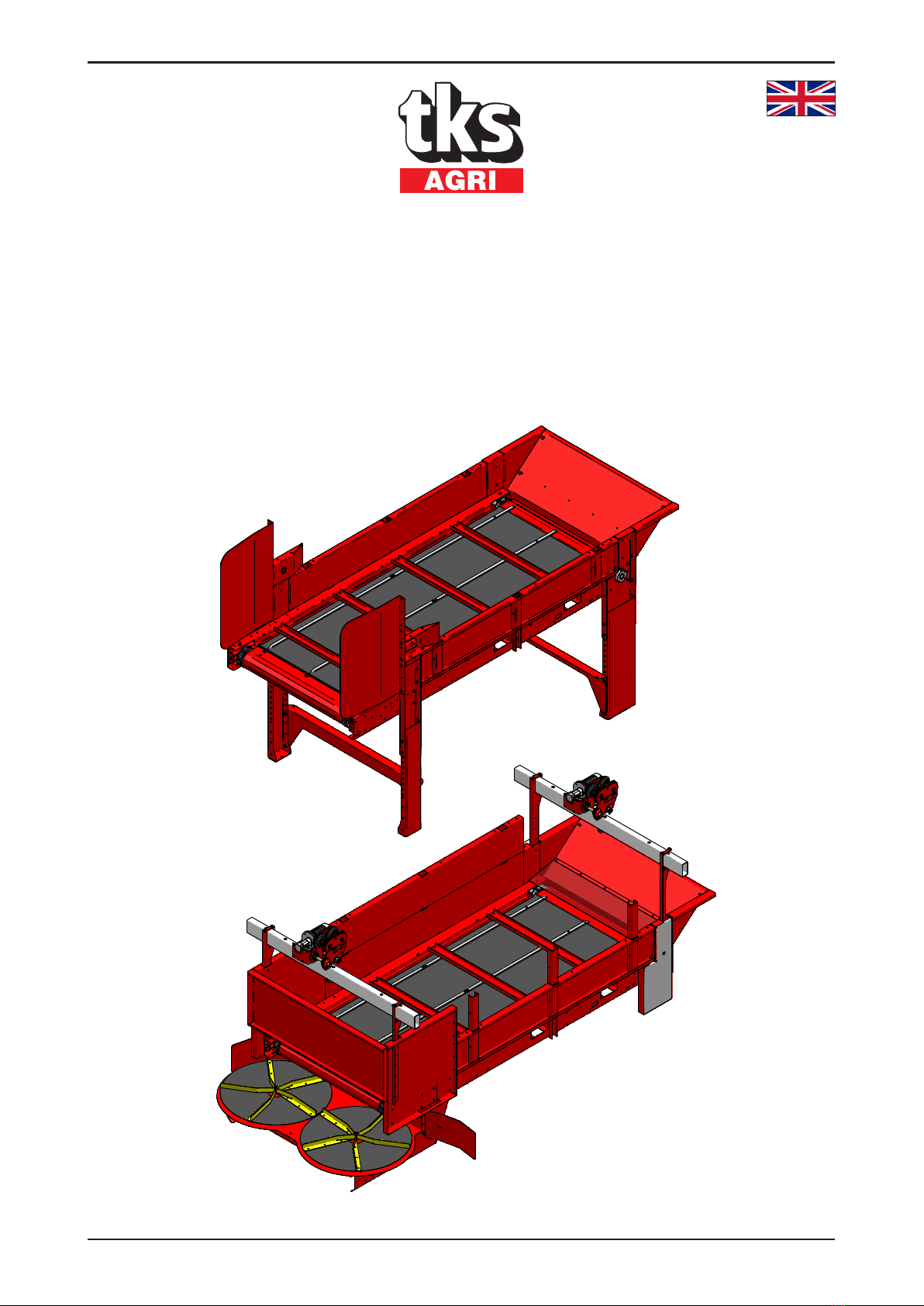

TKS R2 Guide

TKS

1

988732R2 Reservoir EN, issue 1, 2010-08

Operator’s manual -

Spare parts list

R2

Reservoir

TKSTKS

2

CE - Certicate of conformity

We,

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norge

declare that the product:

TKS - R2 Reservoir

has been built in conformity with the Machine Directive 2006/42/EC and meets the

relevant fundamental health and safety requirements.

Kverneland, 20 August 2010

Tønnes Helge Kverneland

General manager

Enter the serial number

of the machine here:

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specication of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

TKS

3

Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/ or repairs.

Claims must be reported within the guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to TKS

or TKS’s distributor/ importer within the 10th of the month following the one in which the defect was

reported.

The defective parts shall be marked with the claim number and be kept for up to 6 months so that

TKS or TKS’s distributor/ importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any consequential

damage.

The guarantee is not valid if:

a) third party spare parts are used, or the product is repaired or altered without the

approval of TKS.

b) the operating and servicing instructions have not been followed.

c) the machine has been used for other purposes than those for which it is designed.

The guarantee does not cover damage due to normal wear and tear.

Ofcial safety regulations specify requirements that apply to the users/ owners and manufacturers

of this machine, relating to the careful review of safety hazards that may arise when this type of

machine is used correctly.

Therefore, TKS and our importer/ distributor are not responsible for the functioning of components

that are not shown in the spare parts catalogue for this product. TKS reserves the right to change

the design of the product without this implying any obligations in relation to previously supplied

machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number; see page 7 on Machine identication.

