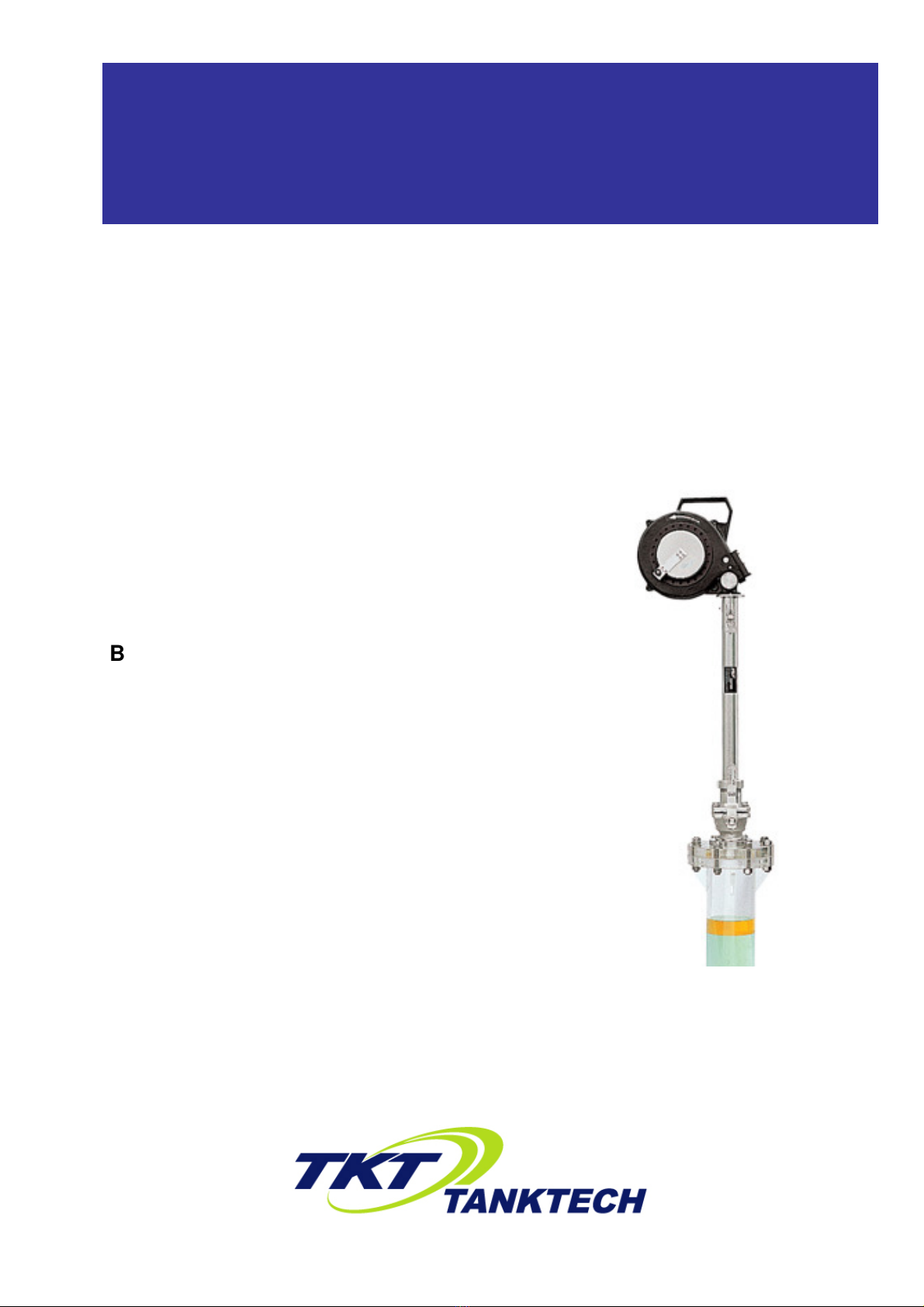

TKT T2000-TSS-02 User manual

Model T2000-TSS-02

Gas-Tight(Closed) Type

MODEL : T2000-TSS-02

Protect operator

Protect environmental pollution

Easy construction

Easy operation & maintenance

Benefits of T2000

-

T

SS

-

0

2

Instruction Manual

For Cargo Liquid Sampling Device

