Tone NITRO Guide

INSTALLATION AND USER INSTRUCTIONS

AUGUST 2021

VERSION 2.0

INSTA

DIGITAL MANUAL

DISCLAIMER

Congratulations on purchasing your new TONE product. The information in this

document affects your safety and your legal rights and responsibilities. Read this

entire document carefully to ensure proper configuration before use. Failure to read

and follow instructions and warnings in this document may result in serious injury to

yourself or others, damage to your TONE product, or damage to other objects in the

vicinity. This document and all other collateral documents are subject to change at the

sole discretion of TONE. For up-to-date product information, visit http://www.tone-

swiss.com and click on the product page for this product.

By using this product, you hereby signify that you have read this disclaimer and warning

carefully and that you understand and agree to abide by the terms and conditions

herein. You agree that you are solely responsible for your own conduct while using

this product, and for any consequences thereof. You agree to use this product only

for purposes that are proper and in accordance with all applicable laws, rules, and

regulations, and all terms, precautions, practices, policies and guidelines TONE has

made and may make available.

TONE accepts no liability for damage, injury or any legal responsibility incurred directly

or indirectly from the use of this product. The user shall observe safe and lawful

practices including, but not limited to, those set forth in this document.

Copyright © 2021 by TONE Kaffeemaschinen AG

All rights reserved. No part of this publication may be reproduced, distributed, or

transmitted in any form or by any means, including photocopying, recording, or other

electronic or mechanical methods, without the prior written permission of the publisher.

For permission requests, write to the publisher, addressed at the address below.

TONE Kaffeemaschinen AG

Rheinweg 4

8200 Schaffhausen

Switzerland

+41 52 620 06 06

contact@tone-swiss.com

www.tone-swiss.com

1. INTRODUCTION / GENERAL

2. SAFETY REGULATIONS

3. REQUIREMENTS FOR THE LOCATION OF OPERATION

4. DESCRIPTION OF THE DEVICE

5. INSTALLATION

1.1 General

1.2 Unpacking the device

1.3 Mode of Operation

1.4 Requirements for the beverages

1.5 Technical specification

1.6 Declarations

2.1 General safety regulations

2.2 Electrical hazard

2.3 Operating overpressure

2.4 Danger due to operational cooling

2.5 Danger due to operational heating up

2.6 Danger from sheet edges

2.7 Danger due to flammable refrigerant

3.1 General requirements

3.2 Electrical connections

3.3 Location of operation

4.1 Graphic illustration of the device

4.2 Graphic illustration “NITRO CONTROL PANEL”

4.3 Graphic illustration “SUCTION HOSE”

4.4 Graphic illustration “CLEANING SET”

4.5 Graphic illustration “DRIP TRAY”

4.6 Scope of delivery

5.1 Assembly of the PERLATOR-UNIT

5.2 Assembly of the TAP-UNIT

5.3 First time installation

5.4 Connection of the SUCTION HOSE

5.5 Switching on the device / Ready for operation

5.6 Setting the NITRO effect / foaming

5.7 NITRO or PURE-mode

5.8 Setting the cooling

5

7

8

8

8

9

9

12

9

12

9

12

10

12

10

13

10

14

11

14

15

15

5

7

6

8

5

7

6

8

6

8

7

8

8

TABLE OF CONTENS

6. HYGIENE AND CLEANING

7. MAINTENANCE

8. TECHNICAL DOCUMENTATION

9. TROUBLESHOOTING

EG DECLARATION OF CONFORMITY

6.1 Hygienic handling

6.2 Cleaning schedule

6.3 Equipment areas to be cleaned

6.4 Approved cleaning agents

6.5 Preparation / Switch off machine and remove TAP UNIT

6.6 Cleaning of the TAP UNIT

6.7 Cleaning the PERLATOR UNIT and the MIXER HOUSING

6.8 Preparation of the cleaning liquid

6.9 Dry cleaning

6.10 Empty liquid from device

7.1 Cleaning

7.2 O-rings, Perlators and tap unit

7.3 Air filter

7.4 Condenser fins

8.1 Exploded drawing

8.2 Flow diagram

8.3 Circuit diagram

8.4 Electrical assembly compressor

16

22

23

27

25

16

22

23

22

24

23

24

23

24

16

17

17

18

18

19

20

21

21

05

1. INTRODUCTION / GENERAL

1.1 GENERAL

This manual provides essential information

for safe operation of your NITRO dispensing

system / cold beverage processing system.

Please therefore read the enclosed safety

instructions carefully.

This applies in particular to safety during

installation, operation and cleaning. Please

keep this manual in a safe place

where it is accessible to all users.

Errors and technical changes reserved.

The TONE Kaffeemaschinen AG (in ac-

cordance with its policy) is constant-

ly developing the products further. The

TONE Kaffeemaschinen AG therefore

reserves the right to make changes and im-

provements to the product described in this

documentation without prior notice.

Reproduction of any kind without the prior

written permission of TONE Kaffeemaschin-

en AG is strictly prohibited. All other brands

and names mentioned in this documenta-

tion refer to the corresponding companies

or their products. TONE Kaffeemaschinen

AG claims no right of ownership of brands

or names other than its own.

Disclaimer: Despite careful control of the

contents, TONE Kaffeemaschinen AG ac-

cepts no liability for the content of external

links. The operators of the linked sites are

solely responsible for the content of their

sites.

Please read the operating instructions care-

fully before use and keep them in a way that

they are accessible to all users!

WARNING SIGN

ATTENTION!

MANDATORY SIGN!

PLEASE READ IT.

INFORMATION SIGN!

INFORMATION.

1.2 UNPACKING THE DEVICE

WARNING!

Check immediately whether

any damage can be seen on

the outer packaging of the

device.

Check immediately whether any

damage can be seen on the outer

packaging of the device. Immediately

report any damage to the transporter

or contract partner and document it.

If you do not do this as an entrepreneur,

the goods will be considered

„approved“ and the recipient will no

longer be able to rely on the transport

damage later.

After you have carefully unpacked the

device, please check whether the device has

any external damage.

Keep the packaging in case the device

may have to be shipped by a forwarding

agent. The packaging materials (boxes,

plastic bags) must never be allowed

to fall into the hands of children.

If any defects or damage to the device

are found, please inform the dealer

where you purchased the device

immediately so that the matter can be

dealt with.

INTRODUCTION / GENERAL

06

1.3 MODE OF OPERATION

This cold beverage processing system

combines various functionalities in one

device:

▪ Designed for bag-in-box applications/

sucking a beverage from a pressureless

container

▪ Vacuum switch switches off automatically

when the bag-in-box is empty

▪ Designed for Cold Brew Coffee and certain

other beverages. Suitable for operation with

air, nitrogen and CO2 and adjustable via

„NITRO CONTROL PANEL“ on

the unit or external gas supply

▪ Enrichment of the drink with atmospheric

nitrogen (78%)

▪ Cooling the beverage in the appliance

Cooling block

▪ Tapping the drink in stout-style

1.4 REQUIREMENTS FOR THE

BEVERAGES

WARNING!

The liquids must be filtered

to a filtration grade of at

least 100 µm!

This device was primarily developed

for use with Cold Brew Coffee. However,

use with other beverages such as tea is

also possible if guidelines are followed.

The liquids used must be consumable

liquids. High-proof spirits, syrups

as well as not filtered liquids are

forbidden. It is essential to note that

the liquids must be filtered to a filtration

grade of at least 100 µm (100 microns)

(cf. common disposable filters made of

filter paper), otherwise the pump inside the

device or the PERLATOR UNIT may become

clogged and the device will be damaged.

