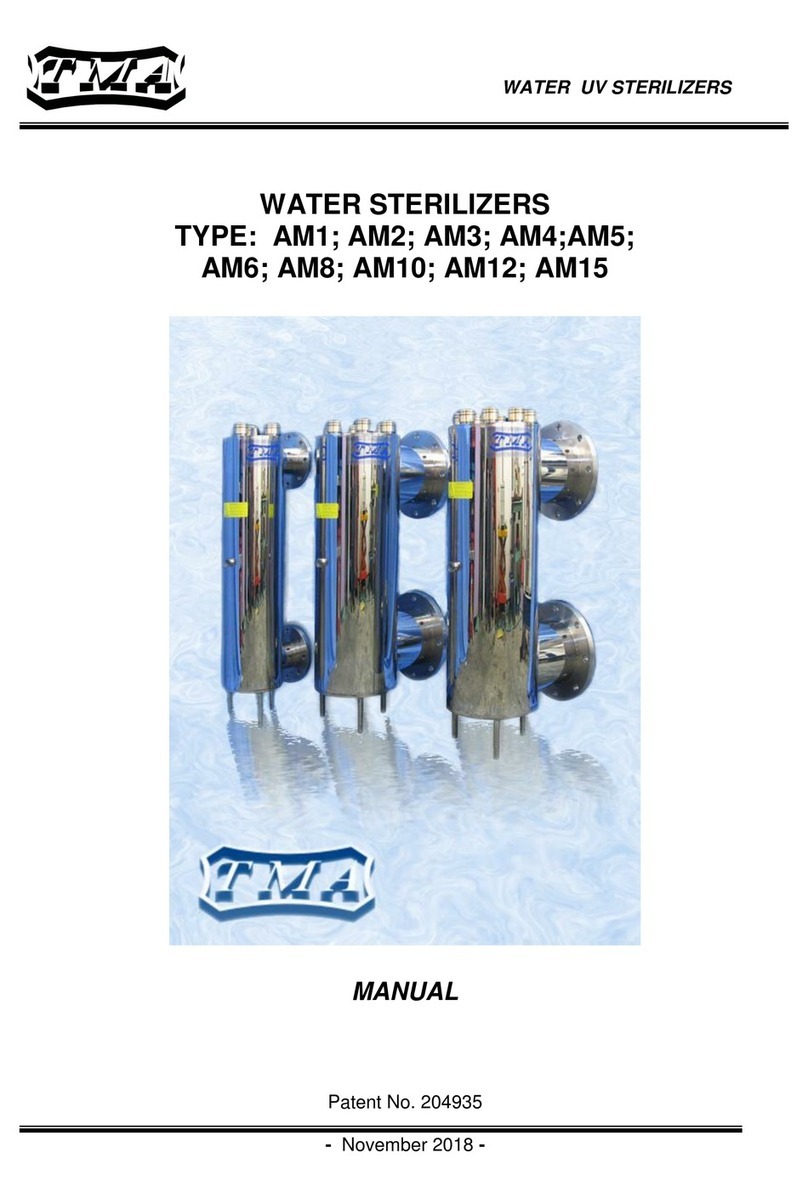

TMA AM1 User manual

WATERSTERILIZERS

TYPE: AM1;AM2;AM3;AM4;AM5;

AM6;AM8;AM10;AM12;AM15

MANUAL

Patent nr204935

- 2012 -

WATER

UV STERILIZERS

TMA

AM1-AM15

2

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

!

User Safety

Warning

1.READTHE MANUAL.

Beforeproceedingwithanyactivitywiththe sterilizersread the manual.

2.RETAINTHE MANUAL.

Retainthe manualforreferenceduringthe wholetimethe deviceisinoperation.

All precautionsand warningsshall be obeyed bythe useratall timesduringthe operation

ofthe device.

3.POWERSUPPLY.

Deviceisexclusivelydesigned tobe supplied from220-230V 50Hzmains. It shall be

installed and grounded inaccordancewiththismanualand the localelectricalcode.

Toguardagainst electricalshock, unplugthe deviceeverytimeworkistobe done on it.

4.GROUNDING.

Operation ofthe devicewithout connected groundingisinadmissible. Ungrounded

operation might lead tooccurrenceofelectricalshock and seriousbodilyharmwithdeath

included.

5.ULTRAVIOLETRADIATION.