TKSTKS

4

Content

CE - Certicate of conformity . . . . 2

Guarantee................... 3

Introduction.................. 6

Machine identication.......... 7

Dimensions R2 Reservoir....... 8

Technical data............... 17

Model description ............ 18

Safety ..................... 19

1 Installing the rails................25

1.1 Recommended rail sizes on .........

1-rail suspension ................26

1.2 Recommended rail sizes on .........

2-rails suspension . . . . . . . . . . . . . . . 26

2 Installation and use of Reservoir R2 27

2.1 Installing the Reservoir in conjunction

with stationary cutter . . . . . . . . . . . . 28

2.2 Use of stationary Reservoir in .......

conjunction with stationary cutter ..28

2.3 Installing the Reservoir on rails in . . . .

conjunction with cutter...........29

2.4 Use of Reservoir on rails in ........

conjunction with cutter ..........29

2.5 Installing stationary Reservoir in . . . . .

conjunction with ceiling-mounted . . . . .

cutter.........................30

2.6 Use of stationary Reservoir in .......

conjunction with ceiling-mounted.....

cutter . . . . . . . . . . . . . . . . . . . . . . . . 30

3 Installing the power supply ........32

3.1 Check list before starting the ........

machine ......................32

4 Controls K2/R2...................33

5 Circuit diagram ..................34

6 Controls R2/K2 FeedRobot ........40

7 Model description and use of ........

spreader unit ....................43

8 Using the machine with spreader .....

unit............................45

9 Main measurements for machine . . . . .

with spreader ....................46

10 Width adjustment on spreader unit . 47

11 Remote control ..................48

12 ECS Electrical documentation .......

for R2 ..........................49

13 Circuit diagram ..................50

13.1 Circuit diagram for input and .......

distribution ....................50

13.2 Circuit diagram for PLS module....51

13.3 Circuit diagram for photocell ......52

TKS

5

14 Maintenance and care ............53

Recycling - waste to resource -.....56

Notes .............................57

Spare parts list R2 Reservoir .........58

TKSTKS

6

Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. A network of helpful dealers will be able to advise you on its use, as well as provide

servicing and spare parts.

All TKS products are designed, tested and built in close cooperation with farmers and machine

workshops to ensure optimal efciency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine‘s manner

of operation before starting to use it. There are many conditions and variables that can affect the

machine’s functionality and manner of operation. It is therefore vital that you consider all known

conditions and adapt usage according to these. A good understanding of the machine‘s manner of

operation and performance, together with a high degree of knowledge with regard to feeding and

feed types/consistencies will ensure the best possible result. The machine is a highly advanced

feed robot that operates without the need for supervision and must be used in accordance with the

applicable instructions from the manufacturer and other regulations in force at any given time.

By being thorough and making the necessary adaptations to local conditions, you will ensure the

best possible results.