Furthermore, it should be noted that it is

essential to clean the device after use with

fresh beverages. Only when used with

pasteurized beverages do other cleaning

intervals apply.

Read „CLEANING PLAN AND

INTERVAL“ for information on cleaning-

related issues. Non-compliance will

void the warranty!

1.5 TECHNICAL SPECIFICATION

Produkt / Product:

Typ / Type:

Baujahr / Date of manufacture:

Klimaklasse / Climate class:

Kühlmittel / Refrigerant:

Masse/ Weight:

Serien-Nr. / Serial - No.:

1/N/PE AC 230 V 50 Hz 1,6 A

Getränkezubereitungssystem /

Beverage preparation system

TONE NITRO

2021

N

R290 (50g)

24 kg

TONE-2021-30-1001

SCHULTES MASCHINENBAU GMBH

Am Beetacker 5

63856 BESSENBACH,

DEUTSCHLAND

The weight refers to the machine without

attachments.

WIDENECK

CANISTER

FLEXIBLE

CANISTER

MODE OF OPERATION

07

DECLARATIONS

1.6 DECLARATIONS

We declare under its sole responsibility

that the product „NITRO 2.0“ to which

this declaration refers, complies with the

following directive(s) and standard(s):

LIST OF TECHNICAL REGULATIONS:

• Richtlinie 2006/42 / EG -

Maschinenrichtlinie

• Richtlinie 2014/30 / EU -

Elektromagnetische Verträglichkeit

(EMV)

• Richtlinie 2011/65 / EU - Beschränkung

gefährlicher Stoffe (RoHS)

• NSP-Richtlinie neu 2014/35/EU

All parts in contact with the

medium/liquid and sealants

used in this device comply with

the requirements of the FDA

(Food and Drug Administration) and/or are

made of stainless steel.

2. SAFETY REGULATIONS

2.1 GENERAL SAFETY REGULATIONS

This device corresponds to

the current state of the art.

Operational safety is only

guaranteed if the operating

instructions are followed.

Work instructions must be

followed taking into account the following

dangers.

During the installation and operation of the

NITRO dispensing system we also point out

that the following relevant laws, ordinances,

guidelines and regulations must be observed

and complied with:

1. Equipment and product safety law - GPSG

2. Occupational Safety and Health Act -

ArbSchG

3. Industrial safety ordinance - BetrSichV

4. Food hygiene regulation – LMHV

5. Beverage Dispensing Systems Ordinance

- SchankV (until 30.06.2005)

6. Technical rules for beverage dispensing

systems (TRSK and DIN standards)

7. Ordinance on Hazardous Substances

(Gefahrstoff V)

8. Generally accepted rules of technology

Relevant country-specific rules, guidelines

and regulations are to be applied.

Conversions or changes to safety-relevant

components or elements are generally

prohibited and automatically lead to the

expiration of the manufacturer‘s warranty.

▪ Check the device at least once a day

for visible damage and defects. Contact

a qualified service technician if you need

to make any changes or repair work. The

power cord may only be replaced by

authorized service personnel. Use only

original spare parts and accessories.

▪ Make sure that only authorized

personnel work on the device and that

the operating personnel is provided with

operating instructions and this user manual.

▪ Make sure that no unauthorized person

changes settings on the device or interferes

with the device.

We accept no liability for damage resulting

from the use of non-original spare parts

or accessories, as well as from improper

handling or use outside the device‘s

intended purpose.

2.2 ELECTRICAL HAZARD

Electric shock can be fatal or

lead to serious injury!

Unauthorized interference

with the electrical system is

therefore strictly prohibited.

Water and electricity

produce a deadly mixture!

08

OPERATING OVERPRESSURE

The device is supplied with a moulded

safety plug and may only be connected

to a grounded safety socket. If there is no

corresponding socket outlet with earthing

contact, the connection may only be carried

out by authorised personnel, whereby the

regulations valid at the place of installation

(e.g. in Germany VDE-DIN standard) must

be observed.

2.3 OPERATING OVERPRESSURE

Some components are under

overpressure during

operation and are therefore

a potential source of danger.

Do not loosen or dismantle

any parts that are under

excess operating pressure.

2.4 DANGER DUE TO OPERATIONAL

COOLING

The evaporation temperature

in the coolant circuit can be

as low as -10°C. There is

therefore a potential source

of danger if maintenance,

servicing, cleaning etc. are

carried out on components at the

appropriate temperature without suitable

protective measures.

2.5 DANGER DUE TO OPERATIONAL

HEATING UP

Do not touch the compressor,

condenser, motors and

piping and in particular the

radiator grille on the rear of

the device, as these parts

can heat up during operation,

which may cause injury if touched.

2.6 DANGER FROM SHEET EDGES

There is a residual risk of

injury at sheet edges and

corners despite constructive

prevention.

2.7 DANGER DUE TO

FLAMMABLE REFRIGERANT

The unit is filled with 50g of

flammable refrigerant

(R290). Due to the design

and other precautions, the

risk of flammability can be

excluded as far as possible.

3. REQUIREMENTS FOR THE LOCATION

OF OPERATION

3.1 GERNERAL REQUIREMENTS

Please also observe the technical

regulations for beverage dispensing

systems TRSK 400 „Installation of

beverage dispensing systems“.

Low voltage can damage the compressor.

The same applies if several units are

supplied with power via one power

connection.

The power plug must be freely

accessible.

3.2 ELECTRICAL CONNECTIONS

(see 1.6 Technical specification)

FUSE PROTECTION:

max. 1,6 A

VOLTAGE:

1/N/PE AC 230 V 50 Hz 1,6 A

POWER: 300 W

9

LOCATION OF OPERATION

3.3 LOCATION OF OPERATION

Adequate ventilation and extraction must

be ensured. For this purpose the distance

to the next wall should be at least 20 cm.

Attention:

▪ Never cover and/or block

the air slots. Otherwise

there will be insufficient

cooling capacity and the

cooling system may fail.

▪ Never place the device near

heat sources or direct sunlight.

▪ Under no circumstances should liquid

enter the device, otherwise there is a danger

of short circuit!