Direct exposuretoUV radiation isharmfultohuman skinand sight, whichcan causefrom

reddeningofskintoseriousburns, orultimatelyloss ofeyesight, dependingon the timeof

exposure.

Insuchcasesone shall contact physician assoon aspossible.

Thisdevicemayonlybe operated and installed byqualified personnel.

Beforeinstallation,servicingorrepairsverifythe qualificationsofpersonneland limit

theseactivitiestosuchpersonnel.Anyactivitieson thisdevicecan onlyproceed

afterthoroughfamiliarization withthisinstruction.Noncompliancewiththe

precautionslisted hereon mightexposepersonneltoseriousbodilyharm(damage

tohuman skinfromUVradiation),ordamagetothe devicealone.The

manufacturer,TMA, isnotresponsiblefordamagetothe devicecaused by

improperinstillation, maintenanceand operation.

TMA

AM1-AM15

3

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

Instalation and operation instructions

Thankyou and congratulationson yourpurchaseofTMAmanufactured UV

sterilization product. Sterilizersmade byTMAaremade fromhighestqualitystainless

steel.The thickness of the chamberwall guaranteeshighfactorof safetyinoperation.All

the rawmaterialsand componentsareofbestqualityand wereprocessed or

manufactured inthe EUcountries.Plastics used inproduction ofthe lamphoods

withstand 110°Cworkingtemperatures.Devicescompleted successfully30 Atmpressure

trials.

InAMmodelsweintroduced additionalguidesforthe quartzsleeveseasingthe

assemblyand disassembly.Thissolution allowsthe sameeaseofassemblyfordevice

workinghorizontallyorvertically.Thisguide preventsthe quartzsleevefrombreaking

duringthe routine maintenance.The turbulentflowinduced bythe guide increasesthe

efficaciencyofdisinfection.Duringthe first100 hoursofoperation the efficiencyof

disinfection isgreaterby15%fromthe rated forthe device. Newfeaturesallowcontinuing

disinfection even withoutthe flowofwaterthroughthe chamber.The designofthe

chambercontributestolowerincidenceofsedimentfromcalciumand magnesiumon the

surfaceofthe quartzsleeve.

The AMmodelsareequipped withmoredurableamalgamatelamps–up to12,000

hoursofservice.The plasticlamphood hasasecondaryfunction asasightglass.This

innovativesolution ofthe useoftransparenttovisiblelightlamphoodsallowsoptical

indication ofthe stateofthe lamp.

Weholdhighhopesthatthe implementationsoftheseinnovativesolutionsfulfill

yourexpectationsfornewand moreefficient productsfromTMA.

1. Introduction

The devicedelivered toyou isdisassembled and shall be protected fromsevere

shocks and drops,asthe quartzsleeveand lampsarebrittleand fragile.The sterilizer

shall be exclusivelytransported inhorizontalposition.The manufacturerisnotresponsible

fordamagearisingfromthe conditionsoftransport.

Beforeinstallation and operation one shall read the instructionsand implementthe

precautionslisted.

Noncompliancewiththeseprecautionsisgroundsforreleasingthe manufacturerfrom

warrantyobligations

TMA

AM1-AM15

4

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

2.Applications

Disinfection withUV radiation isareliable, simpleand inexpensivemethod ofsterilization.

The useofthismethod iswarranted everytimemicrobiologicalrisk exists.

Followingapplicationsmight be listed, amongmanyothers:

-Potablewaterinprivateand municipalinstallations

-Potableand process waterinrestaurant and hotelbusiness

-Process waterinthe production ofmedicinesand cosmetics

-Waterused inprocessingfood

-Waterinbeverageproduction

-Waterinswimmingpools

-Controlofgreen algae inponds

The primaryadvantageofUVsterilization iswaterwithoutmicrobesand damaging

chlorine sooften used insterilization ofwater.

SterilizerusesspeciallowpressureUV lamptoproduceUV radiation ofwavelengthof254

nmwhichcauses photochemicalreaction damaging DNAofmicroorganismsleading

todeathor sterility.

The requirementsforcompletesterilization call forminimumdosageof300J/m

2 for

potablewater. Waterflowingfromthe sterilizerisreadyforimmediateuse.

UV Sterilization doesnot changethe chemicalmakeup ofwater

Thereisno dangerofoverdosingeither.