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 2/10

1. Table of Contents

1. Table of Contents

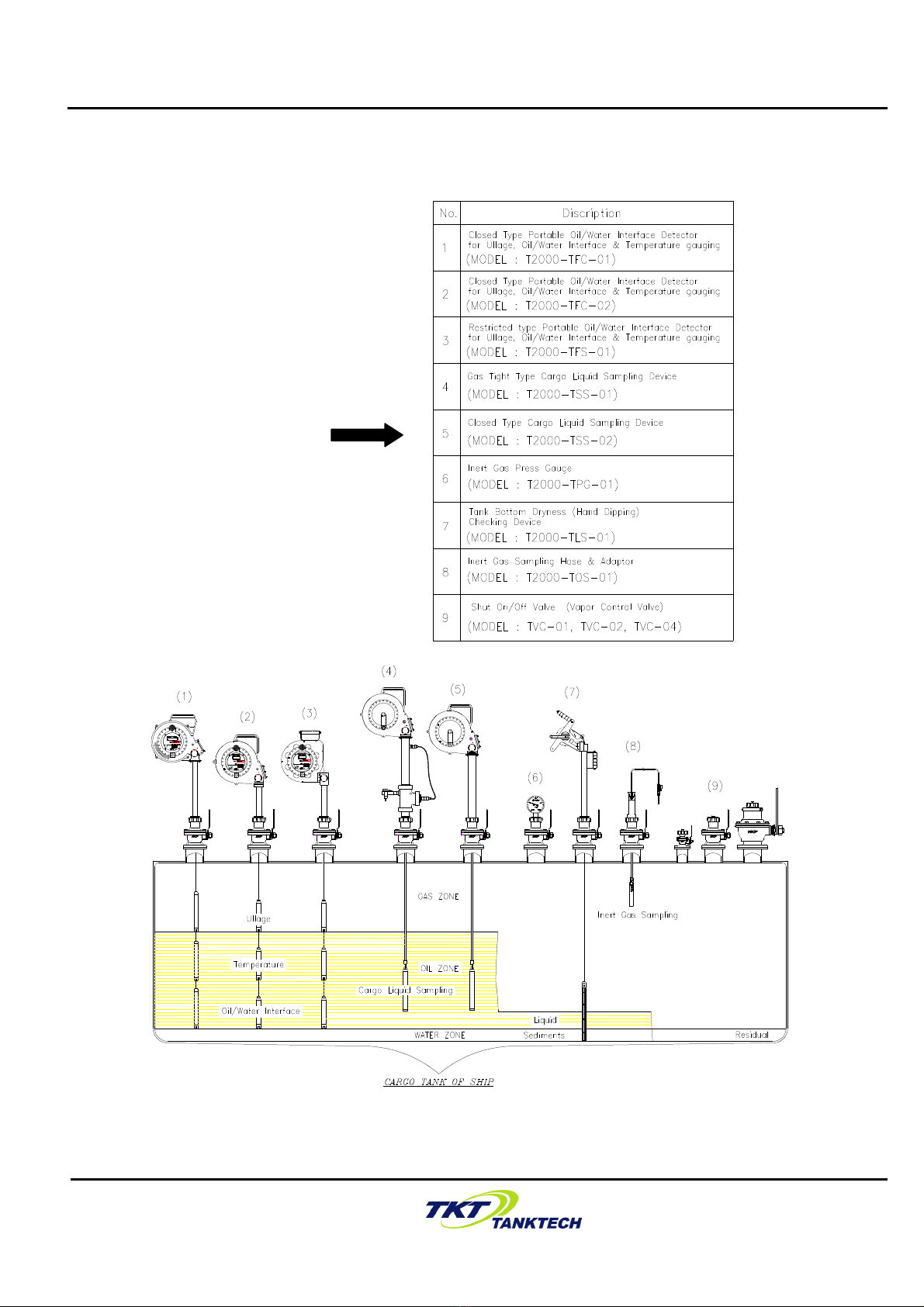

2. All kinds of TANKTECH Portable Measuring System

3. Installation for Cargo Liquid Sampling Device

4. Specification for Cargo Liquid Sampling Device

(Model : T2000-TSS-02)

