TMA V Series User manual

®

Manufactured in Poland

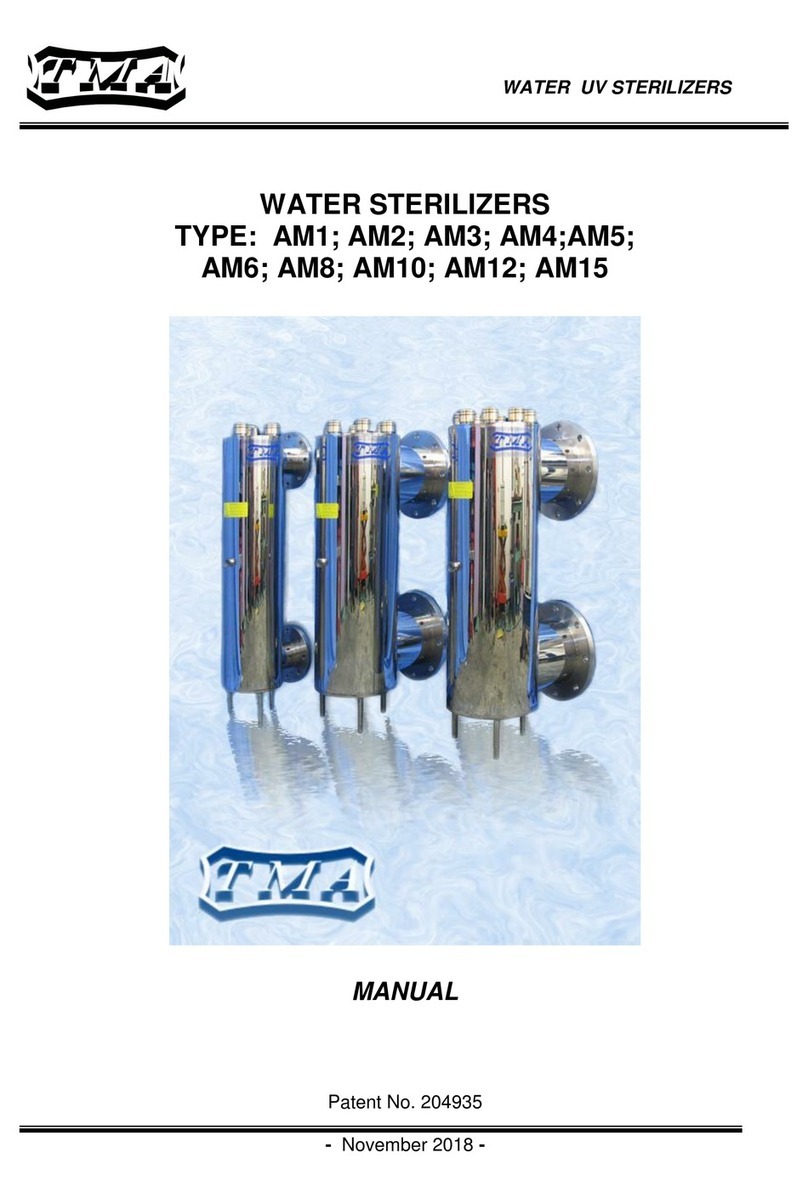

WATER STERILIZERS

V SERIES

MODELS: V9;V12; V20; V20LA; V25; V25LA;

V35; V40; V80; V120

MANUAL

Patent no. 204935

Version - November 2018

WATER AND AIR UV STERILIZERS

TMA

V9 –V120

2

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

TABLE OF CONTENTS:

1. GENERAL INFORMATION ...........................................................................................................4

2. APPLICATIONS.............................................................................................................................5

3. TECHNICAL DESCRIPTION ..........................................................................................................5

4. TECHNICAL SPECIFICATION.......................................................................................................6

5. INSTRUCTIONS FOR INSTALLATION AND OPERATION .............................................................8

5.1. CORRECT ASSEMBLY OF THE CHAMBER ............................................................................8

5.2. CORRECT ASSEMBLY OF THE ELECTRICAL ENCLOSURE ...................................................9

6. CONNECTION OF SOLENOID VALVE OR LEADING THE ALARM SIGNAL OUT IN V20LA,

V25LA, V40, V80, V120.............................................................................................................10

6.1. CONNECTION OF SOLENOID VALVE ...............................................................................11

6.2. LEADING OUT THE ALARM SIGNAL ...................................................................................11

6.3. REMOTE-CONTROLLED ON/OFF SWITCH (IN V20LA-V120)............................................11

7. MAINTENANCE..........................................................................................................................11

8. DESCRIPTION OF INDICATORS IN ELECTRICAL ENCLOSURES...............................................12

8.1. IN V9, V12, V20, V25, V35 ..................................................................................................12

8.2. IN V20LA, V25LA, V40, V80, V120 .....................................................................................13

9. V SERIES STERILIZERS SERVICE...................................................................................................14

9.1. REPLACEMENT OF UV LAMP .............................................................................................14

9.2. RESETTING THE COUNTER IN THE ALARM SYSTEM /IN V20LA, V25LA, V40, V80, V120/ 14

9.3. REPLACEMENT AND CLEANING OF THE QUARTZ SLEEVE /FRAGILE AND BRITTLE/.......15

9.4. TROUBLESHOOTING...........................................................................................................15

10. SPARE PARTS LIST.......................................................................................................................16

11. GRAPHIC ASSEMBLY INSTRUCTIONS .......................................................................................17

11.1. ASSEMBLY OF THE STERILIZERS WITH BRACKETS –V20,V20LA,V35,V40, V80, V120 .......17

11.2. ASSEMBLY OF THE ELECTRICAL ENCLOSURES IN V20LA, V25LA, V40, V80, V120 ........18

11.3. ASSEMBLY OF V9, V12, V25, V25LA ..................................................................................19

11.4. ASSEMBLY OF V20, V20LA, V35, V40, V80........................................................................20

11.5. ASSEMBLY OF V120 ............................................................................................................21

12. DECLARATION OF CONFORMITY............................................................................................22

13. HYGIENIC CERTIFICATE ............................................................................................................23

14. SHIPPING....................................................................................................................................24

15. WARRANTY ................................................................................................................................24

TMA

V9 –V120

3

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

USER SAFETY

WARNING!!!

This device may only be operated and installed by qualified

personnel. Before installation, servicing or repairs verify the qualifications

and limit these activities to such personnel. Any activities on this device

can only proceed after thorough familiarization with this instruction.