TMA

AM1-AM15

5

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

3.Technical Specifications:

SYSTEM

WORKCONTROL

INDICATOR

709

221

250

317

DN 100

1110

400 250

600

MODEL AM4

O220

ELECTRICALENCLOSURE

POWERCORD

POWERSWITCH

WORKING

HOURS

COUNTER

SOLENOIDVALVE

TERMINAL

UVLAMPS

ALARM

INDICATORS

/RED/

POWER

INDICATOR

/GREEN/

TECHNICAL SPECIFICATIONS:

Model AM1 AM2 AM3 AM4 AM5

PowerSupply 220V-230V

ChamberMaterial Stainless Steel

Finish MirrorFinish

Dimensions /length. x width x height./mm 317x220x1110 317x250x1110 335x285x1110

Connection Size/Separation Dist.. DN80/ 735mm DN100/ 735mm

DN100/ 735mm

DN125/ 709mm

DN150/ 683mm

No. of UVLamps x Nominal Power 1x130W 2 x130W 3 x130W 4 x130W 5 x130W

Life of UVLamps ~12 000 h

Operating Temperature 0.5-500C

Operating Pressure 10bar(1MPa)

UVPower@y 254nm 46 W 92 W 138 W 184 W 230 W

Nominal Power 160 W 320 W 480 W 640 W 800 W

Nominal Flow @ transmittance T10=95%,

dose 300J/m225,0 m3/h 45,0 m3/h 78,0 m3/h 100,0 m3/h 144,0 m3/h

Nominal Flow @ transmittance T10=95%,

dose 400J/m218,7 m3/h 34,0 m3/h 58,0 m3/h 75,0 m3/h 108,0 m3/h

Sight glass Muff 1 2 3 4 5

Drain Valve Yes

Orientation Horizontal/Vertical

ELECTRICALENCLOSURE

Material Plastic Steel

Safety Class IP42 IP32

Dimensions /mm 325x250x120 400x400x200 400x600x250

Audible UVLamp Fault Alarm Yes

Optical UVLamp Fault Indicator Yes

Working Hours Counter Yes

Alarm System Yes

Solenoid Cut-Off Valve Terminals Yes

Terminals forRemote Alarm Indicator Yes

Remote ON/OFF Switch Terminals Yes

Weight with Enclosure 96.0kg 98.0kg 100.0kg 115.0kg 125.0kg

UVIntensity Measurement SystemBy Order/Optional/

TMA

AM1-AM15

6

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

SYSTEM WORK

CONTROL

INDICATOR

575

292,5

488

DN250

395

600 250

800

1120

O356

MODEL AM10

ELECTRICALENCLOSURE

WORKING

HOURS

COUNTER

POWER CORD

POWERSWITCH

ALARM

INDICATORS

/RED/

POWER

INDICATOR

/GREEN/

SOLENOID

VALVE TERMINAL

UVLAMPS

TECHNICAL SPECIFICATIONS:

Model AM6 AM8 AM10 AM12 AM15

PowerSupply 220V-230V

ChamberMaterial Stainless Steel

Finish MirrorFinish

Dimensions /length. x width x height./mm 463x340x1100 488x395x1120 544x445x1130

Connection Size/Separation Dist DN200/619mm DN250/575mm DN300/521mm

No. of UVLamps x Nominal Power 6 x130W 8 x130W 10 x130W 12 x130W 16 x130W

Life of UVLamps ~12 000 h

Operating Temperature 0.5-50 0C

Operating Pressure 10bar(1MPa)

UVPower@ 254nm 276W 368W 460 W 552 W 736W

Nominal Power 960 W 1280 W 1600 W 1920 W 2560 W

Nominal Flow @ transmittance T10=95%,

dose 300J/m2201,0 m3/h 287,0 m3/h 430,0 m3/h 526,0 m3/h 730,0 m3/h

Nominal Flow @ transmittance T10=95%,

dose 400J/m2151,0 m3/h 215,0 m3/h 322,0 m3/h 395,0 m3/h 550,0 m3/h

Sight glass Muff 6 pcs. 8 pcs. 10 pcs. 12 pcs. 16 pcs.

Drain Valve Yes

Orientation Horizontal/Vertical

ELECTRICALENCLOSURE

Material Steel

Safety Class IP32

Dimensions /mm 400x600x250 600x800x250 800x800x250

Audible UVLamp Fault Alarm Yes

Optical UVLamp Fault Indicator Yes

Working Hours Counter Yes

Alarm System Yes

Solenoid Cut-Off Valve Terminals Yes

Terminals forRemote Alarm Indicator Yes

Remote ON/OFF Switch Terminals Yes

Weight with Enclosure 195.0kg 200.0kg 240.0kg 250.0kg 280.0kg

UVIntensity Measurement SystemBy Order/Optional/

TMA

AM1-AM15

7

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

Minimalflowofwaterisnot required.

