TKS FeedBelt - Lite User manual

1

TKS Operator's manual

988831FeedBelt LITE EN, issue 1, 2014-04

Operator’s manual

FeedBelt - Lite

2

TKS Operator's manual

Content

1 GENERAL INFORMATION AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 OPERATOR'S MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 MANUAL FEEDING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 AUTOMATIC FEEDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 EXAMPLE OF GROUP ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6 SMS MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7 MAINTENANCE AND CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8 ALARMS AND TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 CIRCUIT DIAGRAM - MASTER CABINET LITE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

10 CIRCUIT DIAGRAM - SLAVE CABINET LITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2 General information and safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 CE - Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Technical data - FeedBelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 Model description and area of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.2 Machine identifi cation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

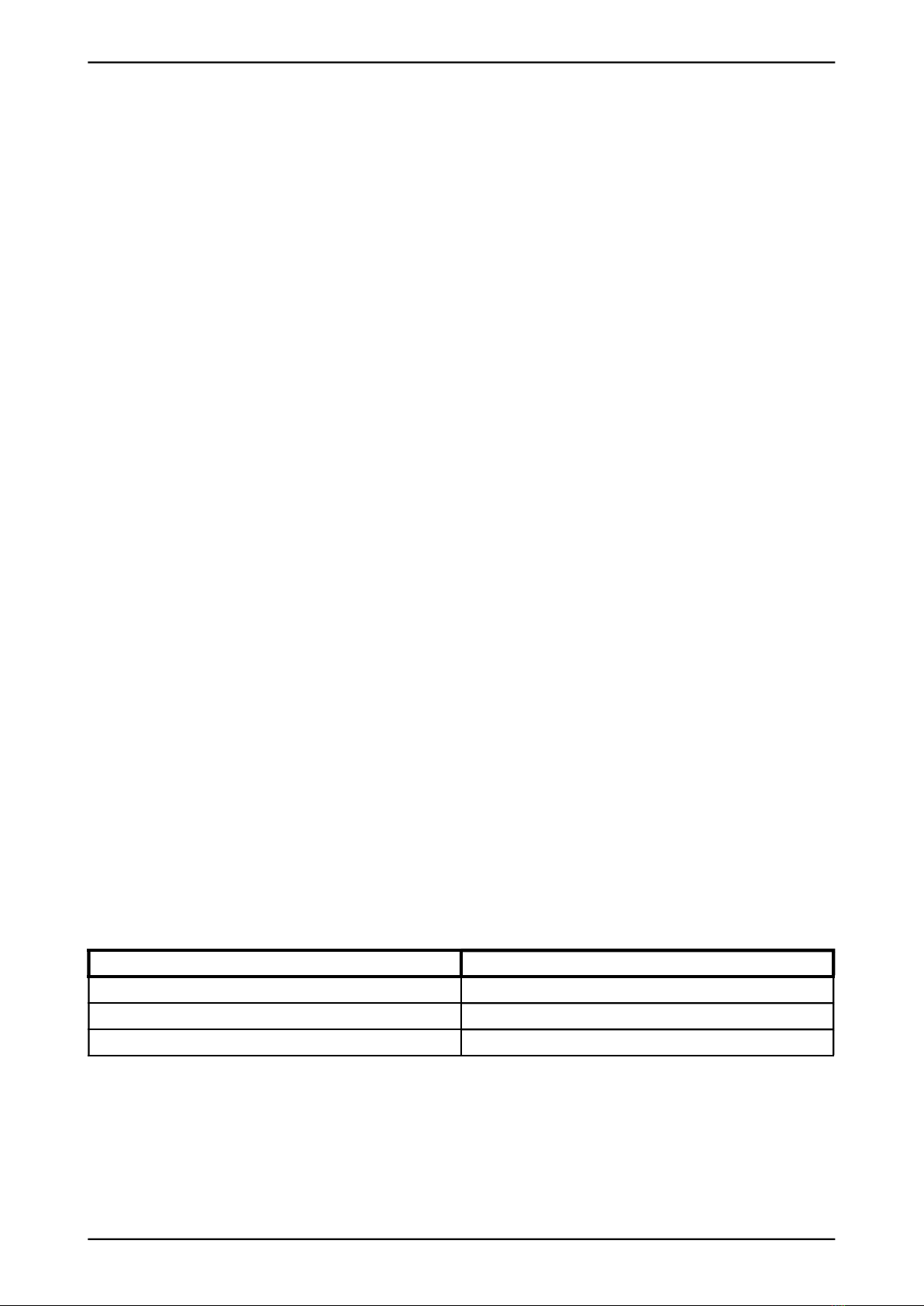

1.4.3 Main dimensions - FeedBelt with 1 center-section. . . . . . . . . . . . . . . . . . . . . . 11

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.2 Additional safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.5.3 Overview of safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5.4 Lifting the FeedBelt by assembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.5 New machine - be careful. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.6 Installation and commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3

TKS Operator's manual

1.6 Recycling - waste to resource - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Operator's manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Use of the PLC - LITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Menu-tree - LITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 PLC menu - screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Other screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 Manual feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Automatic feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 Example of group adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 SMS messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Received messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Sent messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Screw and bolt torque:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.2 Storing the FeedBelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.3 Weekly inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.4 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

7.5 Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.6 Tightening the belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.7 Tensioning the wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.8 Shifting device adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.9 Tighening torque for screws and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.10 Cleaning the FeedBelt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4

TKS Operator's manual

8 Alarms and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 Circuit diagram - Master cabinet LITE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 Circuit diagram - Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Circuit diagram - Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Circuit diagram - Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4Circuit diagram - Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

