Tone NITRO User manual

TONE NITRO

.

1 32

Contents

Page

Seite

1 Implementation

1.1 Introduction

1.2 Mode of operation

1.3 Specifications

1.4 EG Declaration of conformity

1.5 FDA Declaration of conformity

2 Safety instructions

2.1 General safety instructions

2.2 Danger of electric

2.3 Danger of excessive system pressure

2.4 Danger of operating refrigeration

2.5 Danger of operating heating-

2.6 Danger of rotating parts

2.7 Danger of sheet-metal edges

3 Requirements for the setup location

3.1 General requirements

3.2 Electrical connections

3.3 Setup location

4 Installation

4.1 Illustration

4.2 Items delivered

4.3 Bag-in-Box & Nitro Canister

5 Commissioning and Decommissioning

5.1 Commissioning

5.1.1 Commissioning (Step-by-step)

5.1.2 First time Installation

5.1.3 Connection of Bag-in-Box

5.1.4 Start-up the device

5.1.5 Adjusting the air supply for foaming

5.1.6 Adjusting the cooling

5.1.7 NITRO or PUR(e)-Mode

5.2 Daily Operation ending

5.3 Daily check

6 Hygiene, cleaning and maintaining

6.1 Hygienic handling

6.2 Idle time without operation

6.3 Cleaning

6.3.1 Cleaning protocol

6.3.2 Daily Operating ending

6.3.3 Cleaning of Tap unit

6.3.4 Daily cleaning of perlator unit

6.3.5 Filling the cleaning canister

6.3.6 Chemical cleaning

6.4 Maintaining

6.5 Maintenance step A: O-Ring / Nozzle

6.6 Maintenance step B: Chemical purification

7. Flow diagram and circuit diagram

7.1 Flow diagram

7.2 circuit diagram

8. Ersatz- und Verschleißteilliste

9. EG declaration of conformity

10 Part list

11 Trouble shooting

12 Contact data and service

1

1.1

1.2

1.3

1.4 EG

1.5 FDA

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

3

3.1

3.2

3.3

4.

4.1

4.2

4.3 -- -

5.

5.1

5.1.1 ()

5.1.2

5.1.3 “--”

5.1.4

5.1.5

5.1.6

5.1.7 NITRO Pur()-

5.2

5.3

6 ,

6.1

6.2

6.3

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.3.6

6.4 .

6.5 . :

/

6.6 . B:

7. -

7.1 -

7.2

8.

9. EG

10

11

12

2

3

3

3

3

3

4

4

5

5

5

5

5

5

6

6

6

6

7

7

8

9

11

11

11

12

13

14

15

16

16

16

16

17

17

17

18

18

19

19

19

20

21

22

22

22

23

23

23

24

28

29

30

31

32

. 2 32

1 Implementation /

1.1 Introduction /

Dear Valued Customer!

Thank you for choosing TONE NITRO.

Please read and retain these operating

instructions!

Check the device for transport damage

immediately after delivery. As the

circumstances require contact the

manufacturer or shipping company. The

warranty excludes all damage attributable to

improper use.

Errors and technical changes excepted.

Gebrueder Schultes GmbH & Co. KG /

Schultes Maschinenbau GmbH constantly

extends their products according to the

corporate policy. Schultes Maschinenbau

GmbH reserves the right to make changes to

the product describes in this technical

documentation without prior notice.

Reprints of any kind without prior written

authorization by Gebrueder Schultes GmbH &

Co. KG / Schultes Maschinenbau GmbH are

strictly prohibited.

All mentioned brands and names in this

technical documentation refer to the relevant

companies and their products. Gebrueder

Schultes GmbH & Co. KG / Schultes

Maschinenbau GmbH claims no right of

possession to brands and names but their

own.

Please read this manual carefully before

operating and retain it for future reference!

!

, TONE NITRO.

,

!

.

(

), -

.

,

.

.

Gebrueder Schultes GmbH & Co. KG / Schultes

Maschinenbau GmbH

. Schultes

Maschinenbau GmbH

,

,

.

Gebrueder Schultes GmbH & Co. KG / Schultes

Maschinenbau GmbH .

.

Gebrueder Schultes GmbH &Co. KG / Schultes

Maschinenbau GmbH

,

.

,

.

:

, ,

.

Information sign:

Information.

I :

.

Warning sign:

Attention!

:

!

Mandatory sign:

Please ensure that you read

this information carefully

. 3 32

1.2 Mode of operation /

The TONE NITRO unites diverse functions in a

single device:

§ Suction of Cold brew from an

unpressurized vessel

(= Bag-In-Box)

§ Nitrogenation

§ Refrigeration of Cold brew in an

integrated cooling unit

§ Drawing according to Stout-style

TONE NITRO

:

*

(= --)

*

*

* -

1.3 Specifications /

Continuous output capacity

at 17°C

à

7°C

40 l / h

Continuous output capacity

at 22°C

à

7°C

15 l / h

Built in compressor

Yes

Minimal cooling capacity

4 °C

Cold brew tapping

temperature

5°-8°C (+/- 2°C)

Required cooling time

2 – 4 min.

Supply voltage

230 V / 50 Hz

Coolant

R – 134a

Electric power

300 W

Weight

23,5 kg

Measurements

B: 26 cm

T: 32 cm + 12,5

cm (=Spigots)

H: 35 cm

17 ° C

à

7°C

40 /

22°C

à

7°C

15 /

4 °C

5°-8°C (+/- 2°C)

2 – 4 .

230 / 50

R – 134a

300

:

23,5

:

: 26

: 32 cm + 12,5

: 35

Note: No external nitrogen bottle is required as the

device uses atmospheric nitrogen.

:

, ..

1.4 EG Declaration of conformity / EG -

This device conforms to the stipulations of the

following directives:

• EMC directive 2014/30/EU

• LVD directive 2014/35/EU

§ EMV- 2014/30/EU

§ NSP- 2014/35/EU

1.5 FDA Declaration of conformity / FDA -

All parts in contact with the medium and sealing

compounds used in the TONE NITRO conform to

the requirements of the FDA (Food and Drug

Administration).

,

,

TONE NITRO, FDA

(Food and Drug Administration).

. 4 32

2 Safety instructions /

2.1 General safety instructions /

The construction of this device corresponds with

state-of-art technology. Operational reliability is

ensured only if the instrument is properly used

according to the specifications in the operating

manual. Work instructions must be handled having

regard to following endangerments.