Noncompliance with the precautions listed hereon might expose the

personnel to serious bodily harm (damage to human skin from UV

radiation), or damage to the device alone. The manufacturer, TMA, is not

responsible for damage to the device caused by improper installation,

maintenance and operation.

READ THE MANUAL

Before proceeding with any activity with the sterilizers read the manual.

Familiarize the personnel with the manual and safety instructions. Retain the manual for

reference during the whole time the device is in operation. All precautions and warnings shall

be obeyed by the user at all times during the operation of the device.

UV RADIATION

TMA UV Sterilizers use lamps that emit UVC radiation. The design of the sterilizers ensures the

safety of the user. Direct exposure to UV radiation is harmful to human skin and sight. As a result

of direct UV radiation, reddening of skin, serious burns or ultimately loss of eyesight may occur

(depending on the time of exposure). In such cases one shall contact a physician as soon as

possible. Direct exposure to UVC radiation should be strictly avoided. UVC radiation used for

disinfection cannot be used for medicinal or cosmetic purposes.

POWER SUPPLY

The device is exclusively designed to be supplied from 220-230V 50Hz mains. It shall be installed

and grounded in accordance with this manual and the local electrical code.

To guard against electrical shock, unplug the device every time work is to be done on it.

GROUNDING

Operation of the device without connected grounding is inadmissible!

Ungrounded operation might lead to occurrence of electrical shock and serious bodily harm

with death included.

OPERATION SAFETY/SERVICE

The use of original parts provided by TMA ensures appropriate safety and UV disinfection

efficacy conditions. All maintenance activities on this device can only be performed by

qualified personnel. Noncompliance with the safety precautions as well as inadequate use of

the device may result in body and eyesight damage.

TMA

V9 –V120

4

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

1. General information

Thank you for your purchase of TMA manufactured UV sterilization product. All the raw

materials and components are of best quality and were processed or manufactured in the EU

countries. Sterilizers made by TMA are made from highest quality stainless steel. The thickness of the

chamber wall guarantees high factor of safety in operation. All of the devices successfully

completed 30 Atm pressure trials.

The innovative design of the TMA sterilizers allows for continuous work of the devices even

without the flow of water through the chamber. The design of the chamber contributes to lower

incidence of sediment from calcium and magnesium on the surface of the quartz sleeve.

In the sterilizers of the V series we introduced additional guides for the quartz sleeves easing

the assembly and disassembly. The solution allows for the same ease of assembly for device working

horizontally, vertically or at any other angle. The guide prevents the quartz sleeve from breaking

during routine maintenance. The turbulent flow induced by the guide increases the efficiency of

disinfection. During the first 100 hours of operation the efficiency of disinfection is greater by 15%

from the rated for the device.

We provide you with devices equipped with a new electronic control panel (in V20LA,

V25LA, V40, V80, V120) that indicates:

Total work time (days),

Remaining time until UV lamp replacement (days),

Number of ON/OFF cycles,

Visual and audible signal 7 days before the required UV lamp replacement,

Visual and audible signal when UV lamp replacement is required,

Visual and audible signal when UV lamp is burnt out.

The detailed instructions of the new panel are provided on the casing of the electrical

enclosure.

Sterilizers of the V series have a steel muff with a hood that functions as a sight glass. This

innovative solution of a light muff allows for optical control of the working condition of the lamp.

We hold high hopes that the implementations of these innovative solutions in the V series

sterilizers fulfill your expectations concerning the effectiveness and operation of our devices.

The device delivered to you shall be protected from severe shocks and drops, as the quartz

sleeve and UV lamps are brittle and fragile. The sterilizer shall be transported exclusively in horizontal

position. The manufacturer is not responsible for damage arising from the conditions of transport.

Before installation and operation one shall read the instructions and implement the

precautions listed. Noncompliance with these precautions is grounds for releasing the manufacturer

from warranty obligations.

The used electrical and electronic equipment with the crossed-out rubbish bin symbol shall be collected

separately. It is prohibited to put the used equipment with other waste. Inadequate use of the used

equipment may have a negative impact on the environment and people's health. Separate collection

of the equipment contributes to its re-use and recycling. The obligation of the used equipment selective

collection rests on the user, who should provide it to the used equipment collector.

TMA devices are equipped with lamps that emit UV radiation, light sources that contain mercury. The

owners of waste lamps containing mercury are obliged to collect them separately for further re-use and

disposal.

TMA

V9 –V120

5

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

2. Applications

Disinfection with UV radiation is a reliable, simple and inexpensive method of sterilization.

The use of this method is possible whenever microbiological risk exists.

The applications of this method are, among many others:

Potable water in private and municipal installations

Potable and process water in restaurant and hotel business

Process water in the production of medicines and cosmetics

Water used in processing food

Water in beverage production

Water in swimming pools and fountains

Control of green algae and bacterias in ponds

And many more

The sterilizer uses special low pressure UV lamp that produces UV radiation of wavelength of

254 nm, which causes photochemical reaction damaging DNA of microorganisms and their

disintegration.

Water flowing from the sterilizer is ready for immediate use. UV sterilization does not change the

chemical makeup of water.

THERE IS NO POSSIBILITY OF OVERDOSING UV RADIATION

DURING WATER STERILIZATION IN THE CHAMBER.

MINIMAL FLOW OF WATER IS NOT REQUIRED.

INCREASED FLOW THROUGH THE STERILIZER LOWERS THE DOSAGE DELIVERED TO

MICROORGANISMS AND LOWERS EFFICIENCY OF DISINFECTION.

3. Technical description

Sterilizer’s chamber is made from stainless steel AISI 304 or AISI 316.

Power supply is 220-240V + 8%, - 10%, 50-60 Hz.

Electric shock protection by earth terminal.

Power optical indicator in the electrical enclosure enables the indication of the working

condition of the lamp.

Sight glass muff enables the indication of the working condition of the UV lamp.

Models V9,V12,V20,V25,V35 are equipped with a simple power supply.

Models V20LA,V25LA,V40,V80,V120 are equipped with an alarm system with a digital display

that shows the remaining work time of the UV lamp, total work time of the device and the

number of on/off switch cycles. In these models there is a possibility of connecting a solenoid

valve or leading the alarm signal out.

