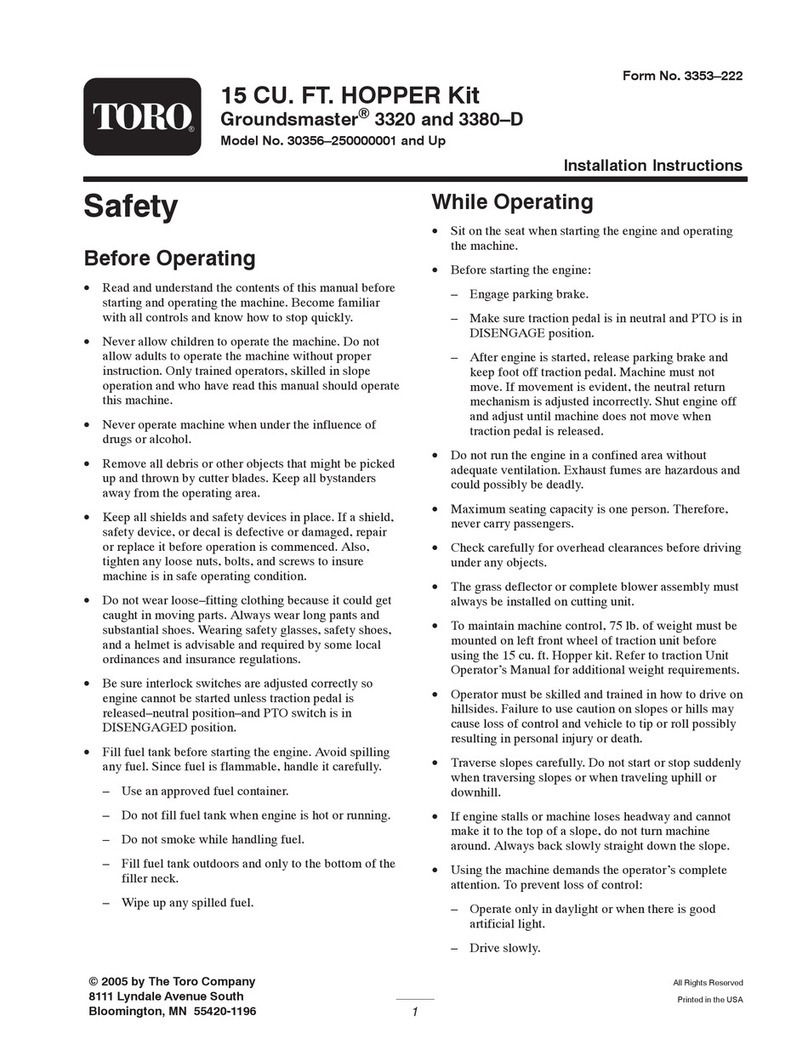

TomTec 400 User manual

1

Table of Contents

Preface………………………………………………………………………... 2

CHAPTER 1.......................................................................................... 3

Introduction………………………………………………………………….. 4

QUADRA TOWER Specifications………………………………………….

5

Warnings, Cautions, Notes and Symbols…………………………………... 6

Requirements………………………………………………………………... 7

Installation…………………………………………………………………… 8

CHAPTER 2…………………………………………………………. 8

Getting Started……………………………………………………….……… 9

Program Mode……………………………………………………................. 10

Parameter Values………………………………………….………………… 11

Manual Mode………………………………………………………………... 12

CHAPTER 3.......................................................................................... 14

Quadra Tower Operations………………………………………………….. 15

Advanced Program Features……………………………………………….. 16

Diagnostics…………………………………………………………………… 20

Aspirate and Dispense Logic………………………………………………... 23

Accuracy and Precision……………………………………………………... 23

QUADRA TOWER Sample Programs…………………………………….. 24

CHAPTER 4.......................................................................................... 26

Fuse Replacement............................................................................................ 27

TOMTEC’s Warranty Policy………………………………………………. 29

TOMTEC’s Return Policy………………………………………………….. 29

Quality Control Testing…………………………………………………….. 30

Certificate of Decontamination……………………………………………... 35

Contacting TOMTEC, Inc.…………………………………………………. 36

2

Preface

The Employees of TOMTEC wish to thank you for purchasing our QUADRA

TOWER.

This manual provides general information, installation instructions and operation

for the QUADRA TOWER.