9.5 Circuit diagram - Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10 Circuit diagram - Slave cabinet LITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1 Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.2 Circuit diagram - Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

FeedBelt - LITE Menu-tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5

TKS Operator's manual

6

TKS Operator's manual

1 General information and safety

1.1 CE - Declaration of conformity

We,

TKS Agri AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norge

declare that the product:

TKS - FeedBelt LITE

has been built in conformity with the Machine Directive and meets the relevant

fundamental health and safety requirements.

Kverneland, 03 Mai 2013

Atle Sjølyst - Kverneland

General Manager

Enter the serial number

of the machine here:

TKS Agri AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specifi cations of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

7

TKS Operator's manual

1.2 Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to TKS

or TKS’s distributor/importer within the 10th of the month following the one in which the defect was

reported.

The defective parts shall be marked with the claim number and be kept for up to 6 months so that

TKS or TKS’s distributor/importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any resulting damage.

Warranty does not apply if:

a) third-party spare parts are used, or the product is repaired or altered without the

approval of TKS

b) the operating and servicing instructions have not been followed

c) the machine has been used for other purposes than those for which it is designed

The guarantee does not cover damage due to normal wear and tear.

Offi cial safety regulations specify requirements that apply to the manufacturers of this machine

relating to the careful review of safety hazards that may arise when this type of machine is used

correctly. Therefore, TKS and our importer/distributor are not responsible for the functioning of

components that are not shown in the spare-parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB!

It must be possible to identify all enquiries relating to this product by the product’s serial number;

see page 8 on Machine identifi cation.

8

TKS Operator's manual

1.3 Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. A network of helpful dealers will be able to advise you on its use, as well as provide

servicing and spare parts.

All TKS products are designed, tested and built in close cooperation with farmers and machine

workshops to ensure optimal effi ciency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine’s manner of

operation before starting to use it.

Many diff erent factors and variables may impact on the machine’s function and operation.

It is therefore very important to consider all known factors and adapt the way in which the machine

is used accordingly.

A good understanding of the machine’s method of operation and performance, together with a

sound knowledge of the feeding process and feed types/consistency, will ensure the best results.

The machine is highly advanced, operates unsupervised and must be used in accordance with the

manufacturer’s instructions and other applicable regulations.

By being thorough and making the necessary adaptations to local conditions, you will ensure the

best possible results.

Yours faithfully

TKS Agri AS

TKS Agri AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

e-post : post@tks-as.no

Phone : + 47 51 77 05 00

Fax : + 47 51 48 72 28

9

TKS Operator's manual

1.4 Technical data - FeedBelt

1.4.1 Model description and area of use

The TKS FeedBelt is designed to transport diff erent types of forage, concentrates and shavings to

milk cows via the feeding passage. The forage is released down over the milk cows into the feed-

ing passage using a scrape carriage.

