TMA AP-POOL-X Series User manual

Made in Poland

WATER UV STERILIZERS

AP-POOL-X SERIES

MANUAL

Patent No. 204935

- December 2019 -

WATER UV STERILIZERS

TMA

MANUAL –AP-POOL-X SERIES

2

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

TABLE OF CONTENTS

1. GENERAL INFORMATION..................................................................................................4

2. APPLICATIONS...................................................................................................................5

3. TECHNICAL SPECIFICATIONS..........................................................................................6

4. TECHNICAL DESCRIPTION...............................................................................................8

4.1. LEADING OUT THE ALARM SIGNAL IN AP-POOL-X1 MODEL ..................................8

4.2. CONNECTION OF SOLENOID VALVE IN AP-POOL-X1 MODEL................................9

4.3. REMOTE-CONTROLLED ON/OFF SWITCH IN AP-POOL-X1 MODEL........................9

4.4. LEADING OUT THE ALARM SIGNAL IN AP-POOL-X2-AP-POOL-X16 MODELS .....10

4.5. CONNECTION OF SOLENOID VALVE IN AP-POOL-X2-AP-POOL-X16 MODELS...10

4.6. REMOTE-CONTROLLED ON/OFF SWITCH IN AP-POOL-X2-AP-POOL-X16

MODELS.............................................................................................................................10

5. INSTRUCTION FOR INSTALLATION AND OPERATION.................................................11

5.1. CHAMBER ASSEMBLY...............................................................................................11

5.2. QUARTZ SLEEVES ASSEMBLY ................................................................................13

5.3. UV LAMPS AND ELECTRICAL ENCLOSURE ASSEMBLY........................................14

5.4. MOUNTING TEMPERATURE SENSOR (MODELS AP-POOL-X2-AP-POOL-X16)....15

6. DESCRIPTION OF ALARMS IN ELECTRICAL CABINET / AP-POOL-X1 /......................16

7. RESSETING COUNTER IN ALARM SYSTEM / ONLY MODEL AP-POOL-X1/................17

8. LEGEND FOR INDICATOR LIGHT ON ENCLOSURE......................................................17

9. MAINTENANCE.................................................................................................................18

10. INSTRUCTION FOR REPLACEMENT OF UV LAMP .....................................................19

11. REPLACEMENT AND CLEARING OF THE QUARTZ SLEEVE .....................................20

12. TROUBLESHOOTING.....................................................................................................21

12.1. PROCEDURES IN THE EVENT OF FAILURE IN MULTI-RADIATOR DEVICES.....21

13. TRANSPORT...................................................................................................................22

14. DIAGRAM –DIMENSIONS .............................................................................................23

15. DIAGRAM –SPARE PARTS LIST ..................................................................................24

16. HYGIENIC CERTIFICATE...............................................................................................25

17. DECLARATION OF CONFORMITY ................................................................................26

18. GRAFICAL MOUNTING INSTRUCTION.........................................................................27

19. WARRANTY....................................................................................................................30

TMA

MANUAL –AP-POOL-X SERIES

3

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

User Safety

WARNING

This device may only be operated and installed by qualified personnel. Before installation, servicing

or repairs verify the qualifications of personnel and limit these activities to such personnel. Any

activities on this device can only proceed after thorough familiarization with this instruction.

Noncompliance with the precautions listed hereon might expose personnel to serious bodily harm

(damage to human skin from UV radiation), or damage to the device alone. The manufacturer, TMA,

is not responsible for damage to the device caused by improper installation, maintenance and

operation.

READ THE MANUAL

Before proceeding with any activity with the sterilizers read the manual.

RETAIN THE MANUAL

Retain the manual for reference during the whole time the device is in operation.

All precautions and warnings shall be obeyed by the user at all times during the operation of the

device.

POWER SUPPLY

Device is exclusively designed to be supplied from 220-230V 50Hz mains. It shall be installed and

grounded in accordance with this manual and the local electrical code.

To guard against electrical shock, unplug the device every time work is to be done on it.

GROUNDING

Operation of the device without connected grounding is inadmissible. Ungrounded operation might

lead to occurrence of electrical shock and serious bodily harm with death included.

ULTRAVIOLET RADIATION

Direct exposure to UV radiation is harmful to human skin and sight, which can cause from reddening

of skin to serious burns, or ultimately loss of eyesight, depending on the time of exposure.

In such cases one shall contact physician as soon as possible.

The used electrical and electronic equipment with the crossed-out rubbish bin symbol shall be collected

separately. It is prohibited to put the used equipment with other waste. Inadequate use of the used equipment

may have a negative impact on the environment and people's health. Separate collection of the equipment

contributes to its re-use and recycling. The obligation of the used equipment selective collection rests on the

user, who should provide it to the used equipment collector.

TMA devices are equipped with lamps that emit UV radiation, light sources that contain mercury. The owners of

waste lamps containing mercury are obliged to collect them separately for further re-use and disposal.

