 Garantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to

TKS or TKS’s distributor/importer within the 10th of the month following the one in which the defect

was reported. The defective parts shall be marked with the claim number and be kept for up to 6

months so that TKS or TKS’s distributor/importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any resulting damage.

The guarantee is not valid if:

a) third-party spare parts are used, or the product is repaired or altered without the

approval of TKS

b) the operating and servicing instructions have not been followed

c) the machine has been used for other purposes than those for which it is designed

The guarantee does not cover damage due to normal wear and tear

Offi cial safety regulations specify requirements that apply to the manufacturers of this machine

relating to the careful review of safety hazards that may arise when this type of machine is used

correctly. Therefore, TKS and our importer/distributor are not responsible for the functioning of

components that are not shown in the spare-parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number.

TKS Agri AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

e-post : post@tks-as.no

Phone : + 47 51 77 05 00

TKS Operator's manual

8

1.3 Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. All TKS products are designed and built in close cooperation with farmers to ensure

optimal effi ciency and reliability.

Please read this instruction manual carefully, and familiarise yourself with the machine’s manner

of operation before starting to use it. The machine is a highly advanced feed machine that operates

unattended. It must be used in accordance with the relevant manufacturer instructions and other

regulations.

Many diff erent factors and variables can aff ect the performance and method of operation of the

machine

It is therefore very important to assess all known factors and adapt the way in which the machine is

used accordingly.

A good understanding of the machine’s method of operation and performance, together with a

sound knowledge of feeding and feed types/consistency will ensure the best results.

Best Regards

TKS AS

TKS Operator's manual

9

TKS Operator's manual

10

1.4

Safety

Please pay particular attention to this symbol.

It designates a safety risk, and describes

precautions that must be taken to avoid

accidents

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Be alert and take precautions when working

with agricultural machinery. Read and observe

the safety instructions in this instruction manual.

Safety at work is your responsibility!

1.4.1

General safety -

instructions

Please read and understand these general

safety instructions.

There is a risk of stones being thrown

upwards and backwards when the machine

is in operation.

Use of the machine

The machine must only be used for the

purpose for which it is designed.

The machine’s method of operation

The operator must familiarise himself with the

machine’s method of operation and function so

that the machine can be used in a safe and

appropriate manner.

Providing notifi cation in the barn

The operator must familiarise himself with how

the machine works and functions, so that it can

be used safely and properly

Keep a safe distance

Humans and animals must be kept away from

the machine when it is in operation.

Keep your distance from working, rotating and

moving parts

Be safety conscious

Never enter the machine when it is in operation.

When performing maintenance, disconnect the

power supply.

Protective guards

Check that all guards are in good order and

installed correctly. Do not start the machine until

this has been done. Damaged guards must be

repaired or replaced immediately

TKS Operator's manual

11

Warning-lights

Warning lights installed on the machine must be

visible from all areas of the barn

Alarm

Ensure that the installed alarm sounds

15 seconds before start (delayed start).

Do not enter the area between the Magazine

and the machine before.

Warning sign

The supplied symbolic warning signs

“No access for unauthorised persons”

be attached to all doors into the barn.

Attention! The machinery starts

automatically.

Spare parts

For safety reasons we recommend that you

only use original spare parts. The use of

third-party spares invalidates the product

guarantee.

Maintenance

Ensure that the machine is properly maintained

and is kept in good condition. Never attempt to

change the mechanical workings of the

machine.

The area in which the machine is operating

Must be physically sealed off or locked to

prevent danger to humans or animals.

Control panel

The power supply must be cut off before

opening the panel.

Emergency stop

Emergency stop switches are located at the

front and the back of the machine.

These buttons are red.

TKS Operator's manual

12

1.4.2

Additional safety -

instructions

The machine is marked with a warning

signs. If these signs are damaged, they must

be replaced. The order number is shown on the

illustrations in this section.