Every effort has been made to avoid errors in text and diagrams; however,

TOMTEC, Inc. assumes no responsibility for any errors, which may appear in

this publication.

It is the policy of Tomtec, Inc. to improve products as new techniques and

components become available. Tomtec, Inc. therefore reserves the right to change

specifications at any time.

We would appreciate any comments on this publication.

TOMTEC, Inc.

1000 Sherman Avenue, Hamden, CT 06514 USA

Phone: (203) 281-6790 Fax: (203) 248-5724

3

CHAPTER

1

General Information

This chapter give background information on

the QUADRA TOWER

Section Includes:

•Introduction

•Specifications

•Accessories

•Standard Warnings, Cautions, Notes

and Symbols used in this Operators

Manual

4

Introduction

Congratulations on the purchase of your QUADRA TOWER

The pipettor instrument is designed to be operated either manually from the front

operator’s panel or through user defined programs.

The overall dimensions of this instrument and the built in flexibility offer a

comprehensive pipetting unit in a very small footprint.

Up to forty Programs can be created and saved within the unit.

CAUTION:

IF THE INSTRUMENT IS USED IN A MANNER

NOT SPECIFIED BY THE TOMTEC

INC., THE PROTECTION BY THE INSTRUMENT

MAY BE IMPAIRED.

NOTE: The Model 400 QUADRA TOWER™ is designated for use with various

liquids and aqueous solutions with a pH near neutral. As the pH of the solution

moves away from neutral, various parts may be affected, depending o the length of

time they are in contact. The user has full responsibility for the selection of

compatible liquids, and for thoroughly rinsing the system after each use.

Damage resulting from improper use of liquids may void the warranty.

5

Specifications

QUADRA TOWER

Environmental Specifications

Operating

environment

INDOOR USE ONLY

•Temperature: 5 °C to 40 °C (41 °F to 104 °F)

•Humidity: 20%–90% (no condensation)

Storage

environment

•Temperature: 0 °C to 60 °C (32 °F to 140 °F)

•Humidity: 5%–90% (no condensation)

Physical Specifications

Dimensions

•Width: 11.75 in. (298.54mm)

•Depth: 14.00 in. (546.10mm)

•Height: 24.50 in. (622.30mm)

Weight

•85.0 lbs (38.55 kg)

Electrical Specifications

Power

requirements

•100 – 120VAC, 50/60 Hz @ 2.0 Amp

or

•230 – 240VAC, 50/60 Hz @ 1.0 Amp

Pneumatic Specifications

Compressed air

requirements

•Internal Compressor supplies required air

(20 – 35 PSI if external supply is used)

6

Warnings, Cautions, Notes & Symbols

Throughout this manual, there may be blocks of text printed in bold type within

boxes or italic type. These blocks are warnings, cautions, and notes, and they are

used as follows:

Note: A NOTE indicates important information that helps you make

better use of the QUADRA TOWER.

Throughout this manual, there may be symbols within triangles, and they are used

as follows:

WARNING:

A WARNING indicates the potential for bodily harm

and tells how to avoid the problem.

CAUTION:

A CAUTION indicates either potential damage to

hardware or loss of data and tells how to avoid the

problem.

The lighting flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of non-

insulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute the risk of

electric shock.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance instructions within the literature.

7

REQUIREMENTS

To install the Model 400 Series QUADRA TOWER check that the following

services are available:

Power source: 100 – 125VAC or 220 – 240VAC, 50/60Hz depending on model.

Optional: Compressed air source 35 – 125 PSI unregulated.

The following items supplied with the QUADRA TOWER is required for the

installation:

Line Cord - Catalog Number 827-001-03 for Domestic and Japan, Catalog

Number 827-210-25 for Europe or Catalog Number 827-001-03 for the United

Kingdom.

AIR PRESSURE CONNECTION

TOMTEC Inc. has incorporated a compressor for the QUADRA TOWER.

However, laboratory air may be used with the external air supply kit (CAT. # 430-

10) instead of the on board compressor.

INSTALLATION

•Connect the correct Line Cord to the power module located on the right side of

the QUADRA TOWER.

•Connect the plug to the correct AC power supply.

WARNING:

TO HELP PREVENT ELECTRICAL SHOCK,

PLUG THE QUADRA TOWER INTO A

PROPERLY GROUNDED POWER SOURCE.

