TOHATSU VE1500A- Ti User manual

Other TOHATSU Water Pump manuals

TOHATSU

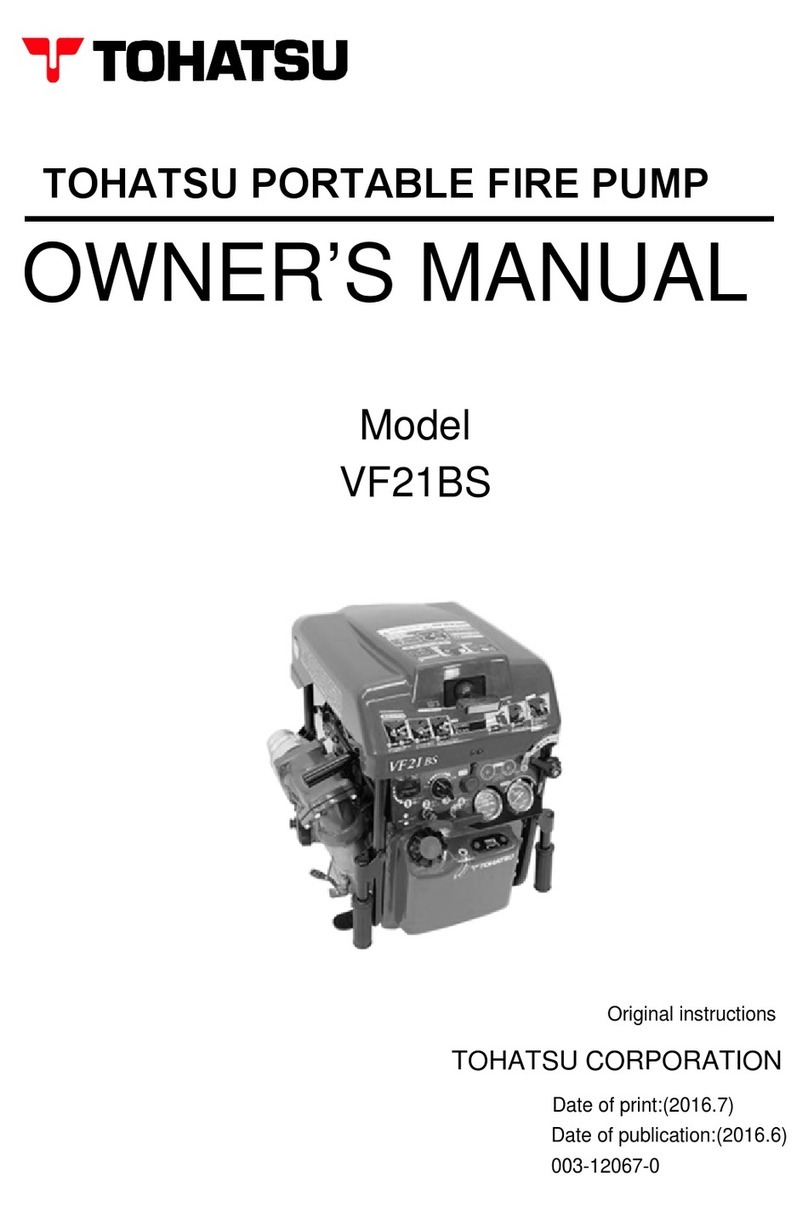

TOHATSU VF21BS User manual

TOHATSU

TOHATSU VC85BS Troubleshooting guide

TOHATSU

TOHATSU VC52AS User manual

TOHATSU

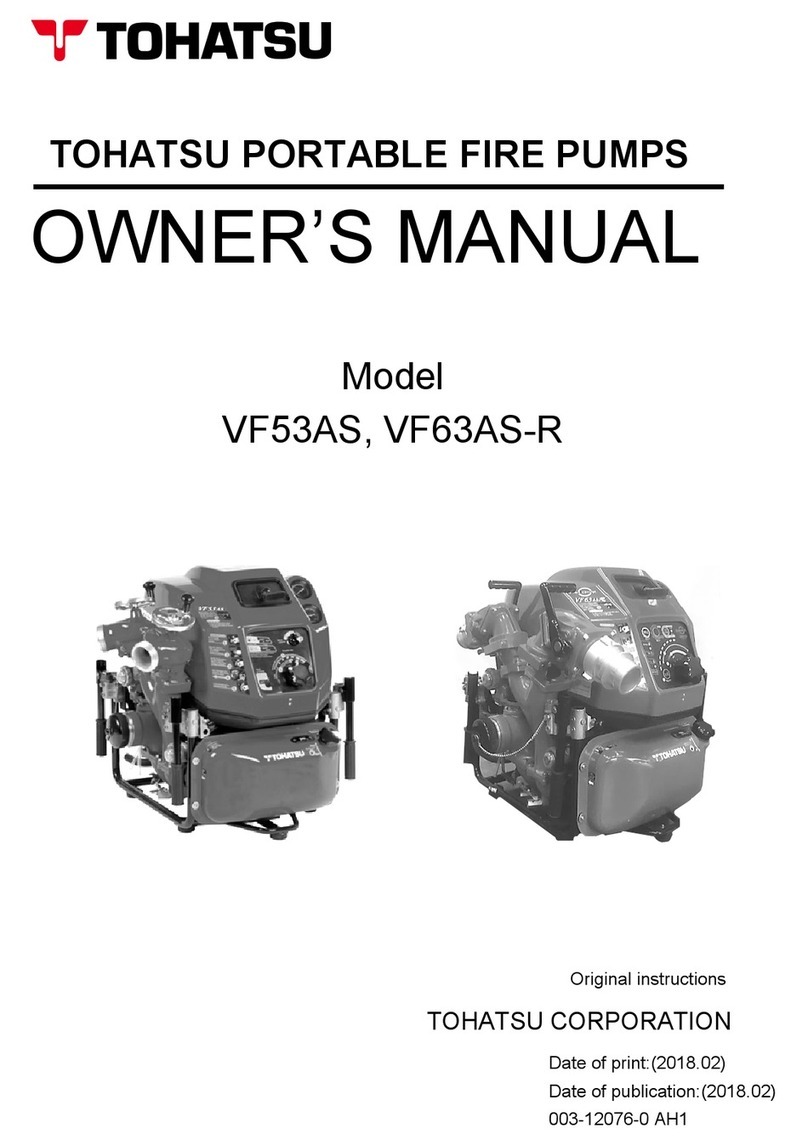

TOHATSU VF53AS User manual

TOHATSU

TOHATSU VE1500A- Ti User manual

TOHATSU

TOHATSU V20E User manual

TOHATSU

TOHATSU VF21BS User manual

TOHATSU

TOHATSU VC52AS User manual

TOHATSU

TOHATSU VE 1500 User manual

TOHATSU

TOHATSU VE1500A-Ti User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual