Toku TNB-08M User manual

Striker Hydraulic

Breaker

TNB-08M

TNB-1M

TNB-2M

TNB-3M

TNB-4M

TNB-5M

TNB-6M

TNB-6E

TNB-6.5E

TNB-7E

TNB-100

TNB-141LU

TNB-151LU

TNB-190LU

TNB-220LU

TNB-230LU

TNB-310LU

TNB-400LU

SERVICE MANUAL

TOKU AMERICA, INC.

Unsafe use of this machine may cause serious injury of death.

Operators and maintenance personnel must read this manual

before operating or maintaining this machine. This manual

should be kept near the machine for reference and periodically

reviewed by all personnel who will come into contact with it.

No.2

1

2

DELIVERY

INSTRUCTIONS

3

4

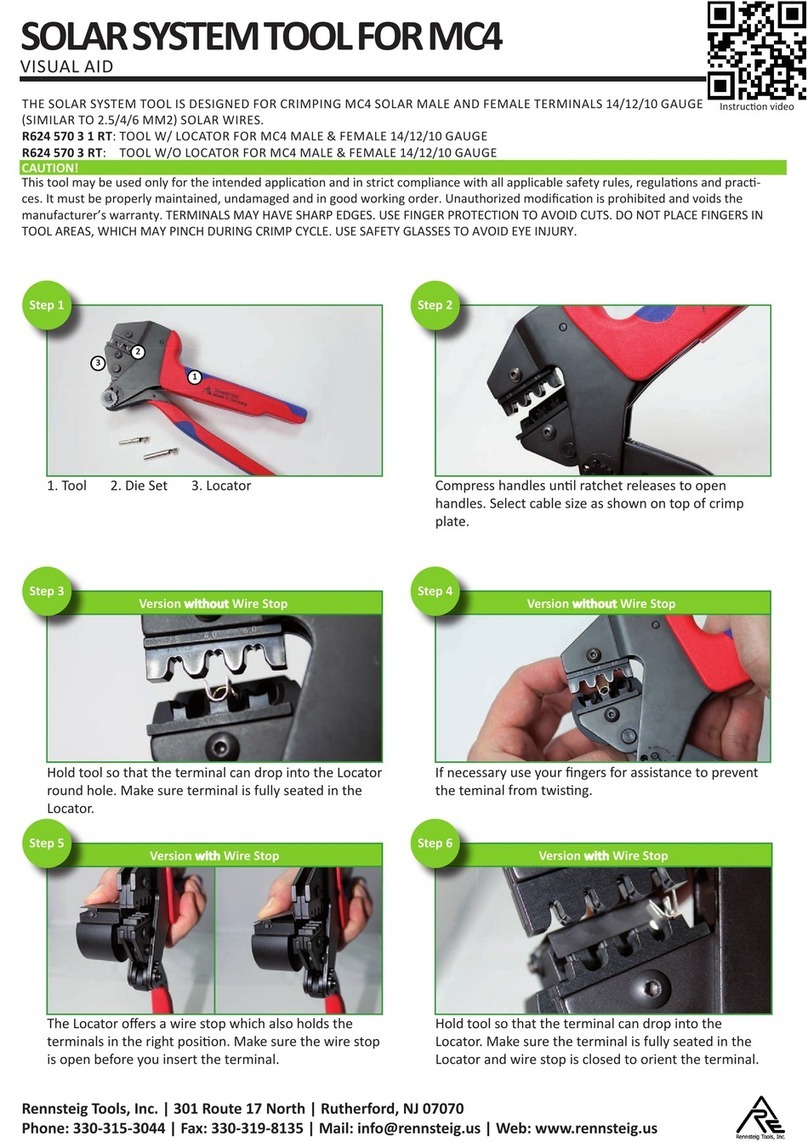

1.INTRODUCTION

The TNB Hydraulic Breaker is an attachment.

In order to operate the TNB Hydraulic Breaker to its full performance level, it is necessary to handle, maintain

and operate the hydraulic breaker properly. If this is not performed the life of the Hydraulic breaker will be

shorten dramatically and will lead to breakdowns.

When delivering the Hydraulic Breaker to the customer, it is necessary that the precaution points are

explained to the customer in detail.