TMA

MANUAL –AP-POOL-X SERIES

4

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

1. GENERAL INFORMATION

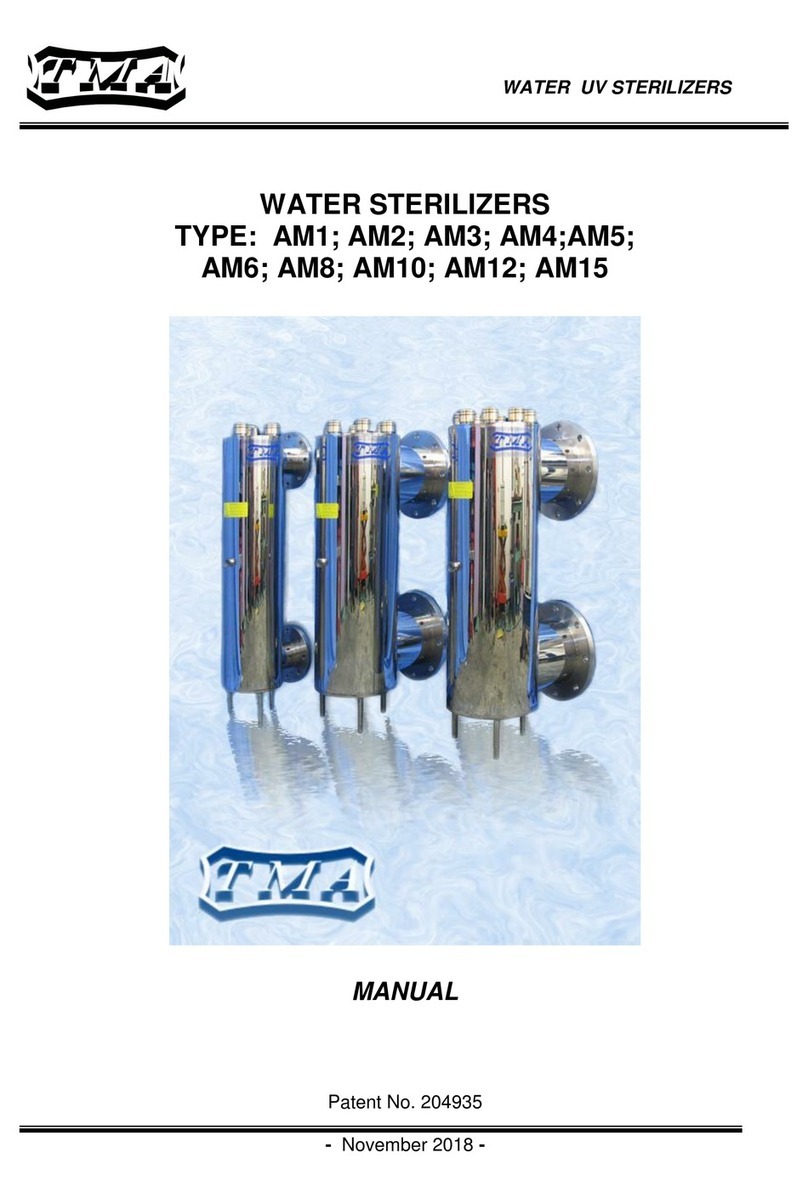

Thank you and congratulations on your purchase of TMA manufactured UV

sterilization product. Sterilizers made by TMA are made from highest quality stainless steel.

The thickness of the chamber wall guarantees high factor of safety in operation. All the raw

materials and components are of best quality and were processed or manufactured in the EU

countries. Plastics used in production of the lamp hoods withstand 110C working

temperatures. Devices completed successfully 30 Atm pressure trials.

AP-POOL-X series sterilizers are equipped with electronic control system and alarm.

Apart from that they are provided with:

Audible UV Lamp Fault Alarm

Optical UV Lamp Fault Alarm

Total Work Time Counter

Number of switches counter

In AP-POOL-X models we introduced additional guides for the quartz sleeves easing

the assembly and disassembly. This solution allows the same ease of assembly for device

working horizontally or vertically. This guide prevents the quartz sleeve from breaking during

the routine maintenance. The turbulent flow induced by the guide increases the efficaciency

of disinfection. During the first 100 hours of operation the efficiency of disinfection is greater

by 15% from the rated for the device.

New features allow continuing disinfection even without the flow of water through the

chamber. Sterilizers do not require control of flow and temperature of water by the user. The

sterilizer without flow could heat up to a maximal temperature of 85 ° C, after that it will turn

off radiators. Return to work will take place at a temperature of approx. 65 ° C.

The design of the chamber contributes to lower incidence of sediment from calcium

and magnesium on the surface of the quartz sleeve.

The AP-POOL-X models are equipped with more durable amalgamate lamps - up to

16,000 hours of service. The plastic lamp hood has a secondary function as a sight glass.

This innovative solution of the use of transparent to visible light lamp hoods allows optical

indication of the state of the lamp.

We hold high hopes that the implementations of these innovative solutions fulfill your

expectations for new and more efficient products from TMA.

MANUFACTURER RESERVES THE RIGHT TO CHANGE THE CONSTRUCTION WITHOUT NOTICE

The device delivered to you is disassembled and shall be protected from severe shocks

and drops, as the quartz sleeve and lamps are brittle and fragile. The sterilizer shall be

exclusively transported in horizontal position. The manufacturer is not responsible for

damage arising from the conditions of transport.

Before installation and operation one shall read the instructions and implement the

precautions listed.

Noncompliance with these precautions is grounds for releasing the manufacturer from

warranty obligations.

TMA

MANUAL –AP-POOL-X SERIES

5

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

2. APPLICATIONS

Disinfection with UV radiation is a reliable, simple and inexpensive method of sterilization.

The use of this method is warranted every time microbiological risk exists.

Following applications might be listed, among many others:

-Water in swimming pools

-Control of green algae in ponds

-Technological waters for cooling machines

-And many others

The primary advantage of UV sterilization is water without microbes and damaging

chlorine so often used in sterilization of water.

Sterilizer uses special low pressure UV lamp to produce UV radiation of wavelength of

254 nm and 185nm, which causes photochemical reaction damaging DNA of microorganisms

leading to death or sterility.

The requirements for complete sterilization call for minimum dosage of 600J/m2 for

swimming pools. Water flowing from the sterilizer is ready for immediate use.

BK/W/0662/01/2019

THERE IS NO POSSIBILITY OF OVERDOSING UV RADIATION

DURING WATER STERILIZATION IN THE CHAMBER

THERE IS NO REQUIRED MINIMUM FLOW OF WATER/LIQUIDS THROUGH THE STERILIZER CHAMBER

Turning off radiators occurs at a temperature of approx. 85°C. Resuming at approx. 65°C

MINIMAL FLOW OF WATER IS NOT REQUIRED.