No. HK/W/0521/01/2015

Valid until: 2020-07-16

TMA

V9 –V120

6

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

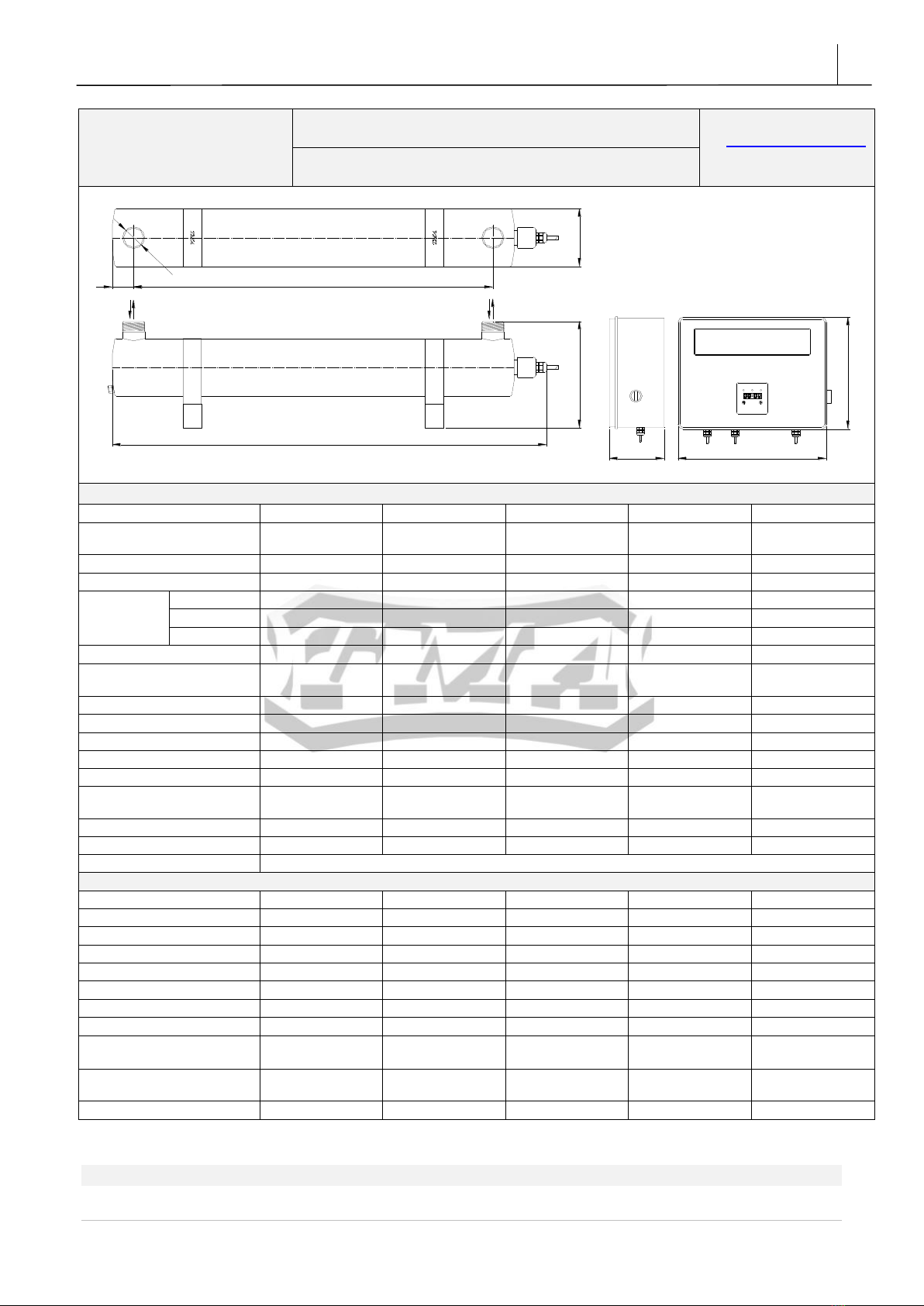

4. Technical specification

TMA

Białostoczek 26;

gm. Zabłudów,

15-592 Białystok

WATER STERILIZERS- V series

Tel. 85 743 12 46; 85 687 14 50

www.tma.pl,www.tma.com.pl;

e-mail:biuro@tma.pl

NIP: 542-000-84-13

Models: V9; V12; V20; V20LA; V25

POWER CORDUV LAMP CABLE

ELECTRICAL ENCLOSURE

www.tma.pl biuro@tma.pl +48 85 743 12 46

®

WYPRODUKOWANE W POLSCE / MADE IN POLAND

ZASILACZ DO STERYLIZATORA UV

POWER SUPPLY FOR UV STERILIZER V6 - V40

Un [ V ] In [ A ] fn [ Hz ] ?Uo ut [ V ]

~220...240 AC 0,10...0,18A 50...60 ?0.96 <330

TMA / BIAŁOSTOCZEK 26, GM. ZABŁUDÓW / 15-592 BIAŁYSTOK / POLSKA

ODŁĄCZYĆ ZASILANIE PRZED INSTALOWANIEM LUB WYMIANĄ ELEMENTÓW

/DISC ONNECT LINE VOLTAGE BEFORE INSTALLINGOR REPLACING PARTS

PRZED INSTALACJĄ PRZECZYTAĆ INSTRUKCJĘ/ R EAD MANUALBEFORE

INSTALLATION

PRZEZNACZONE TYLKO DO PRACY ZE STERYLIZATORAMIFIRMY TMA /

SUITABLE ONLY FOR TMA UV STERILIZERS

ZAWIERA CZĘŚCI NIE PODLEGAJĄCE SERWISOWANIU / NON SERVICEABLE

PARTS INSIDE

UWAGA ! CAUTION !

WYSOKIE NAPIĘCIE, ZAGROŻENIE PORAŻENIA

PRĄDEM ELEKTRYCZNYM - NIE OTWIERAĆ ! /

HIGHV OLTAGE ELECTRICAL SHOCK

HAZARD- DO NOT OPEN !

TYLKO DO UŻYTKU WEWNĘTRZNEGO /

FORIN DOOR USE ONLY

OSTRZEŻENIE ! / DANGER !