Increased flowthroughthe sterilizerlowersthe dosagedelivered tomicroorganismsand

lowersefficiencyofdisinfection,however,itallowsforuseininstallationswithoutthe need

foradditionalbypasses.

StandardFeatures:

-electricalenclosure,

-lampworkinghourscounter,

-audibleand opticalalarm

-terminalsforconnectingelectromagneticvalveshuttingoff flowincaseofpoweror

lampfailure

OptionalAccessories:

1. UV intensitysensor.

4.Description

Sterilizer’schamberismade fromstainless steel.QuartzsleeveswithUVlampsare

mounted inthe chamber.

When mounted vertically,the inletshouldbe located inthe bottompartofthe chamber

and the outletinthe upperpart. When mounted horizontally,the arrangementisoptional.

At the bottomofthe chamberthe drainplugislocated,whichisused toemptythe

chamberfromfluid.The powersupplysystemismounted inthe electricalenclosureand

connected withthe sterilizerbyhi-potentialwires.The enclosurehouses,besidesthe

powersupply,the lampworkinghourscounter,the audibleand opticalalarm,and

indicatinglightswiththe terminalsforelectromagneticshutoff valveincaseoflampor

powerfailure.

4.1.Leading outthealarm signal inAM1model

Tothe terminals1& 2on electronicplate/neutral/ connect alarmsignal.

·Contactsclosed -sterilizerworkingproperly

·Contactsopen -UV lampdamage

-Alarmon

-Powercut off

4.2.Connection ofsolenoidvalveinAM1model

Tothe terminals1& 2/neutral/ on the electronicplateinelectricalenclosure/ connect

solenoidvalvetype NZ(normallyclosed)max. 2a.

·Contactsclosed -sterilizerworkingproperly

·Contactsopen -UV lampdamage

-Alarmon

-Powercut off

4.3.Remote-controlledswitchinAM1model

Afterremovingthe bridge, it ispossibletoconnect remote-controlled switchtothe

terminalsON/OFF /caution:voltage230V!/.

·Contactsclosed -sterilizeron

·Contactsopen -sterilizeroff

TMA

AM1-AM15

8

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

4.4.Leading outthealarm signal inAM2-AM15 models

Tothe terminals1& 2/neutral/ on the terminalblocks inelectricalenclosure/inthe right

bottomcorner/ connect alarmsignal.

·Contactsclosed -sterilizerworkingproperly

·Contactsopen -UV lampdamage

-Alarmon

-Powercut off

4.5.Connection ofsolenoidvalveinAM2-AM15 models

Tothe terminals1& 2/neutral/ on the terminalblocks inelectricalenclosure/ connect

solenoidvalvetype NZ(normallyclosed)max. 2a.

·Contactsclosed -sterilizerworkingproperly

·Contactsopen -UV lampdamage

-Alarmon

-Powercut off

4.6.Remote-controlledswitchAM2-Am15 models

Afterremovingthe bridge, it ispossibletoconnect remote-controlled switchtothe

terminalsON/OFF /caution:voltage230V!/.

·Contactsclosed -sterilizeron

·Contactsopen -sterilizeroff

UV STERILIZER

OUTLET

SOLENOIDVALVE

Zasilanie

elektrozaworu

REMOVE THE DOORSOF

THE ELECTRICAL

ENCLOSURE

POWERLINE

To theterminalsON/OFF/

the sterilizer:

·Closed circuit -sterilizeron

· Opencircuit -sterilizeroff

ELECTRONIC PLATE

INAM1MODELS

bezpiecznik

BALASTCOUNT ON/OFF SWITCH N

~230V

1

12

To the terminals1&2/neutral/ on the electronic

plate in electricalenclosure/ solenoid valvetype

NZ(normallyclosed)max. 2a can be connected.

·Circuit closed -sterilizerworking

properly

·Circuit open -UVlamp damage

-Alarmon

-Powercut off

ZASILANIEALARM

ELECTRICALENCLOSURE

TMA

AM1-AM15

9

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

Power supplyspecifications 220-230V+ 8%, -10%, 50-60 Hz.

