TOMI STERAMIST STERAPAK Quick start guide

1

2

TABLE OF CONTENTS

1. WELCOME TO STERAPAK® ................................................................................................ 3

2. PACKAGE CONTENTS .............................................................. Error! Bookmark not defined.

2a. STERAPAK® CONTROLS .......................................................................................................... 3

2b. STERAPAK® APPLICATOR ........................................................................................................ 4

2c. BIT™ SOLUTION .................................................................................................................... 4

2d. RECHARGEABLE BATTERY ...................................................................................................... 5

3. WARNING LABELS ............................................................................................................ 5

4. USING THE STERAMIST® STERAPAK® ................................................................................. 5

4a. ROOM PREPARATION ........................................................................................................... 5

4b. PERSONAL PROTECTIVE EQUIPMENT (PPE) ........................................................................... 6

4c. H2O2 MONITORING ............................................................................................................... 6

4d. STERAPAK® SETUP ................................................................................................................. 6

4e. FLUSHING (BEFORE FIRST USE OR AFTER 5 DAYS OF INACTIVITY) .......................................... 7

4f. OPERATING THE STERAMIST® STERAPAK® .............................................................................. 8

4g. STERAPAK® STORAGE ............................................................................................................ 9

5. SAFETY DISCLAIMERS ....................................................................................................... 9

5a. BIT™ SOLUTION SAFETY ...................................................................................................... 10

6. PREVENTATIVE MAINTENANCE ...................................................................................... 11

6a. UNIT CALIBRATION ............................................................................................................. 11

7. PRODUCT TROUBLESHOOTING ....................................................................................... 12

NEED ADDITIONAL EQUIPMENT OR SOLUTION?

Request our Product Catalog for a comprehensive list of SteraMist offerings. TOMI can

fulfill BIT Solution reorders, PPE procurement, SteraMist accessory orders, and more.

Call 800-525-1698, email [email protected], or visit www.tomimist.com.

3

1. STERAPAK® INTRODUCTION

Welcome to your brand new SteraMist® SteraPak. TOMI™ Environmental Solutions is proud

to present the cutting edge in disinfection and decontamination technology. This manual

will provide information on how to properly operate your SteraMist® system and to achieve

maximum efficacy and maintain the quality of your machine over time.

2. PACKAGE CONTENTS

Included in the package: SteraPak, Battery and Charger, Power Cord, DI Water bottle

2a. STERAPAK® CONTROLS

ATTENTION: Please handle appropriately. The SteraPak is an enhanced disinfection

device. With a general understanding of how this technology works, you can freely

explore the contents of your new SteraMist device.

4

The interactive control components are labeled above and as follows:

Feature

Purpose

Direct Power Adapter Inlet

Plug inlet for direct power use

Unit Power Rocker Switch

Power unit on/off

Battery Status LED Indicator

An LED indicator for battery power level

Prime/Spray Rocker Switch

Switch between prime and spray modes

DI Water/BIT™ Bottle Holding Space

Compartment for DI Water & Solution bottles

DI Water/BIT™ Bottle Dip Tube

Integrated tube for DI Water & Solution bottles

12V Battery Compartment

Compartment for 12v battery (Included)

Battery Release Lever

Sliding clasp to firmly hold battery in place

2b. STERAPAK® APPLICATOR

The SteraMist Applicator distributes BIT Solution with an air and fluid spray system and

generates ionized Hydrogen Peroxide (iHP) mist after passing through the cold plasma

arc.

The SteraMist applicator has two buttons (A) for two different grip styles. Both buttons

serve to initiate the prime or spray function as predetermined by your SteraMist®

system. The Aerosolizing Nozzle (B) uses air to shear BIT Solution into a fine spray. The

Cold Plasma Arc (C) then ionizes and activates the mist.

2c. BIT™ SOLUTION

7.8% hydrogen peroxide BIT™ Solution is ready-to-use, requires no mixing, and is

activated and ionized by the cold plasma arc of the SteraPak applicator. The bottom of

each bottle is labeled with an RFID tag, which enables SteraPak functionality when

placed inside the bottle holding space. SteraMist equipment will only disburse

32oz/946ml from each BIT-100 bottle, and each bottle has a clearly marked production

date and lot number for reference.