THE CABLE SUPPLIED WITH DOMESTIC

UNITS IS EQUIPPED WITH A THREE

PRONGED PLUG TO ENSURE PROPER

GROUNDING. DO NOT USE AN ADAPTER

PLUG OR REMOVE THE GROUNDING PLUG

FROM THE CABLE; USE A THREE-WIRE

CABLE WITH PROPERLY GROUNDED PLUGS.

8

CHAPTER

2

Installation

This chapter tells you how to connect and

operate the QUADRA TOWER

Section Includes:

•Getting Started

•Program Mode

•Manual Mode

9

Getting Started

QUADRA TOWER

Operator’s Panel

Prior to any operations the QUADRA TOWER must be initialized. This simple

procedure allows the system to run a ‘self-check’ sequence, and then enter the

“Standby mode”. The Procedure is as follows:

•Press the <Run> button.

Once this has been accomplished the QUADRA TOWER can now run a program

from its memory, or be put into the “Manual Mode” to create a user program.

Loading & Shucking Tips:

Now that the unit has been initialized the tips can be loaded.

To Load:

10

To load tips onto the pipettor

head, the Tip Jig (filled with the

appropriate tips) must be placed

level into the wash station as

shown to the left. Pressing <Load

Tips> activates the sequence.

Remove the Tip Jig.

To Shuck:

Simply reverse the procedure

above. Place the Tip Jig back into

the wash station, again making

sure it is well seated in place.

Press <Shuck Tips> to activate

the function. Now you can

remove the Tip Jig, filled with the

tips, to whatever your purpose

may be.

Running a Program

In the interest of a ‘quick start’, the operator can run a stored program by using the

following procedure:

•From the QUADRA TOWER banner message, press <SELECT> to select

“Programs XX” (01 thru 40). Use the Program <up/down> arrows to search

for the desired program number.

SELECT UP / DOWN RUN

Selects 1 of 40

programs

Selects Program

number

Executes

selected program

•Press <RUN> to execute the program.

•You can press <Stop> to pause the program operation at any time.

•Press the <Run> key at anytime to resume or <Stop> again to abort.

Program Mode – Operation

Both units have 40 user configurable programs numbered 01 – 40 that are accessed

through the Front Panel in the SETUP mode. Each program consists of four cycles.

Each cycle contains several functions and parameters which are listed below in

table form. During each step in each cycle, the cycle number (1-4) appears as the

first number on the screen. Please note that the front panel programming is

mirrored in the QUADRA TOWER Program Editor program for your Windows™

based computer. Some users may find that programming in the QUADRA

TOWER Program Editor, then downloading this information to the QUADRA

TOWER may be more efficient than programming directly on the unit.

To create a new program, or edit an existing program, use the following procedure:

11

•Turn on the QUADRA TOWER.

•From the QUADRA TOWER banner message, press <SETUP> to select

“Programs XX” (01 thru 40).

NOTE: Use the Scroll <up/down> arrows to search for the desired

program number. Use the Cursor <right> arrow to search for the

desired program parameter.

SETUP SCROLL UP /

DOWN

CURSOR

RIGHT

Selects

Programs

Selects Program

number

(01 – 40)

Selects

Program

parameter

Parameter Value

Tray Station

1 to 5 – 1 to 4 are the sliding trays and station 5 is the wash bath.

NOTE: use the tip load jig on top of the wash reservoir to load and

unload tips

Tip Height #1 Pressing “Run” will cause the pipettor head assembly to come to a

preset height for the selected station. This preset height is

approximately 1/16 inch (1.5mm) from the bottom of the plate or

reservoir on the selected station. The operator may accept this height

or scroll up or down to the desired height for the application.

As, Ds, aG

V#1:

Aspirate liquid (As), Dispense liquid with touch off (Ds) or Agar –

dispense without touch off (aG). Volume set for this parameter using

the <up/down> scroll buttons from 0 to 450ul. If volume is set to 0,

then the following two parameters do not appear.

#1: A, D or G - The As, Ds or aG functions can be set.

S: Pipetting Speed. Values are 1-4. TOMTEC recommends 3 for most

applications. Viscous fluids may require a slower speed.

Mx Cyc: Mix cycles (0 to 99) using <up/down> value buttons

Vo: Volume for mix cycle (0 to 450ul) using <up/down> scroll buttons.