INCREASED FLOW THROUGH THE STERILIZER LOWERS THE DOSAGE DELIVERED TO

MICROORGANISMS AND LOWERS EFFICIENCY OF DISINFECTION

TMA

MANUAL –AP-POOL-X SERIES

6

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

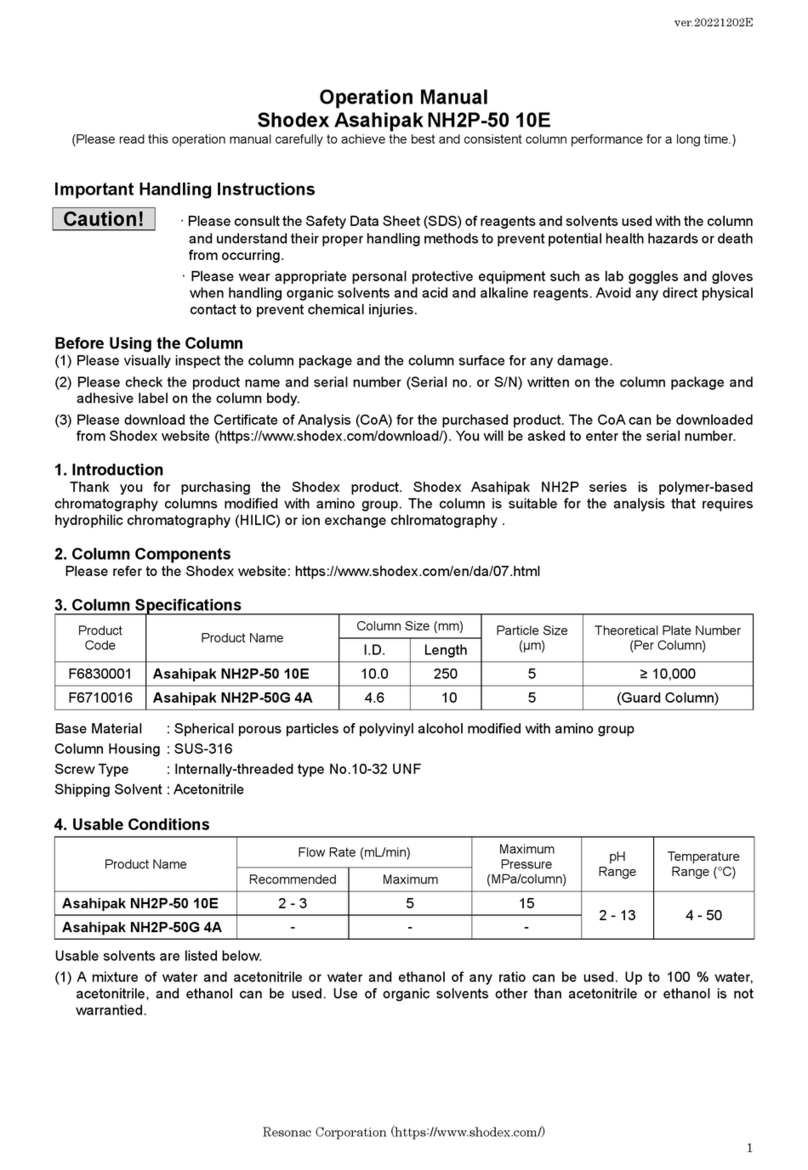

3. TECHNICAL SPECIFICATIONS

a c

b

LL1

Y

X

Z

D

DN

ALARM

INDICATOR

LIGHTS /RED/

SOLENOID

VALVE CORD

UV LAMP CORDS POWER CORD

WORKING HOURS

COUNTER

SYSTEM INDICATOR

LAMP

POWER SWITCH /

INDICATOR LIGHT

UV METER

DRAIN PLUG

MODEL AP-POOL-X 3

TECHNICAL SPECIFICATIONS:

MODEL

AP-POOL-X 1

AP-POOL-X 2

AP-POOL-X 3

AP-POOL-X 4

AP-POOL-X 5

Nominal Flow At Transmittance T10=95%,

Dose 600J/M2

33,0 m3/h

58,0 m3/h

105,0 m3/h

166,0 m3/h

218,0 m3/h

Power Supply

~220V-240V 50-60Hz

Nominal Power

360 W

720 W

1080 W

1440 W

1800 W

Dimensions

X / Y / Z

[mm]

276/220/1700

320/220/1735

375/250/1735

420/340/1740

420/340/1740

L / L1

[mm]

1470 / 72,5

1456 / 110

1430 / 125

1340 / 170

1340 / 170

DN / D

[mm]

3’’ / 220

DN100 / 220

DN125 / 256

DN200 / 306

DN200 / 306

Weight with Enclosure

40 kg

46 kg

80 kg

100 kg

105 kg

STERILIZER CHAMBER:

Chamber Material

Stainless Steel AISI 316 / 316L

Finish

Polished / Powder coating

Safety Class

IP 66

Operating Pressure

3,5 bar (0,35MPa)

Operating Temperature (Recommended)

0,5-50°C

Quartz Sleeve Guide

Yes

Sight glass Muff

1 pcs.

2 pcs.

3 pcs.

4 pcs.

5 pcs.

Sample Valves

Yes

Yes

Yes

Yes

Yes

Drain Valve

Yes

Yes

Yes

Yes

Yes

Temperature sensor

No

Yes

Yes

Yes

Yes

Orientation

Horizontal

LOW PRESSURE UV LAMPS:

No. of UV Lamps

1

2

3

4

5

UV Lamp Power

325W

Rated Life of UV Lamps

16 000 h

UV Radiation Power at 185/254nm

13,6W/115W

27,2W/230W

40,8W/345W

54,4W/460W

68,0W/575W

ELECTRICAL ENCLOSURE:

Material

Plastic

Steel

Safety Class

IP 65

IP42

IP42

IP42

IP42

Electronic Ballasts Safety Class

IP 66

IP 66

IP 66

IP 66

IP 66

Dimensions /mm

325x250x120

400x400x200

400x600x250

400x600x250

400x600x250

Audible UV Lamp Fault Alarm

Yes

Optical UV Lamp Fault Indicator

Yes

Working Hours / Number Of Switches Counter

Yes / Yes

Alarm System

Yes

Solenoid Cut-Off Valve Terminals

Yes

Terminals for Remote Alarm Indicator

Yes

Remote ON/OFF Switch Terminals

Yes

UV Intensity Measurement System

On demand /Optional/

TMA

MANUAL –AP-POOL-X SERIES

7

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

LL1

DN

Z

X

Y

D

ac

b

ALARM

INDICATOR

LIGHTS /RED/

SOLENOID

VALVE CORD

UV LAMP CORDS POWER CORD

WORKING HOURS

COUNTER

SYSTEM

INDICATOR LAMP

/GREEN/

POWER SWITCH /

INDICATOR LIGHT

DRAIN PLUG

UV METER

MODEL AP-POOL-X 16

TECHNICAL SPECIFICATIONS:

MODEL

AP-POOL-X 6

AP-POOL-X 8

AP-POOL-X 10

AP-POOL-X 12

AP-POOL-X 16

Nominal Flow At Transmittance T10=95%,

Dose 600J/M2

314,0 m3/h

510,0 m3/h

682,0 m3/h

820,0 m3/h

1190,0 m3/h

Power Supply

~220V-240V 50-60Hz

3 x ~220V-240V 50-60Hz

Nominal Power

2160 W

2880 W

3600 W

4320 W

5760 W

Dimensions

X / Y / Z

[mm]

488/395/1750

544/445/1750

544/505/1750

628/505/1750

628/565/1750

L / L1

[mm]

1290/197,5

1240/222,5

1190/252,5

1189/252,5

1139/282,5

DN / D

[mm]

DN250 / 356

DN300 / 406

DN350 / 406

DN350 / 508

DN400 / 508

Weight with Enclosure

130 kg

160 kg

190 kg

230 kg

250 kg

STERILIZER CHAMBER:

Chamber Material

Stainless Steel AISI 316 / 316L

Finish

Polished / Powder coating

Safety Class

IP 66

Operating Pressure

3,5bar (0,35MPa)

Operating Temperature (Recommended)

0,5-50°C

Quartz Sleeve Guide

Yes

Sight glass Muff

6 pcs.

8 pcs.

10 pcs.

12 pcs.

16 pcs.