5

2d. RECHARGEABLE BATTERY

The SteraMist® SteraPak (S-PAK-100) is designed to operate on a 12v battery

(included). The battery status LED indicator located on the left face of the unit will

indicate the current charge of the battery (if a battery is being used for operation).

BATTERY STATUS LED INDICATOR GUIDE

Green Light (Steady)

Battery contains sufficient energy to operate SteraPak

Yellow Light (Steady)

Battery requires immediate charging

Red Light (Steady)

Battery is completely discharged and requires charging

Green and Red Light (Alternating)

RFID tag is not against SteraPak RFID reader

3. WARNING LABELS

[Figure 1] This symbol indicates danger due to possible high voltage exposure. This sticker is

displayed on the nozzle guard. Take care to follow warnings and guidance to avoid injury

and damage to equipment wherever this sticker may be displayed.

4. USING THE STERAMIST® STERAPAK®

4a. ROOM PREPARATION

SteraMist SteraPak may be used effectively without disabling HVAC and other

ventilation systems.

Venting into the atmosphere is preferred. Alternatively, an air scrubber with activated

charcoal pre-filter may be placed in the treated area or carbon filters may be placed

over ventilation returns. A small industrial fan may assist aeration speed.

Third-party solution usage is not approved and violates the warranty on your

SteraMist system. Do not combine Binary Ionization Technology® (BIT™) Solution from

different bottles or pour it into any outside container. Relevant chemical information

can be found on the BIT® Solution Safety Data Sheet.

6

4b. PERSONAL PROTECTIVE EQUIPMENT (PPE)

All operators of a SteraMist system should be equipped with the proper PPE for the

job to protect against potential chemical and biological exposure.

For applicators and handlers of the SteraMist SteraPak, the following minimum PPE

must be worn:

• Protective eyewear (e.g., goggles)

• Gloves, long sleeves, and long pants

• PAPR with organic filter, R95/N95 Respirator with Activated Charcoal Filter,

Controlled Air Purifying Respirator with organic vapor filter, or equivalent

Final selection of additional PPE must be done in accordance with site guidelines and

take into consideration the use of the product, as well as any infection or exposure

hazards related to the environment to be treated.

4c. H2O2 MONITORING (OPTIONAL)

Hydrogen peroxide (H2O2) gas monitoring equipment, while optional, verifies suitable

levels for re-entry for safety purposes and process verification

1. The H2O2 monitor must have a dynamic range of 0-20 ppm. The H2O2 sensor is

intended to be used outside the treatment area for low level leak detection and

containment verification.

2. Treatment area must remain unoccupied until a monitoring device registers

hydrogen peroxide levels at 1 ppm. If re-entry is required before aeration is

complete, please wear proper Personal Protective Equipment (PPE). Refer to the

Binary Ionization Technology (BIT) Solution label and package insert for complete

application instructions.

4d. STERAPAK® SETUP

1. Remove your SteraMist SteraPak from the shipment packaging.

2. Inspect warranty seal for any sign of tampering. If the seal is compromised, STOP

and do not use your SteraMist system. Contact [email protected] for further

instructions.

3. Inspect the applicator nozzle. The spray nozzle, positioned immediately behind the

electrodes, is a stainless-steel round with a textured ring. All applicator heads

should be tested by hand to assure the nozzle is properly secured and cannot be

loosened by hand.

Note: Inspect the included Quality Assurance (QA) and Quality Control (QC)

documentation. If unsatisfied, STOP and do not use your SteraMist system.

Contact TOMI™ Environmental Solutions for further instructions.