Se Fig. 6 for their location on the machine

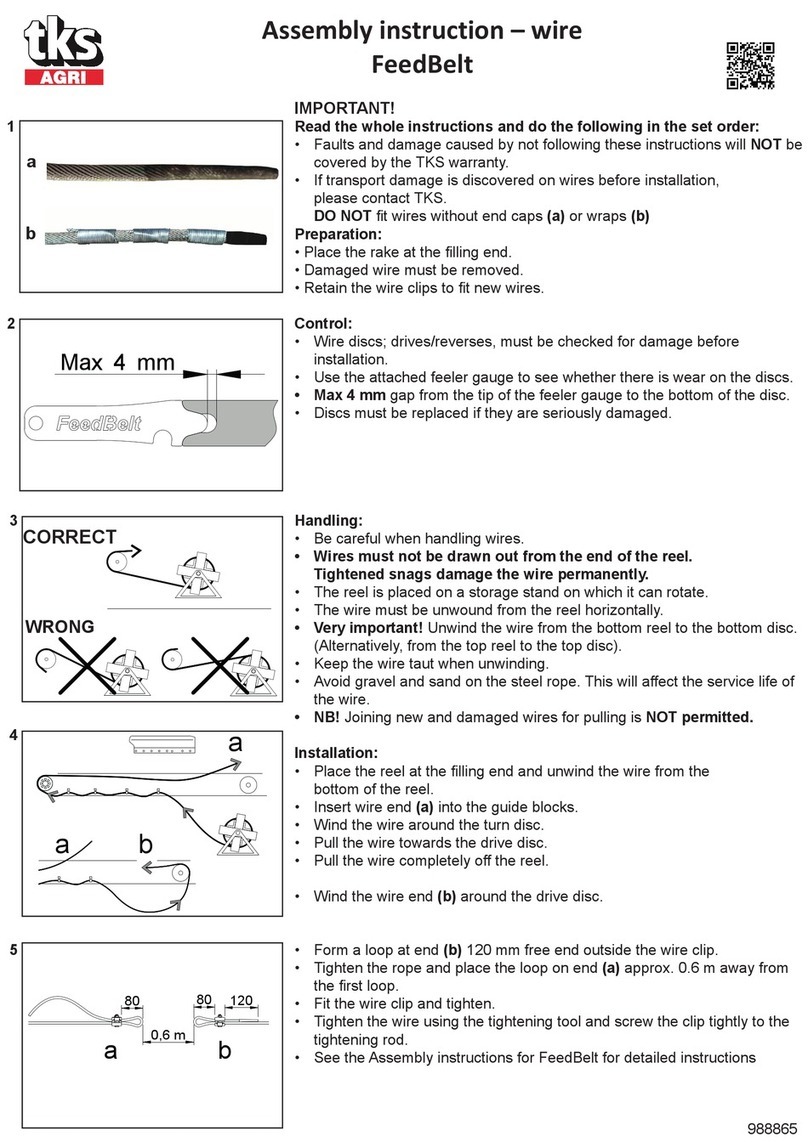

Warning sign UH220532 (Fig. 1)

Ensure that you read and understand the

instruction manual before using the machine,

and before making any adjustments or

performing any maintenance.

Warning sign UH220544 (Fig. 2)

Crush hazard. Keep clear of the area between

the machine and Magazine R2. Keep a safe

distance from the feed cart because it may start

automatically.

Warning sign UH220526 (Fig. 3)

You may damage your fi ngers if you trap them

between the chain and the chain wheel.

Warning sign UH220527 (Fig. 4)

Risk of cutting your hand. There is a risk of

cutting your hand on the drum’s knives when

the drum is in operation.

Warning sign UH220539 (Fig. 5)

Risk of breaking your fi ngers.

You risk breaking your fi ngers if you trap them

between the conveyor and the base.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