While establishing and operating the TONE NITRO.

We refer to the observance and compliance of the

following relevant laws, regulations and policies:

.

,

.

.

TONE NITRO.

:

1. Equipment and Product Safety Act – GPSG

2. Occupational Safety and Health Act – ArbSchG

3. Ordinance on Industrial Safety and Health –

BetrSichV

4. Food Hygiene Regulation – LMHV

5. Beverage Dispensing System Regulation –

SchankV (until 30.06.2005)

6. Technical Rules for Beverage Dispenser Units

(TRSK and DIN standards)

7. Ordinance on Hazardous Substances (GHS 05

Corrosion)

8. General Acknowledged Rules of Technology

1.

-GPSG

2. -ArbSchG

3.

-BetrSichV

4. -LMHV

5. -SchankV

( 30.06.2005)

6.

( TRSK DIN)

7. ( 05

)

8.

Relevant corresponding country-specific policies

and regulations must be applied.

No changes or modifications may be carried out on

parts relevant to safety as it automatically leads to

the expiration of any guarantee rights.

Check the device for externally visible damage or

defects at least daily. Contact a qualified service

technician if changes or repair work arise. The mains

plug may only be replaced by an authorized

technical staff. Use only original replacement parts

and accessories.

Make sure that only authorized persons work on the

device and that the operating personnel is equipped

with this operating instruction.

Make sure that no unauthorized person makes

modifications of the settings or interferes the

operating of the device.

Schultes Maschinenbau GmbH assumes no liability

for errors or damages caused by non-original parts

or accessories, improper handling or use outside the

rules.

.

,

,

.

.

.

.

.

,

.

,

.

Schultes Maschinenbau GmbH

,

,

.

5 32

2.2 Danger of electric current /

The power plug must be removed before

opening the unit!

Opening the device, modifications to the electronics

and exchanging electric components including the

mains plug may only be made by authorized

technical staff. Before carrying out repair work,

always pull out the mains plug. This also applies for

the cleaning process. The device may only be

connected to a grounded protected contact socket.

A device with damaged mains plug must not be

operated.

Never touch any electric components with damp

or wet hands, as it may result into as electric

shock!

!

,

,

,

.

.

.

.

,

!

2.3 Danger of excessive system pressure /

During operation, certain parts of the device

represent a potential source of danger as they

are subject to excess pressure. Do not remove

or dismantle any pressurized parts.

,

.

,

.

2.4 Danger of operating refrigeration /

The evaporating temperature in the coolant circuit

may amount up to -10°C. Therefore, a potential

source of danger exists while maintaining and

cleaning relevant tempered components without

suitable preventive measures.

-10°C. ,

.

2.5 Danger of operating heating-up /

Do not touch the compressor, the condenser,

engines and pipelines as they may heat up during

operation as it may cause injuries.

, ,

, ..

:

.

2.6 Danger of rotating parts /

Do not touch the fan blades while the device is

switched on.

,

2.7 Danger of sheet-metal edges /

Despite constructional prevention, sheet-metal

edges represent a remaining risk of injury.

,

.

6 32

3 Requirements for the setup location/

3.1 General requirements /

Observe the relevant national requirements

regarding the installation location. Please note the

Technical Rules for Beverage Dispenser Units

(TRSK 400 “Installation of Beverage Dispensing

systems”) since TONE NITRO is a modified

dispensing system.

, .

(TRSK 400 “

”), TONE

NITRO

.

Attention: Low voltage can damage the

compressor. The same applies if several devices

are powered by one power connection.

The power plug must be accessible at all times.

:

.

,

.

3.2 Electrical connections /

see Technical data / .

Fuse protection

max. 16 A

Voltage

230 V∼ +/- 10% 50 Hz

Electric power

300 W

. . 16

230 +/- 10% 50 Hz

300

3.3 Setup location /

An adequate ventilation must be ensured. The

distance to the wall should be at least 30 cm.

Attention:

Do not block the ventilation slits. Other than that, a

lack of cooling may occur and result in a system

failure.

Attention:

Never lay the device close to heat sources or into

direct sunlight.

Attention:

Under no circumstances should liquids be poured

into the upper opening of the device, otherwise

there is a risk of short circuit!

.

30 .

:

.

, .

:

.

:

,

!