Using this manual, adjust and perform final checks accordingly. Later, explain to the customer about

operation and maintenance for the hydraulic breaker properly.

2. BEFORE OPERATING THE TNB HYDRAULIC BREAKER, THE DELIVERY

PERSONAL OR INTRUCTOR SHOULD EXPLAIN ABOUT THE PERFORMANCE,

CONDITIONS & SETTINGS FOR THE EXCAVATOR.

1) Has the hydraulic oil and filter been changed.

2) Perform the flushing for the hydraulic breaker (attachment) as shown in the drawing below. Referring

to the chart below, proceed as advised.

Connect the IN & OUT hose,

and open the Stop valve.

Excavator Piping Flushing & Hammering time

New Manufacturer's genuine piping Over 5 mins.

New Piping installed later ( aftermarket) Over 30 mins.

Used Manufacturer's genuine piping Over 5 mins.

Used Piping installed later ( aftermarket) Over 30 mins.

3) Has the hydraulic oil been filled to the upper level of the tank (Boom on the excavator should be

lowered)

4) Has the relief valve pressure setting and pump performance been checked.

Stop valve

Relief valve

Piping for attachment Oil level gauge

5

5) Referring to the hydraulic breaker matching manual for excavators, if it has a Breaker mode (B-Mode),

set to the Breaker mode. For excavators that have computerized flow adjustment, please make sure

the maximum flow is set so that it does not exceed the maximum flow of the hydraulic breaker.

With regards to the adjustment of the computer, please have Maker’s service perform this adjustment.

6) With regards to excavators which do not have computerized flow adjustment, please refer to Sec. 7 of

this manual. In this case the throttle position must be set for the TNB hydraulic breaker and a sticker

must be applied at this position.

7) Checking the following areas; Lock nut for the relief valve, lock nut for the cable, split pin on the rod,

bolts and nuts on the piping flanges hydraulic hose adapters. All of the above must be secured and

tighten.

8) To check and confirm the movement of the hoses.

3. AFTER THE TNB HYDRAULIC BREAKER HAS BEEN MOUNTED, PERFORM A

TEST RUN.

1) When assembling the chisel, grease should be applied to the outside diameter.

2) Stand the hydraulic breaker up and press the chisel into the breaker before grease up.

3) If the hydraulic breaker is disassembled or assembled at a service facility, it will be necessary to release

all air and slowly supply hydraulic oil to the unit. (In this case lower the throttle position for the breaker,

press on the operating pedal about 5-6times,then operate the breaker at half throttle)

The operating time from removing the air to rhe preparation time is shown in the chart below.

Excavator

Air removal

time Seal recovery

time Preparation time

Preparation time

(See Caution 1)

New unit

2 mins.

5 mins.

Less than 50% Throttle

10 mins.

At 70% Throttle

20 mins.

After the hose has

been removed

2 mins.

5 mins.

Less than 50% Throttle

10 mins.

At 70% Throttle

20 mins.

After the Breaker

has been repaired

4 mins.

10 mins.

Less than 50% Throttle

10 mins.

At 70% Throttle

20 mins.

6

Caution 1) During the process of seal recovery, make sure

the hydraulic breaker does not impact when depressing the

operating pedal. Also, when performing the above exercise,

refer to the sketch below by standing the hydraulic breaker

vertically.

4. THE DELIVERY PERSONAL OR INSTRUCTOR SHOULD EXPLAIN THE

FOLLOWING POINTS TO THE CUSTOMER (MAINTENANCE STAFF OR OPERATOR)

1) The basic structure and mechanism for the TNB Hydraulic Breaker.

(Using the Instruction Manual)

2) The new hydraulic piping for the hydraulic breaker attachment and also the hydraulic circuit. (Operation,

High pressure hose, change valve, piping and relief valve etc)

3) Explanation concerning the operation,maintenance,wear parts and precaution points for the TNB

Hydraulic Breaker.

a) Inspection and re-tightening of nuts and bolts (Especially after 10 hours of operation)

b) Exchanging the hydraulic oil at every 600 hours of operation, in case the operating rate of the

breaker is 100%.