4. DESCRIPTION OF THE DEVICE

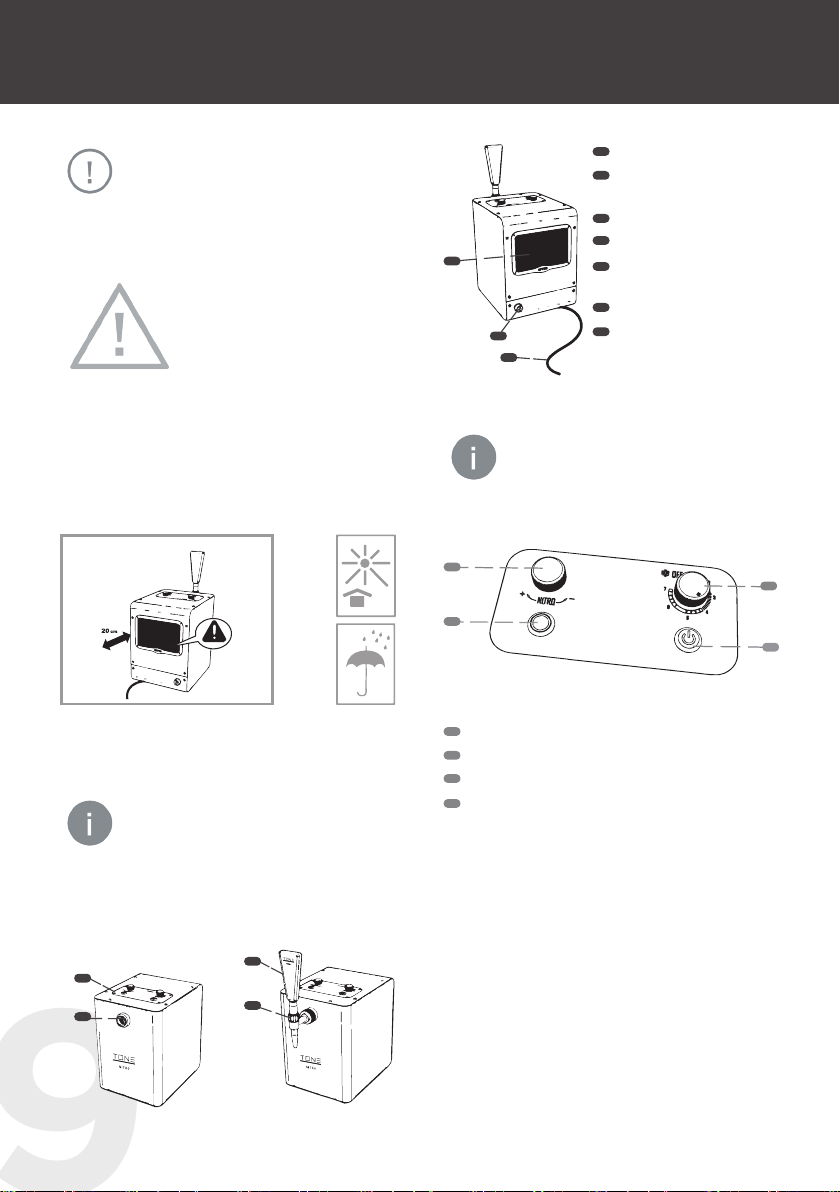

4.1 GRAPHIC ILLUSTRATION OF

THE DEVICE

These instructions are valid for all

variantes of the NITRO 2.0 Series.

NITRO 2.0

MIXER HOUSING

NITRO CONTROL

PANEL

HANDLE

TAP

BEVERAGE

CONNECTION

POWER CABLE

COOLING GRILL

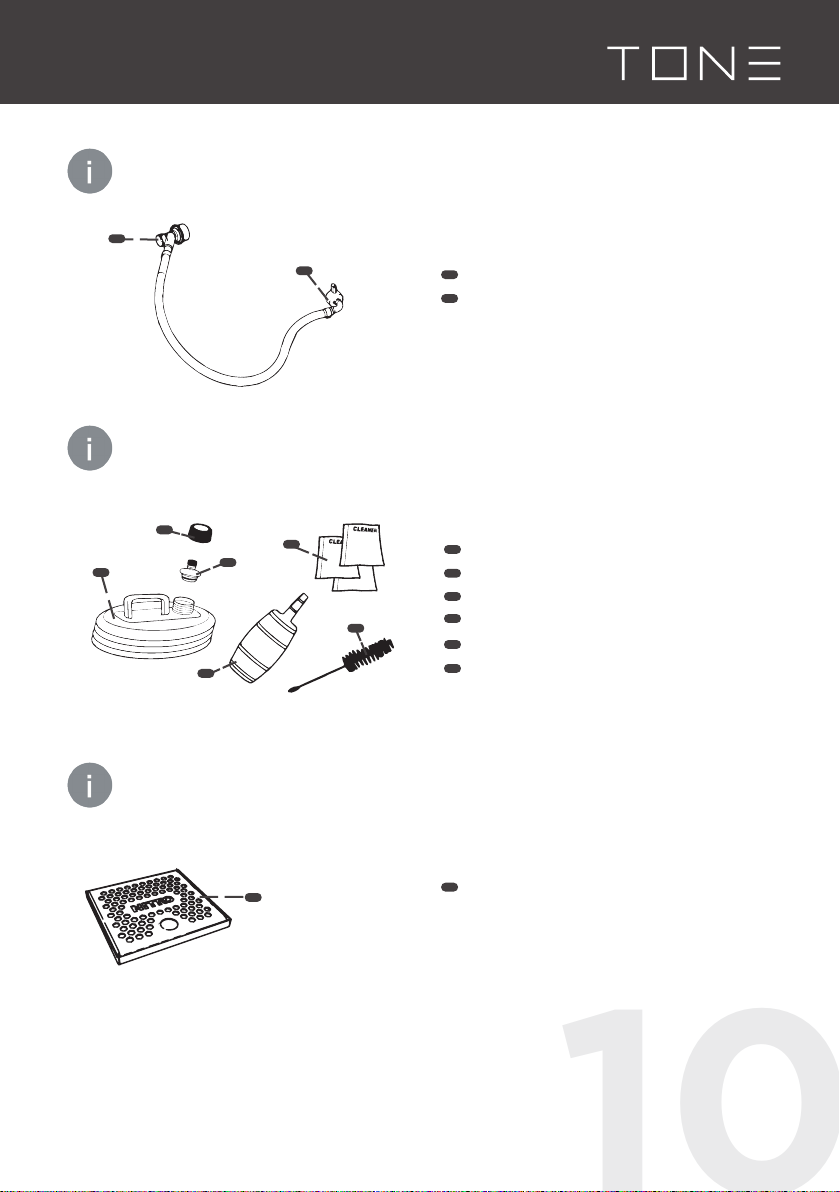

4.2 GRAPHIC ILLUSTRATION

“NITRO CONTROL PANEL”