5. Operation for Cargo Liquid Sampling Device

(Model : T2000-TSS-02)

TANKTECH CO., LTD

HEAD OFFICE :

1506-2, Songjeong-dong, Gangseo-gu, Busan, 618-270, OREA

TEL : +82-51-979-1600 FAX : +82-51-979-1601

E-MAIL : tanktech@tanktech.co.kr

http://www.tanktech.co.kr

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 3/10

2. All kinds of TANKTECH Portable Measuring System

ON

OFF

ON

MADEINKOREA

T2000-TFS-01MODEL

0062/05

LIGHTON

MFG.NO

MFG.DATE

0062/05

LIGHTON MODEL

MFG.NO

MADEINKOREA

ON

MFG.DATE

T2000-TFC-02

GAS:INTERMITTENTBEEP

0062/05

MFG.NO

MFG.DATE

MODEL

WATER:CONTINUOUSBEEP

PORTABLEOIL/WATERINTERFACED ETECT OR

ON

OFF

OIL:FREQUENTBEEP

ON

O

F

F

T2000-T FC-01

MADEINKOREA

DISPLAY

OIL:FREQUENTBEEP

WATER:CONTINU OUSBEEP

GAS:INTER MITTENTBEEP

GAS:INTERMITTENTBEEP

OIL:FREQUENTBEEP

WATER:CONTINUOUSBEEP

O

N

O

F

F

O

F

F

O

N

O

N

O

FF

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 4/10

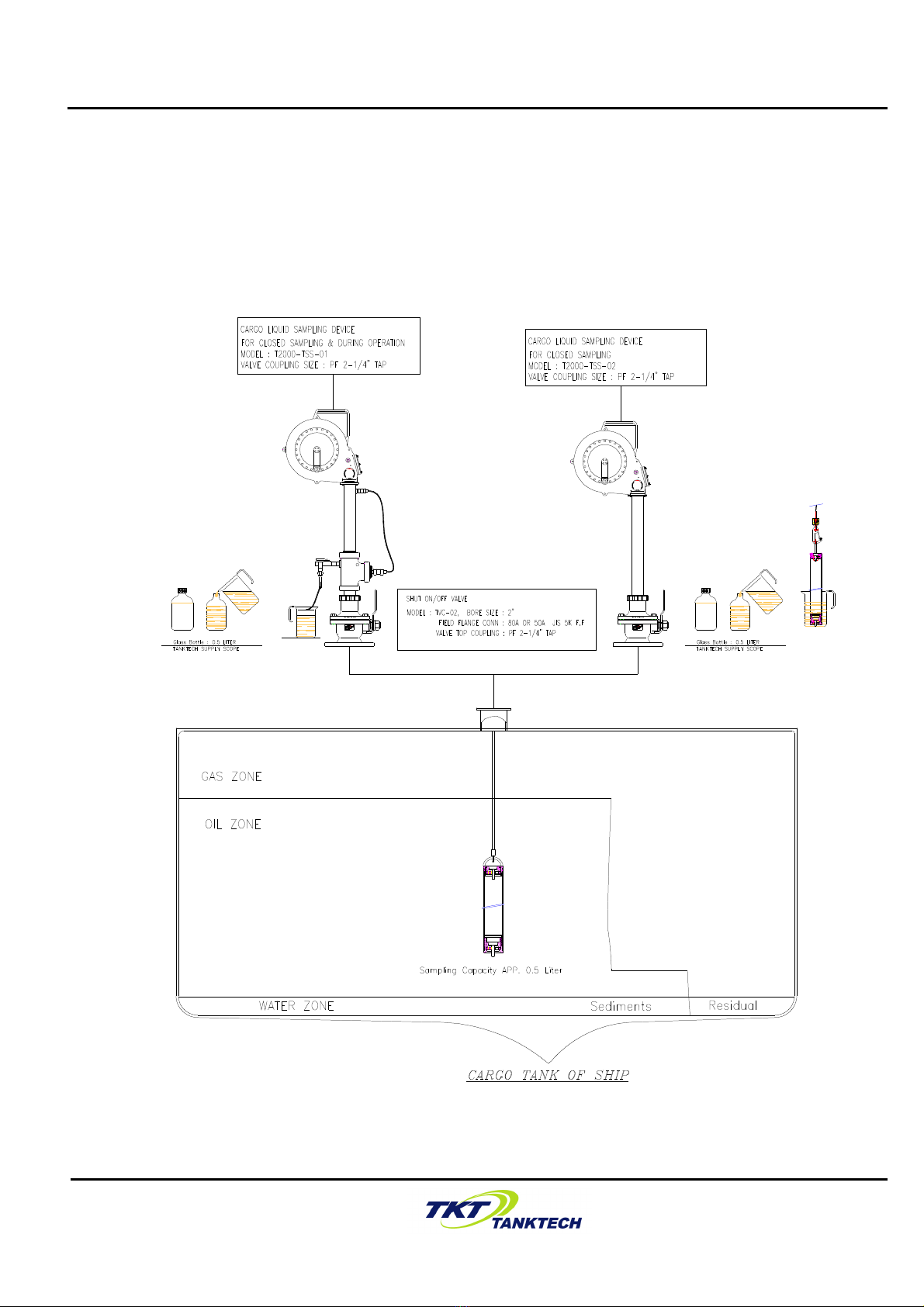

3.