Exchanging the oil filter at every 150 hours of operation, in case the operating rate of the breaker is

100%.

c) Do not use a standard hydraulic breaker for underwater usage.

d) Procedures in greasing the chisel (Press the chisel into the breaker before greasing)

e) Operate the breaker vertically straight (A bending or prying action will during impact will break the

chisel)

f) Procedures for how to change the chisel.

g) How to store the breaker properly.

h) Agency of wear parts at an early stage and changing the parts accordingly. (Chisel, retainer pins,

retainer pin stopper, retainer pin stopper plug and hoses etc.)

4) Operation hour of the breaker on the first day should stay within 80% of the normal operating hours.

7

5. EXPLANATION ON TROUBLE SHOOTING

1) Terminology

a) Does not impact · · · · · · · · · This means the breaker does not operate.

b) Erratic blows · · · · · · · · · · · Breaker impacts without consistency.

c) Impacts but power is weak · · The normal impact strength is not transmitted to the breaker.

d) Oil leakage, Oil ooze

“ Oil leakage” is when the hydraulic oil leaks out continuously for several hours.

“ Oil ooze “ is when hydraulic oil is noticed after disassembly/assembly of the breaker within about

200 hours. The areas where you may notice this oil is around the mating areas, bolts and washers.

Or when the oil is unable to dry and dust is on the area and is unable to clear up or dry. In this case,

this is not abnormal.

At times oil leaking from the hose adapter may drip onto the hydraulic breaker body making it look

like oil is leaking. Take caution.

2) Explain using the Troubleshooting guide section in the Operation, Maintenance and Parts Manual.

3) Explain the Warranty clause for the Hydraulic breaker.

4) Periodic Maintenance

After operating the hydraulic breaker for 600 hours or 6 months, perform a check up for the breaker. Just like

your vehicle, periodic inspection and maintenance is a key factor in keeping your hydraulic breaker operating

for a long time.

6. FINAL INSPECTION SHOULD BE PERFORMED

1) Memo the Excavator Model

2) Memo the hour meter for the excavator

3) Apply the stickers to the appropriate areas.

7. ITEMS WHICH SHOULD BE GIVEN TO THE CUSTOMER

1) Instruction Manual

2) Tool Box (Explain the items which are in the tool box)

Explain how to open and close the stop valve when removing or mounting the breaker. Also about the hose

adapter plugs for the hose and for the excavator.

Take caution to avoid any foreign materials into the system through the hose and hose adapters.

The stickers

8

DISASSEMBLY &

ASSEMBLY

INSTRUCTIONS

9

10

CONTENT

Cleaning the Breaker and Bracket…………………………………………………………………….12

1. Disassembly of the bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 – 1. Side Mount Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 – 2. 1 PC Top Mount Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 – 3. 2 PC Top Mount Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 – 4. Silenced Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 – 5. Assembly / disassembly chart for the bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Disassembly of the hydraulic breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 – 1. Work table and set up of the breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 – 2. Side bolt nut / Cylinder cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 – 3. Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 – 4. Control valve box & valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 – 5. Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 – 6. Side bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 – 7. Hose adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 – 8. Removal of the seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 – 9. Assembly / disassembly chart for the Hydraulic breaker . . . . . . . . . . . . . . . . . . . . 26

3. Plugs torque chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4. Inspection and Repair of the Hydraulic breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 – 1. Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . 30

5 – 2. Chisel bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 – 2 – 1. How to change the Chisel bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 – 2 – 2. How to remove the Chisel bushing when a press is not available . . . . . . . . 33

5 – 3. Chisel holder bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 – 3 – 1. How to change the Chisel holder bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 – 4. Control valve / Control valve box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 – 5. Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5 – 6. Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 – 7. Retainer Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11

CONTENTS

6. Assembly of the Hydraulic breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 – 1. Chisel holder bushing / Chisel bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 – 1 – 1. Chisel holder bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6 – 1 – 2. Chisel bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6 – 2. Chisel holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 – 2 – 1. How to insert the Helisert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 – 3. Side bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6 – 4. Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 – 5. Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 – 6. Packing bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 – 7. Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 – 8. Control valve box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6 – 9. Filling Breaker with hydraulic oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6 – 10. Cylinder cover / Side bolt nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6 – 10 – 1. How to use the Power wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 – 10 – 2. Alternative method of tightening the Side bolt nuts . . . . . . . . . . . . . . . . . . 61