UH220532

UH220544

UH220526

UH220539

UH220527

UH220526

UH220544

UH220539

UH220527

IEF_1b

IEF_1

TKS Operator's manual

13

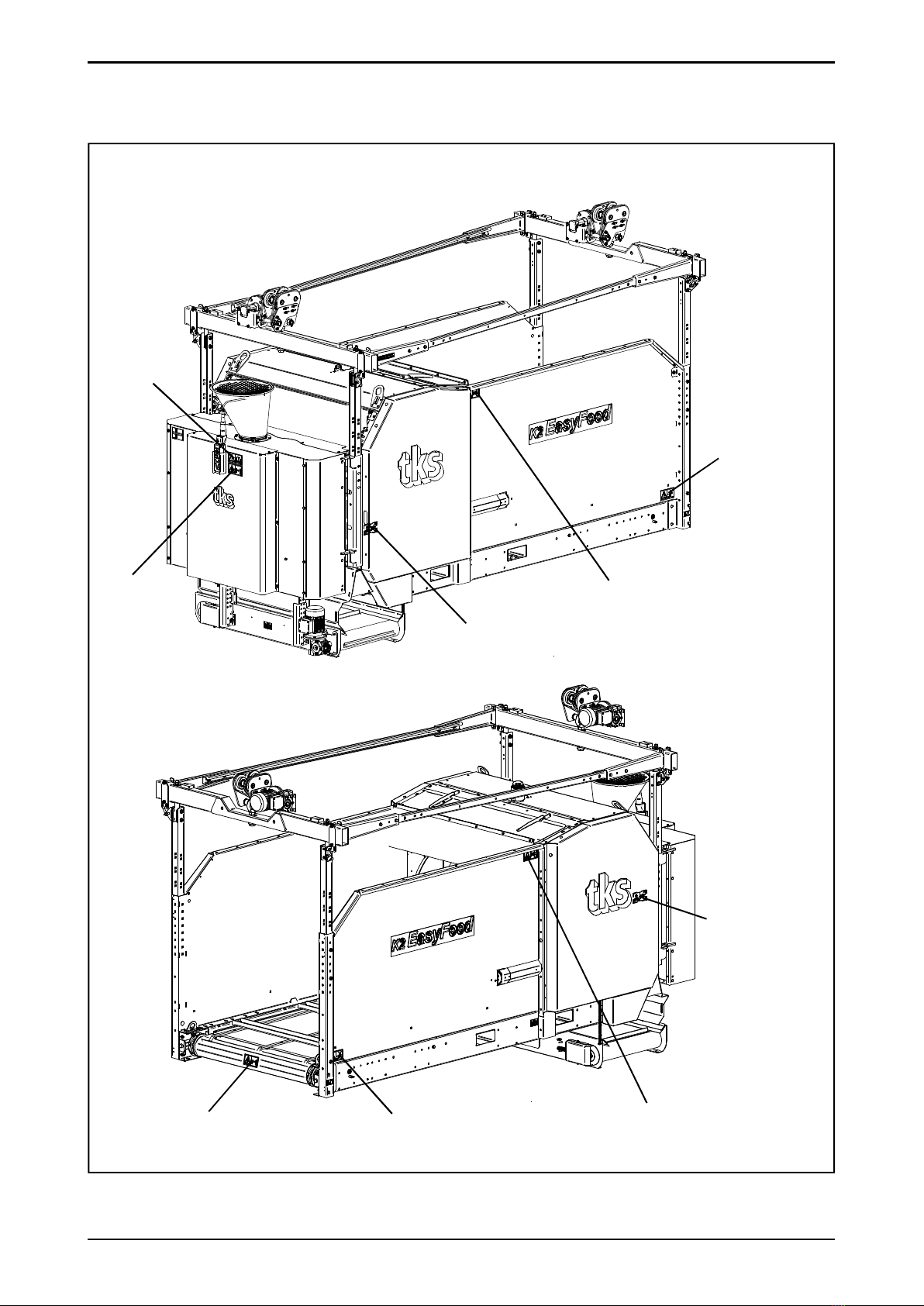

1.4.3 Overview of safety risks

Fig. 6

TKS Operator's manual

14

1.4.4

Lifting the machine

with a crane Only use approved lifting equipment.

The weight of the machine is listed in the

section “Technical Data”. For location of lifting

point see Fig. 7

Caution!

Ensure that no-one is under or close to the

machine when it is being lifted.

Lift the machine using a strap attached to the

main frame of the machine, so that the lift is

balanced.

Check that the straps are properly fi xed before

starting the lift.

Use an extra strap to help keep the machine in

position

1.4.5

New machine caution Read the operator’s manual

Be particularly careful when starting a new

machine for the fi rst time. Installation faults,

incorrect operation, etc. may lead to expensive

repairs and loss of earnings. The TKS product

guarantee does not cover damage resulting

from failure to follow the recommendations

contained in the instruction manual.

Please pay particular attention to this symbol.

It is used to highlight important information, to

help prevent incorrect installation and

operation.

Pay particular attention to the following

when commissioning a new machine:

Check that the machine is correctly installed

and that it is not damaged.