NITRO 2.0

1

5

6

4

2

7

3

1

2

3

4

5

6

7

NITRO-SWITCH ON/OFF

NITRO CONTROL DIAL

COOLING CONTROL DIAL

DEVICE SWITCH ON /OFF

1

2

4

5

1

2

4

5

10

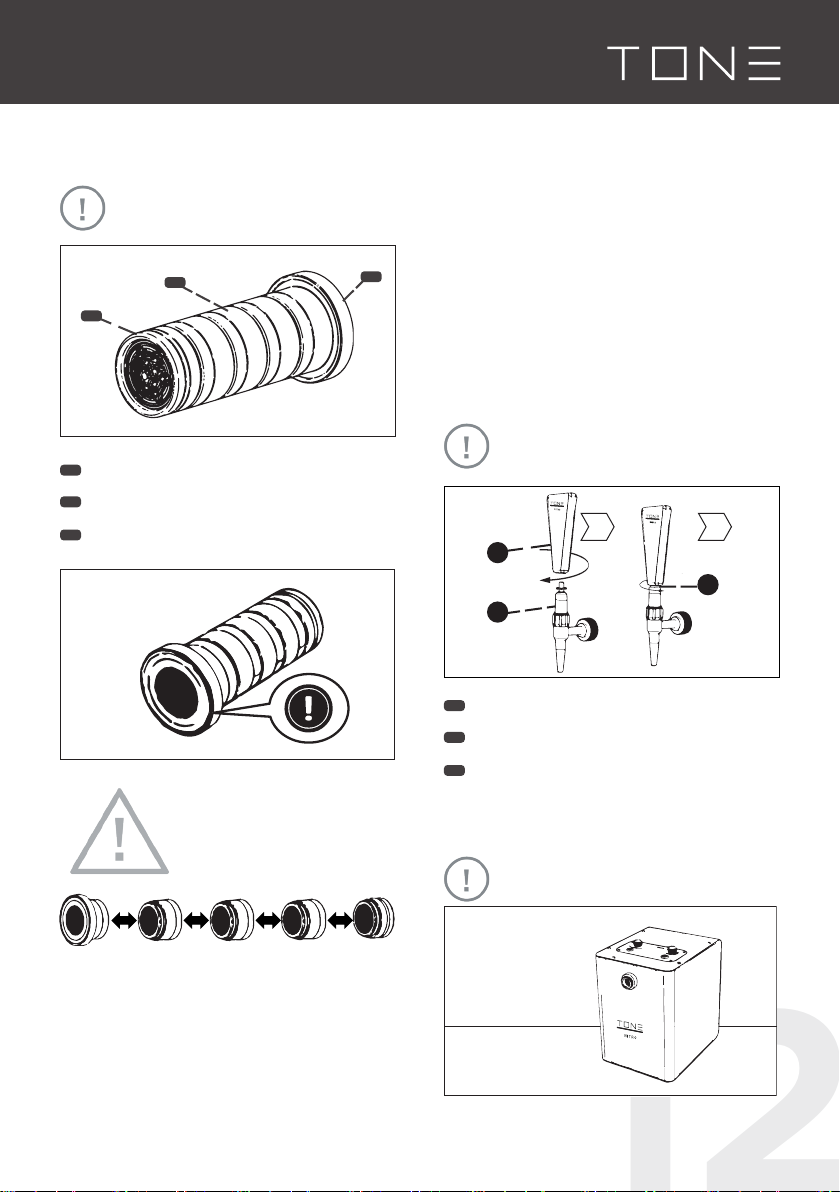

4.3 GRAPHIC ILLUSTRATION “SUCTION HOSE”

4.4 GRAPHIC ILLUSTRATION “CLEANING SET”

4.5 GRAPHIC ILLUSTRATION “DRIP TRAY”

NC PLUG-IN CONNECTOR

SCREW CONNECTION WITH WING NUT

DRIP TRAY “SMALL”

CLEANING CANISTER

CONNECTOR

UNION NUT

CLEANING POWDER

CLEANING BALL

CLEANING BRUSH

1

2

3

4

5

6

6

4

2

5

3

1

2

1

1

1

1

2

11

SCOPE OF DELIVERY

Article No Name Description

TO-103010 PERLATOR-UNIT

PERLATOR-UNIT CONSITING OF:

1X TO-103011-FRONT-PERLATOR A “GREEN”

1X TO-103012-MIDDLE-PERLATOR B “GREEN”

1X TO-103013-END-PERLATOR C “GREEN”

TO-108010 O-RING SET

(ALL)

SPARE O-RING SET CONSITING OF:

1X SEALING RING FOR SUCTION HOSE (TRANSPARENT)

4X O-RING PERLAOT UNIT (RED)

2X O-RAING PERLAOT UNIT (BLACK)

TO-104014 HANDLE HANDLE

TO-105010 SUCTION HOSE

WITH NC/CMB -

CONNECTION

SUCTION HOSE FOR NITRO WITH NC/CMB CONNECTION,

2M LENGHT

TO 106018 DRIP TRAY

“NITRO” DRIP TRAY FOR NITRO DISPENSING SYSTEM, SMALL

TO-103010 QUICKMANUAL QUICK START GUIDE LAMINATED IN PROTECTIVE FOIL;

TO-107010 CLEANING

POWDER

3X PACKAGS RELIABLE QUALITY CLEANER WITH ACTIVE

OXYGEN FOR REGULAR

ALKALINE CLEAINING;

TO-106010 CLEAINING

CANISTER 5L FOLDING CLEANING CANISTER WITH 5L CAPACITY AND NC

NC/CMB - CONNECTION

TO-107014 CLEANING BALL BEVI CLEAN BALL, TRANSPARENT THROUGHOUT, NO GAPS

AND VALVES, FOR INTERIOR AND EXTERIOR CLEANING

TO-107015 CLEANING

BRUSH CLEANING BRUSG FOR CLEANING THE MIXER HOUSING

4.6 SCOPE OF DELIVERY

12

INSTALLATION

5. INSTALLATION (STEP BY STEP)

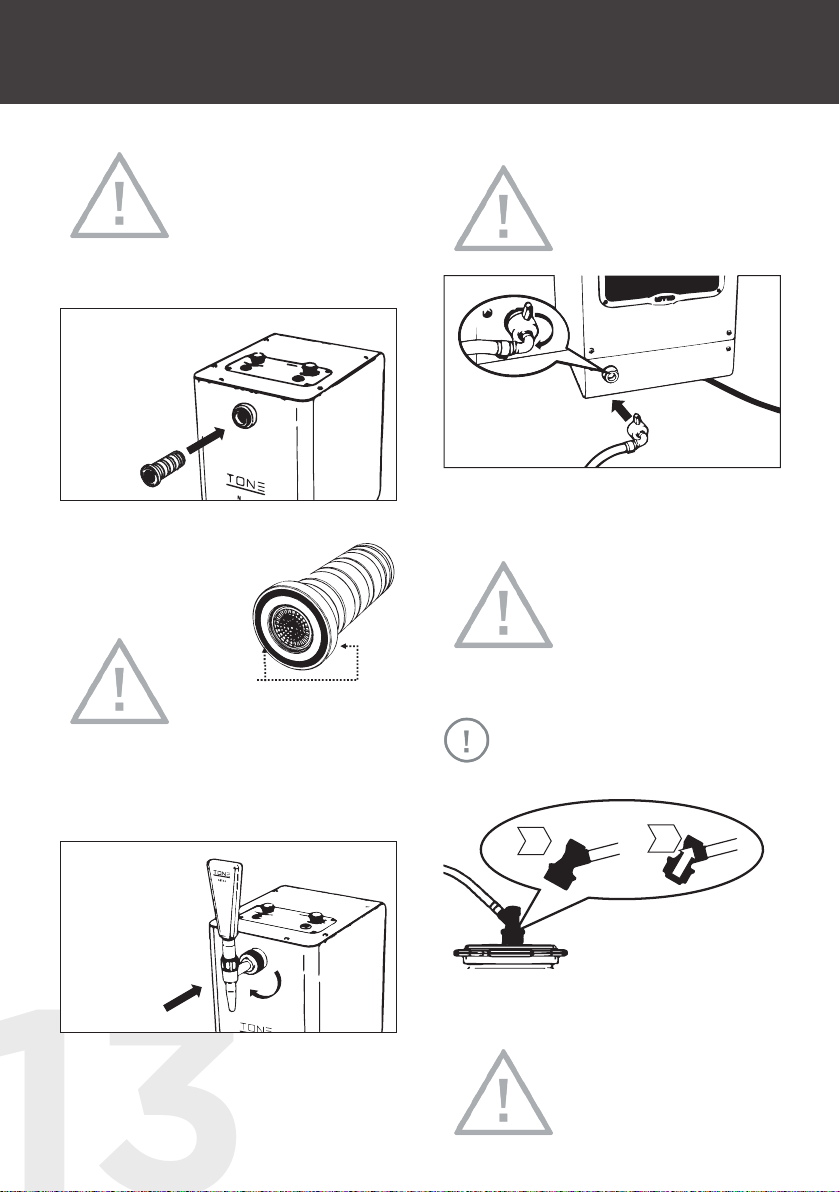

5.1 LOCATION OF OPERATION

2

Front-Perlator A (incl. 2 x black O-rings)

Middle-Perlator B (3 pcs.)