6 – 11. Hose adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 – 12. Checking & Re-charging the cushion chamber with Nitrogen gas . . . . . . . . . . . 64

7. Mounting the Hydraulic breaker onto a Excavator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7 – 1. P – Q Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7 – 2. Purpose of P – Q Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7 – 3. How to measure the P – Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7 – 4. How to set the Hydraulic breaker relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7 – 5. How to set the Hydraulic breaker throttle position . . . . . . . . . . . . . . . . . . . . . . . . . 72

8. Removal / Assembly of the Chisel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8 – 1. Removal of the Chisel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8 – 2. Assembly of the Chisel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9. Special work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9 – 1. How to change the Side bolt when broken . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12

10. Hydraulic Breaker Disassembly / Assembly tools chart (For reference) . . . . . . . . . . . . . 77

1. Cleaning the Breaker and Bracket

To prevent any material from entering the breaker, before replacing parts or overhauling the breaker remove

all dirt and foreign material from the breaker and bracket.

2. Disassembly of the Bracket

2 – 1. Side Mount Bracket

1) Remove the bracket pin and bracket bushing. At this time remove the chisel from the breaker.

2) If there are hoses in the bracket, loosen and remove the hoses on the swivel side.

3) With the bracket bolt nut side of the bracket plate facing up, loosen the bracket bolt nut and remove.

4) Fit the “Eyebolt” onto the top of the plate and lift up the plate straight up.

5) Remove the breaker body the same as the above manner.

6) When assembling, perform this procedure in the opposite direction. But please note when the breaker is

being assembled into the bracket, make sure the bracket key plates fits into the breaker key slot

properly.

Bracket bolt nut

Key slot

Bracket

Bracket ring

Bracket bolt

Bracket pin

Bracket bushing

Washer

Eyebolt

Hyd.Hose (Within the bracket)

13

* Depending on the model, some changes may occur.

2 – 2. 1 PC Top Mount Bracket

1)Remove the bracket pin and bracket bushing. At this time remove the chisel from the breaker.

2)With the bracket bolt nut side of the bracket plate facing up, loosen the bracket bolt nut and remove.

3)Fit the “Eyebolt” onto the top of the plate and lift up the plate straight up.

4)Remove the breaker body the same as the above manner.

5)When assembling, perform this procedure in the opposite direction. But please note when the breaker is

being assembled into the bracket, make sure the bracket key plates fits into the breaker key slot

properly.

* Depending on the model, some changes may occur.

Bracket bolt nut

Key slot

Bracket

Bracket ring

Bracket bolt

Bracket pin

Bracket bushing

Washer

Eyebolt

14

2 – 3. 2 PC Top Mount Bracket

1) Remove the bracket pin and bracket bushing. At this time remove the chisel from the breaker.

2) Loosen the bolt of bracket (B) and remove the bracket (B).

3) With the bracket bolt nut side of the bracket plate facing up, loosen the bracket bolt nut and remove.

4) Fit the “Eyebolt” onto the top of the plate and lift up the plate straight up.

5) Remove the breaker body the same as the above manner.

6) When assembling, perform this procedure in the opposite direction. But please note when the breaker is

being assembled into the bracket, make sure the bracket key plates fits into the breaker key slot

properly.

Bracket ring

Bracket bushing

Bracket pin

Bracket(B)

Bracket bolt nut

Eyebolt

Bracket

Key slot

Bracket bolt

Washer

15

* Depending on the model, some changes may occur.

2 – 4. Silenced Bracket

1) Remove the bracket pin and bracket bushing. At this time remove the chisel from the breaker.

2) Loosen the hex bolt and nut, and remove the bracket (B), top rubber and cover plate.

3) Loosen the hard lock nut and remove the guide plate and guide

spacer.

Remove the hydraulic hose and fit the hose plug to prevent any

material from entering the breaker.

4) Assemble the “Eyebolt” and pull out the

breaker using a wire rope.