Electricshockprotection byearthterminal.

Transparent lamphood allowsfor indication ofworkingcondition ofthe lamp.

5.Instruction for installation and operation

a)Deviceassemblesineitherverticalorhorizontalposition.Temperaturerangefor

installation isfrom0.1to50oC.

b) Upstreamofthe intakeinstall potablewaterfilter,minimumrating0.1mm,

recommended 0.05 mm.Watershall not containmorethan 0.3mgFeand 0.1Mn.

c)Install manualcut-off valves, upstreamofthe intakeand downstreamofthe outlet.

d)Mount electricalenclosureon wall, at least 60 cmfromthe floor.

UVSTERILIZER

ELECTRICALENCLOSURE

OUTLET

SOLENOIDVALVE

SOLENOIDVALVE

CORD

REMOVEDOORSOF THE

ELECTRICALENCLOSURE

POWERLINE

terminalblock in electrical enclosure,after removing

the jumper cable,connectremote switching on/offofthe

sterilizer:

·Closedcircuit -sterilizer on

·Open circuit -sterilizeroff

To the terminals1 &2 /neutral/on theterminal

blocksin electrical enclosure/ solenoidvalvetype

NZ(normallyclosed) max.2a can beconnected.

·Circuit closed -sterilizerworking

properly

·Circuitopen - UVlamp damage

-Alarmon

-Power cutoff

QUICK-BREAK FUSE

CONTACTOR

masa

12345 6 78PE

Blokada

TMA

AM1-AM15

10

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

STERILIZERCHAMBER

QUARTZ SLEEVE

WARNING!!

QUARTZ SLEEVE ISWERY

BRITTLE ANDFRAGILE.

BE CAREFUL.

f)Placethe o-ringoverquartzsleeveand againstthe lipofthe nipple.Nextplacethe

washeroverthe o-ring,screwthe muff ontothisassemblywiththe provided tool.

Turnthe muff toconsiderableresistanceinordertotighten the seal.Tighteningthe

muff shall not breakthe sleeve.

O-RING

STERILIZER CHAMBER

QUARTZ SLEEVE

WASHER

O-RING

STERILIZER CHAMBER

QUARTZSLEEVE

MUFF

O-RING ONMUFF

e)Slide ingently

throughthe nipplethe

quartzsleeves; continue

throughsleeveguides

ontonestsatthe

bottom.

TMA

AM1-AM15

11

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

g)Fill the chamberunderfull pressureand check the sealtightness.

h)Placethe socketon the end forUVlampswithfourpins.Slide inthe fully

connected lampsintothe quartzsleeves.

CAUTION!MOUNTUVLAMPS INPROTECTIVE, PREFERABLYCOTTON,

GLOVES.

Ifthisrequirementisnotmet, the UVlampmaybreakafterthe switchingon ofthe

sterilizer.

O-RINGAFTER BEINGFULLYTIGHTENED,

MUFF DEFORMSO-RING/SUFFICIENT

DEFORMATION/

O-RINGBEFOREMUFFBEINGTIGHTENED

/SMALL DEFORMATION OFO-RING/

TIGHTESTSEALAROUND THEQUARTZSLEEVE SHALL BECREATEDWITH LARGEDEFORMATION

OFO-RING. O-RING ISVISIBLETROUGH THESLEEVE. TIGHTEN MUFF WITH THEPROVIDED TOOL,

ASSEEN.

WASHER

O-RING

STERILIZERCHAMBER

QUARTZ SLEEVE

MUFF

O-RING ONMUFF

PROVIDED TOOL

TMA

AM1-AM15

12

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

LAMPHOOD

STRAINRELIEF

PLACESOCKETON

LAMP ENDWITHFOUR

PINS

UVLAMP

SOCKET

CENTERINGRING

UVLAMP

STRAINRELIEF

INSERTUV LAMP

INTO QUARTZ

SLEEVE

SOCKET

LAMPHOOD

PLACE LAMP HOOD

OVERMUFF

WASHER

O-RING

STERILIZER

CHAMBER

QUARTZ SLEEVE

MUFF

O-RINGONMUFF

CENTERINGRING

i) Placelamphood overmuff.

j) Plugintomains230V, 50 Hz, inthe electricalenclosure, accordingtothe labels.

k)Turndeviceon byusingswitchon the side orfrontofelectricalenclosure.Green

indicatorlight goeson when deviceisconnected topowerand powered up.

l) ReplaceUV lampsafter12,000 hoursofwork.