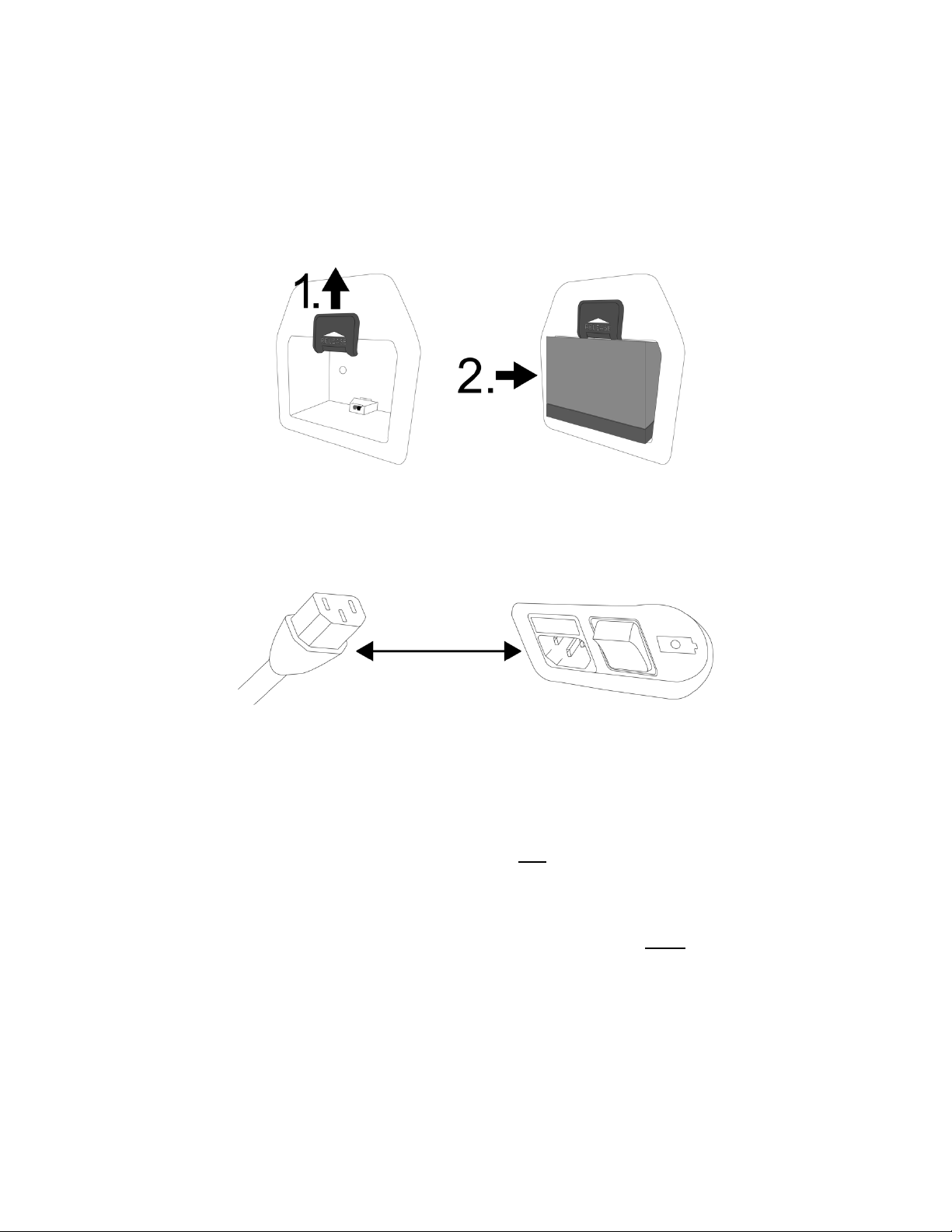

4. If satisfied, insert the 12v battery into the SteraPak.

7

1.) Located on the backside of the unit. Gently apply upward tension to the spring-

loaded release lever and hold it still.

2.) Ensure the red and black battery connectors are aligned with the SteraPak

connectors and push the battery into the cavity. Once correctly secured, a slight

click will be heard.

Note: The SteraPak can also use the AC adapter as a desired power source by plugging

the cord into a power outlet. SteraPak functionality requires a reliable and properly

rated source. Difficulties can arise if the power outlet is not properly tested or rated.