The scrape carriage is controlled via a wire which can be moved to the right or left so that the

forage is distributed to both sides of the feeding passage using the belt and a stop system. The

reversing bow is used to adjust the scrape from right to left.

It is supplied with a main cabinet, which is located at the end where the forage is added.

Control cabinet for drive unit – belt. Three switches which receive signals.

• The belt is powered by a gear motor in the drive roller

• The scraper is powered by a gear motor via the wire and is positioned with the aid of a sensor.

• The belt is fed forwards on top of a channel and returns on rollers placed inside the channel.

• The drive roller has a friction coating to improve the reliability of the belt operation.

• The counter-roller ensures a better connection with the drive roller.

• The belt and wire have sensors that indicate their movement.

• A brush is positioned against the belt next to the drive roller.

The brush ensures that the belt is kept clean.

• The machine is installed at various heights above the feed trough.

• The channel is installed on portals or brackets with a maximum length of 6 m between them.

• The feed is conveyed onto the belt at the opposite end of the drive roller.

• Suitable side panels position the feed in the centre of the belt.

• Forage can be added to the belt from various fi lling sources.

• Feed must be fed onto the belt at an even pace, preferably from a conveyor.

• FeedBelt can operate multiple fi lling sources and conveyors, depending on the control cabinet.

• Forage can be dispensed on a time or weight basis.

• Minimum operating temperature -20°C.

NB! The instructions given in this operator’s manual apply to standard operating conditions.

Individual circumstances may arise at the premises of the user that deviate from the instructions

provided here. Changes to the machines and equipment as a result of such circumstances shall

not constitute grounds for making a claim against the manufacturer or supplier.

NB!

Think safety when using the FeedBelt.

Individual users must observe the provisions, rules and standards that apply in the country

concerned.

FeedBelt

Belt width in mm 500mm

Motor output - belt 2,2kW 230V - 14,1A

Scrape motor eff ekt 1,1kW 230V - 8,6A

IFB_02

10

TKS Operator's manual

1.4.2 Machine identifi cation

The machine’s serial number and the manufacturer’s address are written on a plate on the

machine. See the illustration on this page.

Vennligst bruk opplysningene på skiltplaten ved alle reservedels- og servicehenvendelser.

Please use this information when making any enquiries about spare parts or servicing.

This product is CE marked. This mark, along with the associated written EU confi rmation, means

that the product fulfi ls current health and safety requirements, and complies with the following

directive: Machine Directive.

MFB_01

IFB_02

11

TKS Operator's manual

1.4.3 Main dimensions - FeedBelt with

1 center-section

All dimensions are in mm

Last feeding

Min. scrape height

Min. schifting device height

First feeding

12

TKS Operator's manual

1.5

Safety

Please pay particular attention to this symbol.

It designates a safety risk, and describes

precautions that must be taken to avoid

accidents

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Pay attention and be careful when handling

agricultural machinery. Read and take note of

the safety instructions in this manual

Safety at work is your responsibility!

1.5.1

General safety

instructions

Please read and understand these general

safety instructions.

Use of the machine

The machine must only be used for the purpose

for which it is designed.

How the machine works

The operator must familiarise himself with how

the machine works and functions, so that it can

be used safely and properly.

Keep a safe distance

Keep away from operating, rotating and

moving parts.

Think safety at work

Never climb on the machine’s belt while it is

operating. The power supply must be

disconnected

before any maintenance is carried out.

Protective screens

Check that all screens are in place and installed

correctly. Do not start the machine until this has

been done.

Damaged screens must be repaired or replaced

immediately.

Spare parts

For safety reasons we recommend that you

only use original spare parts. The use of

third-party spares invalidates the product

guarantee.

13

TKS Operator's manual

Maintenance

Make sure that the machine is well-maintained

and kept in good condition.

Never make alterations to the machine’s

structures.

Control panel

The power supply must be isolated before the

panel is opened.