Sample Valves

Yes

Yes

Yes

Yes

Yes

Drain Valve

Yes

Yes

Yes

Yes

Yes

Temperature sensor

No

Yes

Yes

Yes

Yes

Orientation

Horizontal

LOW PRESSURE UV LAMPS:

No. of UV Lamps

1

2

3

4

5

UV Lamp Power

325W

Rated Life of UV Lamps

16 000 h

UV Radiation Power at 185/254nm

81,6W/690W

108,8W/920W

136W/1150W

163,2W/1380W

217,6W/1840W

ELECTRICAL ENCLOSURE:

Material

Steel

Safety Class

IP 42

IP42

IP42

IP42

IP42

Electronic Ballasts Safety Class

IP 66

IP 66

IP 66

IP 66

IP 66

Dimensions /mm

400x600x250

600x800x250

600x800x250

800x800x300

800x800x300

Audible UV Lamp Fault Alarm

Yes

Optical UV Lamp Fault Indicator

Yes

Working Hours / Number Of Switches Counter

Yes / Yes

Alarm System

Yes

Solenoid Cut-Off Valve Terminals

Yes

Terminals for Remote Alarm Indicator

Yes

Remote ON/OFF Switch Terminals

Yes

UV Intensity Measurement System

On demand /Optional/

TMA

MANUAL –AP-POOL-X SERIES

8

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

Standard features:

Sterilizer chamber made from stainless steel (AISI 316/316L),

Electrical enclosure, with control system,

Set of quartz sleeves

Set of UV lamps

Set of O-rings + backup set of O-rings

Terminals for connecting electromagnetic valve shutting off flow in case of power

or lamp failure

Optional Accessories:

-UV intensity sensor

-Sterilizer supports

4. TECHNICAL DESCRIPTION

Sterilizer’s chamber is totally made from stainless steel. Quartz sleeves with UV

lamps are mounted in the chamber.

When mounted vertically, the inlet should be located in the bottom part of the chamber

and the outlet in the upper part. When mounted horizontally, the arrangement is optional. At

the bottom of the chamber the drain plug is located, which is used to empty the chamber from

fluid. The power supply system is mounted in the electrical enclosure and connected with the

sterilizer by hi-potential wires. The enclosure houses, besides the power supply, is equipped

lamp working hours counter, the audible and optical alarm, and indicating lights with the

terminals for electromagnetic shutoff valve in case of lamp or power failure.

Power supply is 220-230V ± 10%, 50-60 Hz (or 3 x 220-230V 50/60Hz).

The device has anti-shock protection by earth terminal.

Sight glass muff enables indication of working condition of the UV lamps.

4.1. LEADING OUT THE ALARM SIGNAL IN AP-POOL-X1 MODEL

Connect alarm signal wires to the terminals 1 & 2 on electronic plate /neutral –without

voltage/.

The contacts 1 and 2 operate with a preset delay of about 2-3 minutes - this is the time to

reach the full efficiency of the device. During this period, terminals 1 and 2 are open.

After 2-3 minutes, the device operates as follows:

CONTACTS 1-2 CLOSED

- sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- Power cut off

TMA

MANUAL –AP-POOL-X SERIES

9

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

4.2. CONNECTION OF SOLENOID VALVE IN AP-POOL-X1 MODEL

There is possible to connect solenoid valve [max. 2A] to the terminals 1 & 2 /neutral/ on the

electronic plate in electrical enclosure.

The contacts 1 and 2 operate with a preset delay of about 2-3 minutes - this is the time to

reach the full efficiency of the device. During this period, terminals 1 and 2 are open.

After 2-3 minutes, the device operates as follows:

CONTACTS 1-2 CLOSED

- sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- Power cut off

4.3. REMOTE-CONTROLLED ON/OFF SWITCH IN AP-POOL-X1 MODEL

After removing the bridge, it is possible to connect remote-controlled switch to the ON/OFF

terminals /caution: voltage 230V!/.

CONTACTS 1-2 CLOSED

- sterilizer on

CONTACTS 1-2 OPEN

- sterilizer off

BALAST ON/OFF SWITCH N L ~230V

1

1 221

UV STERILIZER

OUTLET

SOLENOID VALVE

POWER LINE

To the terminals ON/OFF /caution: voltage 230V!/ on

electronic plate in electrical enclosure, after removing

the jumper cable, connect remote switching on/off of

the sterilizer:

Closed circuit - sterilizer on

Open circuit - sterilizer off

ELECTRONIC PLATE

IN AM1 MODELS

To the terminals 1 & 2 /neutral/ on the electronic

plate in electrical enclosure/ solenoid valve type

NZ (normally closed) max. 2a can be connected.

Circuit closed - sterilizer working

properly

Circuit open - UV lamp damage

- Alarm on

- Power cut off

ELECTRICAL ENCLOSURE

POWER LINE FUSE

AP-POOL-X1 –Diagram for solenoid valve, alarm signal and outside connection of the device.

TMA

MANUAL –AP-POOL-X SERIES

10

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

4.4. LEADING OUT THE ALARM SIGNAL IN AP-POOL-X2-AP-POOL-X16 MODELS

Connect the alarm signal wires to the terminals 1 & 2 /neutral/ on the terminal blocks in

electrical enclosure /in the right bottom corner/.

The contacts 1 and 2 operate with a preset delay of about 2-3 minutes - this is the time to

reach the full efficiency of the device. During this period, terminals 1 and 2 are open.

After 2-3 minutes, the device operates as follows:

CONTACTS 1-2 CLOSED

- sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- Power cut off

4.5. CONNECTION OF SOLENOID VALVE IN AP-POOL-X2-AP-POOL-X16

MODELS

There is possible to connect solenoid valve [max. 2A] to the terminals 1 & 2 /neutral/ on the

electronic plate in electrical enclosure.

The contacts 1 and 2 operate with a preset delay of about 2-3 minutes - this is the time to

reach the full efficiency of the device. During this period, terminals 1 and 2 are open.

After 2-3 minutes, the device operates as follows:

CONTACTS 1-2 CLOSED

- sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- Power cut off

4.6. REMOTE-CONTROLLED ON/OFF SWITCH IN AP-POOL-X2-AP-POOL-X16

MODELS

After removing the bridge, it is possible to connect remote-controlled switch to the terminals 3

& 4 /caution: voltage 230V!, I=0,2A/.

CONTACTS 1-2 CLOSED

- sterilizer on

CONTACTS 1-2 OPEN

- sterilizer off

TMA

MANUAL –AP-POOL-X SERIES

11

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

AP-POOL-X2 - Diagram for solenoid valve, alarm signal and outside connection of the device.