ATTENTION!

1.AnyfaultofUVlamp,including burn out,issignalizedbylighting up ofred

indicator lamp and tripping ofaudiblealarm.

2.Incidentalpowering on theelectricalenclosurewithoutconnectedUVlampsmay

cause damagetoelectronicballastdriving UV lamps.

TMA

AM1-AM15

13

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ATTENTION!

Inthe caseofinstallingsolenoidshut-off valve(terminals1&2)upstream/or

downstream/ofthe sterilizer,trippingalarmorpowerinterruption causesimmediate

shuttingoff offluidflowtothe chamberofthe sterilizer.Terminals1&2haveinternal

connection broken incaseofalarmtrippingand assuchareneutral.Powertosolenoid

shut-off valveshall be connected throughterminals1& 2.

Solenoidshut-off valveservesthe purposeofpreventingunsterilized fluidenteringthe

installation downstreamofthe sterilizerinthe caseofpowerinterruption orlampfailure.

6.Maintenance

a)Ifanysedimentisnoticed on the surfaceofthe quartzsleeve,itisrecommended to

immediatelyclean the sleeve.Negligenceofthisrecommendation can causedrop

inefficiencyofsterilization.

b)Anytimethe sleeveiscleaned orreplaced it isrecommended to

unconditionallyreplace theo-ring creating theseal around thesleeve.

c)When replacingthe UVlamp,itisrecommended,ifitisnecessary,toclean the

sleeve.

d)Inletand outletvalvesshall be opened slowlytopreventthe rushoffluidhittingand

damagingthe quartzsleeve.

e)It isnotrequired tohaveconstantoranyflowthroughthe chamber.Sterilizersare

sodesigned thattheremaybe no flowthroughthe chamberwithno damage

issuingtothe sterilizer.

f)Ultraviolet radiation isdamagingtoskinand eyesight.

g)Waternotfitforconsumption mayrequiretreatmenti.e.deironing,softeningor

filtering. Ifanydoubt, pleasecontact yourdealer.

h)Incaseofhighturbidityand wastewater,the choiceofequipmentand efficiency

shouldbe made bythe dealer.

i) Avoidfrequentturningon and off the equipment. One on-off cyclelowersthe UV

lamplifebyabout 10-20 hours.

j) Flowratethroughthe devicecan be increased,however,thislowersthe delivered

dosageand lowersthe efficiencyofdisinfection.

k) Bioassaysamples shall becollectedintosterileopaquecontainersas notto

expose thesampletothelighttoavoidphotoreactivation ofmicroorganisms,

whichcanrebuildtheirdamagedDNAinpresence oflight.

l) Incasethe red indicatorlightison,replacementofthe UVlampisnecessary.The

part numbercan be found on transparent plasticlamphood placed overthe muff.

m)Even shortlived surge,toabove254V,can damagethe electronicballastdriving

the UV lamps.

n)Usingfaultyorpostend oflifeUVlamps/end oflifesetabout12,000 working

hours/ can lead todamagetoelectronicballast located Inthe electricalenclosure.

o)Excessivehumidityand waterinside the quartzsleevecan causedamagetothe

electronicballast drivingthe UV lamp.

p)The leakagecurrent goingintogroundingis1,5maforeachUV lamp.

7.Instruction for replacementofUV lamp.

Inordertoreplacethe UV lampone shall:

a)Disconnect frompowersupply/neutraland life/,

b)Put on protectivegloves, preferablymade ofcotton,

c)Takeoff plastichood,

TMA

AM1-AM15

14

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

d)Slide out the UV lampfromthe quartzsleeve,

e)Takeoff socket fromthe endsofUV lamp,

f)Placesocket on the end ofanewUV lampand slide it intothe sleeve

g)Reversethe remainingsteps.

ATTENTION!

InmodelAMsterilizersUV lampsmust havespecialcenteringringat bothends.

When the UVlampsareshipped fromthe manufacturer,the centeringringsareprovided

witheverylamp.