7 32

4 Installation /

4.1 Illustration /

frontal view /

rear view /

side view /

8 32

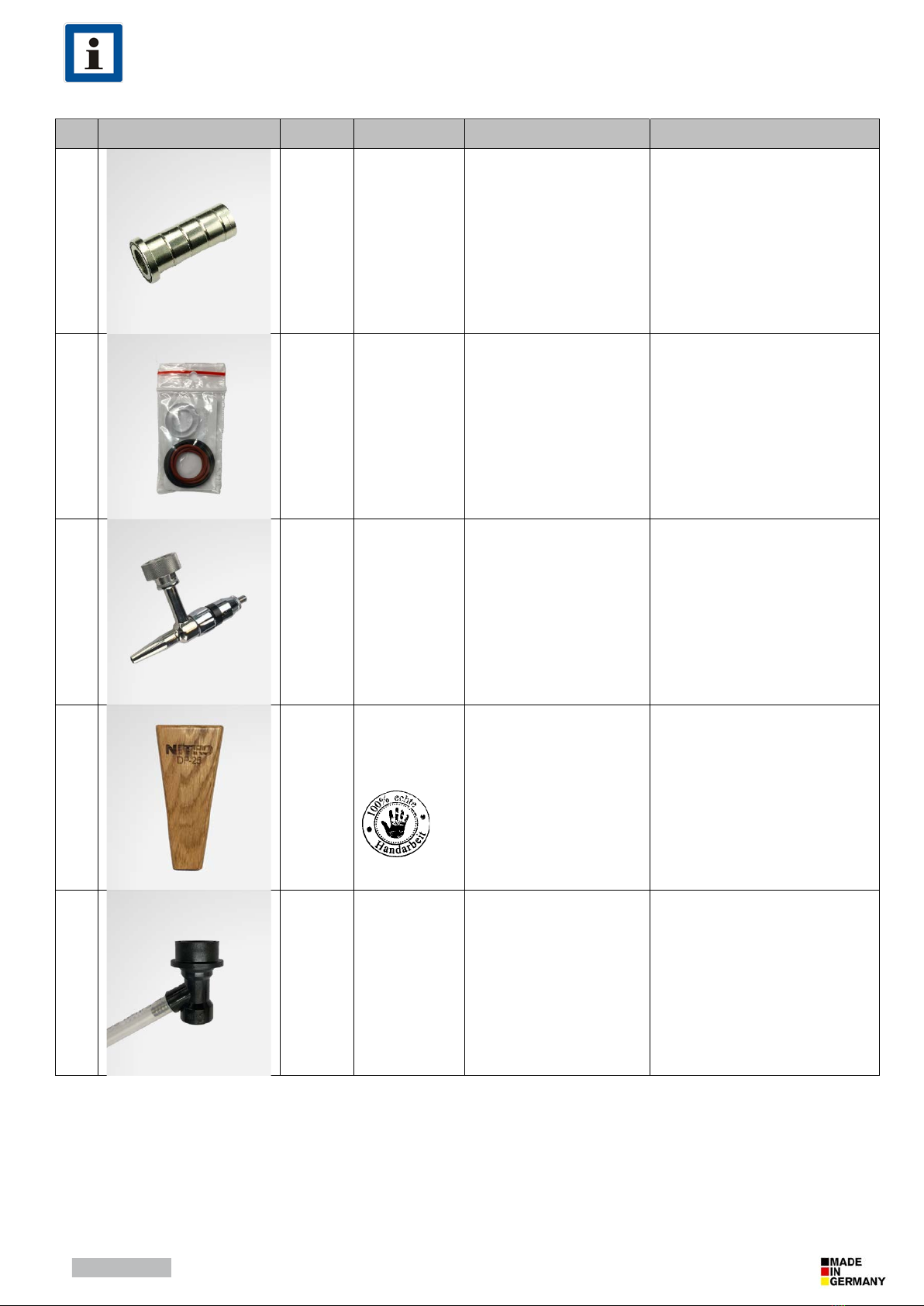

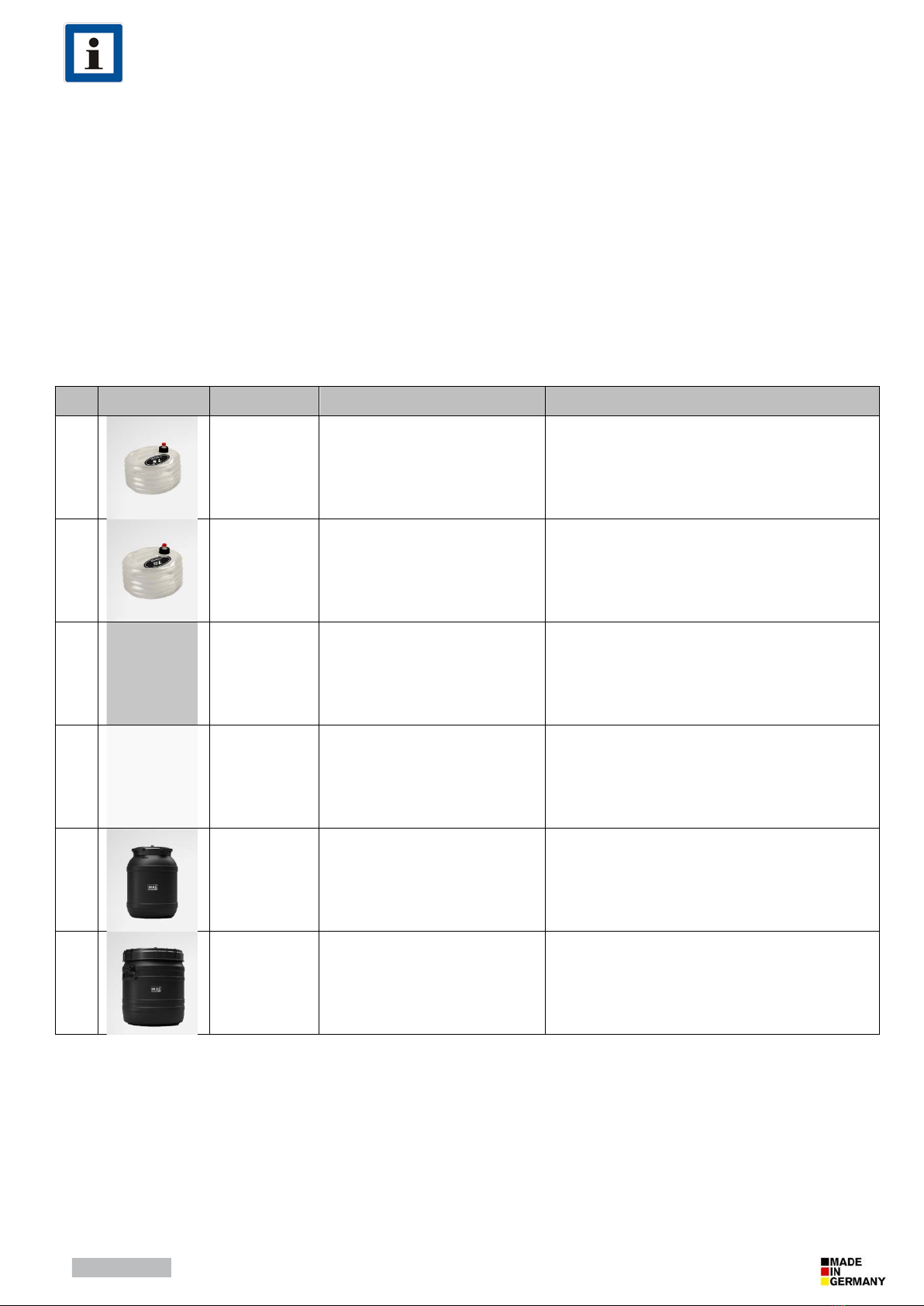

4.2 Items delivered /

The following items are packaged with the device.

:

Pos.