5. INSTRUCTION FOR INSTALLATION AND OPERATION

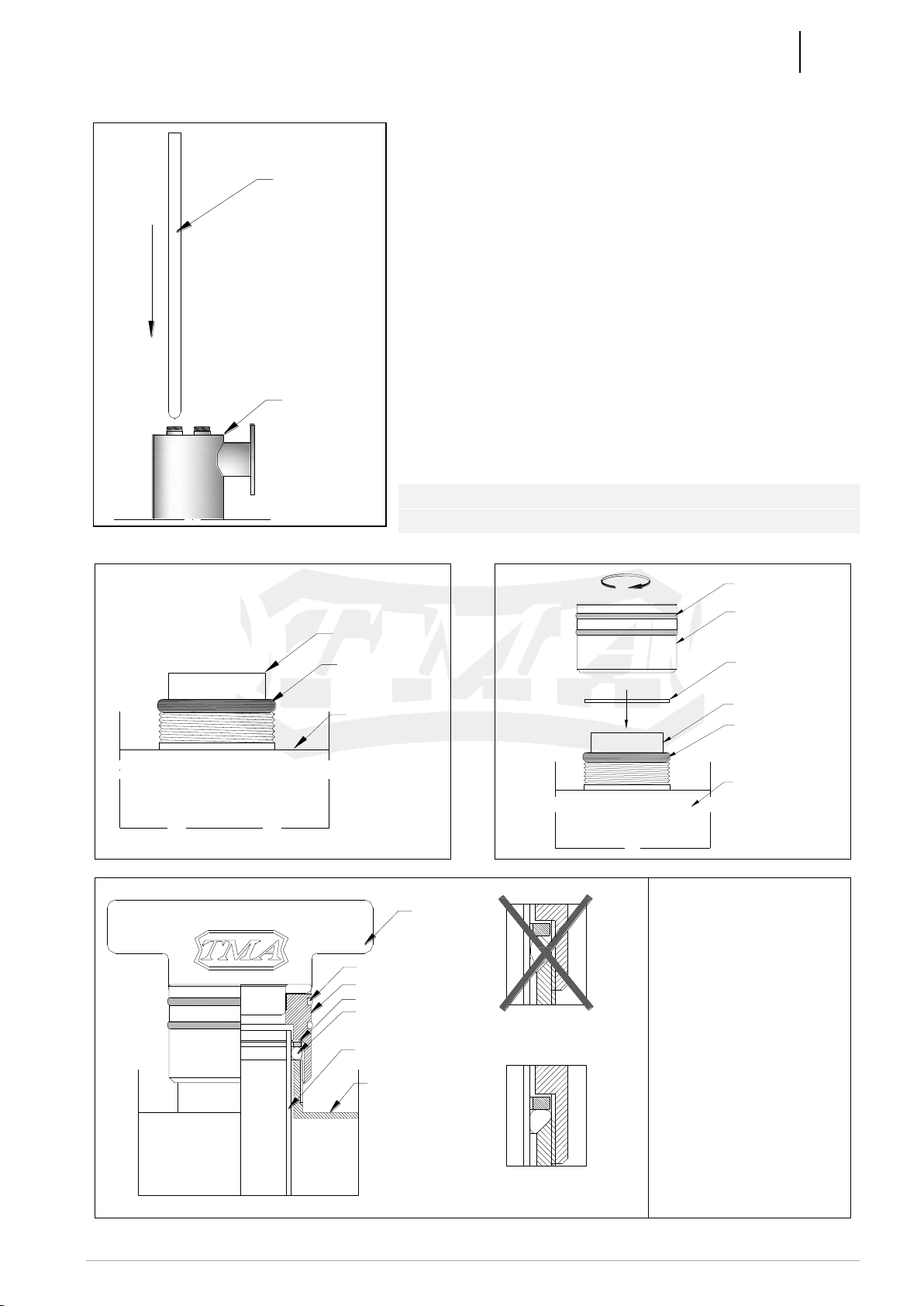

5.1. CHAMBER ASSEMBLY

a) Device assembles in horizontal position. Temperature range for installation is from 0.1

to 35oC. DO NOT ALLOW THE CHAMBER TO FREEZE.

b) Correct assembly shall prevent the creation of air gap in the chamber.

c) By-pass installation is recommended.

d) Assembly cannot cause strain on the nipples.

e) It is forbidden to mount the sterilizer on flanges without appropriate support.

f) Upstream of the intake install potable water filter, minimum rating 0.1 mm,

recommended 0.05 mm.Water shall not contain more than 0.3mg Fe and 0.1 Mn.

g) Install cut-off valves on both sides.

UV STERILIZER

ELECTRICAL ENCLOSURE

OUTLET

SOLENOID VALVE

SOLENOID VALVE

CORD

REMOVE DOORS OF THE

ELECTRICAL ENCLOSURE

POWER LINE

terminal block in electrical enclosure, after removing

the jumper cable, connect remote switching on/off of the

sterilizer:

Closed circuit - sterilizer on

Open circuit - sterilizer off

To the terminals 1 & 2 /neutral/ on the terminal

blocks in electrical enclosure/ solenoid valve type

NZ (normally closed) max. 2a can be connected.