8. Replacementand Clearing oftheQuartzSleeve(Warning:Verybrittle).

Inordertoreplacequartzsleeveone shall:

a)RemoveUV lampaccordingtop. 7. /Instruction forreplacement ofUV lamp/,

b)Unscrewmuff,

c)Removewasherand o-ringfromthe quartzsleeve,

d)Slide the sleeveout ofguidesand nippleofthe sterilizer,

e)Clean thoroughlythe sleeveusinggenerallyavailableglass cleaners,drythe

interiorofthe sleeve,

ATTENTION!!! SLEEVE IS MADE OFPURE QUARTZAND IS VERYBRITTLE.

f)Slide carefullythe neworcleaned quartzsleeveintothe chamberofthe sterilizer,

g)Place newo-ring overthe sleeve, then placethe washer,

h)Tighten the muff overthe o-ringand washerwiththe provided tool.Check the

properplacementofthe o-ring,itshouldbe lodged intothe conicalgrooveinthe

nippleofthesterilizer,

i) Open graduallythe cut-off valves,flood the chamber,and check the sealaround

the sleeve. Ifit springsaleak, tighten the muff till tight sealisobtained,

j) Placethe UV lampaccordingwithp. 7ofthisManual.

Warning!Atthetime ofreplacementorclearing ofthequartzsleeve

theo-ring must bereplaced.

9. Transport

Shipsterilizeronlyinhorizontalposition.It shouldbe disassembled forshipping.The

quartzsleeveand lampshouldbe packed separatelyastheyarebrittle.Theyshouldbe

sufficientlywell packed towithstand roughhandling.

10. Warranty

Manufacturergrantswarrantyforthe period of60 monthsfromthe dateofsaleon the

chambermade fromstainless steel.

Powersupplyand controlcircuitryison 24 monthswarranty.

Warrantydoesnot coverthe UV Lampsand the quartzsleeve.

The manufacturercannotbe heldliableforanydamagesarisingfromuseorfailureofthe

equipment.

The warrantycoversonlyreplacement orrepair offaultypartsorequipment

TMA

AM1-AM15

15

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

A. LEGEND FORINDICATORLIGHTONENCLOSURE

Lighted colourindicatorlightsinform the operatorofthe status ofthe the sterilizer. Certain

conditions can be identified fromthe configuration oflights.Forthese correctiveactions arelisted

below:

Alarm

Red Light

SystemLight

Green Light

Power

Green LIght Problem Action

OFF ON ON Nofault -

OFF OFF OFF NoPower Checkpower

source

ON OFF ON

1.Burnoutorfaulty

UV lamp

2.Faultyballast

1. NewUV lamp

2. Newballast

OFF

OFF ON Alarm System Fault

ContactDealer.

Newalarm

system.

B. TROUBLESHOOTING

Problem Cause Action

Burnout UV Lamp

Waterinside the quartzsleeve-

.short circuit–open circuiton

circuit breaker

Muff nottightened

sufficiently.

Wornout o-ring

Takequartzsleeveout, dry

interior, changeo-ring,and

assembleback.Tighten muff.

IfUV lampdoes notwork–

electronicballastdamaged –

replace –contact dealer

UV lampgoes off End oflifeoflampcaused by

numberofworkinghoursand

number on-off cycles.

Replace UV lamp.

TMA

AM1-AM15

16

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ULTRAVIOLETWATERSTERILIZERAM1-AM15 DWG#

TITLE AM1, AM2 -GENERAL ARRANGEMENT 1

735208

317

DN80

200

1110

MODEL AM1

ZASILANIEALARM

250

325 120

ELECTRICALENCLOSURE

SOLENOID VALVECORD /TERMINALS1&2/

REMOTEPOWER SWITCH /TERMINALS3&4/

POWER CABLE

POWER SWITCH

WORKING

HOURS

COUNTER

UVLAMPCABLE

O220

ELECTRICALENCLOSURE

SYSTEMWORK

CONTROL

INDICATOR

735208

317

220

DN100

400

400

200

SOLENOIDVALVE

CORD

UVLAMP

POWERCORD

POWERSWITCH

1110

WORKING

HOURS

COUNTER

MODEL AM2

ALARM

INDICATOR

/RED/

POWER INDICATOR /GREEN/

O220

TMA

AM1-AM15

17

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ULTRAVIOLETWATERSTERILIZERAM1-AM15 DWG#