Picture /

Amount /

-

Article- No. /

Article name /

Product Information /

1

1

103010

“”

Perlator-unit

„green“

, /

Perlator unit consisting of:

1 X - 103011-- A

“”/ „green“

3 X - 103012- - B

”” / „green“

1 X - 103013- C

“”/ „green“

2

1

108011

O-Ring Set

(hose)

O-ring set silicone for suction

hoses

3

1

102010

"TONE Nitro"

Tap "TONE Nitro"

TONE Nitro

Nitro DP

Tap for TONE Nitro with "Nitro

DP” laser engraving

4

1

104010

V

"TONE Nitro"

Handle V „TONE Nitro“

- “” TONE Nitro

V-

“Nitro DP-25”,

Handle for TONE Nitro in

V-form with "Nitro DP-25”

Laser engraving, handmade

from German oak

5

1

105010

CMB-

Suctionhose with CMB

– connection

TONE NITRO CMB-

Suction hose for TONE Nitro

with CMB connection

9 32

6

1

109010

EU

Power cable EU (L)

EU

Power cable EU (L)

Power cable EU (L)

Power cable EU (L)

7

1

106018

Drip tray

TONE Nitro

Drip tray for TONE Nitro

systems

8

1

107016

Cleaning plan

Cleaning plan for protocolling

the performed cleaning

operations

9

1

107017

Cleaning set

:

5

3X

consisting of

Cleaning canister 5l

Cleaning powder 3X

cleaning ball

cleaning brush

Page 10 of 32

Seite 10 von 32

4.3 Bag-in-Box & Nitro Canister / Bag-in-Box & Nitro Kanister

The TONE NITRO is designed only for drawing COLD

BREW COFFEE sucked in from unpressurized vessels

(=Bag-in-Box or Nitro Canister). Operating the device

with other liquids is strictly prohibited as it may lead to

soiling or blockage inside the system. This results in a

loss of warranty!

The Bag-in-Box vessels dispose of a high oxygen barrier

so that no ambient air can access the coffee to prevent

mold formation.

TONE NITRO

,

(=Bag-in-Box Nitro

Canister).

,

.

!

“--”

,

.

Pos.

Picture /

Article- No. /

Article name /

Product Information /

1

106010

5

Canister 5l

5 TONE Nitro

Flexible canister with 5l capacity for TONE

Nitro

2

106011

10

Canister 10l

10 TONE Nitro

Flexible canister with 10l capacity for TONE

Nitro

3

106012

6,4

Canister 6,4l

6,4 UV -,

Tone Nitro

NC-Keg,

4

106013

15

Canister 15l

15 UV -,

Tone Nitro

NC-Keg,

5

106014

26

Canister 26l

26 UV -,

Tone Nitro

NC-

,

6

106015

55

Canister 55l

55 UV -,

Tone Nitro

NC-,

11 32

5 Commissioning and Decommissioning /

5.1 Commissioning

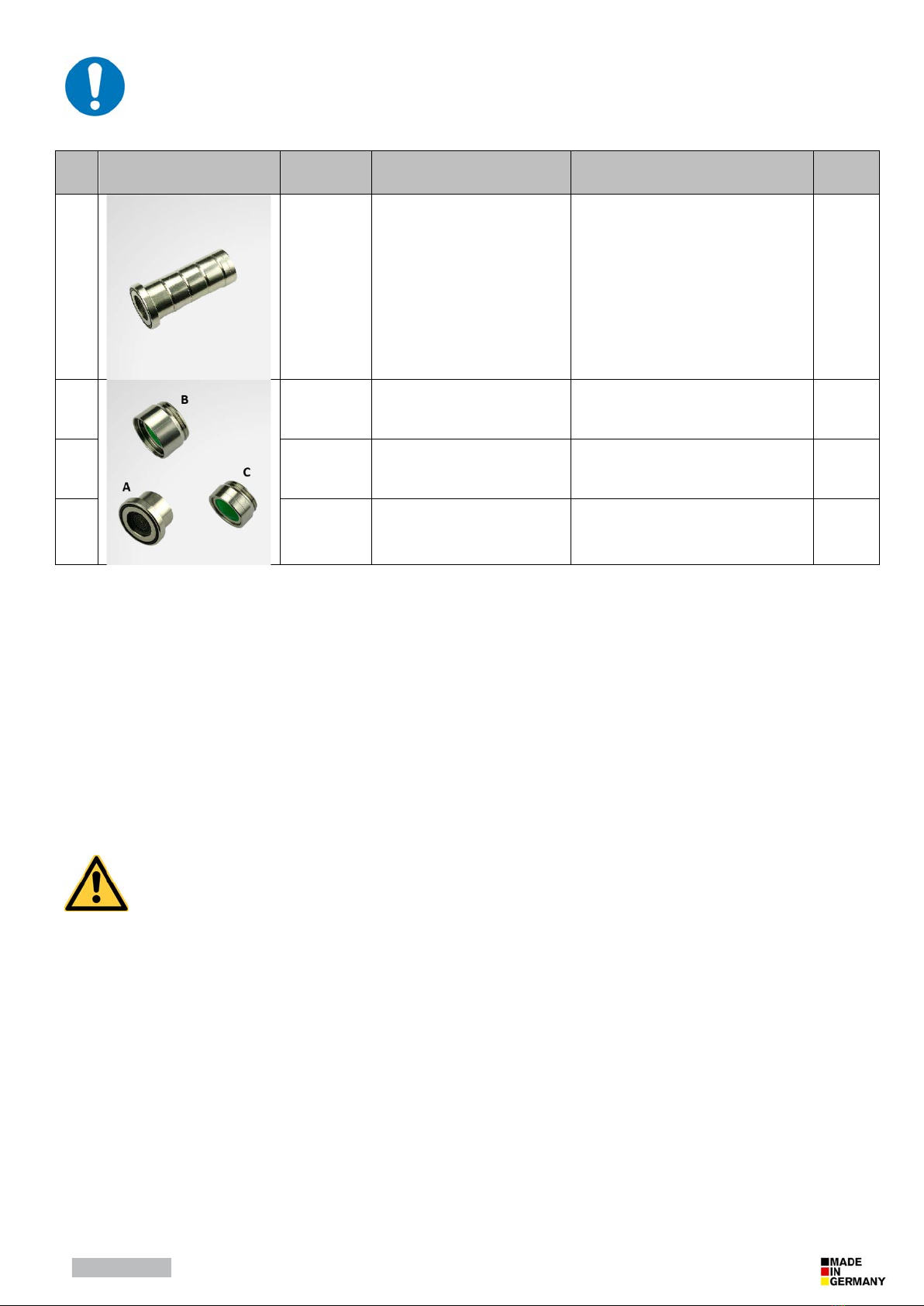

5.1 .1 Commissioning (Step-by-step) / ()

Pos.

.