If volume is set to 0, then the following four parameters do not

appear.

Mx Asp Ht: Mix Aspirate Height. Values are 0 to 8630.

S: Pipetting speed. Values are 1-4.

Mx Disp Ht: Mix Dispense Height. Values are 0-8630.

S: Pipetting speed. Values are 1-4.

12

Tip Height #2 Tip height is set to go to a preset height for the plate or reservoir.

During each program cycle, only 1 tray can be selected. The user

may then use the <down> scroll or value buttons to fine tune the tip

movement into the tray.

As, Ds, aG

V#2:

Aspirate liquid (As), Dispense liquid with touch off (Ds) or Agar –

dispense without touch off (aG). Volume set for this parameter using

the <up/down> scroll buttons from 0 to 450ul. If volume is set to 0,

then the following two parameters do not appear.

#2: A, D or G - The As, Ds or aG functions can be set.

S: Pipetting Speed. Values are 1-4. Tomtec recommends 3 for most

applications. Viscous fluids may require a slower speed.

W, M, S: Wash Tips (W) pause minutes (M), or pause seconds (S) using the

<up/down> value buttons.

n: Dependent on W, M or S, the program will wash the tips for n cycles

or pause the program for n minutes or n seconds using the

<up/down> scroll buttons from 0 to 99.

Tips E,K,L,S:

Empty (E) is used to dispense any residual and resets the pipetting

volume to 0ul in the head. Skip (K) is used to continue to next cycle

in program. Load (L) is used to load tips from the tip jig. Shuck (S)

is used to “Shuck” or unload tips into the tip jig.

L, N, P, Q, R: Loop with pause (L) is used to loop cycle. Loop with NO pause (N)

is used to loop cycle. Pause (P) will hold the cycle until user

intervenes. Quit (Q) quits the program at this cycle. Continue or

GOTO (R) continues the program or calls for another program that is

defined in the next parameter.

n: Value for L, N, P, Q or R. Value depends upon previous parameter.

This is the end of the first cycle. Each program contains up to four cycles.

Furthermore, in order to expand the programming capabilities, one program can

call (GOTO) another program.

Both units save each step of the program once the user exits by pressing the STOP

button. There is no need to specify a SAVE command. The unit saves programs

automatically upon exiting the program setup mode.

Manual Mode -Operation

Manual operations on the Quadra Tower are performed using the Manual Mode

Buttons and Tray Buttons. The user may start by:

1. Adding reagent reservoirs or plates as the user finds necessary on the trays.

2. Loading tips onto the pipettor head.

3. Selecting the Aspirate Button without selecting a tray button. This method will

allow the user to pipette and air gap before aspirating liquid samples.

4. Select a tray button then select Aspirate button. This method will allow the user

to pipette directly out of the tray without an air gap.

ASPIRATE:

13

Air gap? <nnn> - Allows user to define air gap µl (0-450ul)

Vol? <nnn> - Volume to Aspirate

AsHt: <nnnn> - A default height is preset. This height is approximately

1/16 inch (1.5mm) from the bottom of the plate or reservoir on that station.

The operator may scroll up or down from this height to the desired height.

This aspirate button with no selected trays will allow the user to define in micro

liter volume, the air gap before pipetting a liquid. Furthermore, with a tray pre-

selected, this function will aspirate a volume (up to 450µl) at a user defined height.

DISPENSE:

Vol? <nnn> - Volume to Dispense

DsHt: <nnnn> - A default height is preset. This height is approximately

3/16 inch (5mm) from the bottom of the plate or reservoir on this station. It

is 1/8 inch (3.5mm) higher than the default aspirate height described above.

The operator may scroll up or down from this height to the desired height.

Once liquid or air has been aspirated, the user may then dispense this sample into a

selected tray, or without selecting trays 1-4 then the pipetting head will dispense

the sample into the wash reservoir. The dispense height is user defined.

LOAD TIPS:

The user must place tip load jig on top of wash reservoir. Furthermore, make sure

that no tips are already on the pipettor head.

SHUCK TIPS:

The user must place tip load jig on top of wash reservoir. The tip load jig must

also be empty before shucking tips off of the pipettor head.

