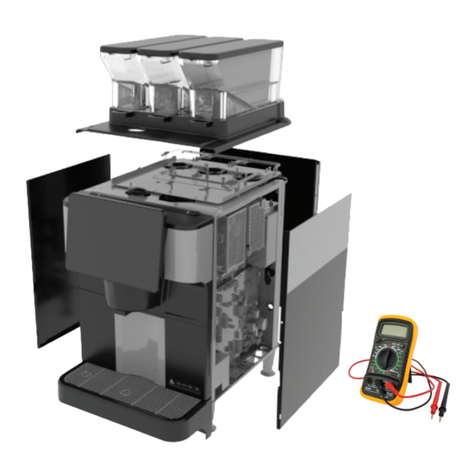

COFFEE PREPARATION PROCEDURES

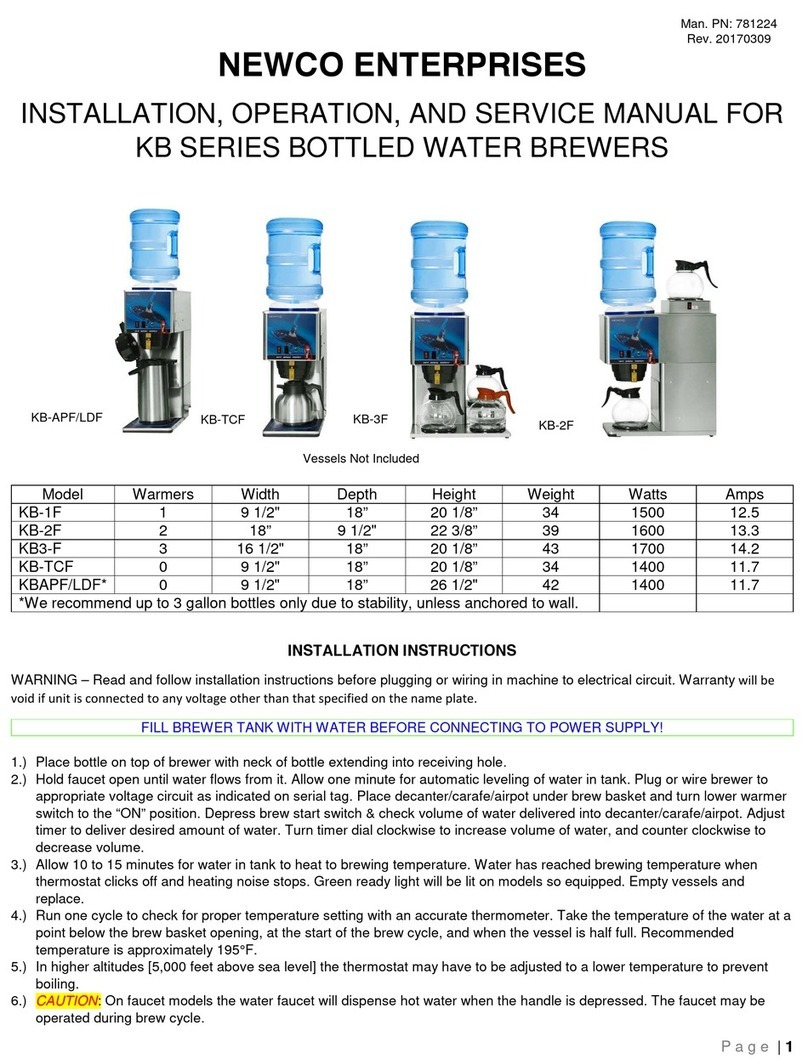

1) Place filter into brew basket.

2) Put the proper amount of coffee into the filter.

3) Slide the brew basket into holder.

4) On warmer models, place empty decanter on warmer located directly under the brew basket and turn corresponding

warmer switch to ON position. On thermal models, place dispenser or airpot directly under the brew basket.

5) Press brew start switch. (Brew cycle may be cancelled by turning the rocker switch back to the off position.)

6) Hot water will be delivered through the sprayhead. This distributes the hot water evenly over the coffee bed

within the brew basket. The coffee brew will drain from the brew basket into the decanter below.

7) The resultant coffee brew should be crystal clear and have the desired properties attainable through excellent

extraction.

8) TURN OFF WARMER WHEN NOT IN USE. (Red light indicates warmer is on.)

9) To clean brew basket simply remove from brew rails and dump filter into waste basket. The brewing process, as

described above, can now be started again.

10) On units with a "CHANGE BOTTLE" light, this indicator will come on at any time the bottle empties. The bottle

should be changed at this time. The brewing circuitry will be disabled until bottled water supply is repenished.