End-Perlator C (has two grooves)

Attention:

Pay attention to the O-rings!

These are located in a groove

on the front and rear side of

the FRONT PERLATOR A!

A ventilated perlator does not present

a significantly increased risk of aerosol

formation. The supplied nitrogen is

sufficiently cleaned by air filters.

To prevent the perlators from being

contaminated with biofilm growth, the

individual perlators (Perlator - A „green“,

!

Perlator - B „green“, Perlator - C „green“)

must be cleaned after use. In addition, the

inserts (103019 Perlator spare part „green“)

should be replaced at regular intervals. Read

„MAINTENANCE“ for information on cleaning

In the front piece Perlator - A „green“ there

are two O-rings: one at the front and one at

the back. Make sure that the O-rings are in

the notch of the stainless steel part before

inserting the perlator-unit into the mixer

Housing. If the O-rings are missing, the tap

cannot seal and the unit will drip on the

mixer Housing

5.2 ASSEMBLY OF THE TAP-

UNIT

1

2

3

1

21

HANDLE

TAP

CONTER NUT

Screw the HANDLE onto the TAP HANDLE.

Then lock it with the CONTER NUT.

5.3 FIRST TIME INSTALLATION

Place the device in its place.

1

2

3

1

2

3

1

23

1

2

3

21

13

CONNECTION OF THE SUCTION HOSE

Attention:

Keep ventilation and

exhaust air slots free and

do not block them under

any circumstances! When

installing the device at a new

location for the first time, it must be left to

stand quietly for at least 30 min. before use.

Insert PERLATOR

UNIT into MIXER

HOUSING.

Attention:

Pay attention to the O-rings! These are

located in a groove on the front and rear

side of the FRONT PERLATOR A!

Screw the TAP HANDLE UNIT onto the

external thread of the MIXER HOUSING and

tighten lightly (hand-hot).

2 X O-RING

Attention:

Under no circumstances

should pliers be used for

tightening!

Screw the SUCTION HOSE WITH THE

SCREW CONNECTION to the rear opening

(BEVERAGE CONNECTION).

Attention:

Clean the SUCTION

HOSE WITH SCREW

CONNECTION and the

BEVERAGE CONNECTION

with disinfectant spray

before use.

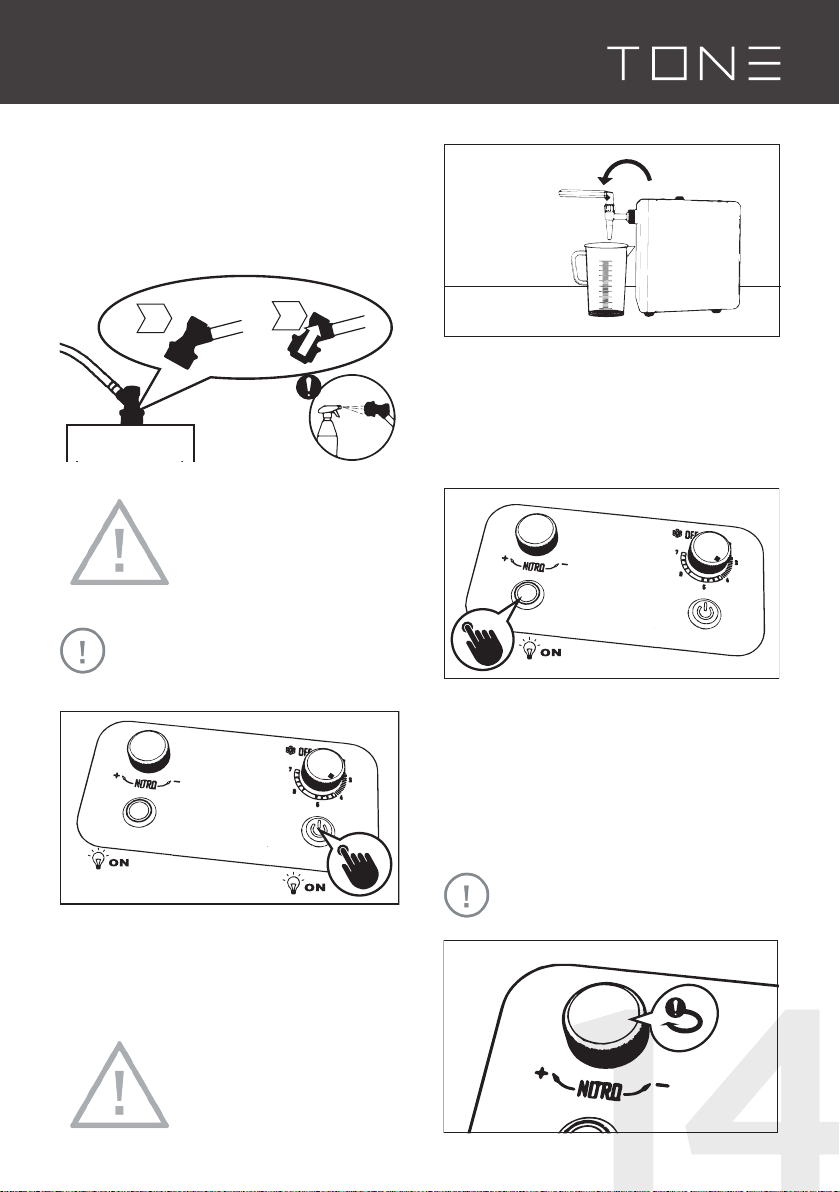

5.4 CONNECTION OF THE

SUCTION HOSE

!

2

1

!

Open the valve on the connector by pulling

the snap lock upwards and plug it onto the

coupling. Attention:

Plug the connector flush

onto the coupling. Make

absolutely sure that the

connector is plugged flush

14

SWITCHING ON THE DEVICE

onto the coupling, otherwise the system will

suck in air as well and the system will „spit“

air when tapping and/or the valve inside the

connector will not open and the system will

not suck in fluid.

!

2

1

!

Attention:

Each time the CONNECTOR

is reconnected to the NC/

CMB CONNECTION, the

coupling must be cleaned

using a disinfectant spray.