Yours faithfully

T. Kverneland & Sønner AS

MEKANISKE

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

Phone : + 47 51 77 05 00

Fax : + 47 51 48 72 28

TKS

7

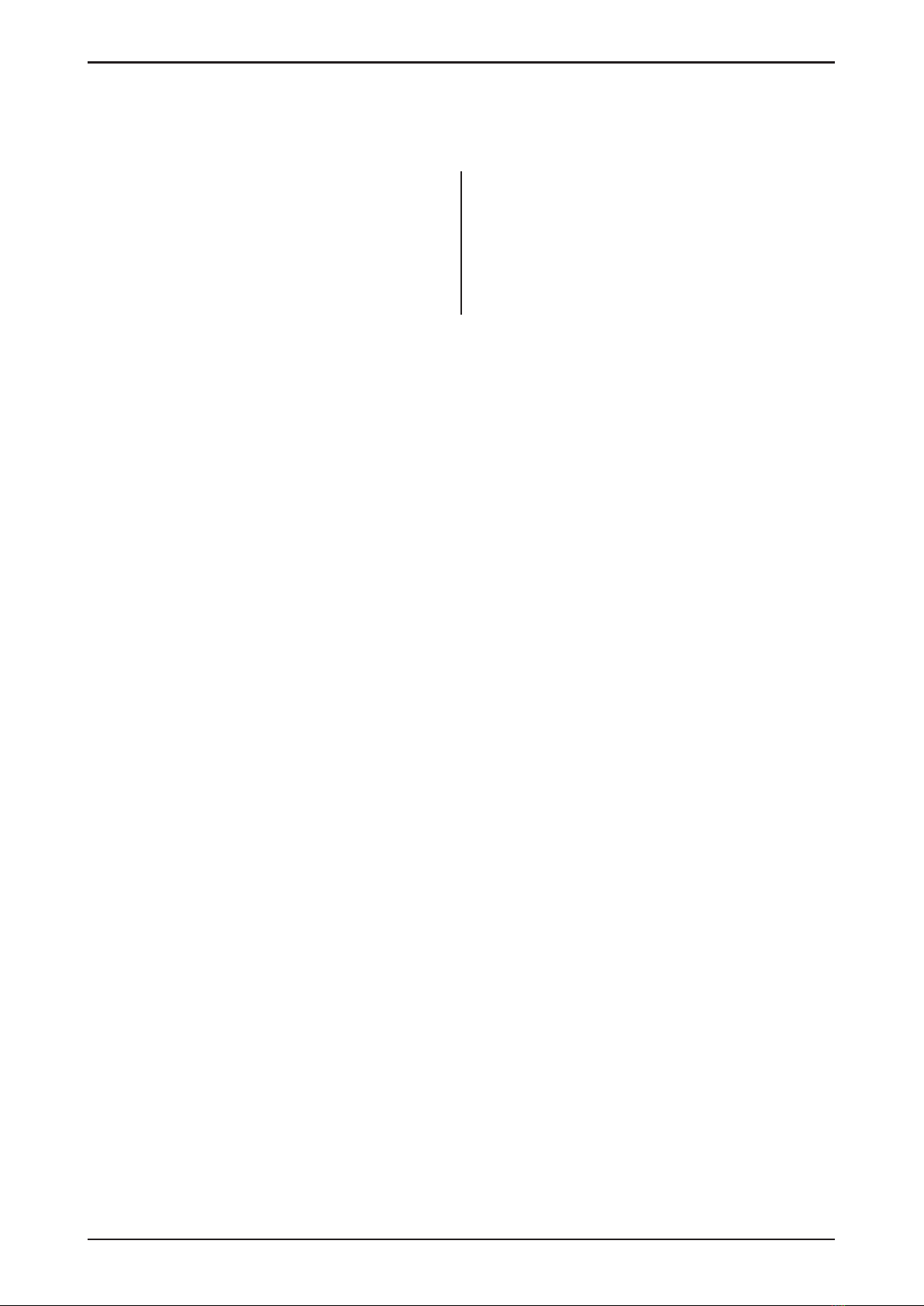

Machine identication

The machine’s serial number and the address of the manufacturer are written on the machine.

See the illustration on this page.

Please use the information on the name plate when making any enquiries about spare parts or

servicing.

This product is CE marked. This mark, along with the associated written EU conrmation, means

that the product fulls current health and safety requirements, and complies with the following

