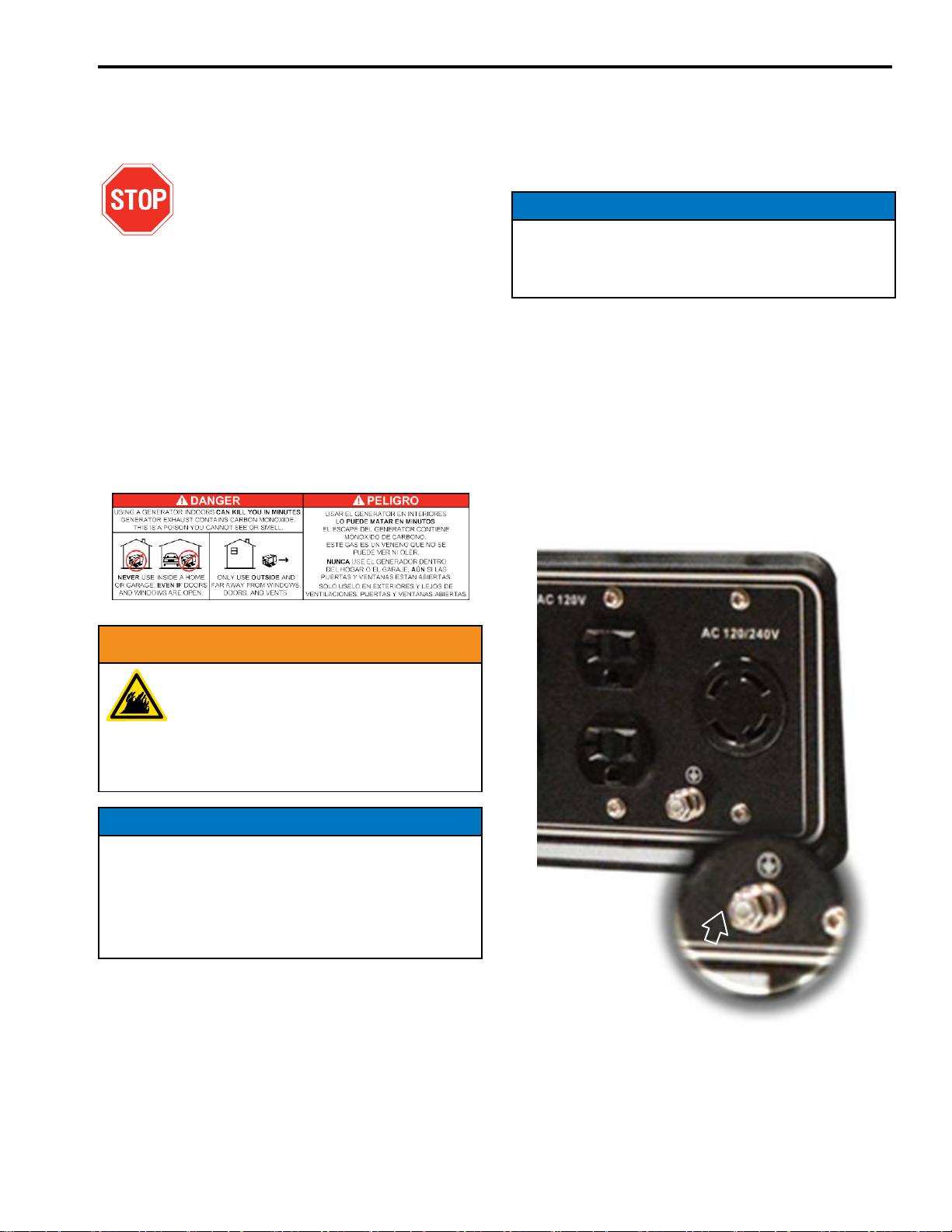

Never use the generator in a location

that is wet or damp. Never expose the

generator to rain, snow, water spray or

standing water while in use. Protect the

generator from all hazardous weather

conditions. Moisture or ice can cause a

short circuit or other malfunction in the

electrical circuit.

Never operate the generator in an

enclosed area. Engine exhaust

contains carbon monoxide. Only

operate the generator outside and away

from windows, doors and vents.

Voltage produced by the generator

could result in death or serious injury.

•

Never operate the generator in

rain or a floodplain unless proper

precautions are taken to avoid being

subject to rain or a flood.