Picture /

Article- No. /

Article name /

Product Information /

Amount

-

1

103010

"n"

Perlator-unit

„green“

, /

Perlator unit consisting of:

1 X - 103011-- A

“”/ „green“

3 X - 103012- - B

”” / „green“

1 X - 103013- C

“”/ „green“

-

2

103011

- A ""

Perlator – A „green“

TONE Nitro

Perlator for TONE Nitro

1

3

103012

- B ""

Perlator – B „green“

TONE Nitro

Perlator for TONE Nitro

3

4

103013

- C ""

Perlator – C „green“

TONE Nitro

Perlator for TONE Nitro

1

Attention: The parts can be screwed together and

it is not necessary that the rings sit flush.

There is a remaining risk of injury on the screw

threads despite constructional prevention.

:

, ,

.

,

.

12 32

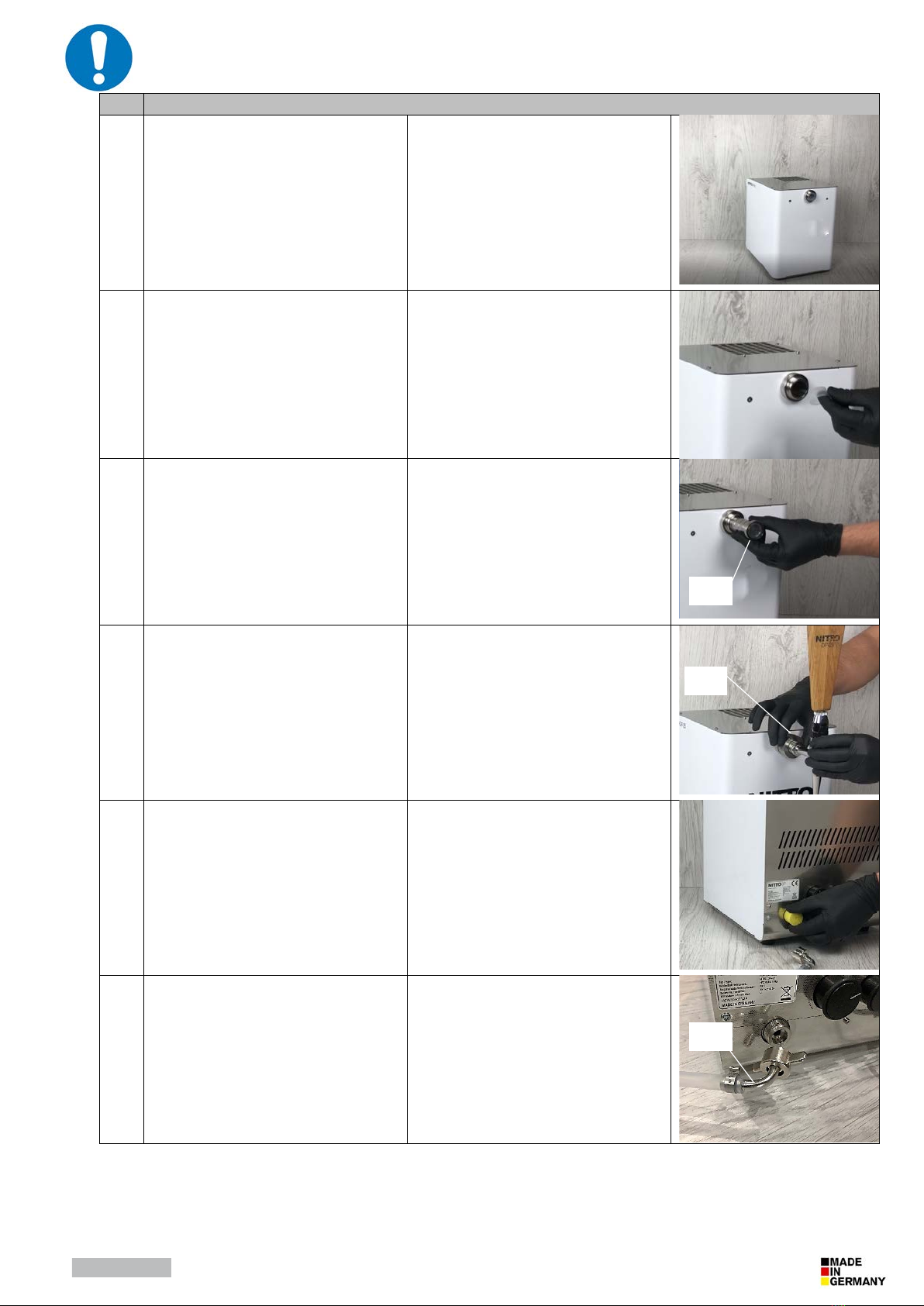

5.1.2 First time Installation /

No.

1.

Place the device at the setup

location.

(cf. 3.3 Setup location)

.

(. 3.3 )

2.

Remove the plug from the

machine.

.

3.

Place the Perlator unit (3) in the

front opening.

(Note: Pay attention to the O-rings.)

”” (3)

.

(:

)

4.

Screw the tap handle unit (4) on

the device und tighten it slightly.

(Note: Do not use pliers to tighten

the screws.)

(4)

.

(:

,

.)

5.

Remove the yellow plug on the

backside of your machine.

.

6.

Connect the suction hose (7) to the

machine.

(7) .