Circuit closed - sterilizer working

properly

Circuit open - UV lamp damage

- Alarm on

- Power cut off

QUICK-BREAK FUSE

CONTACTOR

masa

12 345 6 78PE

Blokada

TMA

MANUAL –AP-POOL-X SERIES

12

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

Vertical

Forbidden

Supports

Horizontal

Supports

Supports

Horizontal

Horizontal

Forbidden

TMA

MANUAL –AP-POOL-X SERIES

13

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

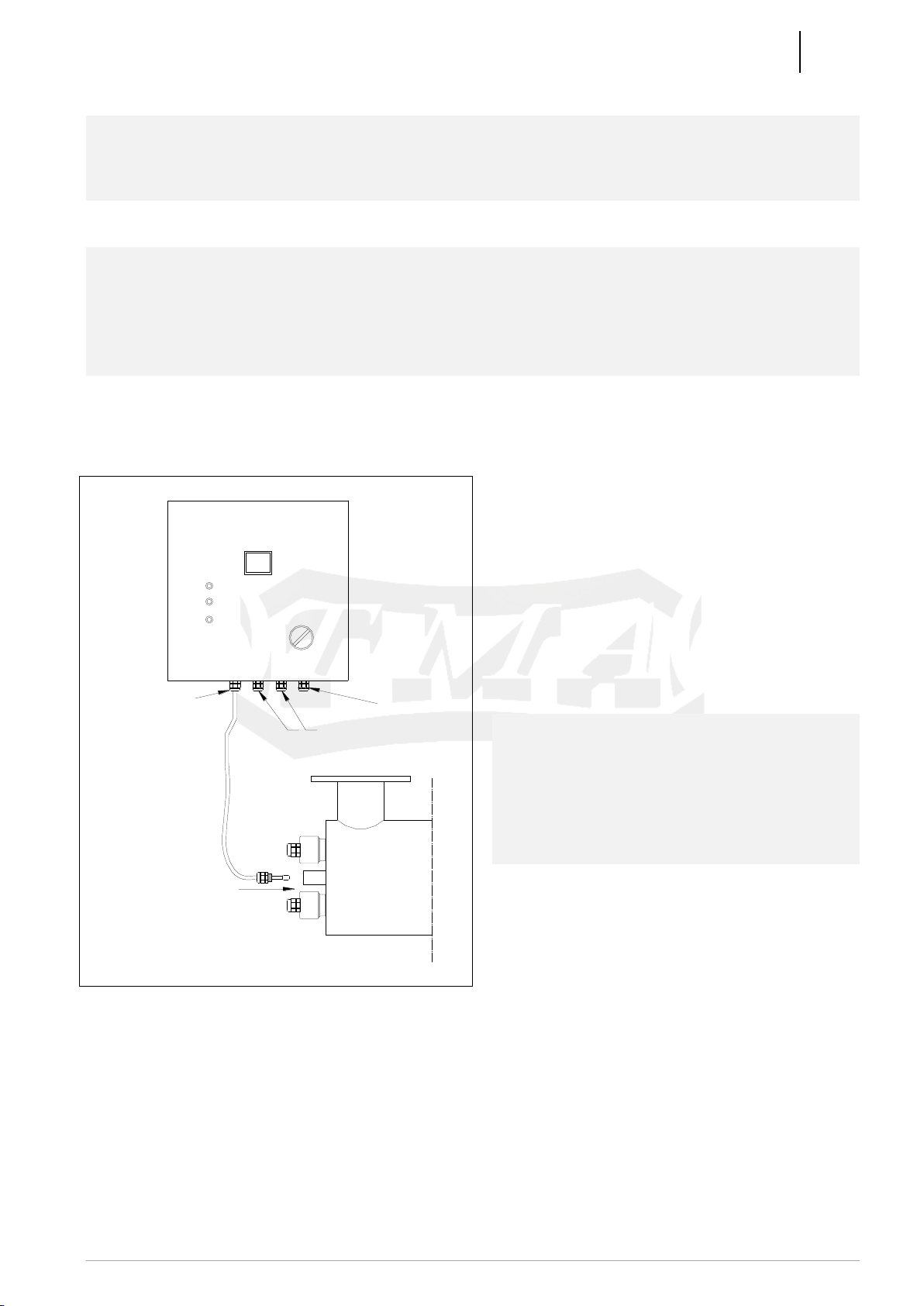

5.2. QUARTZ SLEEVES ASSEMBLY

(GRAFICAL MOUNTING INSTRUCTION ON PAGE 27-29)

a) Slide in gently through the nipple the quartz

sleeves; continue through sleeve guides onto

nests at the bottom.

b) Place the O-ring over quartz sleeve and against

the lip of the nipple. Next place the washer over

the O-ring, screw the muff onto this assembly

with the provided tool. Turn the muff to

considerable resistance in order to tighten the

seal. Tightening the muff shall not break the

sleeve.

c) Fill the chamber under full pressure and check

the seal tightness.

!!! ATTENTION !!!

Tightening the muffs with other tools may cause

quartz sleeves breakage.

O-RING

STERILIZER CHAMBER

QUARTZ SLEEVE

WASHER

O-RING

STERILIZER CHAMBER

QUARTZ SLEEVE

MUFF

O-RING ON MUFF

O-RING AFTER FULLY TIGHTENED,

MUFF DEFORMS O-RING

/SUFFICIENT DEFORMATION/

O-RING BEFORE MUFF TIGHTENED

/SMALL DEFORMATION OF O-RING/

WASHER

O-RING

STERILIZER CHAMBER

QUARTZ SLEEVE

MUFF

O-RING ON MUFF

PROVIDET TOOL

Tightest seal around

quartz sleeve shall be

created with the

largest possible

deformation of O-ring.

O-ring is visible

through the sleeve.

Tighten muff with the

provided tool, as seen.

STERILIZER CHAMBER

QUARTZ SLEEVE

WARNING!!

QUARTZ SLEEVE IS WERY

BRITTLE AND FRAGILE.

BE CAREFUL.

TMA

MANUAL –AP-POOL-X SERIES

14

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

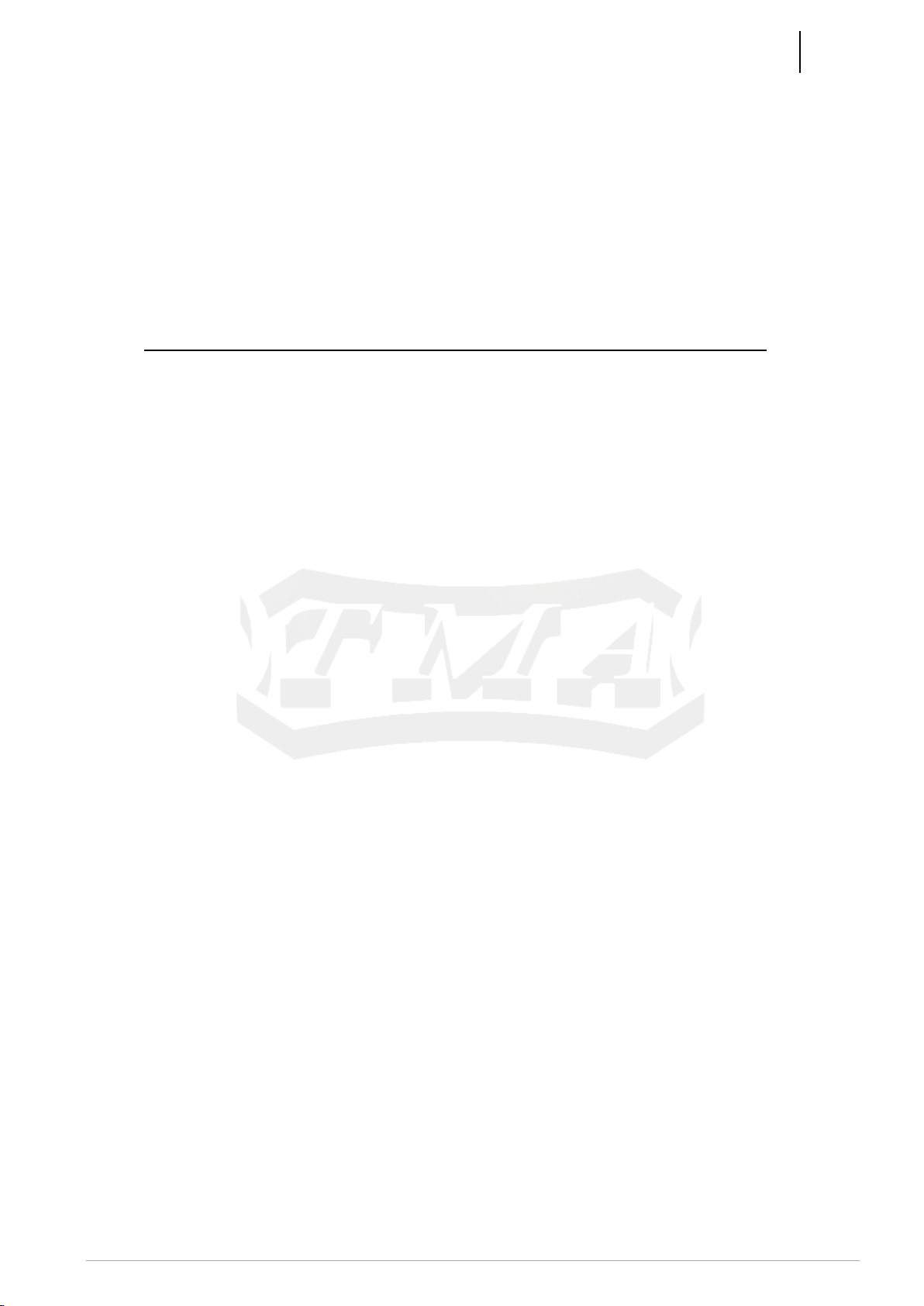

5.3. UV LAMPS AND ELECTRICAL ENCLOSURE ASSEMBLY

(GRAPHICAL INSTRUCTIONS AT PAGE 27-29)

a) Mount electrical enclosure on wall, at least 60 cm from the floor.

b) Place the socket on the end of UV lamp with four pins. Gently slide the fully connected

lamp into the quartz sleeve.