Lubricate the machine where shown in

chapter 5 Maintenance

Remember that the operator has a

responsibility to ensure that your product is

properly and securely installed.

IEF_37

C

F

D

G

E

A

B

TKS Operator's manual

15

2 Using the control box 2.1 Constituent parts – radio-

controlled remote operation

A – Attachment handle. Can be

swung down for better viewing when th

control box is positioned on a fl at surface.

B – Screen 5.6”

C – Charging contact

D – On/Off switch

E – Grip

F – Charging cable

G – Wall plate (screws not included)

2.2 Location and connection

Mount the wall plate in an appropriate place.

The control box is not waterproof and must not

be exposed to water splash or placed in an en-

vironment with condensation. It is a good idea

to place the control box close to the machine’s

parking position or in an offi ce from where you

can see the machine. A socket for the charging

cable should be in the immediate vicinity.

2.3 Battery

The control box has a battery included.

This is maintenance-free. The battery should

be charged at all times. The battery charger

has automatic charge limits, and can always be

connected to the control box and the mains.

The feed machine runs in accordance with the

program stored in the machine’s control box.

It is a good idea to turn off the screen to save

battery power.

2.4 Screen

Turn on the screen. The start-up screen is

displayed.

The control has a touch screen. You can press

it with your fi nger or using a special pen. Only

one press at a time. Do not press too hard, as

this can damage the screen. If the screen has

not been active for a few minutes, it will enter

screen saver mode. The screen will be off in

this mode. Press any part of the screen to

reactivate it.

NB! Clean the screen using a moist cloth.

2.5 Warranty

The warranty will lapse if the control box is

opened.