3

4

7

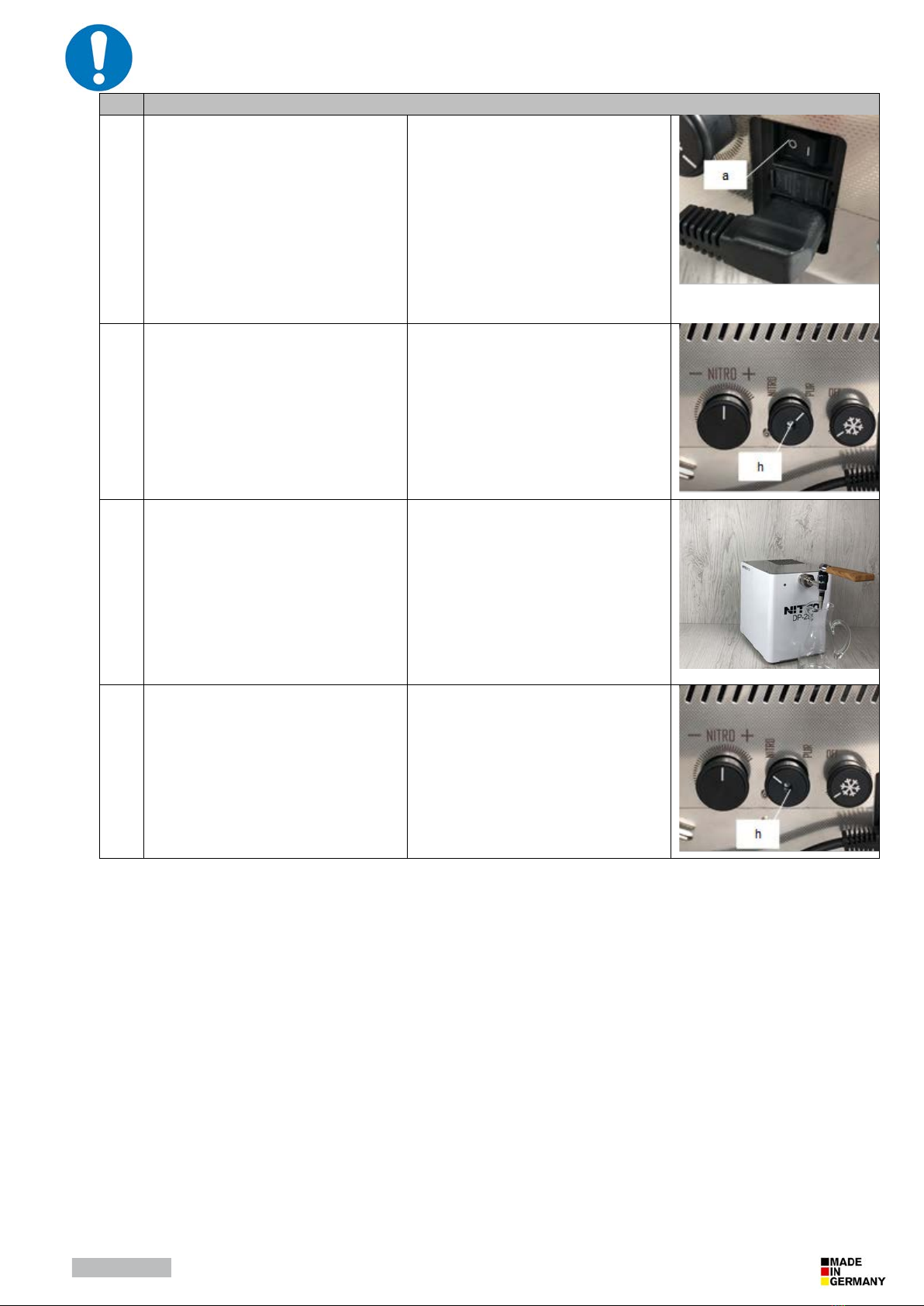

13 32

7.

Set the unit switch (a) on the back

of the device to “0 OFF“ and

connect the IEC (power) connector

(5) to the socket (c).

(a)

“0

.”

IEC (power) (5) (c).

8.

Set the thermostat (b) on the back

of the device up to the wanted

temperature.

(Note: Do not set the thermostat to

MAX. Otherwise may cause the

device to freeze.)

(b)

.

(:

.

.)

Attention:

During the initial installation at a new setup location

the device must be left to stand for approx. 30 min

prior to operation.

:

. 30

.

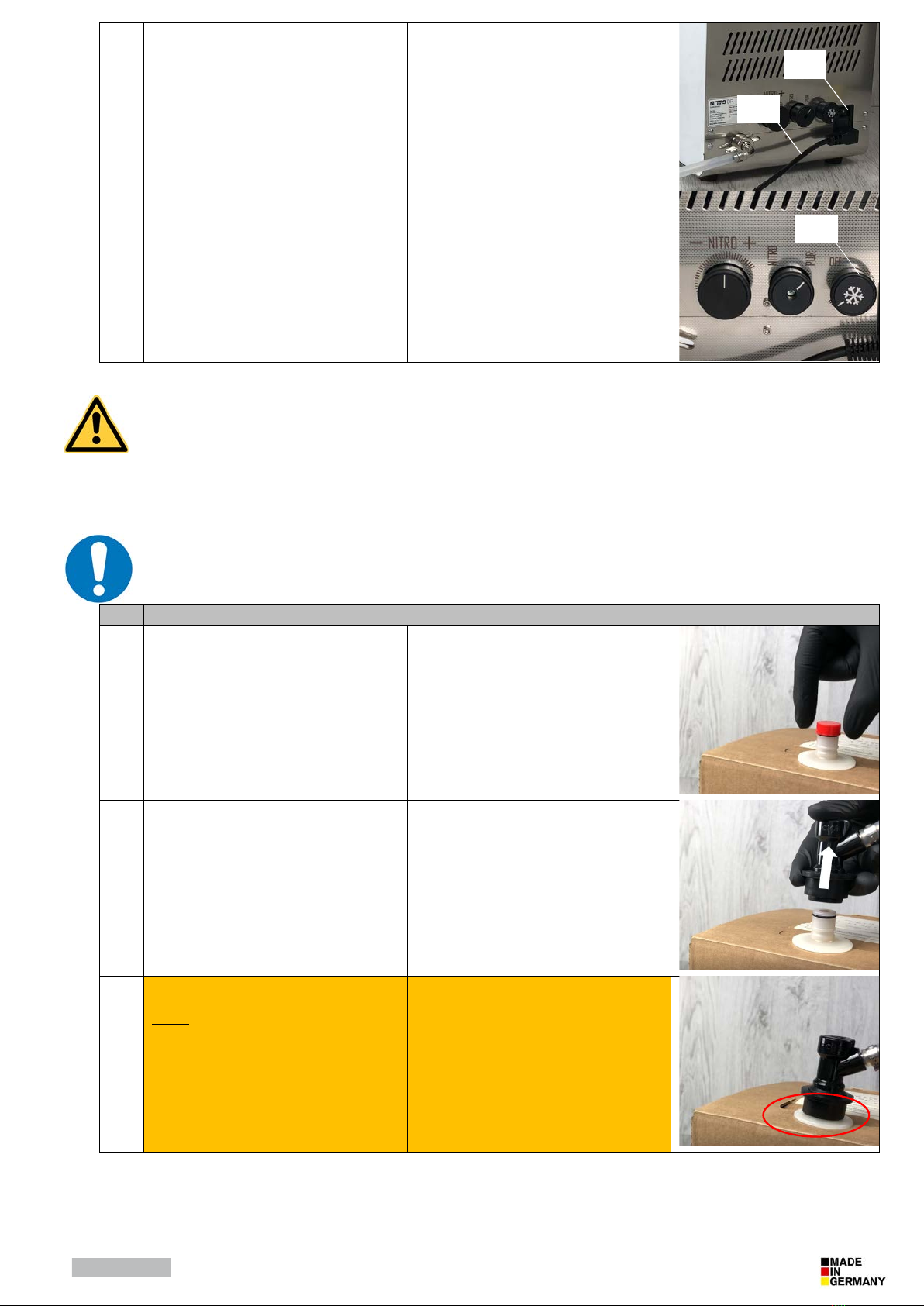

5.1.3 Connection of Bag-in-Box / “- ”

No.

