www.tmgindustrial.com 3 / 11TOLL FREE: 1-877-761-2819

IMPORTANT SAFETY INFORMATION

Your Safety

YOU are responsible for the SAFE operation and maintenance of your TMG 3-PTO Forest skidding winch. YOU must

ensure that you and anyone else who is going to use, maintain or work around the 3-PTO Forest skidding winch be familiar

with the using and maintenance procedures and related SAFETY information contained in this manual. This manual will

take you step-by-step through your working day and alerts you to all good safety practices that should be used while using

the 3-PTO Forest skidding winch.

Remember, YOU are the key to safety. Good safety practices not only protect you but also the people around you. Make

these practices a working part of your safety program. Be certain that EVERYONE using this equipment is familiar with the

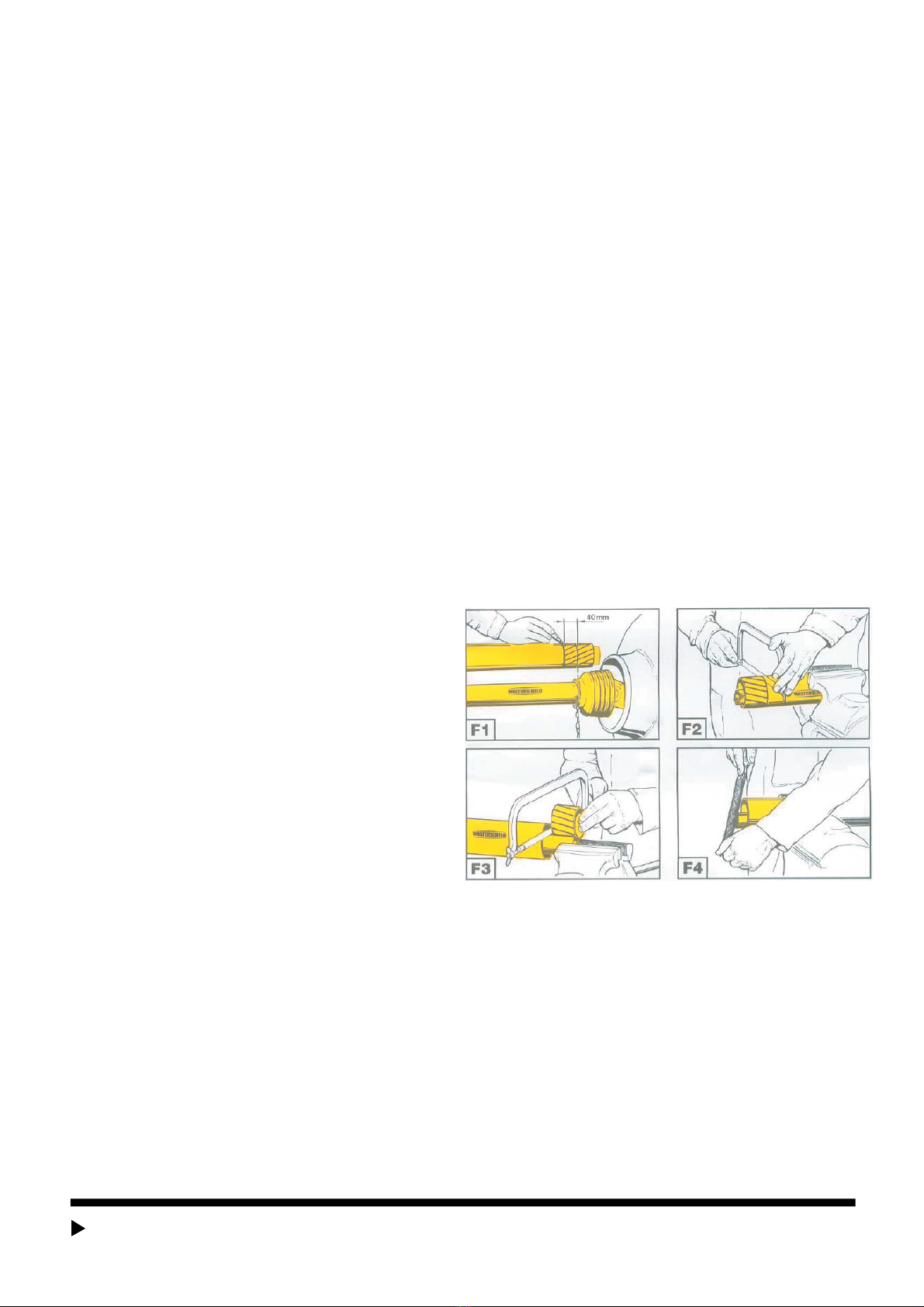

recommended using and maintenance procedures and follows all the safety precautions. Most accidents can be

prevented. Do not risk injury or death by ignoring good safety practices.