directives: Machine Directive 2006/42/EC

IR2_02

TKS

3430

2470

530

1060 300

Kan justeres 400 mm i høyde,

og settes for hver 50 mm

Laveste høyde

1490

1490

3430

2470

2960

TKS

8

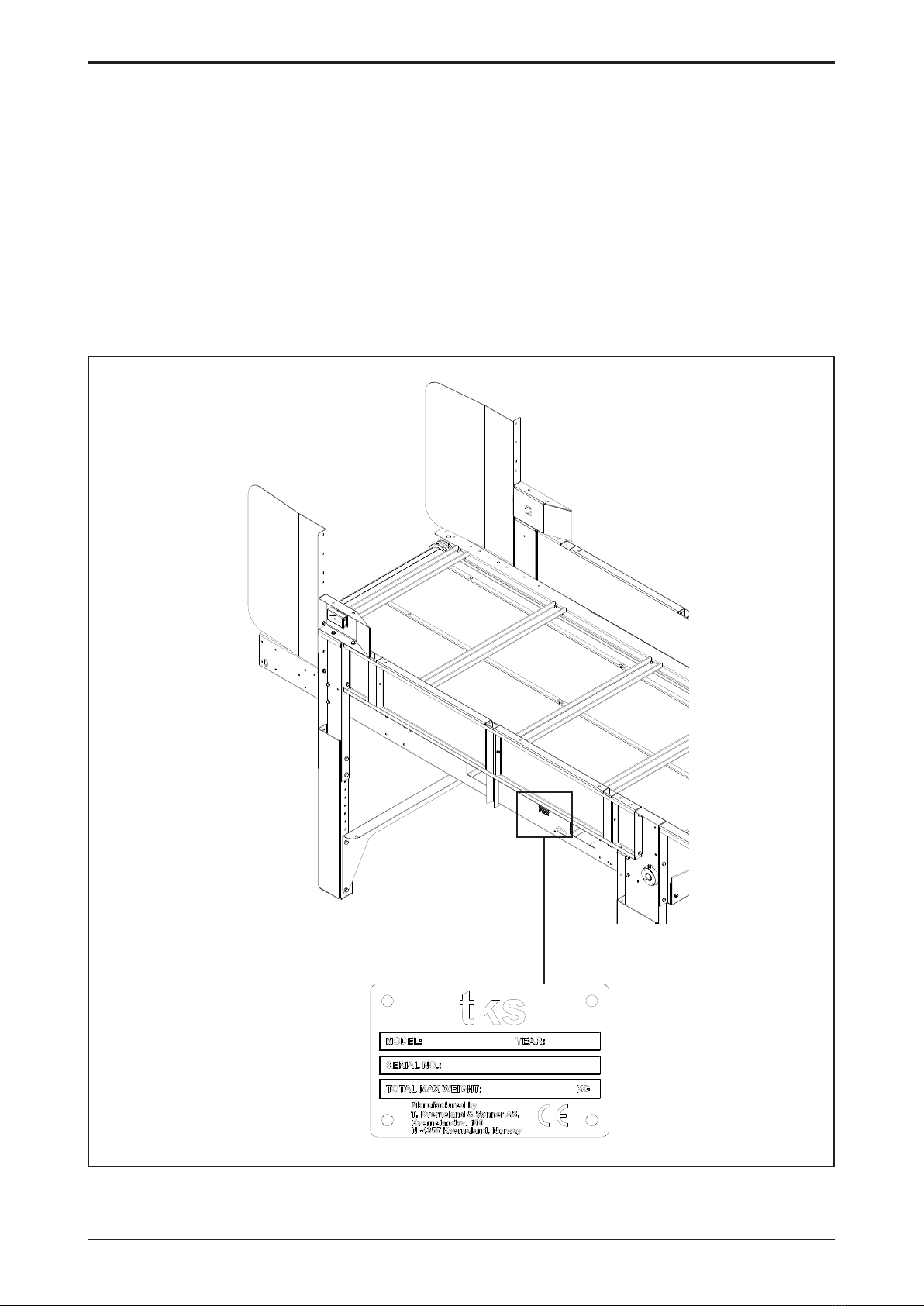

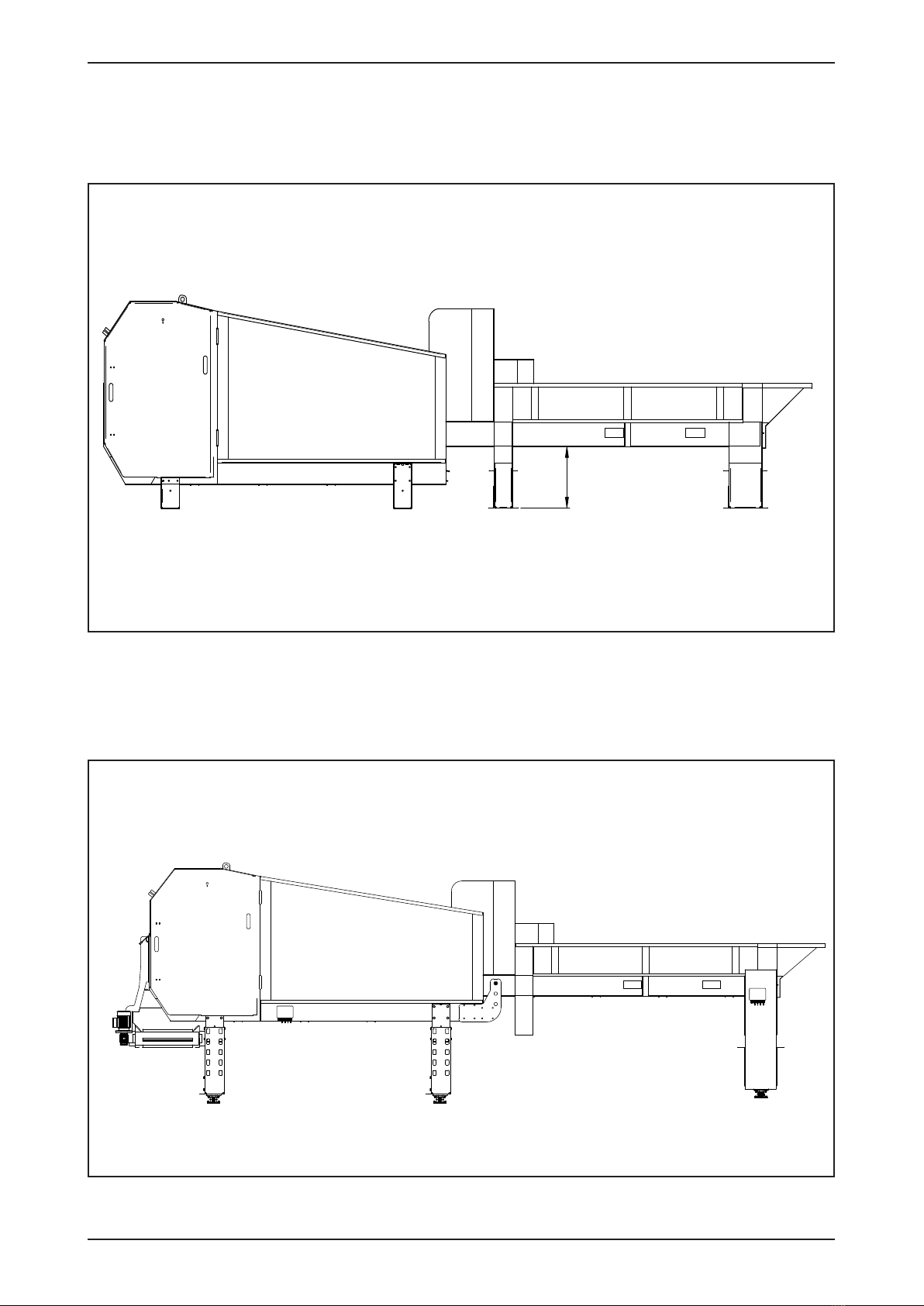

Dimensions R2 Reservoir

All measurements are in mm

R2 Reservoir autolling 3m

R2 Reservoir stationary 3m

IR2_13

IR2_06

TKS

1490

4550