1.

Remove the red plug from the bag-

in-box (alternatively from nitro

canister).

-- (

).

2.

Open the valve by pulling up the

snap lock.

,

3.

The Connector must be mounted

flush with the bag-in-box

connector.

Note: If not, air may also be drawn

in, which negatively affects the

performance of the system.

“--

”.

: ,

,

a

5

b

14 32

5.1.4 Start-up the device / Operational conditions

/

No.

1.

Set the unit switch (a) on the back

of the device to “1 ON“. The device

initiates automatically and powers

down after reaching the factory-

made configured temperature and

pressure: The device is ready to

use after approx. 5 min.

(Note: This process may take up to

2 mins longer during initial

commissioning.)

(a)

“1

.“.

:

. 5 .

(:

2

.)

2.

Turn the central rotary knob (h)

90 degrees to the right to set the

device on “PUR”.

(h) 90

,

“PUR”.

3.

Place a glass under the tap and pull

the tap handle 90 degrees

forward: The device starts to suck

in the liquid and after shortly

thereafter it runs out of the spigot

chilled. To stop this process, fold

the tap handle back to the starting

position.

90

:

,

.

,

.

4.

As soon as the liquid runs, turn the

rotary knob (h) 90 degrees to the

left and set to “NITRO”.

,

(h) 90

“NITRO”.

15 32

5.1.5 Adjusting the air supply for foaming

No.

1.

Adjust this setting by turning the

knob

(Note: The delivery pump looses

efficiency if the ventil is opened to

much and therefore too much air is

sucked in.)

,

(:

,

,

.)

2.

Turn the left rotary “NITRO”

clockwise (to the right) to add

more air (+).

“ NITRO”

(),

(+).

Turn the left rotary “NITRO”

counterclockwise (to the left) to

reduce air (-).

“ NITRO”

(),

( -)

(Note: The fine adjustment is very

sensitive and should therefore only

be carried out in 5-10° steps.)

(:

,

5-10°).

3.

If the system only emits air,

proceed as follows:

1. Close the tap (fold the tap handle upwards

again).

2. Turn the "NITRO" rotary switch at least

half a turn (180°) to the left.

3. Place a glass underneath and pull the tap

handle forward by 90°.

4. If the result still does not meet your

expectations, repeat this procedure.

5. As soon as liquid flows out of the tap, the

fine adjustment can be made during the

tapping (see pos.2).

,

:

1. (

).

2. “NITRO”

(180°) .

3.

90°.

4.

,

.

5.

,

(.

.2).

4.

After locating the perfect setting,

push the rotary knob back in

,

5.

Place a glass under the tap and pull

the tap handle 90 degrees

forward: The device starts to suck

in the liquid and after shortly

thereafter it runs out of the spigot

chilled and foamed.

To stop this process, fold the tap

handle back to the starting position.

90 :

,

.

,

16 32

5.1.6 Adjusting the cooling

No.

1.

Turn the right rotary knob on the

back of the device to the right for

less cooling and to the left for

more cooling.

(Note: Do not set the thermostat to

MAX. Otherwise may cause the

device to freeze.)

.

(:

.

.)

(Hinweis:

2.

If you want to turn off the cooling completely, turn

the rotary switch all the way to the left until you

hear a “click”.

,

,

“”.