14

TKS Operator's manual

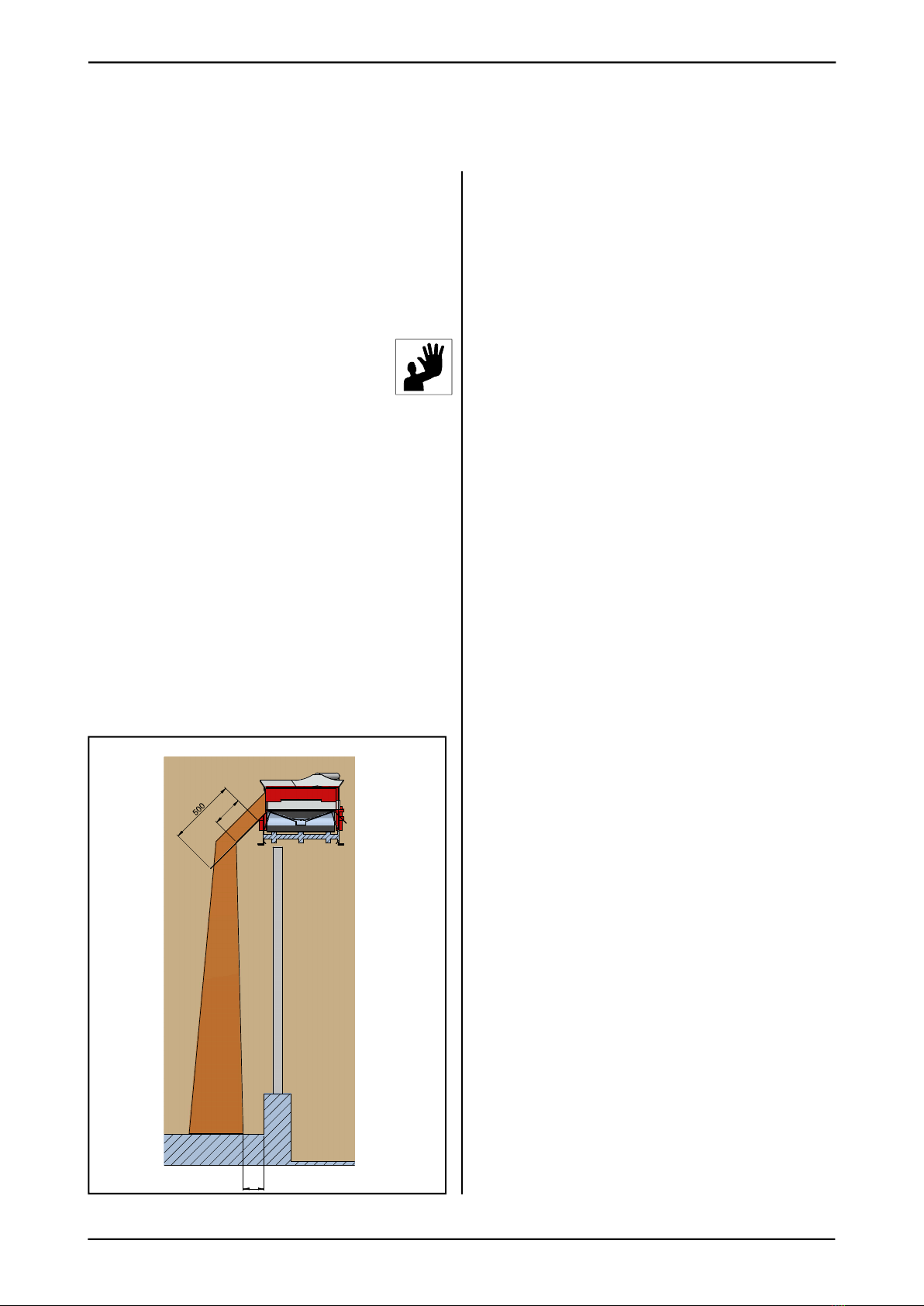

Fig. 3

1.5.2

Additional safety

instructions The machine is marked with a warning

signs. If these signs are damaged, they must

be replaced. The order number is shown on the

illustrations in this section.

See picture on page 8 for their location on the

machine.