4080

3590

1490 29702090

5360

6320

5850

9

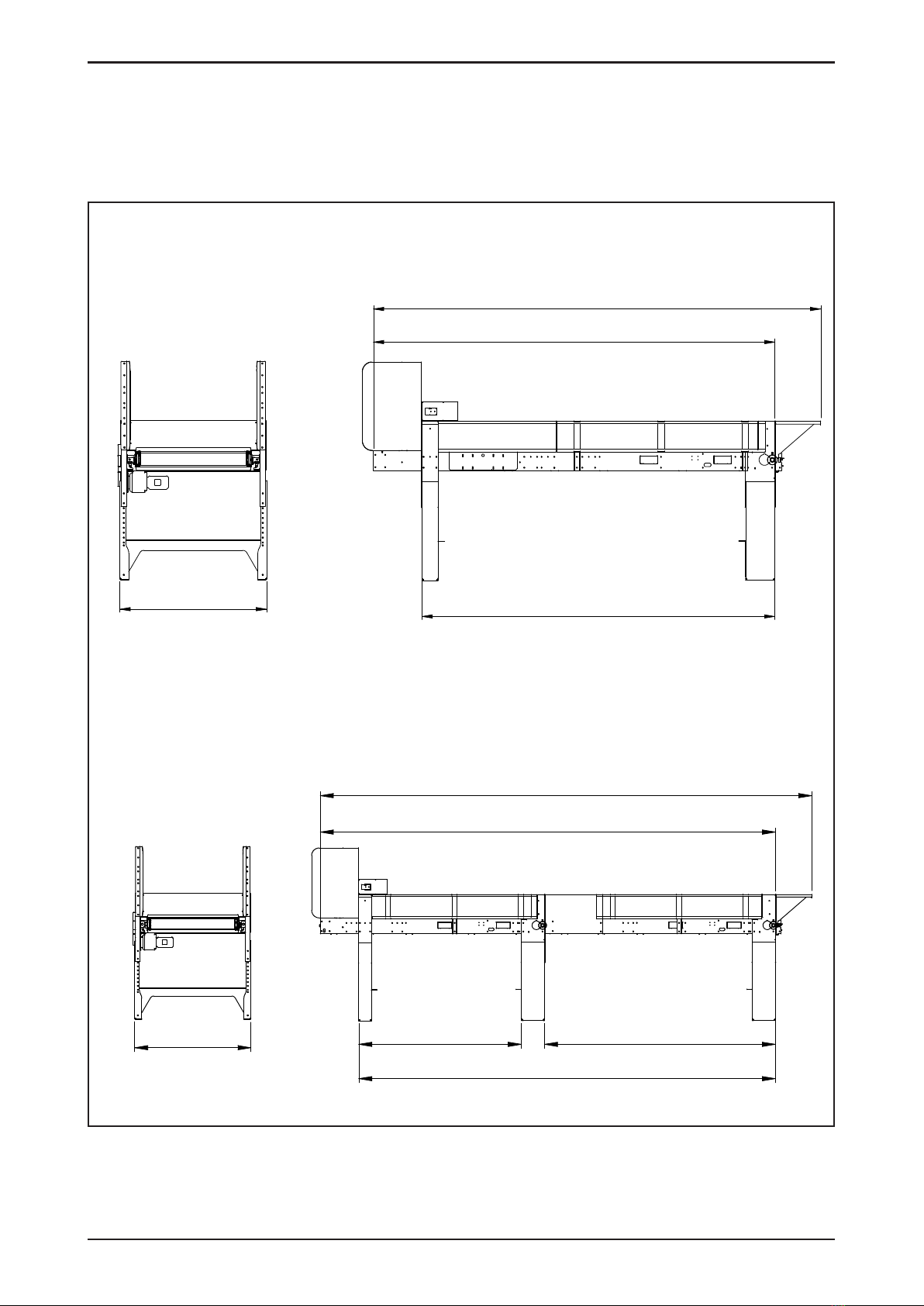

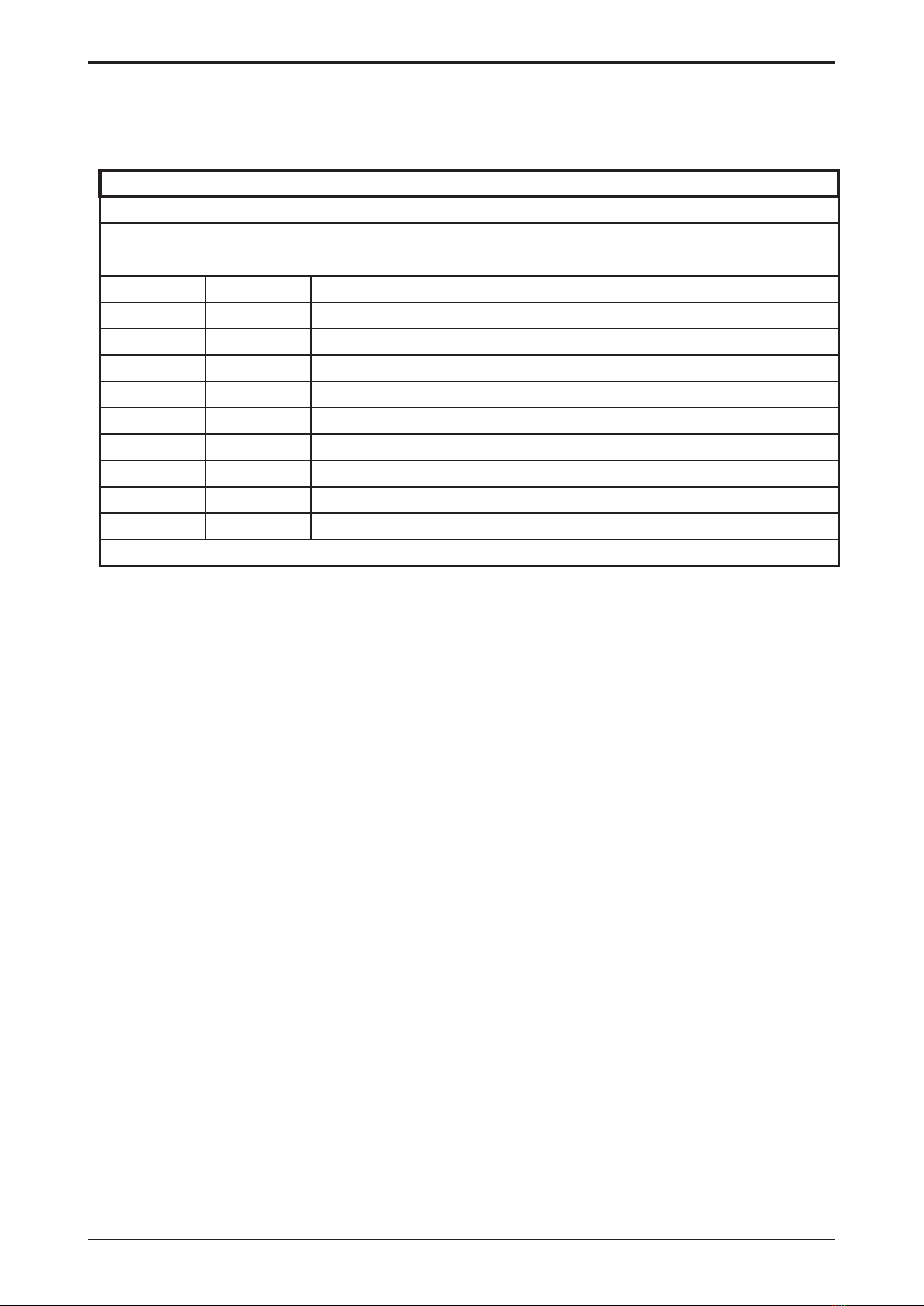

R2 Reservoir 3m + 1m

R2 Reservoir 3m + 3m

IR2_07

IR2_08

TKS

500

TKS

10

IR2_24

IR2_25

K2/R2 with frame, side dispenser with weight

R2 Reservoir stationary lling

TKS

1000-1200

750-950

1100

1360

11

K2_53

K2_54

K2/R2 with frame, side dispenser

K2/R2 with frame, side dispenser and conveyor

TKS

1

3

2

4

TKS

12

K2 with weighing cell unit

K2_55

Wiring diagram, Junction box

1Weighing cell amplier

2 Weighing cell foot

3 Junction box 4 weighing

4 10 m cable, shielded 4x0.25

TKS

13

Conguring the weighing cell amplier

Conrm all choices by pressing both keys simultaneously.

Reset by ipping all dipswitches up and pressing both keys simultaneously, then press all