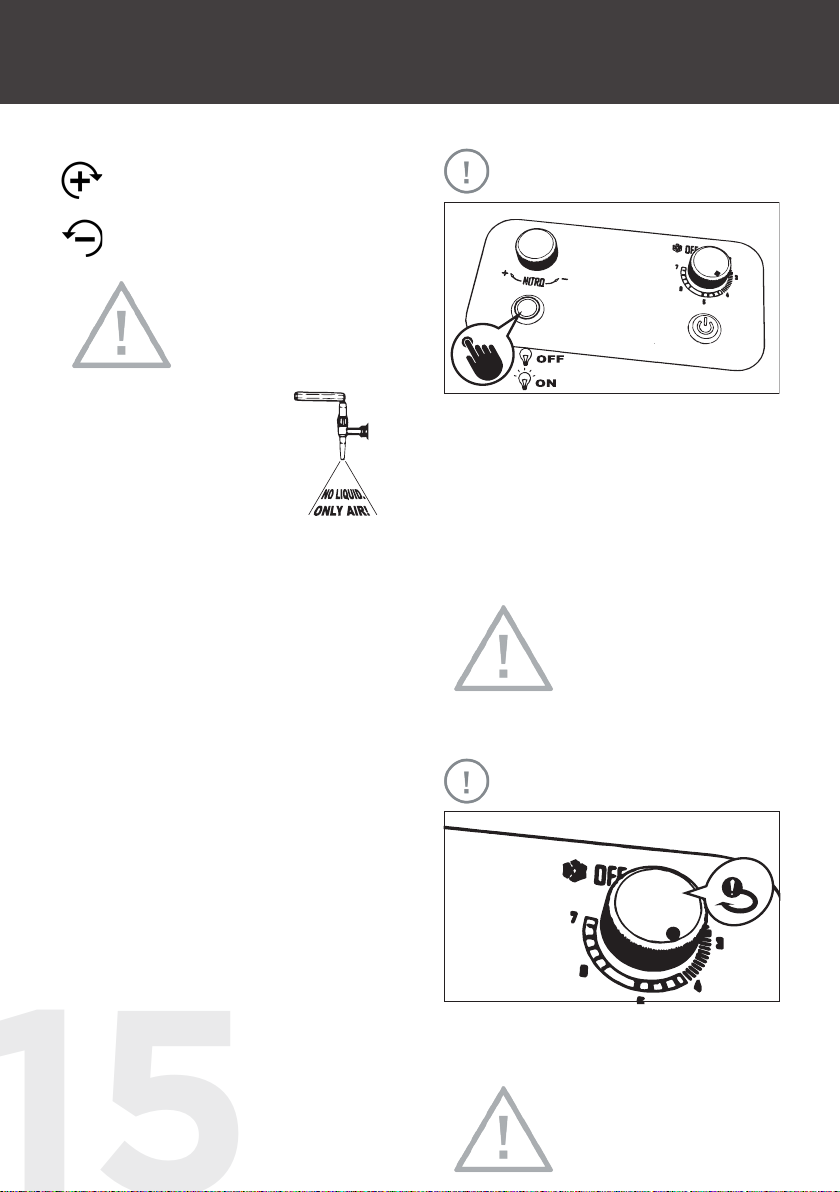

5.5 SWITCHING ON THE

DEVICE/READY FOR

OPERATION

!

Press the DEVICE SWITCH in the NITRO

CONTROL PANEL so that it clicks into place

and lights up. The unit starts automatically

and switches off after reaching the set

temperature and pressure.

Attention:

The unit is ready for

operation after approx. 15 -

25 min.

Place the glass under the TAP and pull the

HANDLE forward by 90°. The machine sucks

in the liquid and after a short time it flows

out of the tap cooled.

To stop the dispensing process, flip the

HANDLE back up.

!

Press the NITRO SWITCH in the NITRO

CONTROL PANEL so that it locks into place

and lights up. The NITRO function is now

activated.

Now the NITRO settings can be made to

adjust the foaming. More information under

„5.6 Setting the foaming“.

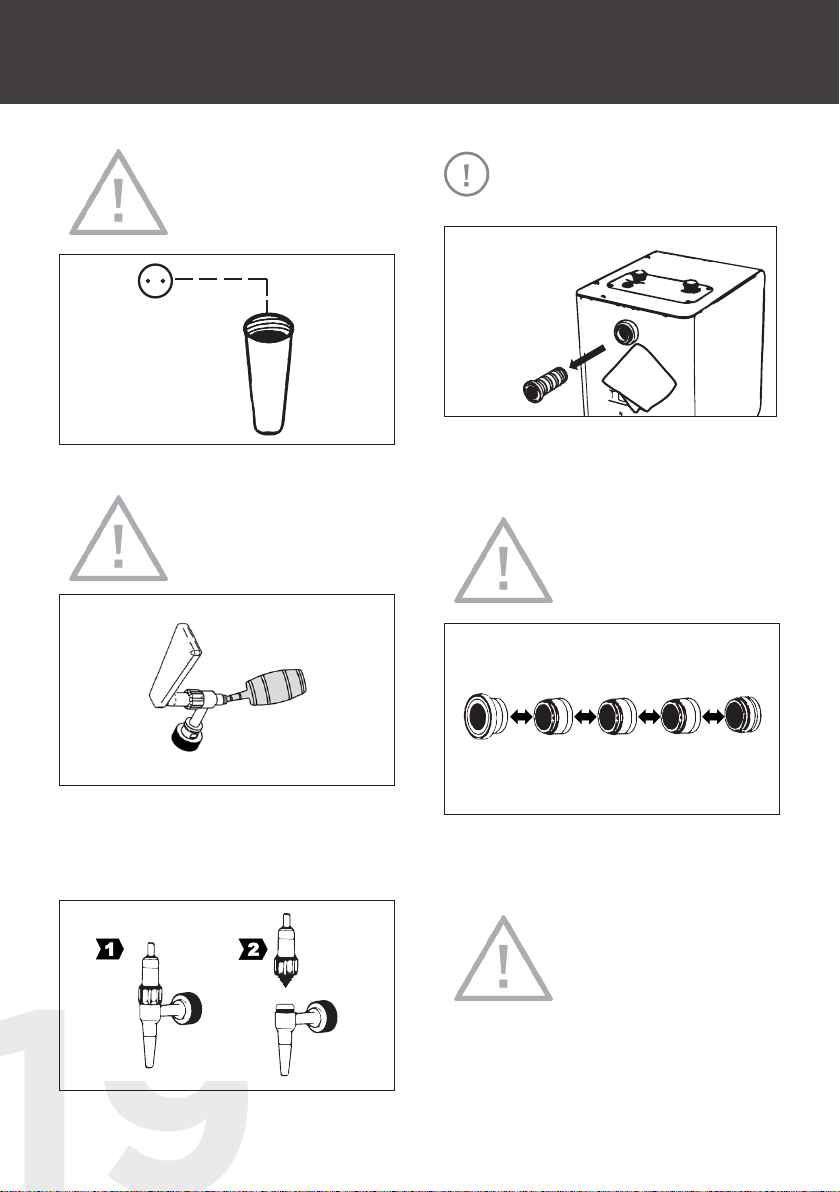

5.6 SETTING THE NITRO

EFFECT/ FOAMING

15

NITRO OR PURE-MODE

TURN FOR MORE NITRO TO THE

RIGHT / CLOCKWISE!

TURN FOR LESS NITRO TO THE

LEFT / COUNTERCLOCKWISE.

Attention:

The fine adjustment is

very sensitive and should

therefore only be carried

out in 5-10° steps. Tap in

between every now and then

and check the result.

If the system only emits

air, proceed as follows:

1. Close tap (fold tap

handle upwards again).

2. Turn rotary switch „NITRO“ at least half a

turn (180°) to the left.

3. Place a glass underneath and pull the tap

handle forward by 90°.

4. If the result still does not meet your

requirements, repeat step 2-3.

A total of about eight (8) rotations are

possible. As soon as liquid flows out of the

tap, fine adjustment (1-2° steps) can be

made during tapping.

The system takes over the adjustment as

soon as a „Pfff“ sound is heard.

If your system is only emitting air, you can

do a SYSTEM RESET.

1. To do this, turn the NITRO dial

counterclockwise until you reach a stop.

A total of about eight (8) rotations are

possible.

2. Then tap. The system should now only

dispense liquid despite activated NITRO

(after 2 glasses at the latest).

3. Turn clockwise for two full turns. Now

proceed as usual when setting the NITRO

effect.