!!! CAUTION !!!

MOUNT UV LAMPS IN PROTECTIVE, PREFERABLY COTTON GLOVES.

If not done as required, the UV lamps may break after turning on the device.

LAMP HOOD

STRAIN RELIEF

PLACE SOCKET ON

LAMP END WITH FOUR

PINS

UV LAMP

SOCKET

CENTERING RING

UV LAMP

STRAIN RELIEF

INSERT UV LAMP

INTO QUARTZ

SLEEVE

SOCKET

LAMP HOOD

PLACE LAMP HOOD

OVER MUFF

WASHER

O-RING

STERILIZER

CHAMBER

QUARTZ SLEEVE

MUFF

O-RING ON MUFF

CENTERING RING

c) Place lamp hood over muff.

d) Plug in to mains 230V, 50 Hz, in the electrical enclosure, according to the labels.

e) Turn device on by using switch on the side or front of electrical enclosure. Green

indicator light goes on when device is connected to power and powered up.

f) Replace UV lamps after its end of life time.

TMA

MANUAL –AP-POOL-X SERIES

15

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

ATTENTION!

1. Any fault of UV lamp, including burn out, is signalized by lighting up of red indicator lamp

and tripping of audible alarm.

2. Incidental powering of the electrical enclosure without connected UV lamps may cause

damage to electronic ballast driving UV lamps.

ATTENTION!

In case of installing solenoid shut-off valve ( terminals 1 & 2) upstream /or

downstream/ of the sterilizer, tripping alarm or power interruption causes immediate shutting

off of fluid flow to the chamber of the sterilizer / Section 4.3-4.6/. Terminals 1 & 2 are neutral.

Power to solenoid shut-off valve shall be connected through terminals 1 & 2.

Solenoid shut-off valve serves the purpose of preventing unsterilized fluid entering the

installation downstream of the sterilizer in the case of power interruption or lamp failure.

5.4. MOUNTING TEMPERATURE SENSOR (MODELS AP-POOL-X2-AP-POOL-

X16)

UV STERILIZER

POWER LINE

UV LAMPS

SCREW PLASTIC

GLAND INTO THE

STERILIZER

TEMPERATURE

SENSOR

ELECTRICAL ENCLOSURE

a) Choose the temperature sensor cord

(ended with strain relief PG11).

b) Loosen the cable gland

c) Install the strain relief into the hole at

the center of sterilizer (between the UV

lamps mountings)

d) Move the wire to the end of the hole.

e) Tighten the strain relief.

ATTENTION!

Improper mounting of temperature sensor

can cause a short circuit, resulting in failure

of whole device

Turning off radiators occurs at a

temperature of approx. 85°C. Resuming at

approx. 65°C

TMA

MANUAL –AP-POOL-X SERIES

16

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

6. DESCRIPTION OF ALARMS IN ELECTRICAL CABINET / AP-POOL-X1 /

Display indications

Cause

Solving the problem

- Blinking digit 7 on the display.

- An intermittent sound signal

- 7 days left to the end of life

time of UV lamp

- change UV lamp after 7

days.

HOLD 3 s.

PRZYTRZYMAĆ 3 s.

Hold left button more than 3

seconds to silence the sound alarm

- Blinking number 0 on the display.

- An intermittent sound signal

- UV lamp reached its end of

life time.

HOLD 3 s.

PRZYTRZYMAĆ 3 s.

Hold left button more than 3

seconds to silence the sound alarm

(max 2 times)

- Blinking number 0 on the display.

- Blinking 3 LED’s over display

- Continuous sound signal

- UV lamp is damaged or

reached its end of life time.

Change UV lamp

- The display shows weird characters.

- Two or three LEDs appear on the display

at the same time

- Possible damage to the

display or the

microprocessor.

Please Contact your dealer

- No indication on the display

- No indication on LED above display

- No audible alarm

- No power at the input of the

control cabinet.

- Check power supply.

- Check the fuse in the

alarm system

TMA

MANUAL –AP-POOL-X SERIES

17

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

7. RESSETING COUNTER IN ALARM SYSTEM / ONLY MODEL AP-POOL-X1/

COUNTER IN THE ALARM SYSTEM SHOULD BE RESSETED EACH TIME THE UV

LAMP IS REPLACED

a) Disconnect from power supply /neutral and life/.

b) Replace UV Lamp –see p. 9. INSTRUCTION FOR REPLACEMENT OF UV LAMP

c) Connect device to Power supply (power switch should be turned off)

d) Hold the right button under display.

01

NACISNĄĆ I PRZYTRZYMAĆ OK

CZEKAJ 10 SEKUND

e) Turn on the power switch while still holding the right button for more than 10 seconds.

f) Short sound signal will confirm resetting the work time counter.

8. LEGEND FOR INDICATOR LIGHT ON ENCLOSURE

Lighted color indicator lights inform the operator of the status of the sterilizer. Certain

conditions can be identified from the configuration of lights. For these corrective actions are

listed below:

Alarm

Red Light

Power Supply

Green Light

Power

Green Light

Problem

Action

OFF

ON

ON

No fault

-

OFF

BLINKING

ON

No fault –heating the

UV lamps

-

OFF

OFF

OFF

No Power

Check power

source

ON

OFF

ON

1.Burned out or faulty

UV lamp

2.Faulty starter

1.Replace UV

lamp

2.Replace starter

OFF

OFF

ON

Alarm System Fault

Contact Dealer.

Replace alarm

system.