Installation for Cargo Liquid

Sampling Device

TANKTECH TANKTECH

O

N

O

F

F

O

N

O

FF

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 5/10

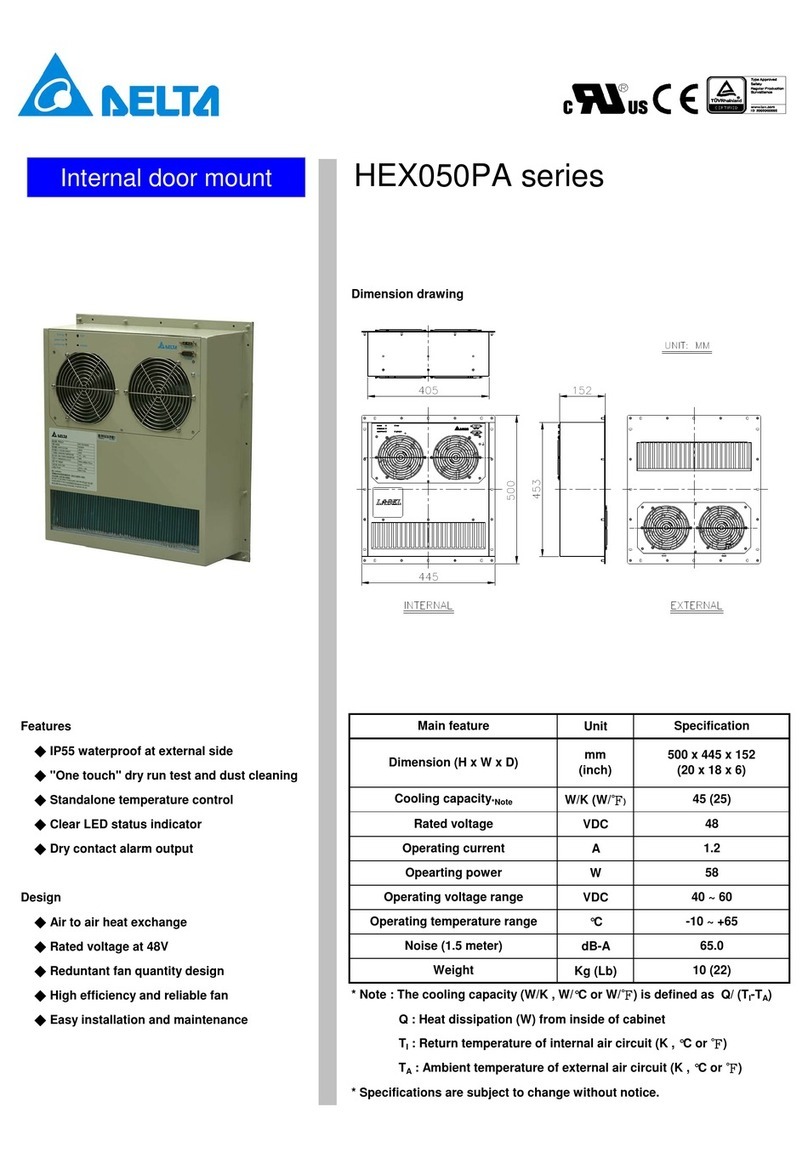

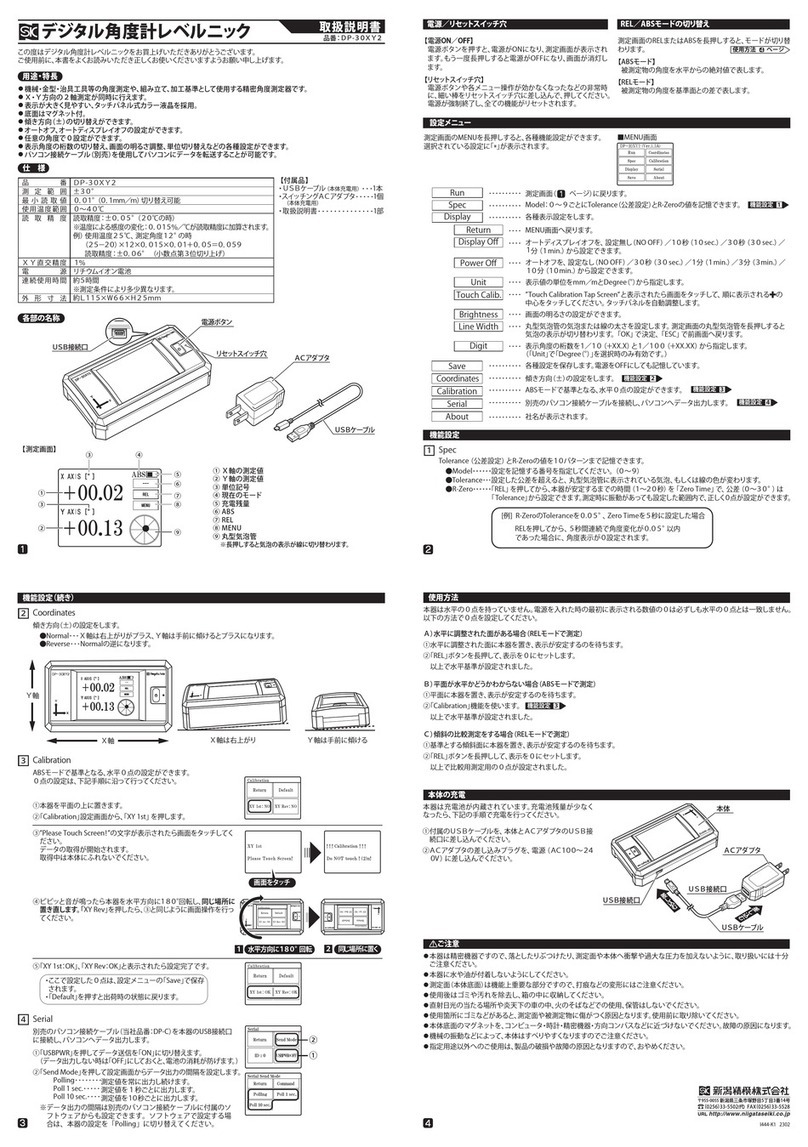

4. SPECIFICATION

.

4-1 General Description

This device is used to pick the sample of the storage oil in tank.

The cargo owner requires cargo sample to be taken from the tank through tank gauging station

the analyze the cargo liquid.