WASH TIPS:

Vol? <nnn> - Volume to wash tips

DsHt: <nnnn> - Dispense height of pipettor head – Aspirate height is

predetermined in the settings

The user must make sure that the tip load jig is removed. The wash tips function

performs a tip wash in the wash reservoir. The aspirate height is user defined.

Function Buttons

<F1> - Upload or Download programs to Quadra Tower Program Editor.

QUADRA TOWER must be connected to a Windows™ based computer via serial

connection. Use <up/down> scroll or value buttons to change parameter.

<F2> - Diagnostic parameters. Tomtec Service uses this tool.

<F2><F2> - Alignment Wizard. The alignment wizard is selected by pressing the

F2 button twice. To use, the operator should place a standard SBS 96 well

microplate on each of tray station 1,2,3, and 4. Pressing <Run> will cause the

pipettor head to move to a height just above the wells. The nest, holding the

microplate, may be aligned to the tips by loosening the four screws securing the

nest. After alignment the screws are retightened.

<SETUP><SETUP> - Global Parameters

14

CHAPTER

3

Technical Data &

Trouble Shooting

This chapter covers a deeper understanding of

QUADRA TOWER usage along with

troubleshooting.

Section Includes:

•QUADRA TOWER operations

•Advanced Program Features

•Diagnostic Display

•Aspirate and Dispense Logic

•Accuracy & Precision

•QUADRA TOWER Sample

Programs

15

QUADRA TOWER OPERATIONS

The QUADRA TOWER is designed for use by a variety of individuals with

various pipetting skills and requirements. For those who have simple aspirate and

dispense tasks, they may not want to set up automated programs. The TOWER has

manual pushbuttons to facilitate this simple type of operation, select the volume,

set the tip height and execute the function.

The QUADRA TOWER will accommodate pipeline pipetting. This is aspirating

several aliquots into the tips and separating each with an air gap. The higher

volume buffer or diluents should be aspirated first. The compound, or specific test

reagent, which is normally a smaller volume, should be aspirated last. On the final

dispense, the larger volume buffer is used to wash out the smaller volume reagent.

This will improve your pipetting precision.

When using pipeline pipetting

with separation air gaps, it is

recommended that the first

dispense be made near the top of

the well. This will prevent the air

gaps from creating air bubbles in

the bottom of the well. Air

bubbles can affect the readout on

some applications.

Normally, the dispense function is followed by a mix function using titration. The

QUADRA TOWER program allows setting the number of mix cycles, the volume

to be mixed, the aspirate height, and the dispense height. The number of mix

cycles is dependant on the application. Three is a reasonable number but more

may be beneficial. The aspirate height should be set near the bottom of the well.

The dispense height should be set near the top. This turns the liquid over on each

cycle. The volume should be set for approximately 70% of the liquid volume in

the well.

Again, this facilitates turning the liquid over rather than moving it up and down

within the tip. If the liquid is low in viscosity, i.e., mainly aqueous, you may use

mix speed 3 or 4. However, if the liquid has noticeable viscosity, then mix speed 1

or 2 is desired. If the mix speed is too fast, the liquid will not flow up into the tip

at the same rate the piston moves. That condition is not conducive to good mixing.

Adding Cycles

The programming of the QUADRA TOWER is set up using 4 cycles per program.

Four cycles are not sufficient for many programs. Thus, after 4 cycles in one

program, you may automatically call 4 more cycles in another program. The only

limit is that the memory of the QUADRA TOWER will only accommodate a total

16

of 40 programs of 4 cycles each. As stated above, additional programs may be

stored on a computer and downloaded to the QUADRA TOWER.

The cycles are structured to facilitate programming. The first four steps select a tip

height, a volume, an aspirate or dispense function. This is followed by the

availability of a mix function asking cycles and volumes. If either mix cycles or

volume is set to zero, the mix function is skipped. If a number of cycles is set,

along with a volume, then an aspirate and dispense height are added. This is

followed with another height – aspirate - dispense set of functions.

Having two aspirate/dispense functions in a cycle facilitates aspirating an air gap

then a reagent. This also accommodates the dispense function, followed by a mix

sequence, followed by the dispensing of the blow out air gap.

Following these functions, comes the parameter for the tips. The tips may be

‘Shucked’ (S), ‘Loaded’ (L), or ‘Emptied’ (E). If (S) or (L) is selected, the

program automatically pauses with the pipettor head at the top or home position.