5. Using the power button located on the bottom of the left face, power on your

SteraPak unit. You are now ready to begin the priming process.

For any additional questions, please refer to the Troubleshooting section of this

manual, or contact [email protected] directly for further instructions.

4e. UNIT FLUSHING (BEFORE FIRST USE OR AFTER 5 DAYS OF INACTIVITY)

Refer to introductory diagrams for controls layout before attempting to run your

SteraPak for the first time.

1. Fill DI Water Bottle with Distilled or Deionized (DI) Water ONLY. Tap water

contains minerals and impurities which can clog the nozzle.

2. Screw on and secure the dip tube. Place DI Water bottle upright into the holding

space to activate the unit RFID functionality.

8

3. Turn on the SteraPak by switching the power button located on the left side of the

body to the ON (–) position and set the rocker switch on the right side of the

SteraPak to the “Prime” position.

4. Direct the nozzle towards a receptacle to capture primed fluid before pressing and

holding either button on the applicator. When a steady, uninterrupted stream is

observed, the SteraPak is primed.

5. Switch your SteraMist SteraPak to Spray Mode by pressing the rocker switch on

the right side to “Spray”. Press the applicator button and check to confirm the

following:

- Consistent, purple cold plasma arc.

- Persistent, cone shaped mist profile.

DO NOT TOUCH THE COLD PLASMA ARC.

6. Uncap and remove the dip tube from the DI Water Bottle. Replace the bottle into

the holding space to ensure RFID contact. Hold down either button on the

applicator to purge the visible length of the dip tube.

7. Your SteraMist SteraPak is ready for spraying or storage. Proceed to the following

section to operate your unit.

4f. STERAMIST® STERAPAK® OPERATION

1. Insert the SteraPak battery into the cavity to operate cordlessly or plug the

provided power cord into both a standard electrical outlet and the SteraPak.

2. Open a new bottle of BIT™ Solution. Firmly fasten the dip tube into the BIT™ bottle

and insert the bottle upright into the holding space, ensuring RFID functionality.

3. To turn on the SteraPak, switch the power button located on the left side of the

body to the ON (–) position and set the rocker switch on the right side of the

SteraPak to the “Prime” position.

4. Direct the nozzle towards a receptacle to capture primed fluid before pressing and

holding either button on the applicator. When a steady, uninterrupted stream is

observed, the SteraPak is primed.

6. Switch your SteraMist SteraPak to Spray Mode by pressing the rocker switch on

the right side to “Spray”. To activate the handheld applicator, push on one of the

Applicator buttons.

7. Hold the applicator arm’s length (around 24”) from the surface being treated,

apply the BIT™ solution in a thin, even layer utilizing broad even strokes at a rate

of 5 seconds per square foot.

a. BIT™ solution should be thoroughly applied per the directions for use on the

BIT™ Solutions product label.

9

b. Treated surfaces should have a fine, mist-like coating. Drips or running

solution indicate overtreatment and may not provide optimal results.

c. For best coverage, move the applicator to directly spray surfaces rather than

tilting the applicator and spraying at an angle.

d. To deactivate the handheld applicator, release the button. To avoid arc

malfunction, wait 10 seconds between depressing the trigger and spraying

again. Failure to do so may result in damage to the unit.

8. To turn off the SteraPak, switch the power button on the left face to the OFF (O)

position. (If using direct power, power the unit OFF (O) and unplug the power cord

from both the outlet and the SteraPak).

9. Before removing PPE and opening space for re-entry, use an H2O2 monitor to

confirm that hydrogen peroxide levels within the treatment area are 1ppm or less.

Once this level is achieved, areas are safe for normal use.

4g. STERAPAK® STORAGE

1. Ensure the SteraMist SteraPak is off or unplugged from the power source.

2. DI water should be left in the lines unless there is danger of the unit freezing. Do

not allow BIT™ Solution to remain in the line during long periods of inactivity.