Cover plate

Silenced Bracket(A)

Top rubber/ plate

Bracket(B)

Bracket Pin

Guide spacer

Guide plate

Bracket bushing

Bracket ring

Guide plate

Hard lock nut

Eyebolt

16

5) Pull out the side spacer.

6) Pull out the chisel holder spacer.

7) Pull out the back spacer.

8) Pull out the under spacer A & B.

9) When assembling, perform this procedure in the opposite direction.

But please assemble the chisel holder spacer after assembling the side spacer.

(Assembly procedure of the spacer is 8), 7), 5), 6) )

Side spacer

Chisel holder spacer

Back spacer

Under spacer B

Under spacer A

17

* Depending on the Model, some changes may occur.

2 – 5. Assembly / Disassembly chart for the Bracket

Model TNB 08M 1M 2M 3M 4M 5M 6M 6E

(1) Bracket bolt/nut Width across flats (mm) 24 27 30 30 32 36 41 46

Bolt size (mm) (M16) (M18) (M20) (M20) (M22) (M24) (M27) (M30)

Torque (Ft. Lb./N·m) 130/176 188/255 253/343 253/343 304/412 433/588 650/882 723/980

(2) 2PC bracket Width across flats (mm) 24 24 24 24 24 24 30 30

bolt/nut Bolt size (mm) (M16) (M16) (M16) (M16) (M16) (M16) (M20) (M20)

Torque (Ft. Lb./Nm) 140/190 140/190 140/190 140/190 140/190 140/190 273/370 273/370

Silenced bracket Width across flats (mm) 24 24 24 24 24 24 30 30

bolt/nut Bolt size (mm) (M16) (M16) (M16) (M16) (M16) (M16) (M20) (M20)

Torque (Ft. Lb./N/·m) 140/190 140/190 140/190 140/190 140/190 140/190 273/370 273/370

(3) Hyd. hose Width across flats (mm) 19 27 27 27 27 27 27 36

IN/OUT Size (inch) 3/8 1/2 1/2 1/2 1/2 1/2 1/2 3/4

Torque (Ft. Lb./Nm) 36/49 43/59 43/59 43/59 43/59 43/59 43/59 87/118

(4) Guide bolt/nut Width across flats (mm) 19 24 24 24 24 24 24 30

Bolt size (mm) (M12) (M16) (M16) (M16) (M16) (M16) (M16) (M20)

Torque (Ft. Lb./N·m) 56/76 140/190 140/190 140/190 140/190 140/190 140/190 273/370

(5) Gas valve Width across flats (mm) - - - - - - - 17

cover plate Bolt size (mm) (M10)

Torque (Ft. Lb./Nm) 32/44

(6) Control valve Width across flats (mm) 17 17 19 19 19 19 19 24

plate Bolt size (mm) (M10) (M10) (M12) (M12) (M12) (M12) (M12) (M16)

Torque (Ft. Lb./Nm) 32/44 32/44 56/76 56/76 56/76 56/76 56/76 140/190

(7) Eyebolt for

Top/Side brackt Bolt size (mm) M8 M8 M8 M12 M12 M12 M12 M12

Eyebolt for Silenced

bracket Bolt size (mm) M10 M10 M12 M12 M12 M12 M12 M16

(8) Eyebolt for

cylinder cover Bolt size (mm) M8 M8 M8 M12 M12 M12 M12 M12

(9) Eyebolt for

chisel holder Bolt size (mm) - - - M12 M12 M12 M12 M12

(10)Eyebolt for

cylinder Bolt size (mm) M8 M8 M8 M12 M12 M12 M12 M12

(2)

(7)

(1)

(7)

(6) (2)

(4)

18

2 – 5. Assembly / Disassembly chart for the Bracket

Model TNB 6.5E 7E 100

141

LU

151

LU

190

LU

220

LU

230

LU

310

LU 400

LU

(1) Bracket Width across flats (mm) 46 55 55 60 65 75 75 90

bolt/nut Bolt size (mm) (M30) (M36) (M36) (M39) (M42) (M48) (M48) (M60)

Torque (Ft. Lb./Nm) 723/980 1012/1372 1012/1372 1192/1617 1445/1960 2024/2744 2024/2744 3614/4900