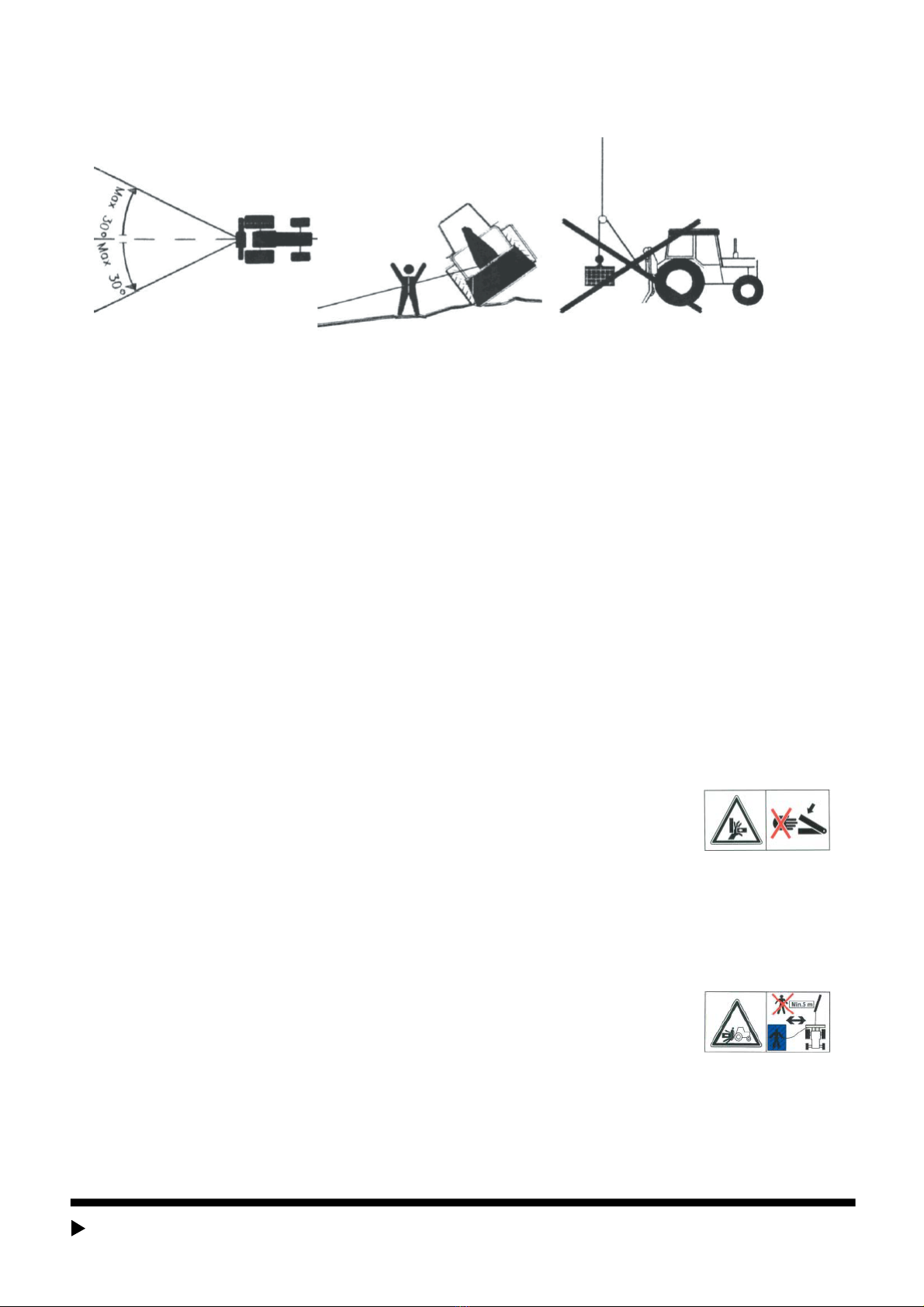

When working with the winch you need to observe the safety instructions!

In order to prevent accidents carefully read and observe the following instructions:

General

1. Apart from the instructions in this user manual you should also observe all general safety and accident preventing

regulations.

2. When working with the winch, it is necessary to comply with the rules of safety at work.

3. Only persons, who are older than 18, are allowed to work with the winch.

4. Safety and warning plates on the machine provide important instructions for safe use. Observe them for your safety.

5. The winch or its flawless operation should be checked before every use or at least once every working day. Defects

should be removed by an expert. Before first use or after significant alterations and at least once a year the winch must be

examined by an expert.

6. When using public transport routes observe traffic signs and regulations.

7. When using the winch wear personal protective equipment (helmet, gloves, appropriate footwear...).

8. Before starting and driving check the surrounding area (children). Maintain adequate visibility.

9. Riding on the winch during transport is not allowed.

10. Connect the winch according to the instructions.

11. For on road travel the machine must be in the following condition. If the winch covers the rear lights of the tractor and