Never store or ship the SteraMist SteraPak without fully flushing the system.

3. Using isopropyl alcohol, clean all residues present from the nozzle tip guard,

electrodes, electrode posts, spray nozzle, air cap, and retaining ring.

4. To prevent unit damage from freezing temperatures: Store under climate-

controlled conditions at the suggested parameters outlined in Section 5.

5. SAFETY DISCLAIMERS

GENERAL SYSTEM MAINTENANCE OUTLINED IN SECTION 4.

If the SteraPak will not be used for more than 5 days consecutively and prior to long

term storage, refer to Section 4e. To prepare for shipment, refer to Section 7a.

Only qualified SteraMist Service Technicians may repair or maintain this equipment.

Review and follow all label directions and warnings for BIT™ and SteraMist products.

Read and understand the BIT™ Safety Data Sheet and retain the document in an

employee-accessible location.

10

Minimum Power Requirements: The SteraMist® SteraPak (S-PAK-100) is designed to

operate on a 12v battery or standard 110V/240V, 50/60 Hz, 15-amp grounded power

receptacle with a grounding pin. The unit is rated 120 VAC, 60 Hz, 4.5A. If using a generator,

generator must have an inverter to protect the electronic controls from damage.

The fine mist generated by SteraMist may activate optical smoke detectors. Optical-based

smoke sensor systems are typically the most susceptible to false alarms. Prior to treatment,

the facility or asset undergoing remediation must be evaluated for the likelihood of whether

the optical smoke detectors will be activated by the mist. Take appropriate measures prior

to treatment.

Before inserting the battery and plugging in power cord, make sure the power switch is in

the “OFF” position. The “OFF” position is engaged when the “O” symbol is pressed down.

Grounding Instructions: Do not modify the power cord provided. This machine must be

properly grounded to ensure safety. Grounding reduces shock risk by providing an escape

for electric current. Improper connection of the equipment can result in mechanical failure

or electrical shock.

Do not put fingers, tools, or any other foreign objects into the nozzle, electrode area, or

high energy electrical arc. Note the warning symbol on the nozzle guard. This could cause

injury, damage equipment, and void warranty.

Always keep the applicator nozzle pointed away from yourself and others.

The use of any other solution besides BIT™ Solution in your SteraPak and other SteraMist

products is strictly prohibited. Doing so may result in injury, machine failure, unintended

results, and voided warranty.

Recommended Use Environment:

Environmental Operational Parameters

Areas of Use

Indoor or Outdoor Use

Supply Voltage Fluctuation

No More Than +/- 10% of Ratings

Operation Temperature

5-40°C (41-104°F)

Maximum Operating Altitude

2000m (6562ft) Above Sea Level

Duty Cycle the SteraPak for over 60 minutes of continuous spraying (active duty). NOTE:

32oz bottles may require changing after approximately 30 minutes of continuous spraying.

5a. BIT™ SOLUTION SAFETY

Hazards to Humans and Domestic Animals

DANGER: BIT™ Solution may cause irreversible eye damage. Harmful if absorbed through

skin. Do not get in eyes, or on clothing. Avoid contact with skin. Wear appropriate

protective eyewear such as goggles, face shield, or safety glasses. Wash thoroughly with

11

soap and water after handling and before eating, drinking, using tobacco, or using the toilet.

Remove and wash contaminated clothing before reuse.

Physical and Chemical Hazards: This product is incompatible with strong oxidizing and

reducing agents.

First Aid Procedures for Contact with BIT™ Solution:

If in Eyes: Remove contact lenses, if present, hold eye open and rinse slowly and gently with

water for 15-20 minutes. Call a Poison Control Center or doctor for treatment advice.

If on Skin: Take off contaminated clothing. Rinse skin immediately with plenty of water for

15-20 minutes. Call a Poison Control Center or doctor for treatment advice. Have the

product container or label with you when calling a Poison Control Center, or doctor, or

going for treatment.