PROMIENNIKI UV NALEZY WYMIENI AĆ PO UPŁYWIE OKRESU ICH ŻYWOTNOŚCI (PATRZ INSTRUKCJA) /

UVLAMPS SHOULD BE REPLAC ED AFTER THEIR ENDOF LIFE TIME (SEE MANUAL)

a

b c

LZ

DN

INLET / OUTLET

DY

INLET / OUTLET

X

L1

TECHNICAL SPECIFICATIONS:

Model

V9

V12

V20

V20LA

V25

Power Supply

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

Material

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Finish

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Dimensions

X / Y / Z

395x94x70mm

640x100x70mm

660x130x240mm

660x130x240mm

960x100x70mm

L

274mm

518mm

495mm

495mm

815mm

DN / D

DN15 (R ½”)

DN20 (R 3/4”)

DN25 (R 1”)

DN25 (R 1”)

DN25 (R 1”)

Safety Class

IP66

IP66

IP66

IP66

IP66

No. of UV Lamps x Nominal

Power

1x 15W

low pressure

1x 24W

low pressure

1x 24W

low pressure

1x 24W

low pressure

1x 40W

low pressure

Life of UV Lamps

About 9 000 h

About 9 000 h

About 9 000 h

About 9 000 h

About 9 000 h

Operating Temperature

0,5-45 0C

0,5-45 0C

0,5-45 0C

0,5-45 0C

0,5-45 0C

Operating Pressure

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

UV Power at 254nm

4,0 W

7,8W

7,8W

7,8W

15,0W

Nominal Power

16W

25W

25W

25W

41W

Nominal Flow at transmittance

T10=95%,dose 400J/m2

0.50m3/h

1.00m3/h

2.00m3/h

2.00m3/h

2.00m3/h

Optical Power Indicator

Yes

Yes

Yes

Yes

Yes

Drain Valve

No

No

Yes

Yes

Yes

Orientation

From horizontal to vertical

ELECTRICAL ENCLOSURE

Material

Aluminum/ABS

Aluminum/ABS

Aluminum/ABS

Plastic ABS

Aluminum/ABS

Safety Class

IP 41

IP 41

IP 41

IP65

IP 41

Dimensions

390x83x70mm

390x83x70mm

390x83x70mm

325x250x120mm

390x83x70mm

Audible UV Lamp Fault Alarm

No

No

No

No

No

Optical UV Lamp Fault Indicator

Yes

Yes

Yes

Yes

Yes

Optical Power Indicator

Yes

Yes

Yes

Yes

Yes

Total work time counter

No

No

No

Yes

No

Solenoid Valve Terminals

No

No

No

Yes

No

Terminals for Remote Alarm

Indicator

No

No

No

Yes

No

UV Intensity Measurement

System

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

Weight with Enclosure

2.7kg

3.6kg

6.2kg

7.4kg

4.7kg

TMA

V9 –V120

7

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

TMA Company reserves the right to make design changes without notice.

TMA

Białostoczek 26;

gm. Zabłudów,

15-592 Białystok

WATER STERILIZERS-V series

Tel. 85 743 12 46; 85 687 14 50

www.tma.pl,www.tma.com.pl;

e-mail:biuro@tma.pl

NIP: 542-000-84-13

Models: V25LA; V35; V40; V80; V120

L

Z

DN

b

ac

NALEPKA

L1

XY

INLET/OUTLET ELECTRICAL ENCLOSURE

INLET/OUTLET

TECHNICAL SPECIFICATIONS:

Model

V25LA

V35

V40

V80

V120

Power Supply

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

~220V-240V 50-

60Hz

Material

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Finish

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Satin (Ra<0,8µm)

Dimensions

X / Y / Z

960x100x70mm

960x130x240mm

960x130x240mm

960x130x240mm

960x130x240mm

L

815mm

880mm

880mm

880mm

880mm

DN / D

DN25 (R 1”)

DN40(R1 1/2”)

DN40 (R 1 1/2”)

DN40 (R 1 1/2”)

DN50 (R 2”)

Safety Class

IP66

IP66

IP66

IP66

IP66

No. of UV Lamps x Nominal

Power

1x 40W

low pressure

1x 40W

low pressure

1x 40W

low pressure

1x 75W

low pressure

1x 130W

low pressure

Life of UV Lamps

About 9 000 h

About 9 000 h

About 9 000 h

About 9 000 h

About 9 000 h

Operating Temperature

0,5-45 0C

0,5-45 0C

0,5-45 0C

0,5-45 0C

0,5-50 0C

Operating Pressure

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

10bar(1MPa)

UV Power at 254nm

15,0W

15,0W

15,0W

25,0W

46,0W

Nominal Power

41W

41W

41W

80W

160W

Nominal Flow at transmittance

T10=95%,dose 400J/m2

2.00m3/h

3.60m3/h

3.60m3/h

5.90m3/h

11.00m3/h

Optical Power Indicator

Yes

Yes

Yes

Yes

Yes

Draining System

No

Yes

Yes

Yes

Yes

Orientation

From horizontal to vertical

ELECTRICAL ENCLOSURE:

Material

Plastic ABS

Aluminum/ABS

Plastic ABS

Plastic ABS

Plastic ABS

Safety Class

IP65

IP 41

IP65

IP65

IP65

Dimensions

325x250x120mm

390x83x70mm

325x250x120mm

325x250x120mm

325x250x120mm

Audible UV Lamp Fault Alarm

Yes

Yes

Yes

Yes

Yes

Optical UV Lamp Fault Indicator

Yes

Yes

Yes

Yes

Yes

Optical Power Indicator

Yes

Yes

Yes

Yes

Yes

Total work time counter

Yes

No

Yes

Yes

Yes

Solenoid Valve Terminals

Yes

No

Yes

Yes

Yes

Terminals for Remote Alarm

Indicator

Yes

No

Yes

Yes

Yes

UV Intensity Measurement

System

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

On demand/

Additional charge

Weight with Enclosure

5.9kg

8.6kg

9.8kg

10.2kg

11.5kg

TMA

V9 –V120

8

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

ATTENTION!

Minimal flow of water is not required for the devices to work.

Increased flow through the sterilizer lowers the efficiency of disinfection.

The device is comprised of stainless steel chamber and electrical enclosure.

5. Instructions for installation and operation

5.1. CORRECT ASSEMBLY OF THE CHAMBER

(graphic instructions at the end of the Manual)

INLET OUTLET

INLET

OUTLET

Vertical

INLET OUTLET

INLET

OUTLET

Diagonal

INLET/OUTLET INLET/OUTLET

INLET/OUTLET INLET/OUTLET

Horizontal

ATTENTION!!!

The sterilizer shall be mounted in a way that prevents the creation of air pockets in the chamber:

connectors shall be placed upwards in the horizontal position, water inlet on the bottom in the

vertical and diagonal position. The UV lamp shall always be mounted in a horizontal or upward

position.

TMA

V9 –V120

9

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

FILTER min.