switches down except for no. 8

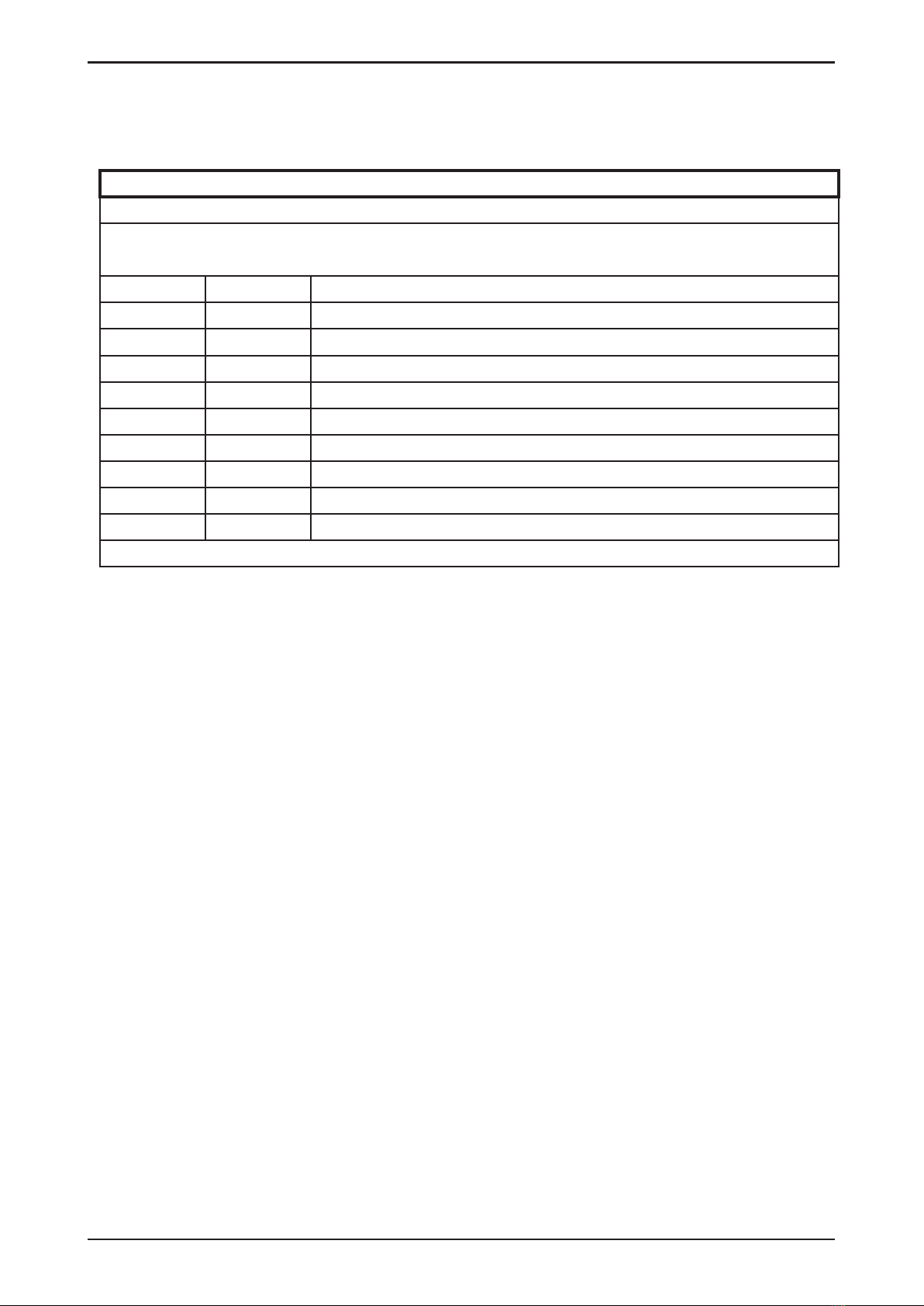

Code Value Function

3 15 Middlings

4 150 Max. change in kg

23 4 Number of weighing cells

26 2000 Weighing cell capacity 2,000 kg

34 U U = 0-10V

38 6000 Max. weight on cart in kg

24 2 Converts millivolts to kg; can be changed to show the correct weight

22 Value Enter value shown on the display + 100 kg

49 7 Speed of weight measurement

If all you see are dashes when you plug in the display, swap cables 2 and 3

TKS

1

2

3

4

TKS

14

R2 with weighing cell unit

K2_56

Wiring diagram, Junction box 2

1 Lug for making connection

2 Weighing cell foot 2T

3 Junction box 4 weighing

4 10 m cable, shielded 4x0.25

TKS

15

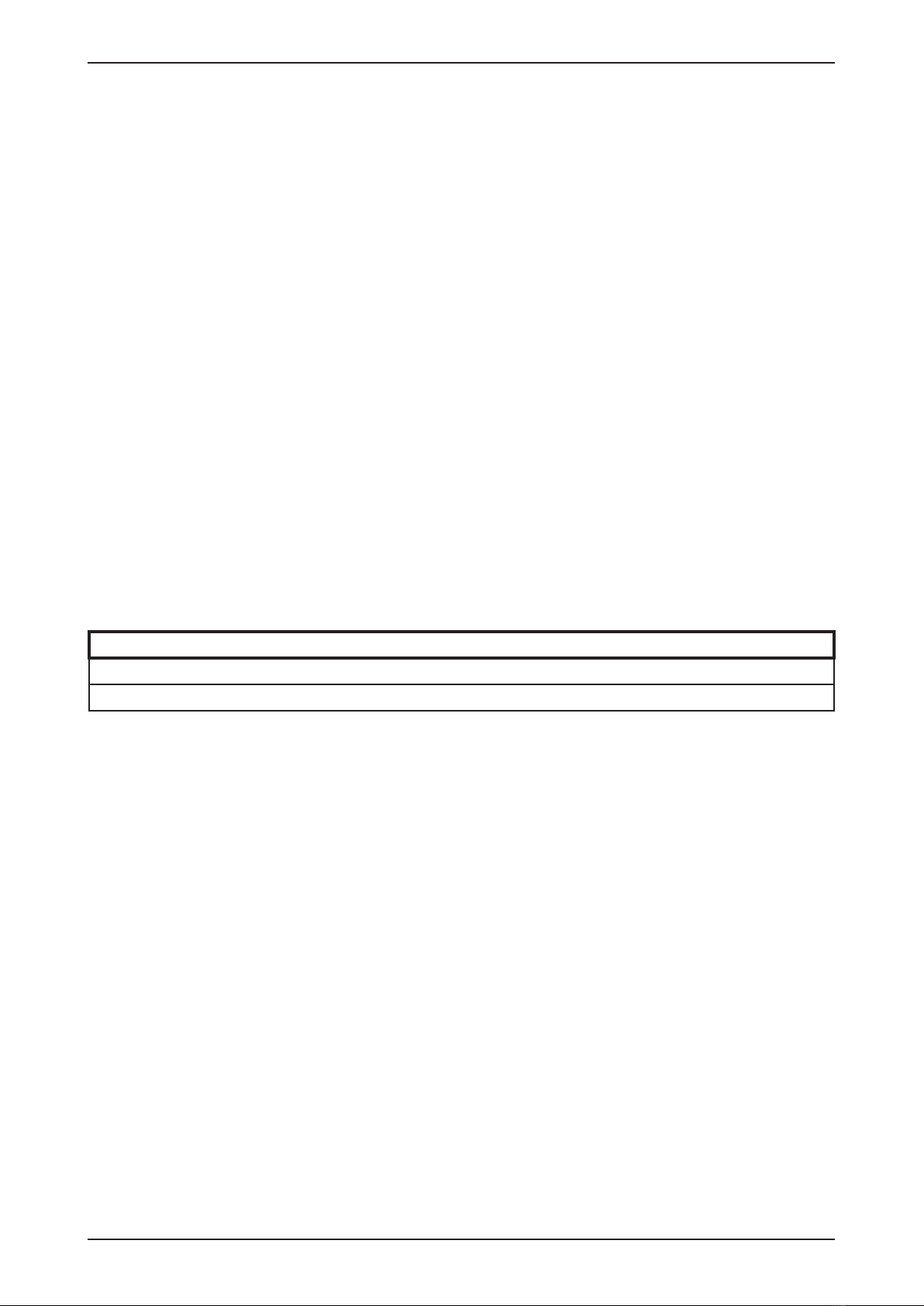

Conguring the weighing cell amplier

Conrm all choices by pressing both keys simultaneously.

Reset by ipping all dipswitches up and pressing both keys simultaneously, then press all

switches down except for no. 8.

Kode Value Function

3 15 Middlings

4 150 Max. change in kg

23 6 Number of weighing cells

26 2000 Weighing cell capacity 2,000 kg

34 U U = 0-10V

38 6000 Max. weight on cart in kg

24 2 Converts millivolts to kg; can be changed to show the correct weight

22 Value Enter value shown on the display + 100 kg

49 7 Speed of weight measurement

If all you see are dashes when you plug in the display, swap cables 2 and 3.

TKS

240

450

6800

3300

2680

250

300

300

2200

300

2950

550

3620

1300

Min.

TKS

16

R2 Reservoir suspension, double-rail

R2 Reservoir stationary, together with K2 on rails

IR2_11

NB! The round bale must go underneath the crossbeam on the suspension.

IR2_10

TKS

17

Technical data

WEIGHT R2 RESERVOIR 590 Kg

POWER

LOOR BELT 0,75 KW

ELECTRICITY

CONTROL CURRENT 24 V (DC)

VOLTAGE 230/240 V (N/BY 400V)

VOLTAGE TOLERANCE +/- 10%

TKSTKS

18

Model description and area of use

The TKS R2 Reservoir is an add-on unit for use with K2 CombiCutter and TKS Robot carriages.

The Reservoir can be used for storing feed for up to 24 hours.

It is suitable for round/square bales, blocks from silage pits and for silage loads.

The Reservoir can be supplied in different sizes holding from 2 to 6 round bales and is suitable for

most uses.

It is important to take size into account when choosing a reservoir so that it is capable of storing

feed for a full 24 hours. The R2 Reservoir can therefore be supplied as a stationary unit or on rails

for use in combination with a cutter.

Operation

The Reservoir is operated using one or two geared motors, depending on the size of the Reservoir.

Round bales and silage can be loaded into the machine from the rear and from both sides.

The pendant control is located at the front of the Reservoir but can be pulled out during operation

in order to operate the reservoir while also monitoring the mass.