TMA

MANUAL –AP-POOL-X SERIES

18

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

9. MAINTENANCE

a) UV radiation is harmful to eyes and skin. It is forbidden to directly observe UV

lamp (radiator) during operation.

b) It is recommended to check cleanness of the quartz sleeve whenever the UV lamp is

replaced.

c) If any sediment is noticed on the surface of the quartz sleeve, it is recommended to

immediately clean the sleeve. Negligence of this recommendation can cause drop in

efficiency of sterilization.

d) Any time the sleeve is cleaned or replaced it is required to

unconditionally replace the O-ring creating the seal around the sleeve.

e) Inlet and outlet valves shall be opened slowly to prevent the rush of fluid hitting and

damaging the quartz sleeve.

f) There is no need for minimal flow through the device as it is designed in such a way

that there may be no flow through the chamber with no damage to the sterilizer. When

there is no flow of water through the chamber can heat up to approx. 85°C that is

when turning off radiators occurs. Sterilizer is resumed to work after reaching

temperature of approx. 65°C.

g) UV sterilizer should work constantly - his long-term exclusion may cause secondary

infection in the installation, which is very difficult to remove.

h) It is recommended that before the UV sterilizer a filter is installed.

i) Water not fit for consumption may require treatment i.e. deironing, softening or

filtering. If any doubt, please contact your dealer.

j) In case of high turbidity and waste water, the choice of equipment and efficiency

should be made by the dealer.

k) Sterilizers must be sized for the maximum momentary flow of water (matching them to

the daily flows may result in incomplete disinfection)

l) Avoid frequent turning on and off the equipment. One on-off cycle lowers the UV lamp

life by about 10-20 hours.

m) Sterilizers should not be installed in such a way that their work was dependent on

other devices, e.g. pumps, pressure-water.

n) Flow rate through the device can be increased; however, this lowers the delivered

dosage and lowers the efficiency of disinfection.

o) The lamp needs about 2 minutes to reach full capacity at temperature of water about

12-16 °C. If the water is at temperature 5-12°C, the time might be about 3-5 minutes.

p) If the sterilizer is left idle for longer period of time or it can freeze, we recommend that

the water be drained from the chamber. The chamber is provided with drain valve.

q) Bioassay samples shall be collected into sterile opaque containers as not to

expose the sample to the light to avoid photo reactivation of microorganisms,

which can rebuild their damaged DNA in presence of light.

r) In case the red indicator light is on, replacement of the UV lamp is necessary. The

part number can be found on transparent plastic lamp hood placed over the muff.

s) Even short lived surge, to above 254V, can damage the electronic ballast driving the

UV lamps.

TMA

MANUAL –AP-POOL-X SERIES

19

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

t) Using faulty or post end of life UV lamps / operating time above their durability period /

can lead to damage to electronic ballast located in the electrical enclosure. When

replacing the UV lamp, protective gloves should be worn.

u) Excessive humidity and water inside the quartz sleeve can cause damage to the

power supply of the UV lamp.

v) The leakage current going into grounding is 1,5 mA for each UV lamp.

w) Fans in control cabinets should be replaced every 50 000h.

x) In control cabinets there are mounted protection devices as below:

Sterilizer type

Protection device

AP-POOL-X1

Fuse 2A

AP-POOL-X2

Circuit breaker C6

AP-POOL-X3

Circuit breaker C6

AP-POOL-X4

Circuit breaker C10

AP-POOL-X5

Circuit breaker C10

AP-POOL-X6

Circuit breaker C13

AP-POOL-X8

Circuit breaker C16

AP-POOL-X10

Circuit breaker C20

AP-POOL-X12

Circuit breaker C16

AP-POOL-X16

Circuit breaker C16

10. INSTRUCTION FOR REPLACEMENT OF UV LAMP

(GRAPHICAL INSTRUCTIONS AT PAGE 28-29)

ATTENTION!

1. Always wear protective gloves (preferably cotton) when replacing / installing the UV lamp.

Do not touch the UV lamp with your bare hand.

2. When installing the UV lamp, hold the lamp by the glass.

3. Holding or inserting the UV lamp by the lampholder may damage it.

In order to replace the UV lamp one shall:

a) Disconnect from power supply /neutral and life/,

Replacing the radiator does not require shutting off the water flow through the chamber.

b) Put on protective gloves, preferably made of cotton,

c) Take off plastic hood,

d) Slide out the UV lamp from the quartz sleeve,

DO NOT UNSREW THE STEEL MUFF!

e) Remove sockets from connectors of the UV Lamp,

f) Remove old UV lamp from the quartz sleeve,

g) Carefully place the new UV lamp in the sleeve,

h) Reverse the remaining steps.

TMA

MANUAL –AP-POOL-X SERIES

20

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; Tel. +48 857431246; VAT EU PL5420008413

ATTENTION!

In model AP-POOL-X sterilizers UV lamps must have special centering ring at both ends.

When the UV lamps are shipped from the manufacturer, the centering rings are provided with

every lamp.

11. REPLACEMENT AND CLEARING OF THE QUARTZ SLEEVE

(WARNING: VERY BRITTLE)

(GRAPHICAL INSTRUCTIONS AT PAGE 28)

In order to replace quartz sleeve one shall:

a) Disconnect the power supply,

b) Cut off the liquid flow through the chamber,

c) Allow for lamp to cool down from operating temperature,

d) Remove UV lamp according to p. 10. /Instruction for replacement of UV lamp/,

e) Unscrew the steel muff using special spanner,

f) Take off the washer and O-ring from the quartz sleeve,

g) Slide the sleeve out of guides and nipple of the sterilizer,

h) Every time the UV lamp is replaced, when it is necessary to clean the quartz sleeve

use common glass cleaners and then inside of the sleeve should be thoroughly dried

so that no liquid is left there,

ATTENTION! SLEEVE IS MADE OF PURE QUARTZ –VERY BRITTLE

ATTENTION!

AT THE TIME OF REPLACEMENT OR CLEARING OF THE QUARTZ SLEEVE, THE O-RING MUST BE REPLACED

i) Slide carefully the new or cleaned quartz sleeve into the chamber of the sterilizer,

j) Place new O-ring over the sleeve, then place the washer,

k) Tighten the muff over the O-ring and washer with the provided tool. Check the proper placement of the

O-ring, it should be lodged into the conical groove in the nipple of the sterilizer,

l) Open gradually the cut-off valves, flood the chamber, and check the seal around the

sleeve. If it springs a leak, tighten the muff till tight seal is obtained,

m) Place the UV lamp according with p. 10 of this Manual.

This manual suits for next models

11

Table of contents

Other TMA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Shimadzu

Shimadzu GC quick start guide

Labnet

Labnet 35 operating instructions

Sartorius

Sartorius Sartocheck 4 plus operating instructions

Thermo Scientific

Thermo Scientific Cryofuge 5500i GMP Instructions for use

Atop

Atop IJG7001 Series Hardware installation guide

Yamato

Yamato NeoCool Circulator CF301 instruction manual

Izon

Izon AUTOMATIC FRACTION COLLECTOR V2 quick start guide

S.C.A.T. Europe

S.C.A.T. Europe SymLine asecos Assembling and installation manual

Westlab

Westlab 665-090 product manual

AGS

AGS Merlin 1000S Installation & operation manual

Covaris

Covaris E220 evolution user manual

Agilent Technologies

Agilent Technologies 1260 Infinity II user manual