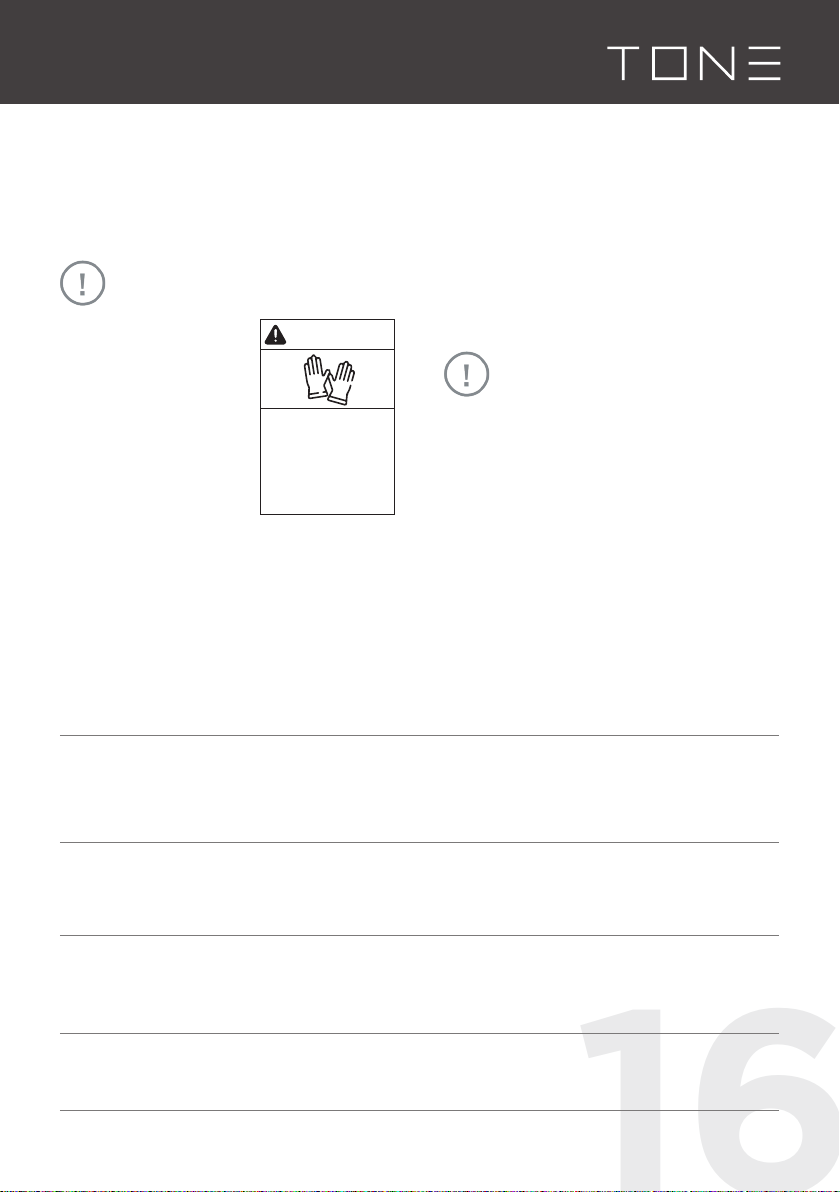

5.7 NITRO OR PURE-MODE

!

Press the NITRO SWITCH in the NITRO

CONTROL PANEL so that it clicks into place

and lights up. The NITRO function is now

activated.

Press the NITRO SWITCH in the NITRO

CONTROL PANEL so that it no longer

engages and stops glowing. The NITRO

function is now deactivated.

Attention:

If NITRO is deactivated, it

may well be that approx. 1-2

glasses still comes out with

NITRO, since there was still

pressure in the system shortly before.

5.8 SETTING THE COOLING

Turn the COOLING CONTROL DIAL clockwise

for more cooling and counterclockwise for

less cooling.

Attention:

The setting of 1-4 are ideal

16

HYGIENE AND CLEANING

for cold brew and tea. From 5-7 the cooling

block can freeze!!!

6. HYGIENE AND CLEANING

6.1 HYGIENIC HANDLING

Please note the respective national

regulations for cleaning

dispensing systems

valid at the installation

site. Since the device

is basically a beverage

dispensing system, we

recommend that you

clean the beverage

lines in accordance

with the applicable

cleaning regulations in

accordance with TRSK

501 „Cleaning of beverage dispensing

systems“. We also refer to DIN 6650-6

(„Requirements for cleaning and disinfection

of beverage dispensing systems“)

▪Before every connection and every

change of beverage type, pipes

and connecting parts and tap

NAME DESCRIPTION WHEN AND HOW?

COLD BREW

COFFEE AND TEA

(FRESH)

COLD BREW (WITH/WITHOUT

ADDITIVES) FRESHLY PREPARED DAILY,

WATER AND DRY CLEANING

COLD BREW

COFFEE AND TEA

(PASTEURIZED)

COLD BREW (WITH/WITHOUT

ADDITIVES) FRESHLY PREPARED EVERY 7 DAYS,

WATER AND DRY CLEANING

FRUIT JUICE

CONCENTRATES

(WITHOUT FRUIT

PULP)

FRUIT JUICE CONCENTRATES (WI-

THOUT FRUIT PULP) WITH/WITHOUT

ADDITIVES FRESHLY PREPARED

DAILY,

WATER AND DRY CLEANING

WINE, OTHER

ALCOHOLIC

BEVERAGES

WINE, OTHER ALCOHOLIC

BEVERAGES DAILY,

WATER AND DRY CLEANING

fittings must be cleaned.

▪Parts that come into contact

with air and drink must be cleaned

daily (especially tap outlets).

▪Follow the instructions of the detergent

manufacturer. Only use cleaning agents that

also meet the requirements of ASI 6.84 and

DIN 6650-6 for cleaning.

6.2 CLEANING SCHEDULE

Please note that different cleaning intervals

apply depending on the beverage and that

the device must be rinsed regularly with

water. The national legal requirements and

regulations apply!

The hygiene of the device is the sole

responsibility of the user! The following

information is only recommendations!

WARNING

There is a risk of severe

burns when handling

cleaning fluids! Always

observe the safety data

sheets during cleaning

work, wear protective

goggles, gloves and

appropriate clothing!

17

EQUIPMENT AREAS TO BE CLEANED

6.3 EQUIPMENT AREAS TO BE CLEANED

In general, the appliance must always be cleaned after use with freshly prepared drinks, i.e.

with a chemical cleaner and subsequent water rinse. This prevents the appliance from being

contaminated and the beverage lines from taking on a different taste.

NAME DESCRIPTION WHEN AND HOW?

TAP OUTLET

NOZZLE (INSIDE

AND OUTSIDE)

WARM WATER, CLEANING BRUSH DAILY

MIXER HOUSING WARM WATER, CLEANING BRUSH DAILY

TAP (OUTSIDE) WARM WATER, CLEANING BRUSH DAILY

CONNECTOR

(INSIDE AND

OUTSIDE) DESINFECTANT SPRAY

WHENEVER THE BAG-IN-BOX

IS RECONNECTED AND RECON-

NECTED, ESPRECIALLY AFTER PIPE

CLEANING

PERLATOR-UNIT WARM WATER, CLEANING BRUSH DAILY

BEVERAGE

CONNECTION DESINFECTANT SPRAY

WHENEVER THE BAG-IN-BOX

IS RECONNECTED AND RECON-

NECTED, ESPRECIALLY AFTER PIPE

CLEANING

COMPLETE SYSTEM WARM WATER, CLEANING BRUSH EVERY 7 DAYS,

WATER AND DRY CLEANING

6.4 APPROVED CLEANING AGENTS

Other cleaning agents may only be used after consultation with and with the express

permission of the manufacturer, otherwise the guarantee may be invalidated.