Warning sign UH220532 (Fig. 1)

Be careful! Ensure that you read and under-

stand the instruction manual before using the

machine, and before making any adjustments

or performing any maintenance.

Warning sign UH220539 (Fig. 2)

Finger fracture warning sign. Risk of fi nger

fracture if fi ngers are trapped between the

carrier and lower frame.

Warning sign 988010 (Fig. 3)

The belt must be kept tight, it is

therefore important and necessary to retighten

the screws regularly.

Fig. 1

Fig. 2

UH220532

UH220539

988010

IFB_05

15

TKS Operator's manual

1.5.3 Overview of safety risks

Fig. 4

MASTER CABINET SLAVE CABINET

IFB_36

16

TKS Operator's manual

1.5.4

Lifting the FeedBelt -

by assembling

Vær forsiktig!

Use approved lifting equipment only.

Ensure that no one is underneath or near the

FeedBelt when the various sections are fi tted

into place.

1.5.5

New machine -

be careful

Read the operator’s manual

Take special care when starting a new machine

for the fi rst time. Incorrect installation,

operation etc. may lead to costly repairs and

loss of earnings. The TKS product warranty

does not cover damage caused by failure to

follow the instructions given in the operator’s

manual. Pay particular attention to this symbol.

It is used to highlight important information in

order to prevent incorrect installation and use.

Please make a particular note of the

following when starting a new FeedBelt:

Check that FeedBelt has been correctly

assembled and that it is not damaged.

1.5.6

Installation and

commissioning: • The FeedBelt is delivered to the customer

packed in part-assembled sections.

• Before the FeedBelt is assembled, all card-

board, strapping belts and plastic should be

disposed of in an environmentally friendly

manner.

• There are separate installation instructions

for the FeedBelt.

• The FeedBelt must be calibrated prior to

use.

• The length of the guide plates must be

adjusted to ensure the best possible posi-

tioning of the feed on the bunk feeder. Cut if

necessary. See Fig. 5

Fig. 5

17

TKS Operator's manual

Recycling

- waste to resource -

TKS’s products rely on electrical and electronic components in order to work.

These fall under the generic term of EE products. TKS’s products use typical components such as

cables, switches, motors, control units, etc.

When TKS products are thrown away those components containing contaminants should be

treated and sorted in such a way that they do not pollute the environment. Contaminants should be

taken care of safely.

Distributors are obliged to accept EE waste from products in the range of goods they sell.

This waste should be kept safe and sent on to an approved waste recipient or treatment plant.

EE waste must be sorted and transported in such a way that it is not damaged or destroyed.

If you need further information on the treatment of EE waste, please contact your distributor.

Regards

TKS Agri AS

1.6

18

TKS Operator's manual

2 Operator's manual

• Decide how many feeding groups you need and how many times you wish to feed.

• TKS recommends a feeding group for milk cows and a group for each pen otherwise.

Number of feeding sessions:

Milk cows: Ten times a day

Calves and dry cows: Twice a day

Bulls: Four times a day

19

TKS Operator's manual

• When the FeedBelt is not in use, the screen on the PLS shows the time and date.

• This screen will appear if no key is pressed for two minutes.

• The main screen with the scrape position and side will appear when any key is pressed.

• Enter the menu by pressing the Enter key .

• Browse through the menu using the up and down keys ▲▼.

• Exit the menu using the Back key .

• On a screen containing values, the Enter key can be pressed to continue without changing a

value.

• Switch to the screen which shows the next feeding session by pressing the Back key when

the main screen is shown.

• If the cursor ( _ ) is fl ashing on the display, it means that the keypad must be used for entering

numbers.

• If the numbers have decimals, enter the entire number fi rst, followed by the decimal.

• Enter is used for moving the cursor to the next value.

• The keypad is used for activation of various functions in the menu. A number belongs then to a

functions. The number is shown in parentheses ( ) or to the right.

• The table on page 49 can be used to enter animal groups with reference to the keypad.