This allows the operator to place the tip jig on top of the wash station. The

operator then must push run to continue the program. If ‘Empty’ (E) is selected,

the pistons will move to their home or empty position. If liquid is in the tips, it will

be dispensed at the present location.

The final parameter is the ‘Loop’ function (L). This causes the cycle that has just

been finished to repeat. A timed delay can be created by selecting ‘Minutes’ (M)

or ‘Seconds’ (S). The other parameter is ‘Pause’ (P) or ‘Run’ (R). A pause stops

the program until the operator presses the run button to commence action. ‘Run’

(R) allows the program to go to the next cycle. The last parameter is the

continuation. If (L) is set, this number determines how many loops are made. If

this is the 4th cycle ending this program, the continuation parameter calls the next

program for an additional 4 cycles.

Advanced Program Features

The desire of a low cost instrument design creates compromise in the operators

interface. Various programming conveniences are provided by creative

multifunctional use of the available push buttons. These special features are

described as follows:

Setting default program heights:

The height of the tips is controlled by a stepper motor drive moving the head

assembly between pipetting stations. The display shows the number of steps the

head is moving from its home or up position. Each step equates to .001 inch of

vertical travel, i.e., 62 steps equals 1/16 inches, 125 steps equals 1/8 inches, 39

steps equal one millimeter.

To facilitate setting heights for each of the stations, the program uses preset

default values. The actual value required, may then be scrolled up or down from

this value. When in the program mode, selecting a tray and pressing run will cause

that tray to extend. (Pressing F2 will cause the tray to withdraw.) The head will

come to the safe height for that tray. The safe height is set in software it brings the

head assembly to a safe height to a selected station. The safe height provides

sufficient room to change the plate or reservoir as necessary.

Pressing F2 and holding it momentarily, will access the tray safe heights. They are

initially preset by TOMTEC to clear a conventional micro plate on station 3 and 4.

The safe height on station 1 and 2 is set to clear a reservoir. These may be changed

to suit operator preference.

The next height selection in the program is for the volume functions. The default

value is preset by TOMTEC to be near the bottom of a conventional micro plate.

17

This is chosen to be approximate, to minimize scrolling to the desired actual value.

You may scroll the value up or down to the required setting for your application.

Pressing “Run” will move the head assembly to this value. Pressing F2 will bring

it up. If set too low, the stage safety error will appear.

Correcting errors during a run:

Errors of various types may occur while running a cycle. The QUADRA TOWER

programming provides several ways of correcting the error to save the work in

progress. During a program, if the error message occurs, the following corrective

action may be taken.

If an error does occur, the program pauses where it is. Pressing the left cursor key

will show the error message on the display. During the error condition, the

operator has access to the manual push buttons to operate the system manually to

make the required correction. Pressing the program upper scroll button will cause

the head to go up to its home or clear position. The tray buttons provide access to

the plates. The manual aspirate and dispense functions are accessible.

After taking the necessary corrective action, the operator has the choice to return

to the program. If corrective action has failed, pressing the yellow F2 button will

tell the program to “retry” that failed function and proceed to the next. Pressing the

green “run” button, will tell the program to “skip” the function and then proceed.

Pressing the red “stop” button will “abort” the running program.

Some of the pushbuttons have multiple functions. Some are accessed with multiple

pushes. Others are activated at a specific point in the program. They are defined as

follows:

NORMAL OPERATION AS DEFINED BY THE

PUSH BUTTON MARKING

Program Scroll Up: Moves the program access number.

Program Scroll Down: Moves the program access down.

Program Select: Selects the program to be run.

Program Set Up: Selects programming mode of operation.

Parameter Cursor Right: Advances parameter steps.

Parameter Cursor Left: Reverses parameter direction.

Parameter Value Upper: Increase parameter value.

Parameter Value Lower: Decrease parameter value.

Following are the additional functions these

buttons provide:

Setup: Pressing this button twice enters the instrument parameter

mode. This controls the various mechanical operations of the

instrument. “R” stands for the ramp setting for the specific

stepper motor. “S” stands for the stepper motor speed. We

suggest using the factory settings, unless otherwise

necessary.

Carriage: Sets the values for moving the head assembly up and

Down.

Tip Loading:

Sets head motor speed for tip loading.

Tip Shuck:

Sets head motor for this function.

18

Aspirate:

Sets ramp speed for an aspirate function.

