4

1-800-287-1136

Customer/Technical Support

opeRAtoR & pARts MAnUAL -

tAbLe ofContents

1.0 Geng Started

1.1 pRodUCt identifiCAtion ........................................................................................................................................... 5

1.2 WARRAnty RegistRAtion........................................................................................................................................... 5

1.3 sAfety pReCAUtions: CoRded Units onLy..................................................................................................................... 6

1.3 sAfety pReCAUtions: CoRded (ContinUed)................................................................................................................... 7

1.3 sAfety pReCAUtions: CoRded (ContinUed)................................................................................................................... 8

1.4 sAfety pReCAUtions: bAtteRy Units onLy .................................................................................................................... 9

1.4 sAfety pReCAUtions: bAtteRy opeRAted (ContinUed) ....................................................................................................10

1.5 bAtteRy infoRMAtion..............................................................................................................................................11

1.6 LiMited WARRAnty pRoteCtion pLAn ..........................................................................................................................12

2.0 Assembly

2.1 tooL ARRAngeMent................................................................................................................................................13

2.2 pRepARAtion foR Use.............................................................................................................................................14

3.0 Maintenance

3.1 bAtteRy Use ........................................................................................................................................................15

3.2 MAChine MAintenAnCe ............................................................................................................................................16

3.3 vACUUM diAgRAM ...................................................................................................................................................17

3.4 pUMp diAgRAM......................................................................................................................................................18

3.5 1200 eLeCtRiCAL diAgRAM .......................................................................................................................................19

3.6 AC eLeCtRiCAL diAgRAM ..........................................................................................................................................20

3.7 QC poWeR pACk eLeCtRiCAL diAgRAM .........................................................................................................................21

4.0 Troubleshoong and Upkeep

4.1 tRoUbLeshooting..................................................................................................................................................22

4.2 tRoUbLeshooting (ContinUed).................................................................................................................................23

4.3 tRoUbLeshooting (ContinUed).................................................................................................................................24

4.4 tRoUbLeshooting tips ...........................................................................................................................................25

4.5 RepLACeMent (MonthLy) .........................................................................................................................................25

5.0 Parts Diagrams and Specicaons

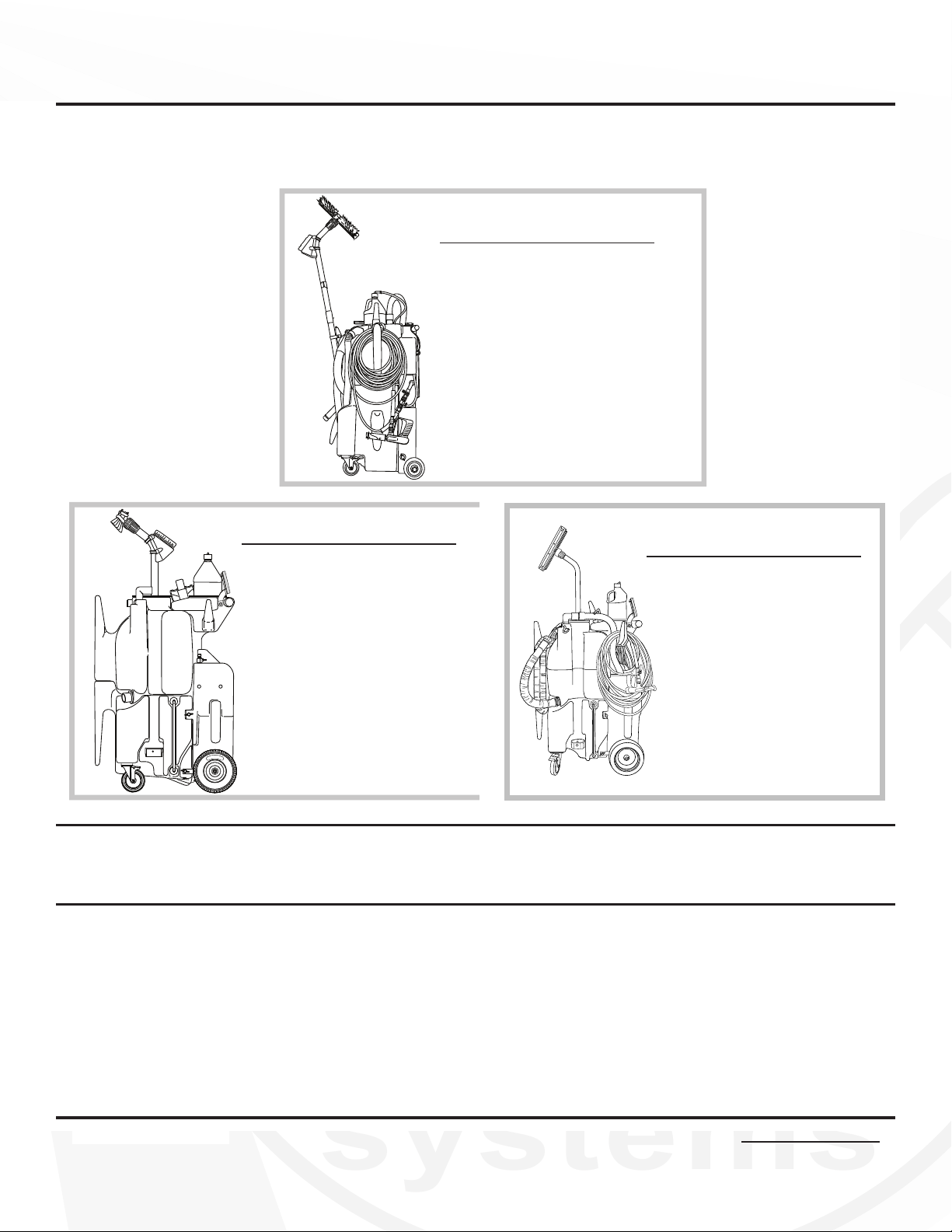

5.1 1200 vAC tAnk AsseMbLy........................................................................................................................................26

5.2 1200 WAteR tAnk AsseMbLy....................................................................................................................................26

5.3 1250 bLACk box AsseMbLy......................................................................................................................................27

5.4 1200 sWitCh pAneL AsseMbLy..................................................................................................................................28

5.5 1200 vALve AsseMbLy.............................................................................................................................................28

5.6 1250 pUMp AsseMbLy ............................................................................................................................................29

5.7 1200 vAC MotoR AsseMbLy .....................................................................................................................................29

5.8 1700/17001 vAC tAnk AsseMbLy.............................................................................................................................30

5.9 1700/17001 WAteR tAnk AsseMbLy .........................................................................................................................30

5.10 1750/17501 pUMp AsseMbLy..................................................................................................................................31

5.11 1700/17001 vAC MotoR AsseMbLy ..........................................................................................................................31

5.12 27001 vAC tAnk AsseMbLy......................................................................................................................................32

5.13 27001 WAteR tAnk AsseMbLy..................................................................................................................................32

5.14 27501 pUMp AsseMbLy...........................................................................................................................................33

5.15 27001 vAC MotoR AsseMbLy ...................................................................................................................................33

5.16 1750/17501/27501 AC bLACk box AsseMbLy ...........................................................................................................34

5.17 QC poWeR pACk AsseMbLy.......................................................................................................................................35

5.18 1700/17001 sWitCh pAneL AsseMbLy .......................................................................................................................36

5.19 27001 sWitCh pAneL AsseMbLy................................................................................................................................36

5.20 1700/17001/27001 vALve AsseMbLy .......................................................................................................................37

5.21 hepA AsseMbLy....................................................................................................................................................37