•

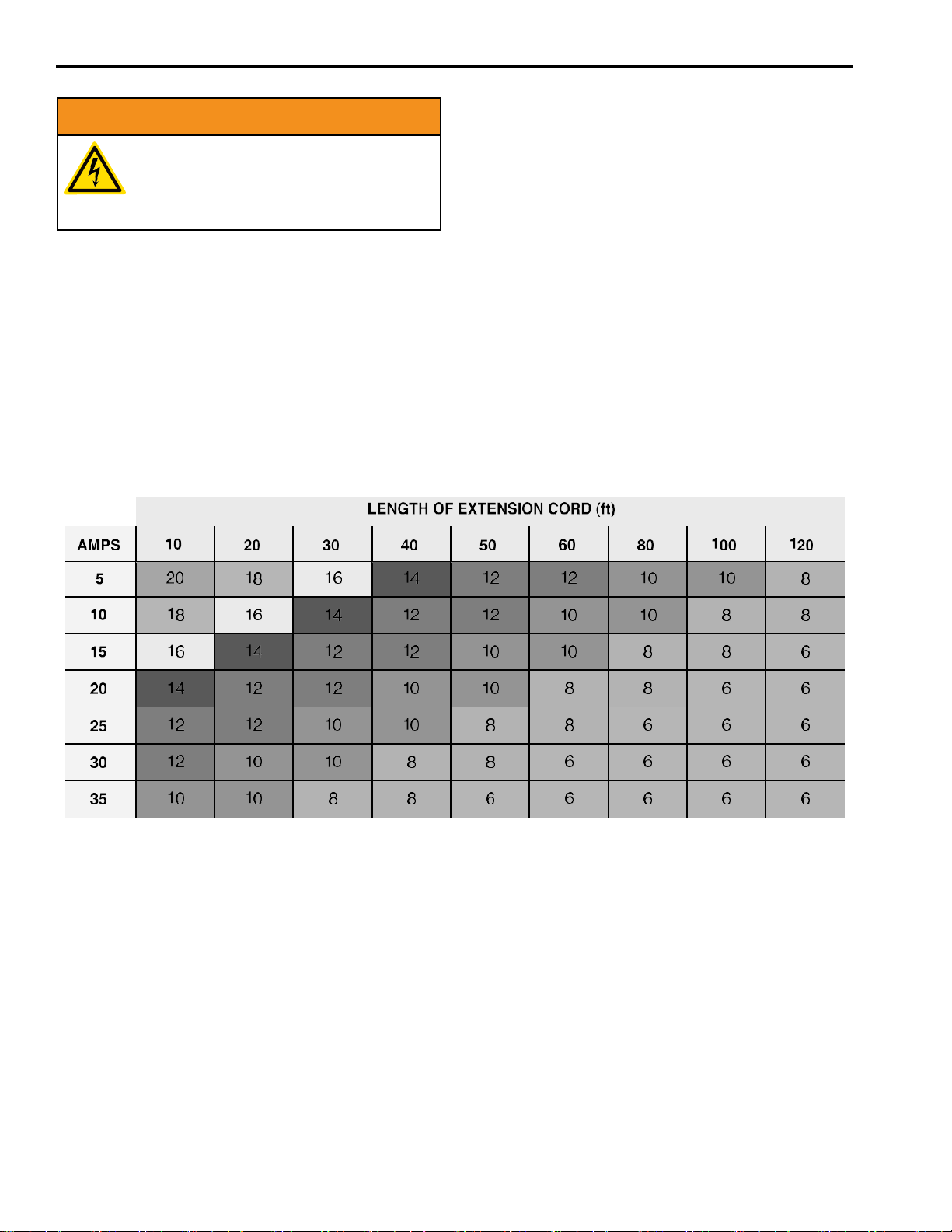

Never use worn or damaged

extension cords.

•

Always have a licensed electrician

connect the generator to the utility

circuit.

•

Never touch an operating generator

if the generator is wet or if you have

wet hands.

•

Never operate the generator in highly

conductive areas such as around

metal decking or steel works.

•

Always use grounded extension

cords. Always use three-wire or

double-insulated power tools.

•

Never touch live terminals or

bare wires while the generator is

operating.

•

Be sure the generator is properly

grounded before operating.

Gasoline and gasoline vapors are

extremely flammable and explosive

under certain conditions. Beware of

Carbon Monoxide and ordorless gas

that kills.

•

Always refuel the generator outdoors,

in a well-ventilated area.

•

Never remove the fuel cap with the

engine running.

•

Never refuel the generator while

the engine is running. Always turn

engine off and allow the generator to

cool before refueling.

•

Only fill fuel tank with gasoline.

•

Keep sparks, open flames or other

form of ignition (such as match,

cigarette, static electric source) away

when refueling.

•

Never overfill the fuel tank. Leave

room for fuel to expand. Overfilling

the fuel tank can result in a sudden

overflow of gasoline and result in

spilled gasoline coming in contact

with HOT surfaces. Spilled fuel

can ignite. If fuel is spilled on

the generator, wipe up anyspills

immediately. Dispose of rag properly.

Allow area of spilled fuel to dry

before operating the generator.

•

Wear eye protection while refueling.

•

Never use gasoline as a cleaning

agent.

•

Store any containers containing

gasoline in a well-ventilated area,

away from any combustibles or

source of ignition.

•

Check for fuel leaks after refueling.

Never operate the engine if a fuel leak

is discovered.