(2) 2PC bracket Width across flats (mm) 30 30 30 36 46 46 60 60

bolt/nut Bolt size (mm) (M20) (M20) (M20) (M24) (M30) (M30) (M39) (M39)

Torque (Ft. Lb./Nm) 273/370 273/370 273/370 480/650 930/1260 930/1260 2140/2900 2140/2900

Silenced

bracket Width across flats (mm) 30 30 30 36 46 46 60 60

bolt/nut Bolt size (mm) (M20) (M20) (M20) (M24) (M30) (M30) (M39) (M39)

Ttorque (Ft. Lb./Nm) 273/370 273/370 273/370 480/650 930/1260 930/1260 2140/2900 2140/2900

(3) Hyd. hose Width across flats (mm) 36 36 36 41 41 41 50 50

IN/OUT Size (inch) G3/4 G3/4 G3/4 G1. G1. G1. G1-1/4 G1-1/4

Tightening torque (Nm) 87/118 87/118 87/118 101/137 101/137 101/137 123/167 123/167

(4) Guide

bolt/nut Width across flats (mm) 30 30 30 36 46 46 46 46

Bolt size (mm) (M20) (M20) (M20) (M24) (M30) (M30) (M30) (M30)

Torque (Ft. Lb./Nm) 273/370 273/370 273/370 480/650 930/1260 930/1260 930/1260 930/1260

(5) Gas valve

cover Width across flats (mm) 19 19 19 19 19 19 19 19

plate Bolt size (mm) (M12) (M12) (M12) (M12) (M12) (M12) (M12) (M12)

Torque (Ft. Lb./N·m) 56/76 56/76 56/76 56/76 56/76 56/76 56/76 56/76

(6)Control valve

plate Width across flats (mm) 24 24 24 24 24 30 30 30

Bolt size (mm) (M16) (M16) (M16) (M16) (M16) (M20) (M20) (M20)

Torque (Ft. Lb./Nm) 140/190 140/190 140/190 140/190 140/190 273/370 273/370 273/370

(7) Eyebolt for

Top/Side

bracket

Bolt size (mm) M12 M20 M20 M20 M24 M24 M30 M30

Eyebolt for

Silenced

bracket

Bolt size (mm) M16 (Hook) (Hook) (Hook) (Hook) (Hook) (Hook) (Hook)

(8) Eyebolt for

cylinder cover Bolt size (mm) M20 M20 M20 M20 M24 M24 M30 M30

(9) Eyebolt for

chisel holder Bolt size (mm) M20 M20 M20 M20 M24 M24 M30 M30

(10)Eyebolt for

cylinder Bolt size (mm) M12 (M20) M20 M20 M24 M24 M30 M30

(1)

(7) (6)

(5)

(4)

(2)

19

3. Disassembly of the Hydraulic Breaker

3 – 1. Work table and set up of the Breaker

1) Remove the gas valve plug from the gas valve on the cylinder cover of the breaker.

2) Using a tool such as a screwdriver, push the valve in and completely remove all of the gas from the

cushion chamber.

3) Before removing the side bolt nut, first loosen the bolts on the control valve box.

4) Secure the hydraulic breaker, loosen the side bolt nut about 2-3mm from the fastening surface.

5) Fit the “Eyebolt”onto the cylinder cover and lift the breaker up. Lower the breaker onto a breaker stand or

a breaker locater so that the breaker does not fall over.

Gas valve plug

Driver

Gas valve body

Gas valve

Control valve box

Loosen the bolts

Loosen about 2 – 3mm

Make sure the pivot is welded

securely and does not remove.

Breaker stand Breaker locater

Other manuals for TNB-08M

1

This manual suits for next models

17

Table of contents

Other Toku Tools manuals

Toku

Toku THA-3BRH19X50 User manual

Toku

Toku TJ-20SV User manual

Toku

Toku TCD-20 User manual

Toku

Toku TPB-90 User manual

Toku

Toku MBC-30S User manual

Toku

Toku AIR TPB-60 Specifications

Toku

Toku TFC-257H User manual

Toku

Toku THA-2BRH19X50 User manual

Toku

Toku TFC-200F User manual

Toku

Toku AA-1.3BR(H)19X50 User manual