0,1 mm

INLET

CONTAMINATED

WATER

POWER LINE

ELECTRICAL ENCLOSURE

OUTLET

DISINFECTED

WATER

WATER SAMPLE

TAKE-UP VALVE

DISTANCE EQUAL TO THE

LENGHT OF THE STERILISER

SHUT-OFF VALVES

HORIZONTAL MOUNTING ARRANGEMENT OF THE UV STERILISER

www.tm a.pl biuro @tma.pl +4 8 85 743 12 46

®

WYPRODUKOWANE W POLSCE /MADE INPOLAND

ZASILACZ DO STERYLIZATORA UV

POWER SUPPLY FOR UV STERILIZER V6 - V40

Un [ V ] In [ A ] fn [ Hz ] ?Uout [ V ]

~220...240AC 0,10...0,18A 50...60 ?0.96 <330

TMA / BIAŁOSTOCZEK 26, GM. ZABŁUD ÓW / 15-592 BIAŁYSTOK / POLSKA

ODŁĄCZYĆ ZASILANIE PRZED INST ALOWANIEM LUB WYMIANĄ ELEMENTÓW

/DISCO NNECT LINE VOLTAGE BEFORE INSTALLING OR REPLACINGPARTS

PRZED INSTALACJĄ PRZECZYTAĆ INSTRUKCJĘ / READ MANUAL BEFORE

INSTALLATION

PRZEZNACZONE TYLKO DO PRACY ZE STE RYLIZATORAMIFIRMY TMA/

SUITABLE ONLY FOR TMA UV STERILIZERS

ZAWIERA CZĘŚCI NIE PODLE GAJĄCE SERWISOWANIU / NON SERVICEABLE

PARTS INSIDE

UWAGA ! CAUTION !

WYSOKIE NAPIĘCIE, ZAGROŻENIE PORAŻENIA

PRĄDEM ELEKTRYCZNYM - NIE OTWIERAĆ ! /

HIGHVO LTAGE ELECTRICAL SHOCK

HAZARD- DO NO TOPEN !

TYLKO DO UŻYTKU WEWNĘTRZNEGO /

FORINDO OR USEONLY

OSTRZEŻENIE ! / DANGER !

PROMIENNIKI UV NALEZY WYMIENIAĆ PO UPŁYWIE OKRESU ICH ŻYWOTNOŚCI (PATRZ INSTRUKCJA) /

UVLAMPS SHOULD BE REPLACED A FTER THEIR END OF LIFE TIME (SEE MANUAL)

1) Temperature range for installation is from 5 to 45oC.

2) Upstream of the intake install potable water filter. Minimum rating 0.1 mm, recommended

0.05 mm. The use of mesh screen filters is recommended (string wound filters may cause the

multiplication of microorganisms).

3) Install manual cut-off valves, upstream of intake and downstream of outlet.

4) Close solenoid valves.

5) Connect the sterilizer chamber to water supply.

6) Mount the quartz sleeve into the chamber.

7) Place o-rings over the quartz sleeve. Next place the washer over the o-ring, screw the muff

onto this assembly. Turn the muff to considerable resistance in order to tighten the seal. Use

provided spanner to retighten the muff. Tightening the muff shall not break the sleeve. The

use of any sealing materials for screwing the muff is prohibited.

8) Slowly open the solenoid valves and check the seal.

9) After checking the seal, place the UV lamp in the sleeve.

10) Push the socket on the UV lamp and slide it inside the quartz sleeve.

11) Push lamp hood on the muff.

12) Check if the strain relief cap is properly screwed.

5.2. CORRECT ASSEMBLY OF THE ELECTRICAL ENCLOSURE

1) Mount the electrical enclosure on the wall, at least 120 cm from the floor.

2) The electrical enclosure in V20LA, V25LA, V40, V80, V120 shall be mounted with the provided

holders –check the graphic assembly instructions on p.18.

3) Plug the unit into grounded outlet 220-230V, 50-60 Hz.

4) Sight glass muff enables indication of working condition of the lamp.

5) Replace the lamp according to the indications for each model /see the table on p.6-7/.

TMA

V9 –V120

10

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

6. Connection of solenoid valve or leading the alarm signal out in

V20LA, V25LA, V40, V80, V120

BALAST ON/OFF SWITCH N L ~230V

1

1 221

ELECTRICAL ENCLOSURE

OUTLET

DISINFECTED WATER

WATER SAMPLE

TAKEUP VALVE

1.REMOVE DOORS

OF THE ELECTRICAL

ENCLOSURE

SOLENOID VALVE

UV STERILIZER

IN MODELS V20LA-V120

After removing the bridge, it is possible to

connect remote-controlled switch to the

terminals ON/OFF /caution: voltage 230V!/.

Contacts closed - sterilizer on

Contacts open- sterilizer off

IN MODELS V20LA-V120

It is possible to connect solenoid valve type NZ

(normally closed) max. 2a, or alarm signal to the

terminals 1 & 2 /neutral/ on the electronic plate in

electrical enclosure/.

Contacts closed - sterilizer working properly

Contacts open- UV lamp damage

- Alarm on

- Power cut off

POWERPOWER

2. TO THE TERMINALS 1 & 2 ON

ELECTRONIC PLATE CONNECT

SOLENOID VALVE OR ALARM SIGNAL

ELECTRONIC PLATE

IN MODELS V20LA-V120

FUSE

ATTENTION! /APPLIES TO V20LA, V25LA, V40, V80, V120/

Any fault or burnout of the lamp shall cause intermittent light and audible signal on the

display of the alarm system /see pt. 14/

In the case of installing solenoid shut-off valve ( terminals 1 & 2) upstream /or downstream/ of

the sterilizer, tripping alarm or power interruption causes immediate shutting off of fluid flow to the

chamber of the sterilizer /diagram 1a/. Terminals 1 & 2 have internal connection broken in case of

alarm tripping and as such are neutral. Power to solenoid shut-off valve shall be connected through

terminals 1 & 2.

Solenoid shut-off valve serves the purpose of preventing unsterilized fluid entering the

installation downstream of the sterilizer in the case of power interruption or lamp failure.

TMA

V9 –V120

11

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

6.1. CONNECTION OF SOLENOID VALVE

Connect solenoid valve type NZ (normally closed) max. 2A to the terminals 1 & 2 /neutral/ on the

electronic plate in electrical enclosure.

Contacts 1 & 2 start working after a preset time delay of 2-3 min –it is a time necessary for the

device to become fully operational. During this time the contacts remain open. After 2-3 min, the

device works according to these rules:

CONTACTS 1-2 CLOSED

–sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- power cut-off

6.2. LEADING OUT THE ALARM SIGNAL

Connect alarm signal wires to the terminals 1 & 2 on electronic plate /neutral/.