A separate operating panel is supplied for use in combination with TKS Robot carriages and should

be installed in a suitable location.

NOTE! The recommendations contained in this instruction manual are based on normal use.

Individual users may encounter situations that require a different approach from the guidelines

given here. Changes to the machine and equipment as a result of such situations do not give

grounds for claims against the manufacturer or supplier.

Accessories:

Extension 1m and 3m

Ceiling-mounted

TKS

19

Safety Please pay particular attention to this symbol. It

means that there is a safety risk, and describes

precautions that should be taken in order to

avoid accidents.

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Pay attention and be careful when handling

agricultural machinery. Read and take note of

the safety instructions in this manual.

Safety at work is your responsibility!

General safety

instructions

Please read and understand these general

safety instructions.

Use of the machine

The machine must only be used for the purpose

for which it is designed.

Operation

The operator of the machine must stay at the

end of the machine where the control panel is

located.

Supervision

The operator should monitor the machine

continually before start-up and during operation.

This is very important in order to ensure opti-

mum operating safety.

How the machine works

The operator must familiarise himself with how

the machine works and functions, so that it can

be used safely and properly.

Keep a safe distance

Humans and animals must be kept away from

the machine when it is in operation.

Keep your distance from working, rotating and

moving parts.

Be safety conscious

Never enter the machine when it is in operation.

When performing maintenance, disconnect the

power supply.

TKSTKS

20

Shields

Check that all shields are sound and correctly

installed. Do not start the machine before doing

this.

Damaged screens must be repaired or replaced

immediately.

Spare parts

Check that all shields are sound and correctly

installed. Do not start the machine before doing

this. Damaged screens must be repaired or

replaced immediately.

Maintenance

Ensure that the machine is properly maintained

and is kept in good condition. Never attempt to

change the mechanical workings of the

machine.

Control panel

The power supply must be cut off before

opening the panel.

This manual suits for next models

1

Table of contents

Other TKS Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Farm King

Farm King BW150 Operator and parts manual

Powder River

Powder River 008-00100 Assembly and operation instructions

Stark

Stark TL7400 Operation and maintenance manual

Meijer Holland

Meijer Holland Meijer KM 8 manual

Arrowquip

Arrowquip Q-POWER 107 Series product manual

Landoll

Landoll 2510 Series Operator's manual