TITLE AM3, AM4 -GENERAL ARRANGEMENT 2

735208

220

317

DN100

1110

ELECTRICALENCLOSURE

400 250

600

POWER

INDICATOR

/GREEN/

ALARM

INDICATORS

/RED/

SYSTEM

WORKCONTROL

INDICATOR

WORKING

HOURS

COUNTER

UVLAMPCORDS

POWERCORD

SOLENOID

VALVECORD

MODEL AM3

O220

POWERSWITCH

709

221

250

317

DN100

1110

400 250

600

MODEL AM4

O220

ELECTRICAL ENCLOSURE

POWER

INDICATORLIGHT

/GREEN/

ALARM

INDICATORLIGHTS

/RED/

SYSTEM

INDICATOR LAMP

WORKING

HOURS

COUNTER

UVLAMPCORDS

POWER CORD

SOLENOID

VALVE CORD

POWERSWITCH

TMA

AM1-AM15

18

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ULTRAVIOLETWATERSTERILIZERAM1-AM15 DWG#

TITLE AM5, AM6 -GENERAL ARRANGEMENT 3

683236

285

335

DN 150

1110

O256

MODEL AM5

400 250

600

ELECTRICALENCLOSURE

WORKING

HOURS

COUNTER

UV LAMPCORDS

POWER CORD

SOLENOID

VALVE CORD

POWER SWITCH

SYSTEM

WORK CONTROL

INDICATOR

ALARM

INDICATORS

/RED/

POWER

INDICATOR

/GREEN/

619268

463

340

DN 200

O306

1110

MODEL AM6

400 250

600

ELECTRICAL ENCLOSURE

POWER

INDICATOR

/GREEN/

ALARM

INDICATORS

/RED/

SYSTEM

WORKCONTROL

INDICATOR

WORKING

HOURS

COUNTER

UVLAMP CORDS

POWER CORD

SOLENOID

VALVECORD

POWERSWITCH

TMA

AM1-AM15

19

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ULTRAVIOLETWATERSTERILIZERAM1-AM15 DWG#

TITLE AM8, AM10 -GENERAL ARRANGEMENT 4

619268

463

340

DN 200

600 250

800

1110

O306

MODEL AM8

ELECTRICALENCLOSURE

POWER SWITCH

WORKING

HOURS

COUNTER

UVLAMPCORDS

POWERCORD

SOLENOID

VALVECORD

SYSTEM

WORKCONTROL

INDICATOR

ALARM

INDICATORS

/RED/

POWER

INDICATOR

/GREEN/

575

292,5

488

DN250

395

600 250

800

1120

O356

MODEL AM10

ELECTRICALENCLOSURE

ALARM

INDICATORS

/RED/

SYSTEM

WORKCONTROL

INDICATOR

WORKING

HOURS

COUNTER

UVLAMPCORDS

POWER CORD

SOLENOID

VALVECORD

POWER SWITCH

POWER

INDICATOR

/GREEN/

TMA

AM1-AM15

20

TMA

|

Bia ostoczek26,gm.Zab udów,15

-

592 Bia ystok; Poland ; Tel. +48 857431246; VATPL5420008413

ULTRAVIOLETWATERSTERILIZERAM1-AM15 DWG#

TITLE AM12, AM15 -GENERAL ARRANGEMENT 5

ELECTRICALENCLOSURE

WORKINGHOURS

COUNTER

521323

DN 300

544

445

O406

1130

MODEL AM12

800 250

800

SYSTEMWORK

CONTROL

INDICATOR

ALARMINDICATORS

/RED/

POWER INDICATOR

/GREEN/

POWERSWITCH

SOLENOID VALVE

TERMINAL

UVLAMPS POWER

SYSTEM

WORK CONTROL

INDICATOR

521323

DN 300

544

445

O406

1130

MODEL AM15

800 250

800

ELECTRICALENCLOSURE

WORKING

HOURS

COUNTER

UV LAMPCORDS

POWER CORD

SOLENOID

VALVE CORD

POWERSWITCH

ALARM

INDICATORS

/RED/

POWER

INDICATOR

/GREEN/

Other manuals for AM1

1

This manual suits for next models

9

Table of contents

Other TMA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

HAVER & BOECKER

HAVER & BOECKER HAVER-UWL 400 operating instructions

Electrothermal

Electrothermal MEL-TEMP 1101D Instruction book

Thermo Scientific

Thermo Scientific Orion Versa Star instruction sheet

Metrohm

Metrohm 916 Ti-Touch Manual - Short Instructions

Buchi

Buchi B-811 Operation manual

Thermo Scientific

Thermo Scientific Orbitrap Fusion Lumos MS Getting connected guide