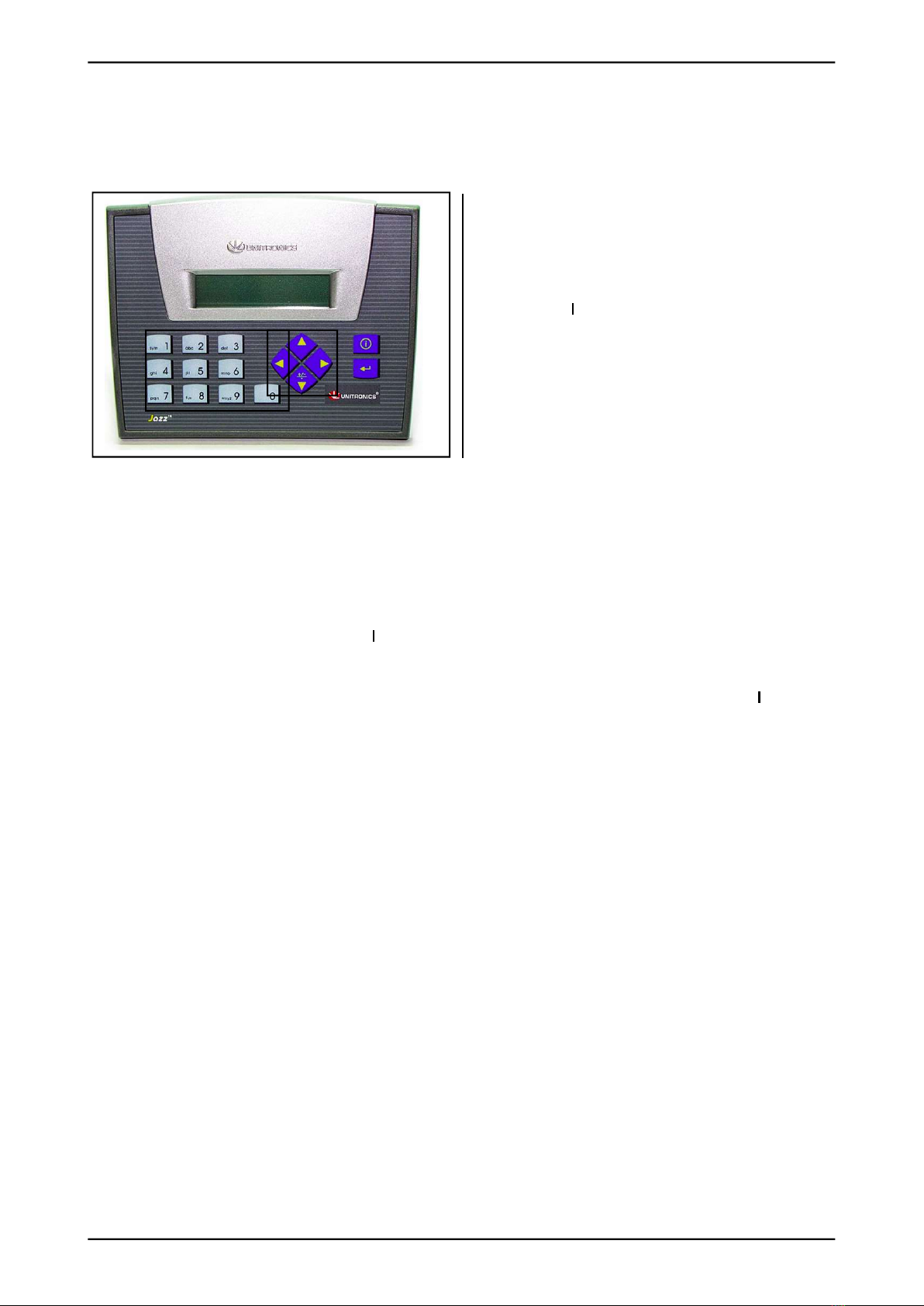

Screen and keyboard

PLS has two lines with non-coloured text on

the screen and a number keypad with a number

of function keys.