Dispense:

Sets ramp speed for a dispense function.

Tip Wash:

Sets piston speed for a wash cycle.

Tip Load

Height:

This sets the height the head assembly comes to, to load tips.

From this setting, the head assembly automatically goes down

500 steps to load the tips.

The software looks for activation of the tip load switch, indicating the tips have

been properly loaded. If the tip load switch is not activated after the first 500 step

increments, the software steps down another 500 step increments looking for the

tip load switch activation. If it occurs again, the procedure is applied a third time.

After the third try, if the tip load switch is not activated, a tip load error occurs.

Please note that the software issues the step command. The stepper motor will

follow the step count within its torque capability. If the opposing force exceeds

the stepper motor torque, the stepper motor simply stalls. After the three

successive attempts, the error message is called for operation correction.

NOTE: the stage safety is bypassed when loading tips.

Tip Shuck

Height:

This is the height the head assembly comes to for shucking

tips.

Pump Shuck

Steps:

This is the number of steps that moves the tip shuck plate to

clear the tip “O” rings to shuck the tips.

µL Liter Factor:

This sets the number of steps per microliter. This is a

calibration factor. See the discussion on accuracy and

precision.

Backlash Factor:

This is the number of steps that the software adds to the

initial movement of the pistons on an aspirate or dispenses

function. It is added any time the pistons make a change in

direction. It is used to improve accuracy at small volumes.

See discussion on accuracy and precision.

Z Offset:

This factor is used to compensate for the mechanical,

dimensional variations between instruments. The Z factor is

used to align the software dimensions to the machine

dimensions. It is a global factor affecting the base line for all

dimensions. It is used to align the head dimensions to the

software values if the head assembly is changed.

After installing and aligning the head assembly, a set of tips are loaded. Place a

piece of paper (20 pound offset is typical), on the metal nest plate of station #1.

From the “Z” offset banner press “run”. The head will move down to its calibrated

height. If the tips are not touching the paper, increase the Z factor setting in the

positive direction (program scroll buttons). If the paper is pinned, decrease the “Z”

factor setting. Use the parameter value button to change from (+) to (-). Set the

“Z” factor so you may just slip the paper out from between the tips and the top of

the nest. Pressing stop will enter this value into the program.

19

Tip Load Light

Switch:

“Yes” or “No”

If “No” is selected, then the setting of the tip load switch is ignored. This should

only be done in an emergency until the tip pin switch can be properly set.

Otherwise, there is no checking function that the tips were properly seated and

sealed.

Manual

Aspirate/Dispense

Speed:

This sets the speed for the manual button functions.

Manual Wash Cycles:

Sets the number of aspirate/dispense cycles used for

the manual wash button selection.

Manual Wash

Aspirate Height:

Sets the aspirate height for the manual wash function.

Yellow F2 Button

This button has several functions depending on the mode of the

current operation.

During a Running

Program:

If an error occurs, to pause the program,

the F2 button signals a “retry” after the

error condition has been remedied.

During the Creation of a

Program:

Pressing F2 will cause the head assembly

to go up to its home position.

When the TOWER is at

“rest” or “standby”:

The first push of F2 brings up a display of

the various light switches in the instrument.

These light switches are used as limit

switches to detect the completion of a

motion. A (1) indicates the light switch is

not blocked. A (O) indicates it is blocked.

The light switch diagnostic display is on

the following pages.

Table of contents

Popular Industrial Equipment manuals by other brands

SPX

SPX Power Team HNS150A Parts List, Assembly, and Operating Instructions

ESAB

ESAB Warrior Feed 304 instruction manual

Artos Engineering Company

Artos Engineering Company FC-200 owner's manual

Humboldt

Humboldt PROMAT HM-4187H product manual

ABB

ABB HT575817 Operation manual

Sima

Sima POLINI KIDS FUN 890 Masha and the Bear quick start guide

Aseptico

Aseptico AA-75CF OPERATION, SERVICE MANUAL & PARTS LIST

Vertiv

Vertiv Liebert DA250 Installer/user guide

Telesis

Telesis PINSTAMP TMP4100 Series Installation & maintenance

Graco

Graco SaniForce SPU.A01AAA1AA0C21 Operation

Behncke

Behncke EWT 80-40 installation instructions

Mecc Alte spa

Mecc Alte spa TR1 Series Use and maintenance manual