Contacts 1 & 2 start working after a set time delay of 2-3 min –it is a time necessary for the

device to become fully operational. During this time the contacts remain open. After 2-3 min, the

device works according to these rules:

CONTACTS 1-2 CLOSED

–sterilizer working properly

CONTACTS 1-2 OPEN

- UV lamp damage

- Alarm on

- power cut-off

6.3. REMOTE-CONTROLLED ON/OFF SWITCH

/CAUTION: VOLTAGE 230V/ BEFORE ASSEMBLY DISCONNECT THE POWER SUPPLY

After removing the bridge, it is possible to connect remote-controlled switch to the ON/OFF

terminals on the electronic plate.

ON/OFF TERMINALS CLOSED

–sterilizer on

ON/OFF TERMINALS OPEN

–sterilizer off

7. Maintenance

a) UV radiation damages skin and eyesight. It is forbidden to directly observe UV lamp during

operation.

b) There is no need for minimal flow through the device as it is designed in such a way that

there may be no flow through the chamber with no damage to the sterilizer.

c) UV sterilizer should run constantly - its long-term shutdown may cause bacterial or viral

reinfection in the installation, which is very difficult to remove.

d) It is recommended to install a filter (e.g. mesh screen ) upstream of the sterilizer's input (using

string wound filters may cause bacterial multiplication).

e) Water not fit for consumption may require treatment, i.e. de-ironing, softening or filtering. If in

doubt, please contact your dealer.

TMA

V9 –V120

12

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

f) In case of high turbidity and waste water, the choice of equipment and efficiency should be

made by the dealer or producer.

g) Sterilizers must be sized for the maximum momentary flow of water (matching them to the

daily flows may result in incomplete disinfection).

h) Avoid frequent turning on and off the equipment. One on-off cycle lowers the UV lamp life

by about 10-20 hours.

i) Sterilizers should not be installed in such a way that their work depended on other devices,

e.g. pumps, pressure tanks, filters.

j) Flow rate through the device can be increased, however, this lowers the delivered dosage

and lowers the efficiency of disinfection.

k) It is recommended to check cleanness of the quartz sleeve whenever the UV lamp is

replaced.

l) Cleaning the quartz sleeve is necessary anytime any deposit is noticed on its surface.

Neglecting this may decrease the efficiency of disinfection.

m) Inlet and outlet valves shall be opened slowly to prevent the rush of fluid hitting and

damaging the quartz sleeve.

n) The device needs about 2 minutes to reach full efficiency at water temperature of about 12-

16°C. If the water is at temperature 5-12°C, it might take about 3-5 minutes.

o) If the sterilizer is left idle for longer period of time or it can freeze, we recommend that the

water be drained from the chamber. The chamber is provided with a drain valve.

p) Bioassay samples shall be collected into sterile opaque containers.

8. Description of indicators in electrical enclosures

Illuminated indicators in the electrical enclosure indicate that the device operates correctly

or that there are problems that can be solved in the following way:

8.1. IN V9, V12, V20, V25, V35

UV lamp work indicator

sight glass muff

Power supply

Green light

Problem

Action

ON

ON

No fault

-

OFF

ON

Old or faulty UV

lamp.

Shut off power supply.

Replace UV lamp.

OFF

OFF

No power connected.

Check power.

OFF/VISIBLE ORANGE

LIGHT

ON

UV lamp damaged or

depressurized.

Shut off power supply.

Replace UV lamp.

TMA

V9 –V120

13

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

8.2. IN V20LA, V25LA, V40, V80, V120

Display indications

Cause

Solution

- Blinking digit 7 on the display.

- An intermittent sound signal.

- 7 days left to the end of UV

lamp life.

- Change UV lamp in 7 days.

HOLD3s.

PRZYTRZYMAĆ 3 s.

Press and hold the left button

for more than 3 seconds to

silence the sound alarm.

- Blinking number 0 on the

display.

- An intermittent sound signal.

- UV lamp reached the end of

its life.

HOLD3s.

PRZYTRZYMAĆ 3 s.

Press and hold the left button

for more than 3 seconds to

silence the sound alarm

(repeat max 2 times)

- Blinking numbers 8 on the

display.

- Blinking 3 LEDs over the display.

- Continuous sound signal.

- UV lamp is damaged or

reached the end of its life time.

Change UV lamp.

- The display shows weird signs.

-2 or 3 LEDs light up over the

display.

- Possible fault of the display or

the microprocessor.

Contact the dealer.

- No indication on the display.

- No indication on LED above

display.

- No audible alarm.

- No power connected at the

input of the electrical

enclosure.

- Check power.

- Check the fuse in the alarm

system.

-No indication on the display or

-blinking digits or

-alarm signal is on.

-Loosened 6 wire tape

connecting the display with the

power supply.

- Shut off power supply.

- Disconnect the tape.

- Reconnect the tape.

TMA

V9 –V120

14

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

9. V series sterilizers service

9.1. REPLACEMENT OF UV LAMP

(graphic instructions at the end of the Manual)

a) Disconnect the power supply,

b) Allow for the lamp to cool down from operating temperature,

Replacement of the UV lamp does not require the stop of fluid flow through the chamber

c) Loosen the strain relief grip on cable,

d) Carefully take off the lamp hood with the UV lamp from the quartz sleeve,

DO NOT UNSREW THE MUFF!

e) Remove the sockets from the connectors of the UV Lamp,

f) Remove old UV lamp from the quartz sleeve,

g) Carefully place the new UV lamp in the sleeve,

h) Reverse the remaining steps.