1. Numeric keypad – group number

2. Back key

3. Enter key

4. Up/down in the menu, browse menu▲▼

2.1 Use of the PLC - LITE

3

2

4

1

Fig. 6

20

TKS Operator's manual

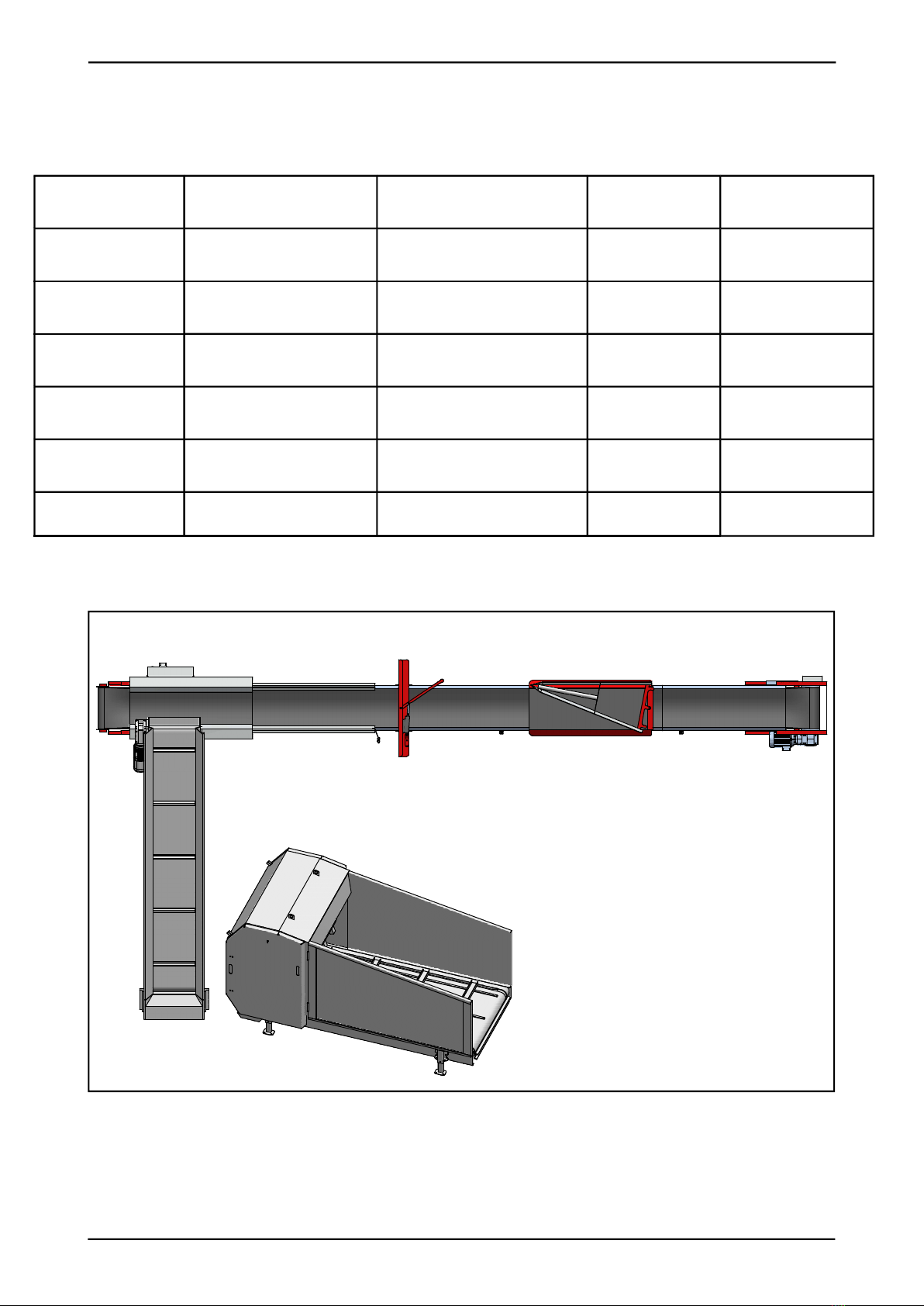

2.2 Menu-tree PLC - LITE

Main screen Time to next feeding

Manual control Manual control

Groups Group number Group options Feed time

Settings FeedBelt setting

Calibration Confi rmation Calibration

SMS Enabling Phone number setting SMS function Status message

Time & Date Time / date settings

Table 1

Filling station

= Front End of operation

= Rear

Left feeding side (L)

Right feeding side (R)Shifting device

Fig. 7

Table of contents