Article Nr.: 107010

Name: TM Desana Max fp

Producer: Thonhauser GmbH (AT)

Description: Chlorine-free disinfectant cleaner with „colour indicator“

in powder form;

18

PREPARATION

6.5 PREPARATION / SWITCH

OFF DEVICE AND REMOVE TAP

UNIT

!!

!!

!

Press the DEVICE SWITCH in the NITRO

CONTROL PANEL so that it is no longer

engaged and stops glowing. The device is

now switched off.

Attention:

The system is still pressurized

after the power is turned off.

Be sure to continue with the

next step!

Place the glass under the TAP and pull

the HANDLE forward by 90° so that the

remaining pressure or liquid can escape

from the device.

6.6 CLEANING OF THE TAP

UNIT

Unscrew the TAP HANDLE UNIT from the

external thread of the MIXER HOUSING.

Attention:

We recommend keeping a

cleaning towel underneath

to catch any liquid that may

leak out.

!!

!!

!

Press the DEVICE SWITCH in the NITRO

CONTROL PANEL so that it is no longer

engaged and stops glowing. The device is

now switched off.

Attention:

The system is still pressurized

after the power is turned off.

Be sure to continue with the

next step!

Unscrew OUTLET from TAP UNIT.

19

CLEANING OF THE PERLATOR

Attention:

Depending on the order,

a different tap model is

included. The illustration

may differ.

CHECK PIPE and flush with water.

Attention:

Depending on the perforated

plate, the flow rate and foam

formation can be influenced.

Flush the TAP UNIT with water. To do

this, place the tap handle 90° to the front

and then rinse with warm water using the

included CLEANING BOTTLE.

Unscrew the TAP VALVE and rinse with

water.

6.7 CLEANING OF THE

PERLATOR UNIT AND THE

MIXER HOUSING

Unscrew the TAP HANDLE UNIT from the

external thread of the

MIXER HOUSING.

Attention:

We recommend keeping a

cleaning towel underneath

to catch any liquid that may

leak out.

Unscrew the PERLATOR UNIT and rinse

it with water. If heavily soiled, place in a

suitable cleaning solution.

Attention:

With some chemical

cleaners, the stainless steel

rings may become slightly

discolored.

20

PREPARATION OF THE CLEANING LIQUID

Clean the MIXER HOUSING mechanically

using the supplied CLEANING BRUSH and

then rinse with CLEANING BOTTLE.

Attention:

We recommend keeping a

cleaning towel underneath

to catch any liquid that may

leak out.

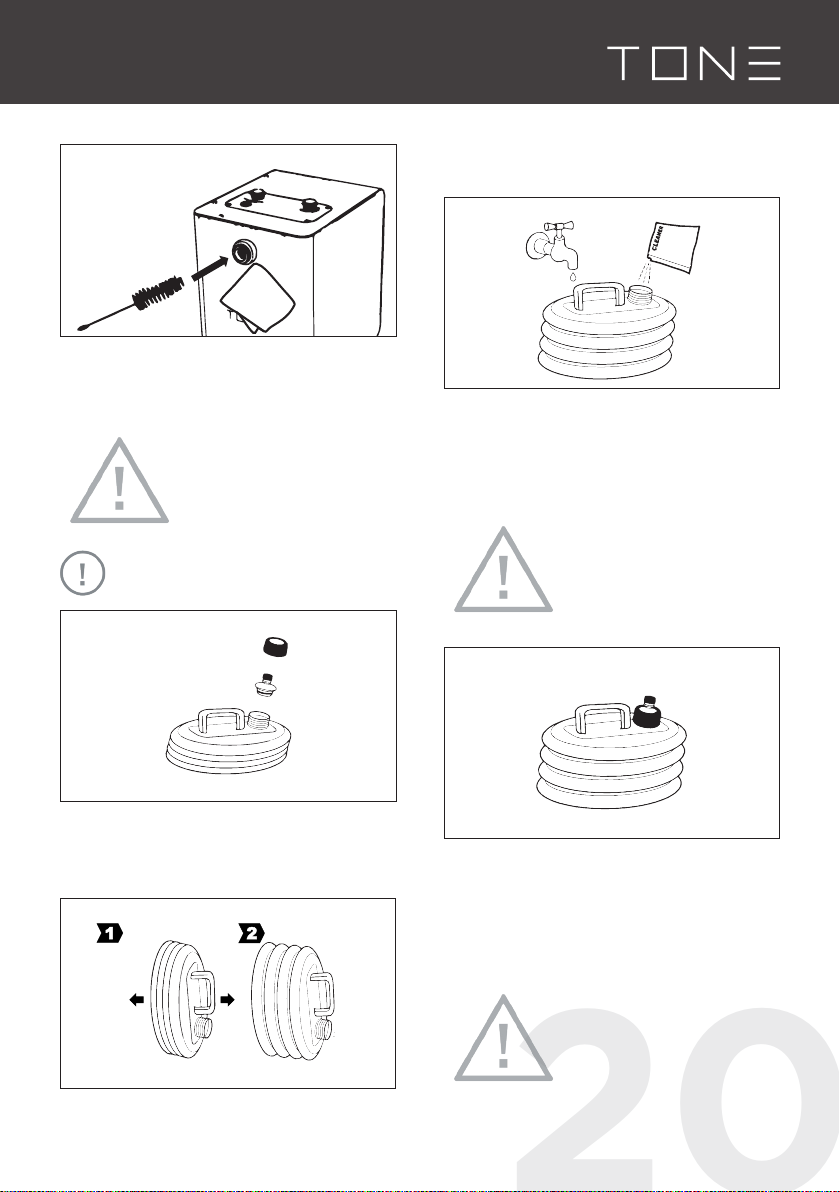

6.8 PREPARATION OF THE

CLEANING LIQUID

Unscrew the black plastic UNION NUT from

the cleaning canister and remove the NC

CONNECTION.

Take the CLEANING CANISTER by the

handle and pull it apart slightly so that the

volume is increased.

Fill the CLEANING POWDER into the

CLEANING CANISTER.

Afterwards pour lukewarm water into the

CLEANING CANISTER.

Attention:

Always wear gloves when

using cleaning agents!

Carefully release the remaining air from the

CLEANING CANISTER.

Reinsert the NC/CMB CONNECTION into

the opening provided for this purpose and

screw it tight using the plastic UNION NUT.

Attention:

The less air in the tank, the

better the system can be

cleaned.

Other manuals for NITRO

2

Table of contents

Other Tone Brewing System manuals

Popular Brewing System manuals by other brands

Brew Monk

Brew Monk 017.070.30 instruction manual

Curtis

Curtis MILANO G3 user guide

Blichmann Engineering

Blichmann Engineering WineEasy Assembly operation maintenance

BRAVILOR BONAMAT

BRAVILOR BONAMAT Bolero 20 operating instructions

BRAVILOR BONAMAT

BRAVILOR BONAMAT B-Compact operating manual

Curtis

Curtis GEM-120A-10 user guide

Blichmann Engineering

Blichmann Engineering BEPS-MLT-5BBL-SW Assembly operation maintenance

Curtis

Curtis RSTB Service manual

Bunn

Bunn Trifecta Service & repair manual

Ss Brewtech

Ss Brewtech Keg WaSsher manual

Newco

Newco KB Series Installation, operation and service manual

Keg King

Keg King KEGMASTER XL user manual