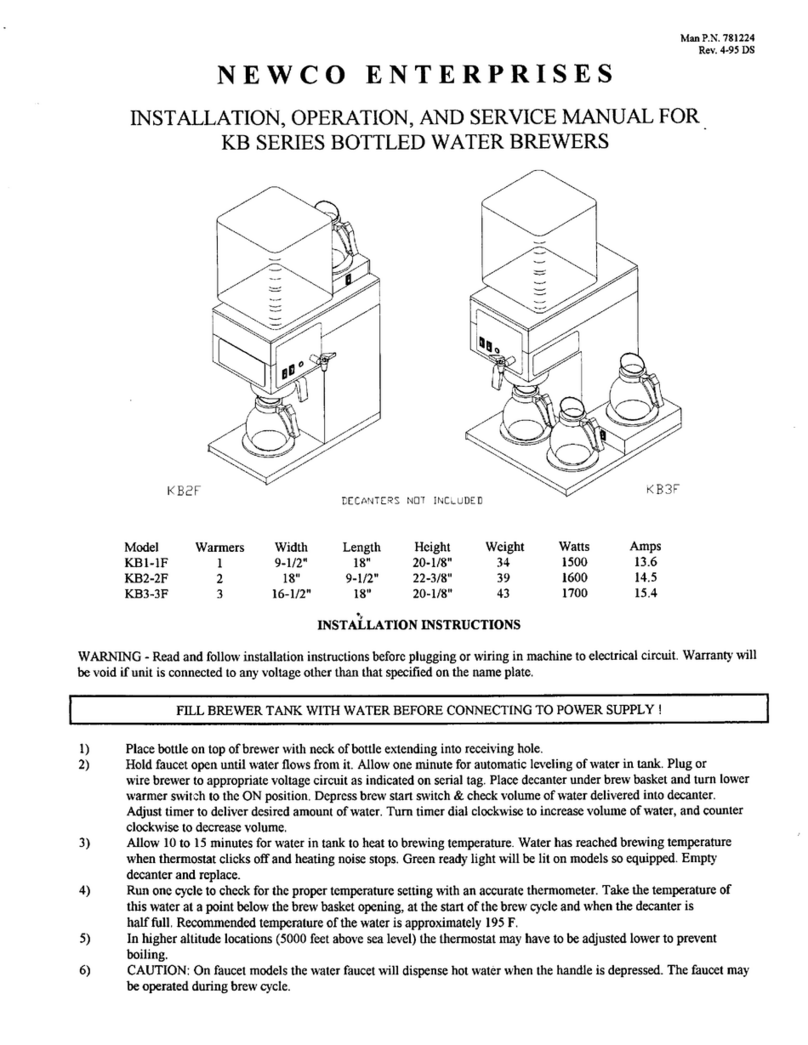

KB SERIES BREWERS - PARTS LIST

TANKS CONTAINERS

781178 Tank ass'y, KB1F, KB3F & KBAP/LD 100550 Decanter, glass 12 cup

781287 Tank ass'y, KB1 & KB3 704235 Dispenser, 85 oz

781219 Tank ass'y, KB2F 700595 Airpot, 2.2L diagonal gloss

781287 Tank ass'y, KB2 110250 Airpot, 2.2L satin

781217 Recieving tank/bracket ass'y w/o probe 110860 Airpot, 2.2L gold diamond

781194 Recieving tank/bracket ass'y w probe 110865 Airpot, 2.2L silver diamond

100033 Element main heating, 1400 watt MISCELLANEOUS PARTS

100633 Hi-limit thermostat, A-AF 102770 Faucet w/ red handle

781181 Gasket, recieving tank 152114 Solenoid valve, Deltrol

152130 Valve repair kit, Deltrol

WARMING PLATES 100024 Sprayhead, S/S 5 hole

100008 Plate, black porcelain 100025 Sprayhead gasket

100010 Warming plate ass'y, black 201173 Sparyhead nut

100020 Plate, brown porcelain 101365 Timer only

100032 Warming plate ass'y, brown 781195 Liquid level (chnge bottle) control

100187 Warming Element, 100 watt 781196 Timer/probe harness KB with Probe

781211 Timer harness only (w/o probe)

BREW BASKETS AND RAILS 100022 Power cord ass'y, 14/3

110986 Brew basket ass'y, brown 100038 Main thermostat ass'y

110985 Brew basket ass'y, black 201985 Brew switch, black, rectangular

110987 Brew basket ass'y. color changing 100085 Lighted rocker switch (red)

781030 Brew rail, RH 781212 KB Ready light ass'y, green

781031 Brew rail, LH 201189 KB change bottle light ass'y, red

100078 Bumper foot with screw

WARRANTY

Newco coffee brewers are warranted against defects in workmanship or materials, under normal use, for 90 days from

the date of purchase. Brewer parts are warranted against defect for 12 months from date of purchase.

Liability in all events is limited to the purchase price paid and liability under the aforesaid warranty is limited to

replacing or repairing any part or parts which are defective in material or workmanship,and returned to our factory, shipping cost

prepaid. No warranty expressed or implied, other than the aforesaid is made or authorized by Newco Enterprises, Inc.

Prompt disposition will be made if item proves to be defective, within warranty. Before returning any item, write or call

Newco, or the dealer from whom the product was purchased, giving model number, serial number, and date of purchase, and

describe nature of the defect. If damage was incurred during transit to you, file claim with the carrier.

TROUBLE SHOOTING GUIDE