4-2 Model No. : T2000-TSS-02

Tape length 30M

Tape graduation

Scale graduation Metric

Tape resolution 1

㎜

Ball valve coupling

(Top mounting of model : TVC-02 ) PF 2-1/4” TAP

Overall dimensions

(height×width×thickness) APP. 950×346×180

㎜

Capacity of sampling bottles 0.5 Liter

Weight 9.1 kg

4-3 Material

MODEL : T2000-TSS-02 ( Body ) ------------------- : Aluminum casting ( JIS – AC4C-T6 )

4-4 Coating

IN / OUT SIDE ----------------------------------------- : Epoxy nylon coating

COLOR ------------------------------------------- : Black

THICKNESS ( IN/OUT SIDE ) ------------------- : 80mic.

CARGO LIQUID SAMPLING DEVICE

FOR CARGO LIQUID SAMPLING

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 6/10

5. Operation for Cargo Liquid Sampling Device

5-1. General Description

Thank you for purchasing the Sampling equipment of TANKTECH .

Products of the our company intend to manage cargo tanker of the land and the marine efficiently.

Before products use, Please carefully read this manual.

Please, ask to users for the right usage to operate the products well.

5-2. About Mark of the Manual

This manual is written with [Warning] and [Caution] markings. These are important for a safe operation.

These precautions stress the important matter for the prevention of the physical accident and possible

damage to the equipment.

5-3. Application for Model : T2000-TSS-02

Sampling Capacity : Approx. 0.5Liter

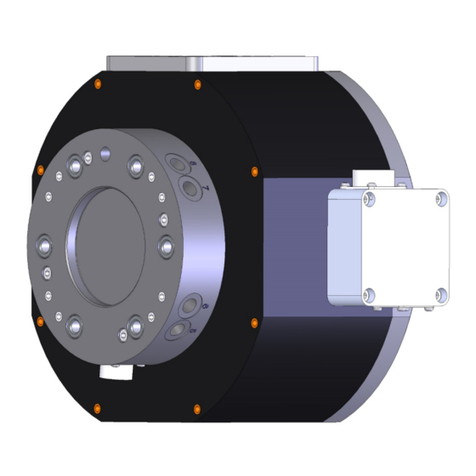

5-4. Name and Shape of Structure

This device is constructed the sampling bottle part, measuring tape to fix the bottle and indicate the depth

of bottle, reel part to move the measuring tape and frame part to fix all device and connect the shut on-off

valve of TANKTECH.

5-5. Sampling Method

1. Connect the suitable bottle with the end of the measuring tape by using the hook.

Insert the bottle into storage barrel and fix it with latch.

Fig 1. Connect of Cargo Liquid Sampling Device

CARGO LIQUID SAMPLING DEVICE

FOR CARGO LIQUID SAMPLING

Warning : When wrong use of equipment may cause body harm to user.

Caution : When wrong use of equipment may cause damage to the set.