Fig. 28

TKS Operator's manual

16

Fig. 29

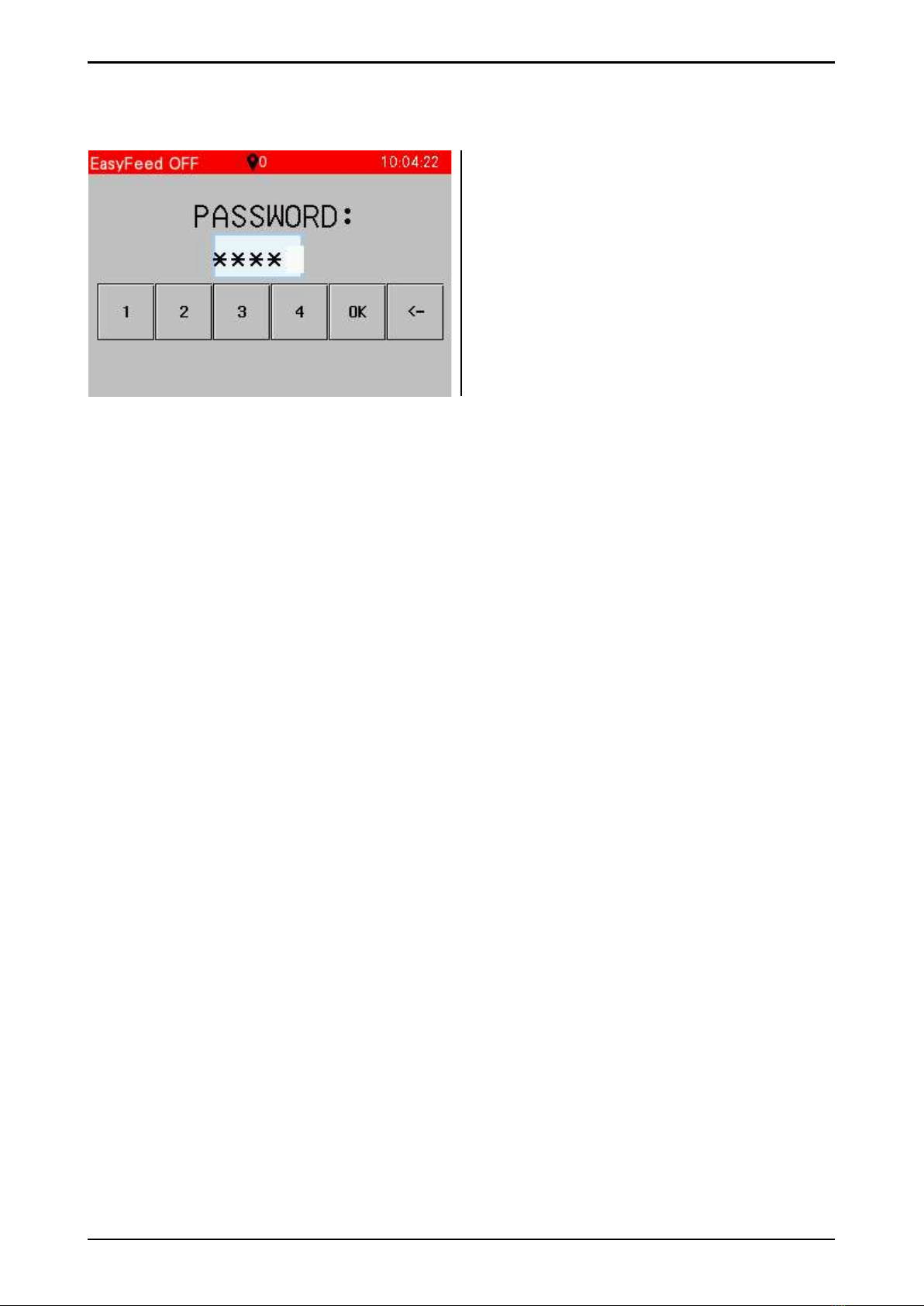

2.6 Password

• Remote operation is protected against

unwanted use.

• Enter a PASSWORD each time the screen is

turned on.

• The password is: 1324

• Confirm with OK

• Delete keystroke error with <-

See Fig. 29

TKS Operator's manual

17

Fig. 30

Fig. 31

2.7 Numeric keypad

Values in fi elds with blue borders can be

changed. Press on the number and a numeric

keypad will appear on the screen.

The Max/Min value that can be entered in this

fi eld is shown at the top of the window. Enter a

new value using the numeric keypad.

If an incorrect value is entered, press the

<─ key and delete the most recently entered

number. Press CLR to delete everything.

To enter a negative value, press – before the

value. Once you have selected a value, press

the ENTER button.

This will save the value and close the keypad

window.

To cancel, press X in the upper right-hand

corner. The old value will continue to be active.

To enter times in the feed dispensing schedule

window, begin by entering hours – then press

period. Now enter minutes.

Make sure that the time is correct.

For example, if you enter 12.65, this will be

ignored – enter 13.05 instead.

2.8 Alphabetic keypad

When you enter values with text (e.g. name of

animal) the screen will display an alphabetic

keypad:

When editing a text fi eld, the old text is

displayed on the screen.

New text can be entered, and the old text will

disappear.

Use the Caps button to switch between

uppercase and lowercase letters.

Press the BACK button to remove the last

symbol registered, or press Clear to delete all

text, then enter the new text.

Note that there is a limit on the number of

letters in the fi eld. The fi rst letters will be

deleted if a long string of text is entered.

When the text has been entered, press the

ENT button. This will save the text and the

keypad window closes.

If you want to cancel, press the X or Esc button

and the old value will remain active.