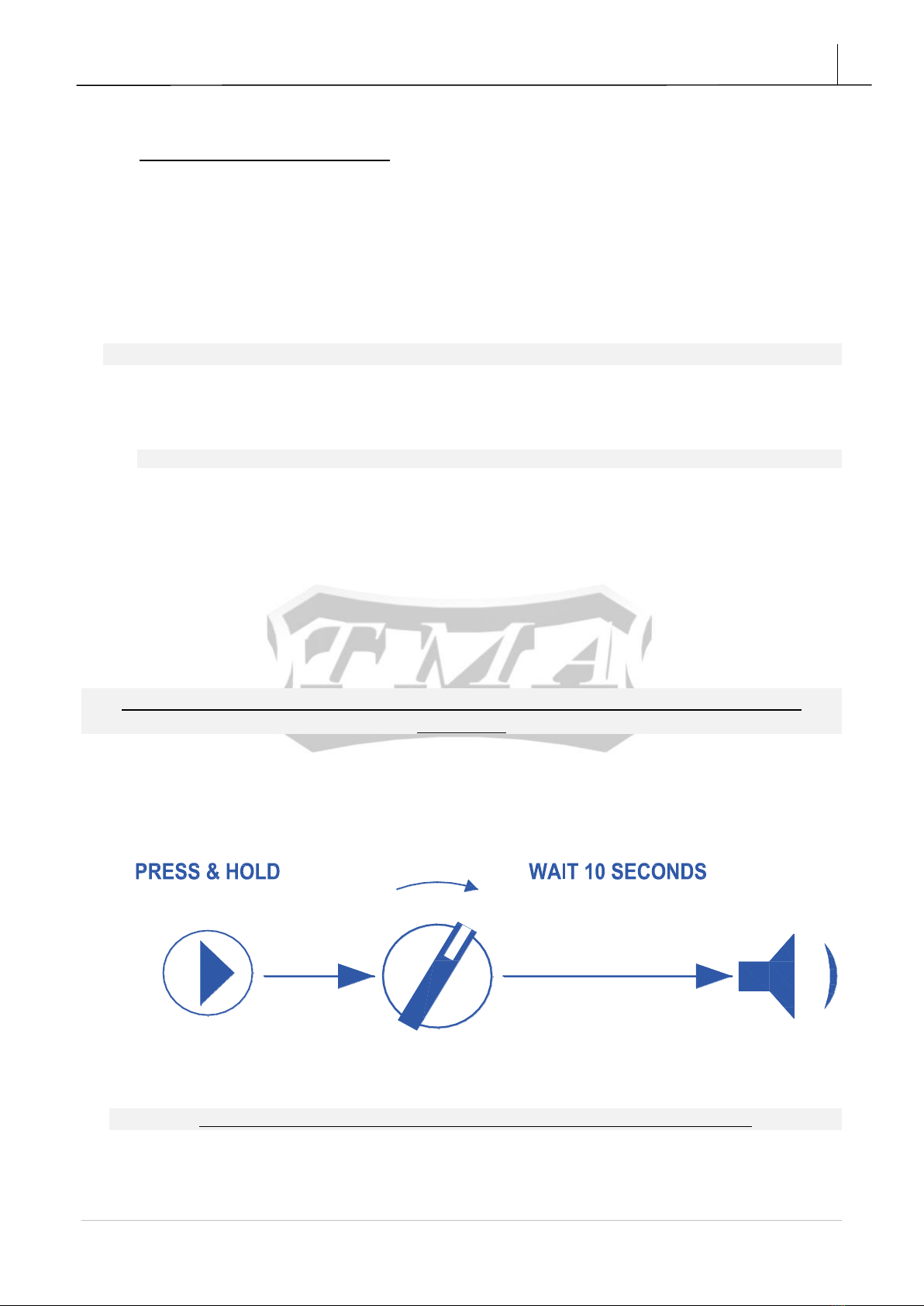

9.2. RESETTING THE COUNTER IN THE ALARM SYSTEM / in V20LA, V25LA,

V40, V80, V120/

The counter in the alarm system needs to be reset each time the UV lamp is

replaced.

a) Disconnect from power supply.

b) Replace the UV lamp –see pt. 9.1. REPLACEMENT OF THE UV LAMP.

c) Connect device to power supply (power switch should be turned off).

d) Press and hold the right button on the display for about 10 s.

01

NACISNĄĆ I PRZYTRZYMAĆ OK

CZEKAJ 10 SEKUND

e) Turn on the device while still holding the right button on the display.

To reset the counter the UV lamp must be connected and fully functional.

f) A short audible signal will confirm the resetting of the counter.

TMA

V9 –V120

15

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

9.3. REPLACEMENT AND CLEANING OF THE QUARTZ SLEEVE /FRAGILE

AND BRITTLE/

(graphic instructions at the and of the manual)

a) Disconnect the power supply,

b) Cut off the liquid flow through the chamber,

c) Remove the water from the chamber,

d) Allow for the lamp to cool down from operating temperature,

e) Remove the UV lamp from the sleeve / see pt. 9.1 /.

f) Unscrew the steel muff using the special spanner,

g) Take off the washer and o-ring from the quartz sleeve,

h) Pull out the quartz sleeve from the sterilizer chamber,

i) Every time the UV lamp is replaced, if it is necessary to clean the quartz sleeve, use common

glass cleaners and dry thoroughly the interior of the sleeve.

j) A new o-ring must be used each time the UV lamp is replaced.

k) Place the sleeve in the chamber of the sterilizer, put on a new o-ring and a washer,

l) Hand tighten the muff with the new o-ring. Use provided spanner to retighten the muff,

m) Open the shut-off valves slowly to pressurize the chamber and watch for leaks at the o-ring,

9.4. TROUBLESHOOTING

Problem

Cause

Action

Burned out UV Lamp.

End of lamp life caused by

number of working hours or

number of on-off cycles.

Disconnect the device from the power

supply.

Replace the UV lamp.

Burned out UV Lamp.

Water inside quartz

sleeve.

Muff not tightened

sufficiently.

Worn out o-ring.

Disconnect the device from the power

supply.

Take quartz sleeve out, dry interior,

change o-ring, and assemble back.

Tighten muff. Replace the UV lamp.

UV lamp electrode glows

red or yellow.

Damaged or depressurized

UV lamp.

Disconnect the device from the power

supply.

Replace the UV lamp.

TMA

V9 –V120

16

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

10. Spare parts list

V SERIES UV WATER STERILIZER

NO.

TITLE

V9–V120 –SPARE PARTS LIST

3

9

3

24

18

11

7

5

6MODELV120

No.

PART

No.

of

pcs.

V9

V12

V20/

20LA

V25/

V25LA

V35

V40

V80

V120

1

STRAIN RELIEF

1 pc.

02.01

02.01

02.01

02.01

02.01

02.01

02.01

02.01

2

LAMP HOOD

1 pc.

02.02.01

02.02.01

02.02.01

02.02.01

02.02.01

02.02.01

02.02.01

01.02.02

3

MUFF

1 pc.

03.04

03.04

03.04

03.04

03.04

03.04

03.04

01.04.02

4

MUFF O-RING

1 pc.

02.03.01

02.03.01

02.03.01

02.03.01

02.03.01

02.03.01

02.03.01

01.03.01

/2pcs./

5

WASHER

1 pc.

02.05

02.05

02.05

02.05

02.05

02.05

02.05

01.05

6

O-RING

1 pc.