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 7/10

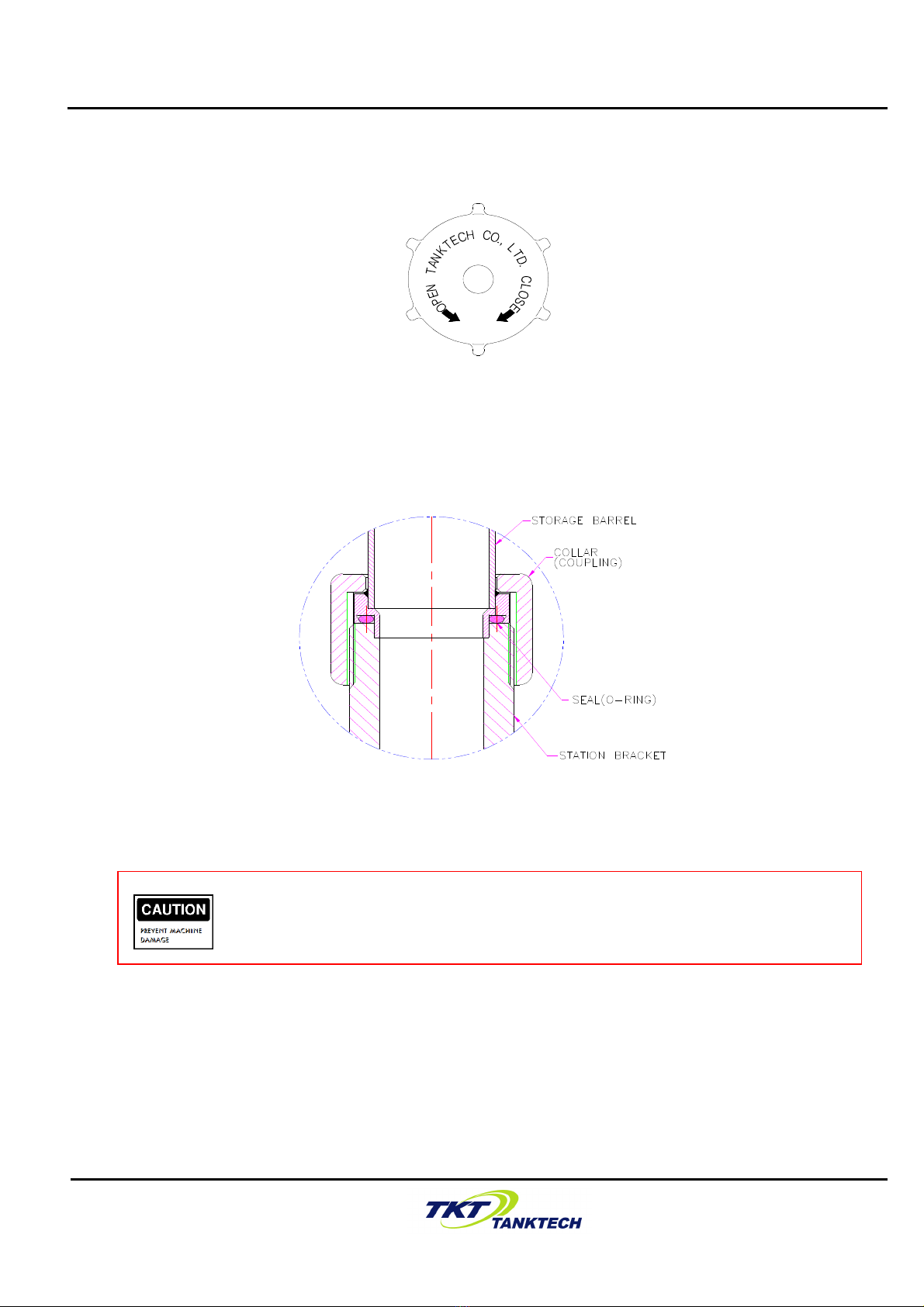

2. Remove the cap of the shut on-off valve, connect the sampling device at the valve.

Fig 2. Remove the cap for Model : TVC-02

Fig 3. Detail of Seal part

MODEL : (TVC-02)Shut On/Off valve (Gauging Station) installed on tank top.

it is available to draw up cargo liquid sample in any desired level,

without releasing dangerous vapor from tank.

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 8/10

3. Open the shut on-off valve.

OPEN

C

L

O

S

E

O

P

E

N

CLOSE

Fig 4. Open handle position

4. Pull handle and drop the sampling bottle slowly.

Fig 5. Reel handle breaker

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 9/10

5. Drop the sampling bottle at the wanted position.

REWIND

Fig 6. Mark of Wind & Rewind

6. Stop the sampling bottle at the wanted position.

7. Turn the cleaner knob on before rewinding the sampling bottle.

※

※※

※

RESET POISITION AFTER CLEANING.

Fig 7. View of cleaning position

- Do not free fall -

Cargo Liquid Sampling Device

TKT-TSS-02 (REV. 2)

Issue date : 2008.07.08

SHEET NO. : 10/10

8. Check that the sampling bottle reach at the top, and close the valve.

CLOSE

OPEN

O

P

E

N

C

L

O

S

E

C

L

O

S

E

O

P

E

N

CLOSEOPEN

Fig 8. View of Liquid winding up

9. Separate the barrel from the sampling device, separate the sampling bottle from the measuring tape.

10. Auto Open(Drain) the Check ball or disc at bottle bottom, bottle the liquid sample.

O

P

E

N

C

L

O

S

E

CLOSE

OPEN

Fig 9. View of Auto Open(Drain) the Check ball or disc