TKS Operator's manual

18

Fig. 32

Fig. 33

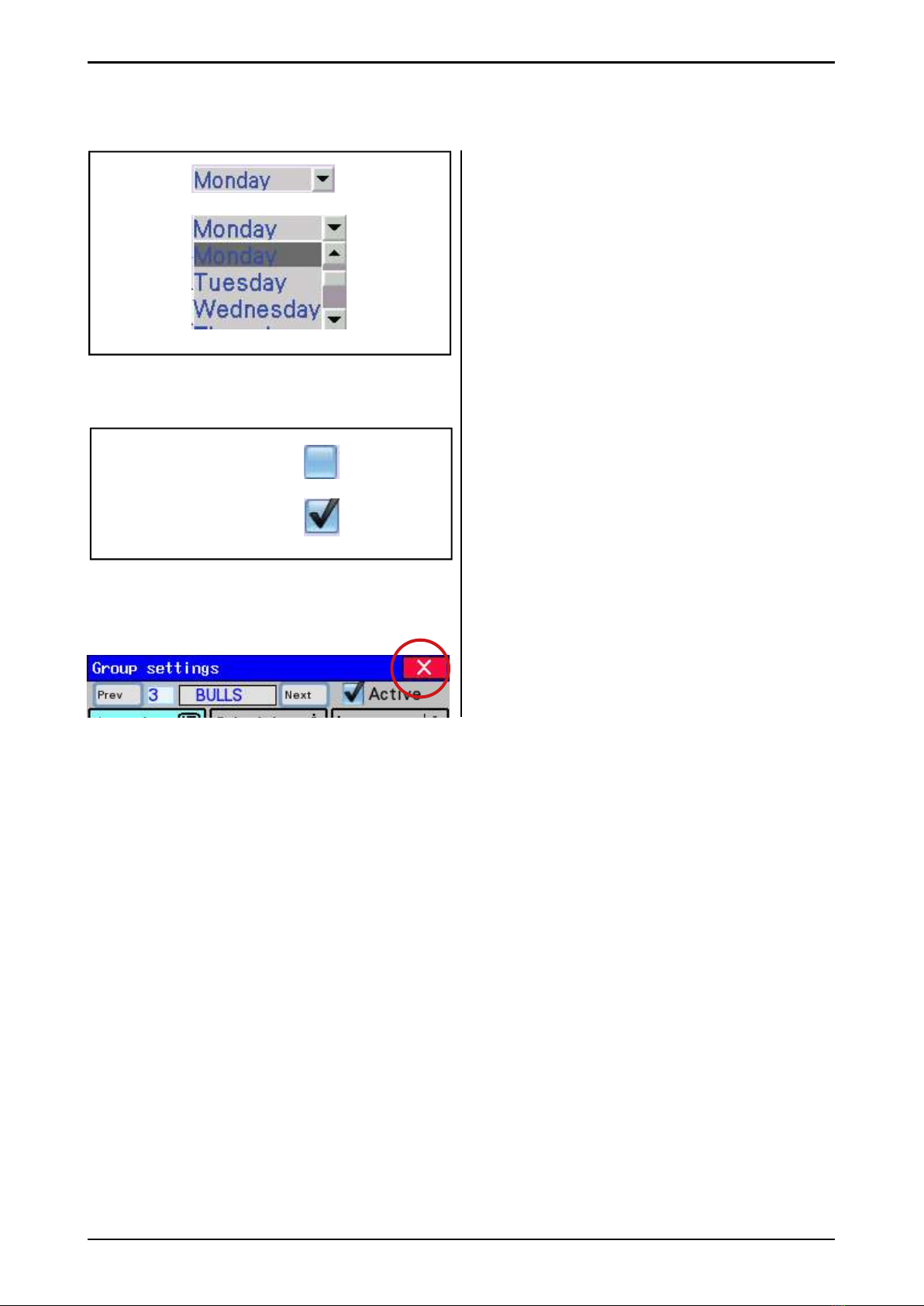

2.9 Selecting values

Selecting pre-programmed values from a

list.