02.06

02.06

02.06

02.06

02.06

02.06

02.06

01.06

7

SOCKET

1 pc.

03.08

03.08

03.08

03.08

03.08

03.08

03.08

03.08

8

UV LAMP

1 pc.

09.07

08.07

08.07

10.07

10.07

10.07

11.07

12.07

9

QUARTZ SLEEVE

1 pc.

06.09

08.09

08.09

10.09

10.09

10.09

10.09

12.09

11

DRAIN VALVE

1 pc.

-------

---------

01.12

-------

01.12

01.12

01.12

01.12

TMA

V9 –V120

17

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

11. Graphic assembly instructions

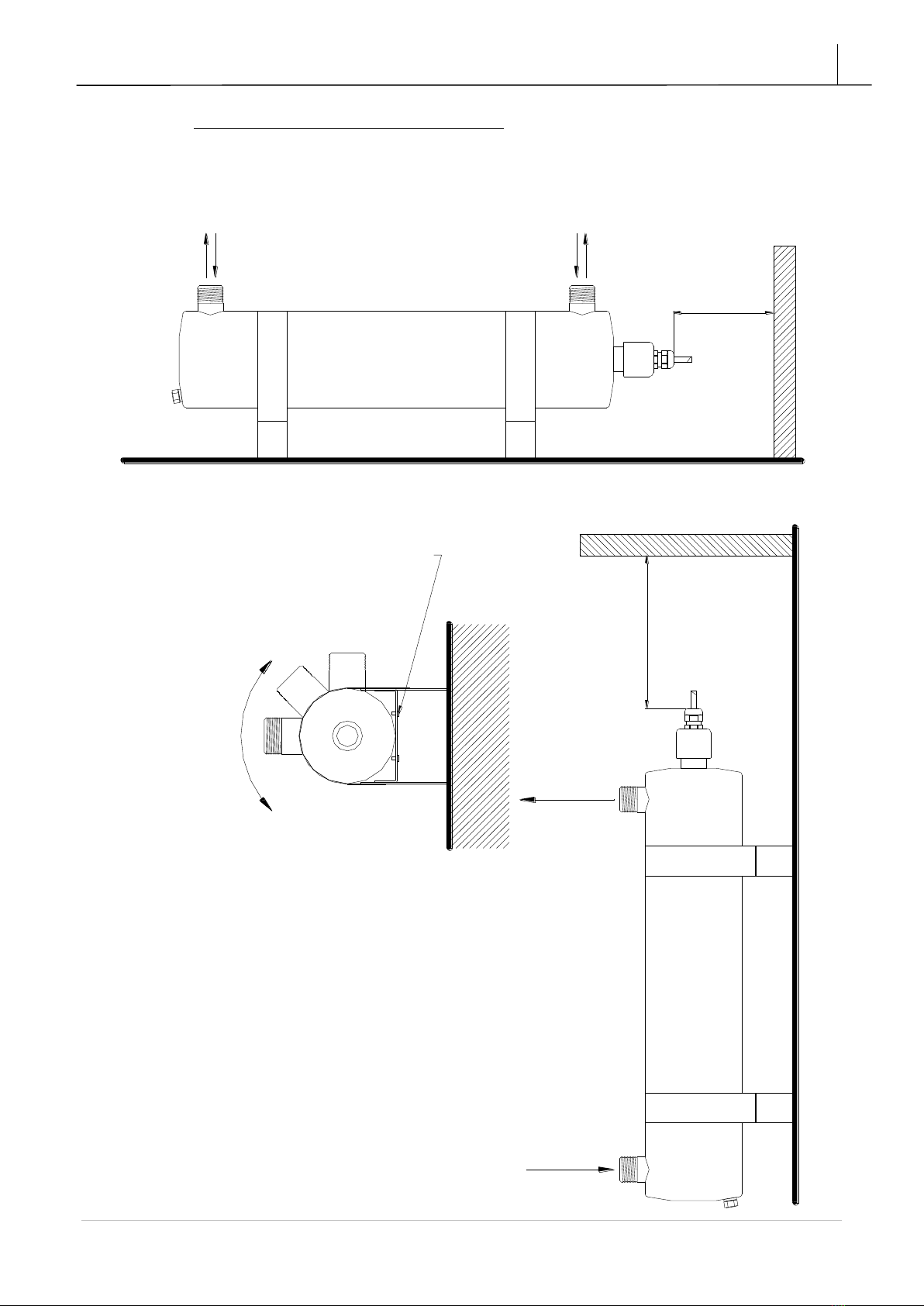

11.1. ASSEMBLY OF THE STERILIZERS WITH BRACKETS –

V20,V20LA,V35,V40, V80, V120

M

M

WHEN THE STERILIZER IS MOUNTED

HORIZONTALY THE INLET END OUTLET CAN

BE LOCATED AT EITHER END.

M - DISTANCE NEED FOR

REPLACMANT OF THE UV LAMP

OUTLET

INLET

WHEN THE STERILIZAR IS MOUNTED

VERTICALY OR AT ANY OTHER ANGLE,

THE OUTLET HAS TO BE LOCATED AT

THE TOP OF CHAMBER

BRACKETS ENABLE THE ADJUSTMENT

OF THE CHAMBER POSITION

FOR THE NEEDS OF INSTALLATION.

1.LOOSEN THE SCREW AND ADJUST

THE POSITION OF THE CHAMBER FOR

THE INSTALLATION NEEDS

2.TIGHTEN THE SCREWS.

TMA

V9 –V120

18

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

11.2. ASSEMBLY OF THE ELECTRICAL ENCLOSURES IN V20LA, V25LA,

V40, V80, V120

Option I

Option I

Option II

Option II

TMA

V9 –V120

19

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

11.3. ASSEMBLY OF V9, V12, V25, V25LA

TMA

V9 –V120

20

TMA | Białostoczek 26,gm.Zabłudów,15-592 Białystok; Poland ; VAT PL5420008413; GIOŚ: E0021166WZ;

Tel. +48 857431246

11.4. ASSEMBLY OF V20, V20LA, V35, V40, V80

This manual suits for next models

10

Table of contents

Other TMA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Barnstead International

Barnstead International Cimarec series Operation manual and parts list

Mi-T-M

Mi-T-M AW-3000-0000 manual

URG

URG URG-3000N Operation manual

Noraxon

Noraxon Ultium 808 user manual

Terra Universal

Terra Universal Cleanroom Airlock Installation and operating guide

Leica

Leica CM1520 Instructions for use