6. PREVENTATIVE MAINTENANCE

6a. UNIT CALIBRATION

The SteraMist SteraPak does not require annual calibration. SteraMist Certified Service

Technicians are available at 1.800.525.1698 to schedule and arrange service repairs as

needed. Please contact TOMI™ for ordering instructions.

FOR GENERAL INFORMATION ON HEALTH AND SAFETY

RELATED TO PESTICIDE USE AND EXPOSURE:

Call the National Pesticides Information Center at:

+1 (800) 858-7378, M-F, 8:00am – 12:00pm PST. Reference EPA #90150-2

FOR EMERGENCIES: Call the Poison Control Center, available 24 hours every day at

+1 (800) 222-1222 or Chemwatch 24-hour Emergency Response at

+1 (855) 237-5573 or +1 (877) 715-9305.

FOR NON-U.S. EMERGENCIES: Please contact TOMI, Chemwatch ER, or the local

Poison Control Center in your country.

NOTE TO PHYSICIAN: Probable mucosal damage may contraindicate

the use of gastric lavage

CAUTION: MAKE SURE THE MAIN POWER IS OFF AND

EQUIPMENT IS UNPLUGGED BEFORE PERFORMING MAINTENANCE.

12

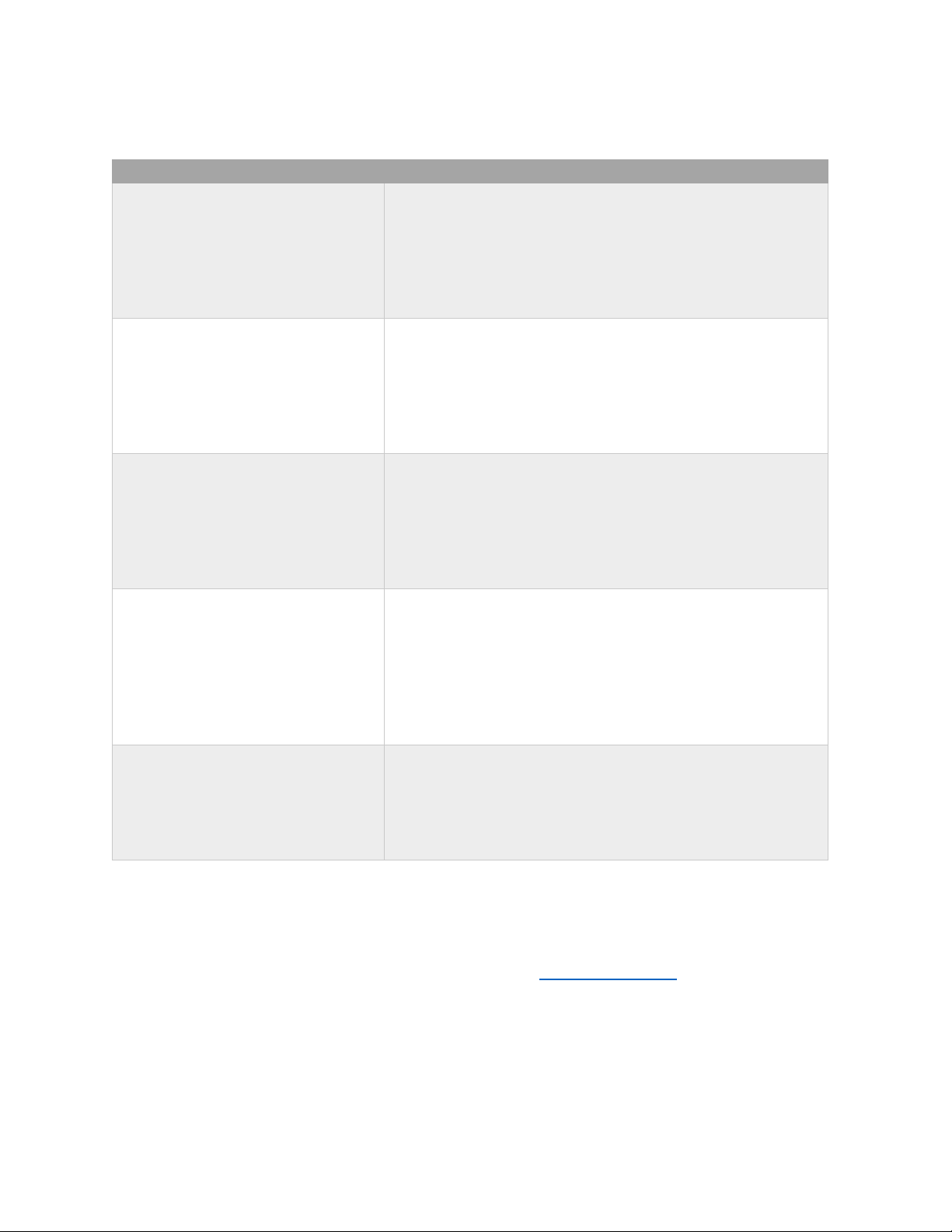

7. PRODUCT TROUBLESHOOTING

Problem

Solution

The SteraMist is on, but no

mist/fog is being produced for

30-45 seconds.

Ensure that all the tube connections are fully seated into

their fittings by pushing the tubes until they bottom out in

the fittings. Make sure the flexible tube is connected to the

fitting at the rear of the BIT™ solution cartridge area. Ensure

that the dip (pick up) tube to the solution is connected to the

generator and that there is still solution in the container.

The atmospheric cold plasma arc

is not contained between the two

electrodes or sounds unusual.

STOP operation immediately. Disconnect the battery or

electric power. Using isopropyl alcohol, clean all residues

present on the tip guard, electrodes, electrode posts, spray

nozzle, air cap, and retaining ring. Reassemble and test. If the

high energy electrical arc is still misfiring, immediately

discontinue use and contact your TOMI™ Representative.

The SteraPak is on but sounds