• Open the list – Press the value or the down

arrow

• Select a value from the list

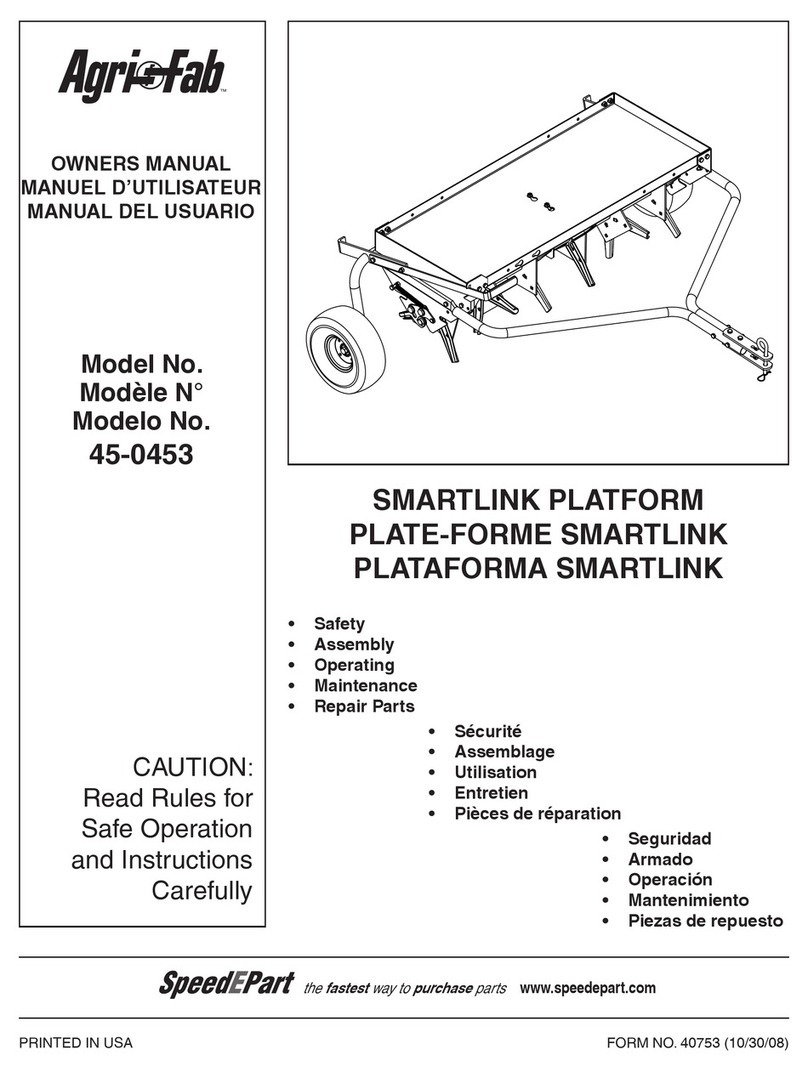

2.10 On/Off button

Activated or deactivated a function using the

on/off key.

• Blank – deactivated

• Ticked – activated

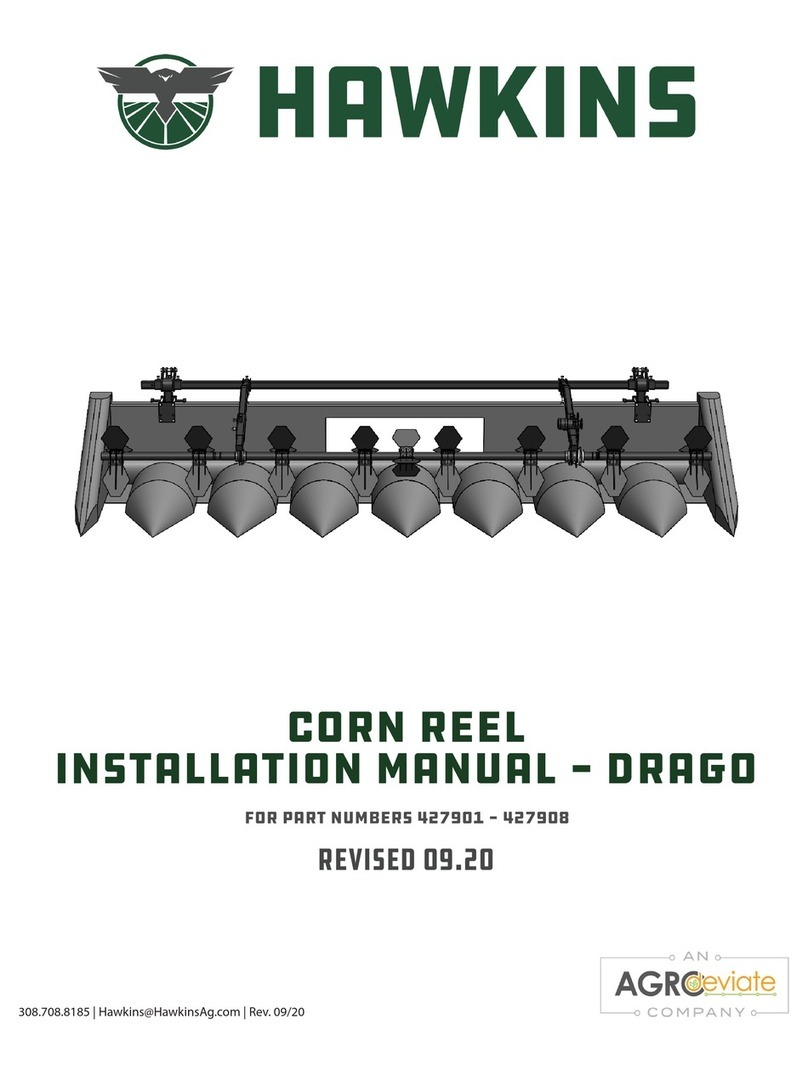

2.11 Close windows

All menus or windows on the screen can be

closed using the cross on a red background in

the upper right-hand corner.