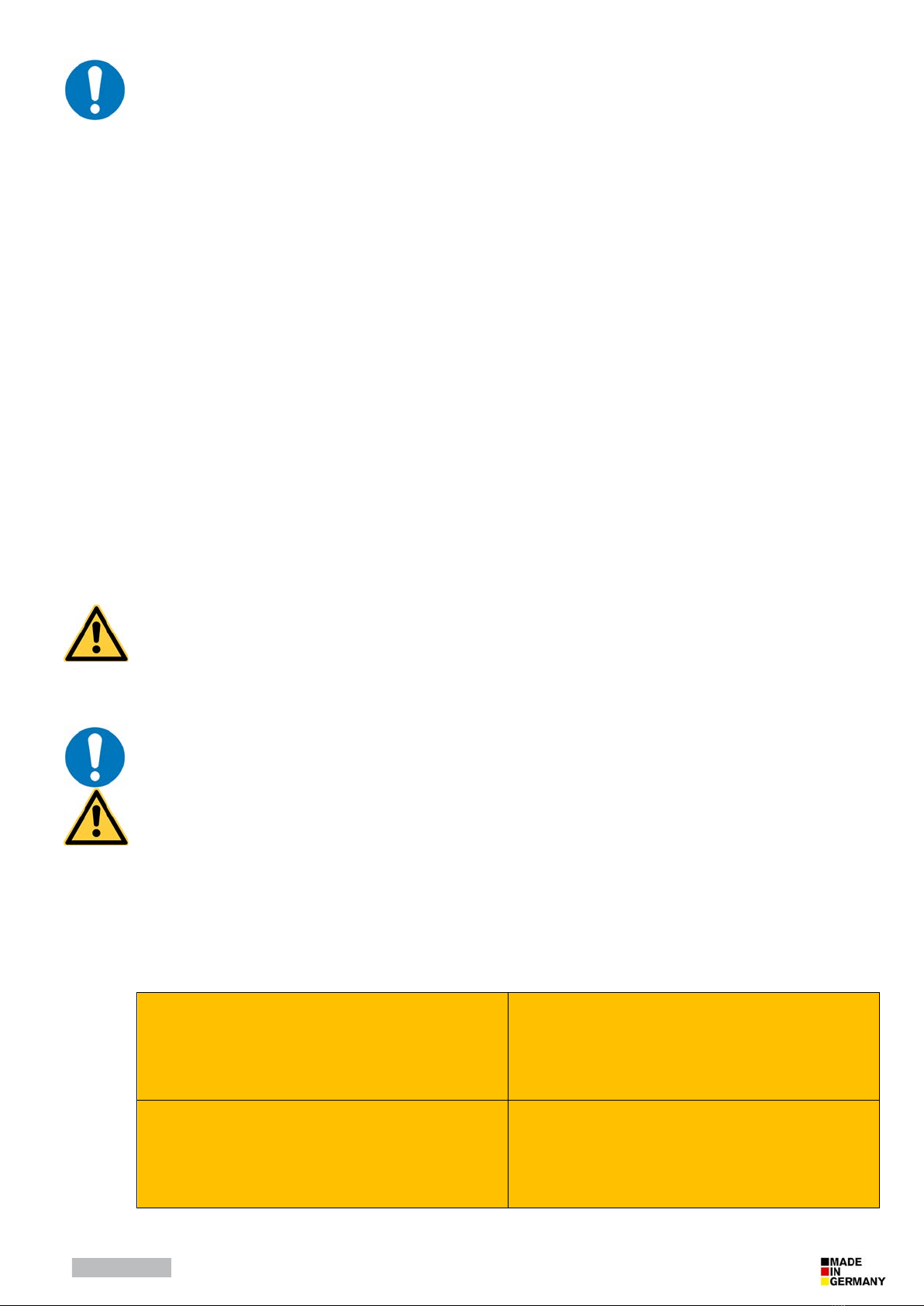

5.1.7 NITRO or PUR(e)-Mode

NITRO- PUR-

The TONE NITRO can be used as a pure

continuous cooler without foaming function (PUR

mode) or as a nitro dispenser (NITRO mode).

TONE NITRO

, ,

( PUR) - ( NITRO).

No.

PUR

1.

Turn the central rotary knob (h)

90 degrees to the right to set the

device on “PUR”.

(h) 90

,

“PUR”.

2.

If you want to turn off the cooling

completely, turn the rotary switch all the

way to the left until you hear a “click”.

,

,

“”.

5.2 Daily Operation ending /

Pay attention to the cleaning protocol (6.3.1) in

chapter 6. Hygiene, cleaning and maintaining.

(6.3.1) 6. ,

.

5.3 Daily check /

Check the tightness of the pipes. This is only

possible by visual inspection.

.

.

17 32

6 Hygiene, cleaning and maintaining /

, .

6.1 Hygienic handling / Hygienische Handhabung

Pay attention to the legal provisions for beverage

dispensing systems valid in the setup location. Since

the TONE NITRO.is a modified beverage dispensing

system, we recommend the cleaning of the device

by the valid cleaning regulation according to TRSK

501 “Cleaning of Beverage Dispensing Systems”. In

addition to that we point out DIN 6650-6 (“Dispense

systems for draught beverages: Requirements for

cleaning and disinfection”).

Prior to each connection and each change of liquid,

all pipes, connecting parts and tap fittings must be

cleaned. Parts that encounter air and liquid must be

cleaned everyday (e.g. the tapping outlet).

Pay attention to the instruction of the producer of the

cleaning fluid. Only use cleaning fluids that meet the

requirements of ASI 6.84 and DIN 6650-6.

,

, .

TONE NITRO

,

501 “

”. ,

DIN 6650-6 (”

:

”).

,

. ,

,

(,

).

.

, ASI 6.84

DIN 6650-6.

There is a risk of severe burning while handling

cleaning fluids! Always pay attention to the

safety data sheet during the cleaning process

and wear goggles and appropriate clothing!

!

,

!

6.2 Idle time without operation /

The device can run to empty for a longer idle

time without operation. To do so connect the

cleaning adapter to the suction hose, pull the

tap handle 90 degrees forward and let the

system pump dry.

Perform this process only after implementing

the chemical purification.

.

,

90

.

.

Idle time less than 10 days

If the idle time is less than 10 days, the device must

be flushed out with water. The dawned Bag-in-Box

vessel must be refrigerated.

10

10 ,

.

“--”

.

Idle time more than 10 days

If the idle time is more than 10 days, the device must

be purified chemically and run to empty. Flush the

device with water before starting up again. Make

sure to refrigerate the open Bag-in-Box vessel.

10

10 ,

.

.

“ ”.

18 32

6.3 Cleaning /

The device must undergo chemical purification

every 14 days.

For this process, customary cleaning fluids suitable

for coffee can be used. We recommend a cleaning

fluid with a color indicator to verify the cleaning

effect.

Since the TONE NITRO is a modified beverage

dispensing system, we recommend listing the

cleaning procedures in a logbook (c.f. Appendix).

14 .

, .

.

TONE NITRO

,

(. ).

Electrical components may be affected or

irreparably damaged during or after the

cleaning process due to liquids (e.g. water or

cleaning fluid).

Therefore, take relevant arrangements before

cleaning the device to prevent the intrusion of

water or cleaning fluid in electrical

components.

The cleaning of the device must be performed

by trained qualified personnel in accordance

with following recommendation:

-

(,

).

,

.

:

6.3.1 Cleaning protocol /

What?

How?

When?

?

?

?

Spigot, Spout

outlet (inside and

outside)

Warm water,

cleaning brush

At least daily,

before and after

operating period

,

(

)

,

,

Spigot (outside)

Warm water,

cleaning brush

At least daily

()

,

Tap head (inside

and outside)

Wash with warm

water

For every new

connection and

reconnection of a

Bag-in-Box

vessel, especially

after cleaning the

pipes.

(

)

“-

-”,

.

Tap perlator rings

Wash with warm

water

At least daily

Spigot (inside),

Tap head (inside

and outside)

Warm water,

cleaning brush

and suitable

cleaning fluid

Weekly

(),

( )

,

.

Complete device

Clean with

suitable chemical

cleaning fluid (cf.

6.3.1)

At least every 14

days

(. 6.3.1)

2

19 32

6.3.2 Daily Operating ending /

No.

1.

Set the unit switch (a) on the back

of the device to “0 OFF“.

(a)

“0

.“.

2.

Place a glass under the tap and pull

the tap handle 90 degrees forward

so that the remaining pressure or

liquid can escape out of the

machine.

90

,

.

6.3.3 Cleaning of Tap unit /

No.

1.

Remove the spigot.

2.

Clean the tap with water. Pull the

tap handle 90 degrees forward and

flush it with warm water using the

added cleaning bottle.

.

90

,

6.3.4 Daily cleaning of perlator unit /

No.

1.

Take out the Perlator unit of the

front opening.

Note: We recommend using a

cleaning cloth to absorb remaining

liquid.

.

:

.

Other manuals for NITRO

2

Table of contents

Other Tone Coffee Maker manuals