unusual.

STOP operation immediately. Disconnect the battery or

electric power. Using isopropyl alcohol, clean all residues

present on the tip guard, electrodes, electrode posts, spray

nozzle, air cap, and retaining ring. Reassemble and test. If the

high energy electrical arc is still misfiring, immediately

discontinue use and contact your TOMI™ Representative.

The solution stream is spraying at

an angle.

Turn off, remove battery, or unplug the SteraMist SteraPak.

Clear the nozzle with the nozzle clean-out tool. If still not

corrected, remove the spray nozzle assembly, and replace

the nozzle gasket. Ensure that the nozzle gasket lays flat and

flush against the nozzle base. Reassemble the spray nozzle

assembly. Tighten to finger tight. Over tightening can cause

deformation of the nozzle gasket.

SteraPak does not start.

Make sure that the SteraMist SteraPak battery is inserted or

plugged in correctly and is turned on. Test the battery level

or the voltage coming from the wall. If using an extension

cord, check that it is not damaged. Call a certified SteraMist

technician.

FOR FURTHER ASSISTANCE, REPAIRS, OR OTHER INQUIRIES, CONTACT US!

TOMI™ Environmental Solutions, Inc.

8430 Spires Way, Suite N | Frederick, MD 21701

Table of contents

Popular Cleaning Equipment manuals by other brands

DIP'N DRY MAX

DIP'N DRY MAX 41709 instruction manual

Larson Electronics

Larson Electronics IND-HVAC-DTW-UVC-R1-SS Series Instruction guide

Kärcher

Kärcher FR Basic manual

Conquip

Conquip Powerbrush instructions

Kaivac

Kaivac NO-TOUCH CLEANING 1200 Series Operator's & parts manual

SkyVac

SkyVac 78 Assembly & user's guide

Fantom Professional

Fantom Professional PROCART 360 Assembly manual

SkyVac

SkyVac Internal 37 Assembly & user's guide

Rustibus

Rustibus 2000 Electric Low Operation manual

ORBOT

ORBOT PACIFIC FLOORCARE MSB-19 ORB operating manual

FLO-DYNAMICS

FLO-DYNAMICS BrakeMate Jr manual

Electric Eel

Electric Eel R Operator's manual