Fig. 34

A

B

C

D

IEF_01

IEF_03

B A

C

D

TKS Operator's manual

19

2.12 Manual button on cabinet or

panel control

Used to dispense feed when the control box is

in use.

When using this, take care to avoid getting

trapped between the machine and

the feed tray or the fi ttings.

A – button for enabling and stop

B – emergency stop switch

C – button for driving machine backwards and

start dispensing feed to the left side

D – button for driving machine forwards and

start dispensing feed to the right side

Note! Operation must always be enabled

before use. Press button A and hold down for

two seconds.

• Drive the machine forwards with button D

and backwards with button C. The machine

only moves when the button is held down.

• Start dispensing feed to the left. Hold button

A down and press button C at the same time.

Release button A.

• Start dispensing feed to the right. Hold

button A down and press button D at the

same time. Release button A.

• Drum, conveyor belt and side dispenser start

up in sequence. Dispense feed by driving

forwards and backwards with buttons

D and C.

• Stop dispensing feed. Press button A.

• Drum, conveyor belt and side dispenser stop

in sequence.

• On a machine without side dispensers, the

feed dispensing process starts in a similar

manner. Hold button A down and press

buttons C or D at the same time. Release

button A.

• Stop dispensing feed. Press button A.

Fig. 35

TKS Operator's manual

20

3 Operation

3.1 Home screen

The main screen appears when EasyFeed is at

rest.

A - Information bar

• Displayed on all screens

• The text indicates what EasyFeed is

currently doing

• Position sign and the machine’s current

position

• Weight symbol and weight of the contents of

the machine in kg

• Clock

• The clock is displayed in green when Auto

ON is enabled

B - Programmable groups 1-20

• Full line – the group is enabled

• Dashed line – the group is not in use,

disabled

• Displays group name

• Displays the next time for Auto dispensing

Pressing on either group opens

Group settings. Se side 22

• When groups 11–20 are programmed, an

arrow key to switch display between groups

1–10 and 11–20 appears

C - Feeding keys

• Feed now (blue) This is used to feed 1 group

with adjustable quantities.

• EasyFeed (yellow) This is used to feed

multiple groups with programmed settings

Se side 38

• Auto (green) This is used to automatically

turn timed feed dispensing on and off .

• Hold the keys down for 3 seconds.

D - Keys for menu and manual operation

• Menu key opens the menu for machine

settings.

• Stop key – stops everything. See side 39

• Activating

• Manual key - Opens window to operate

manual feed dispensing. Se side 53

• Status indicator key – Opens window for

alarms. See side 54

- OK (green) - all clear

- Warning (yellow) - alarm has been tripped,

but the machine can still run

- Stop (red) - the machine is stopped

Fig. 36

A

B

C

D

Fig. 37

Other manuals for K2 CombiCutter

1

Table of contents

Other TKS Farm Equipment manuals

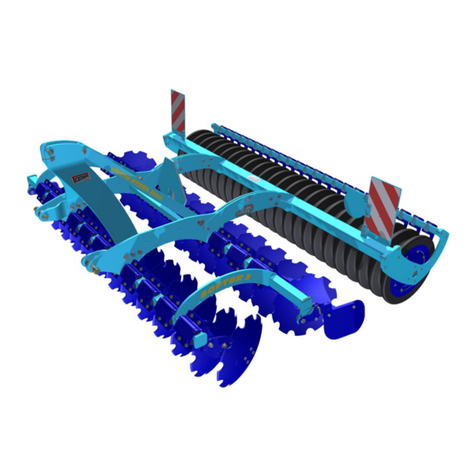

Popular Farm Equipment manuals by other brands

Agri-Fab

Agri-Fab SmartLink 45-0453 owner's manual

AGROdeviate

AGROdeviate Hawkins Corn Reel installation manual

Farmet

Farmet SOFTER 3 operating manual

360 Yield

360 Yield 360 Y-DROP JOHN DEERE 4720 instruction manual

Smithco

Smithco V-STAR 94-201 Service manual

Unverferth

Unverferth Killbros SeedVeyor 102 manual