Toolex 596365 User manual

Thank you for choosing 596365 Digital Display Hand Pallet

Truck,Please read this operation manual before use.

Note:596365 Digital Weight Scale hand pallet truck,is used for weight

distinguish in storage, has the features of promotion and demotion stable, control

portable, safe and reliable. It is used on hardness and flatness ground. It is also

can be used for handbarrow。

Note :1.Usage, maintain and service should meet the requirement of

manufacturers.

2. Not allowed to retrofit or install any attachment. In order to assure

safety.

1.Applicability

1.1 596365 Digital Weight Scale hand pallet truck,is used for weight distinguish in storage,

has the features of promotion and demotion stable, control portable, safe and reliable.。

1.2 The working place must be non-slip, hard and flat ground without holes or obstacles

1.3 The ambience lighting is 50 lux at least

1.4 turning radius is 1216-1336mm

2.Main parameter

Capacity (Kg)

2500

Maximum lift height (mm)

200/190

Lowered fork lift (mm)

85/75

Height of handles (mm)

494/484

Fork length (mm)

1100/1150/1220

Width over the forks (mm)

520/550/685

Steering wheel diameter (mm)

Ф200/Ф180

Fork wheel diameter (mm)

Ф80/Ф74

Noise lever (Kg)

5

Service weight (Kg)

62-70

3. Assembly of hand pallet truck

3.1 Trucks will remove the handle when transportation. So customers should assemble the

truck after purchase。

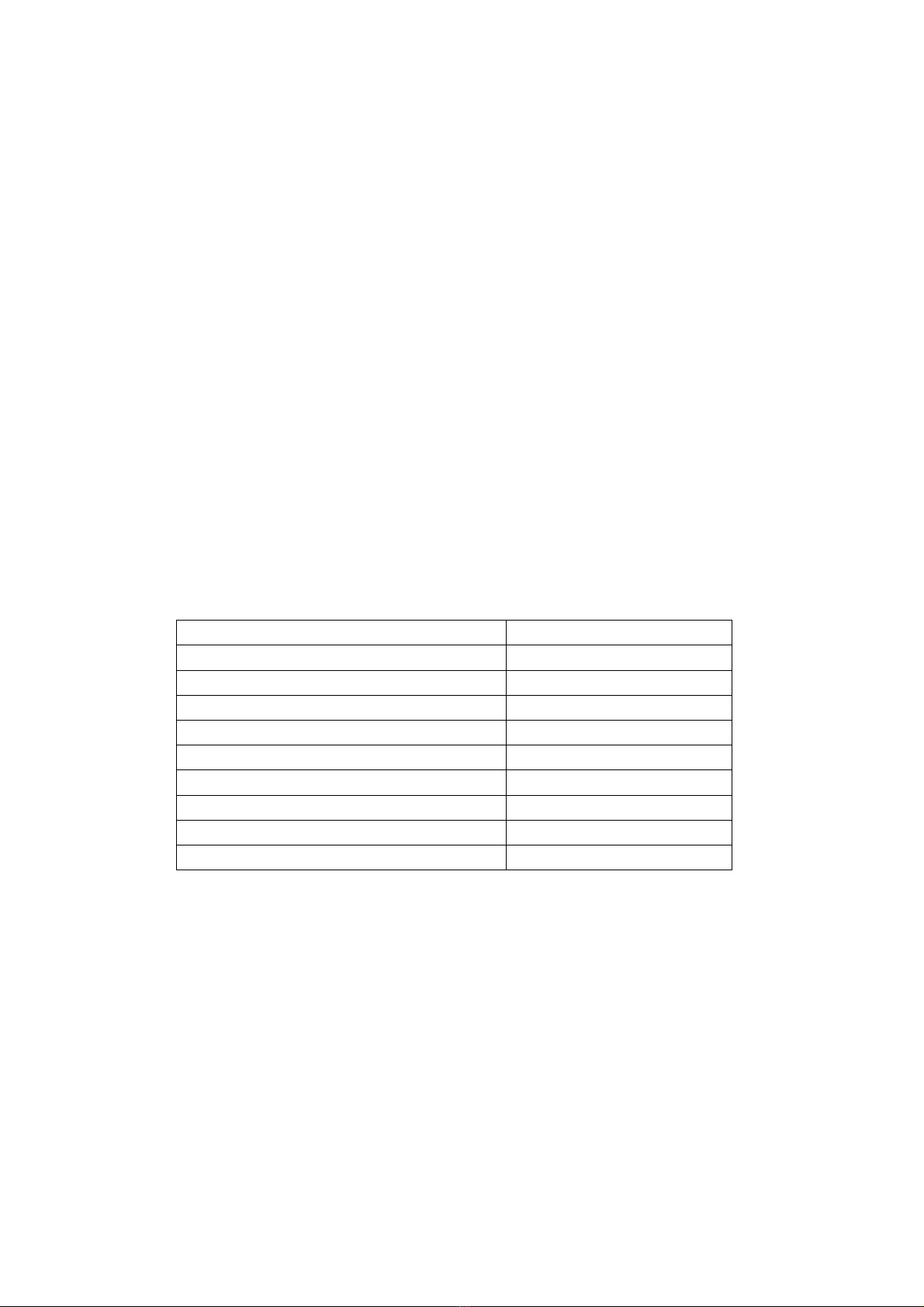

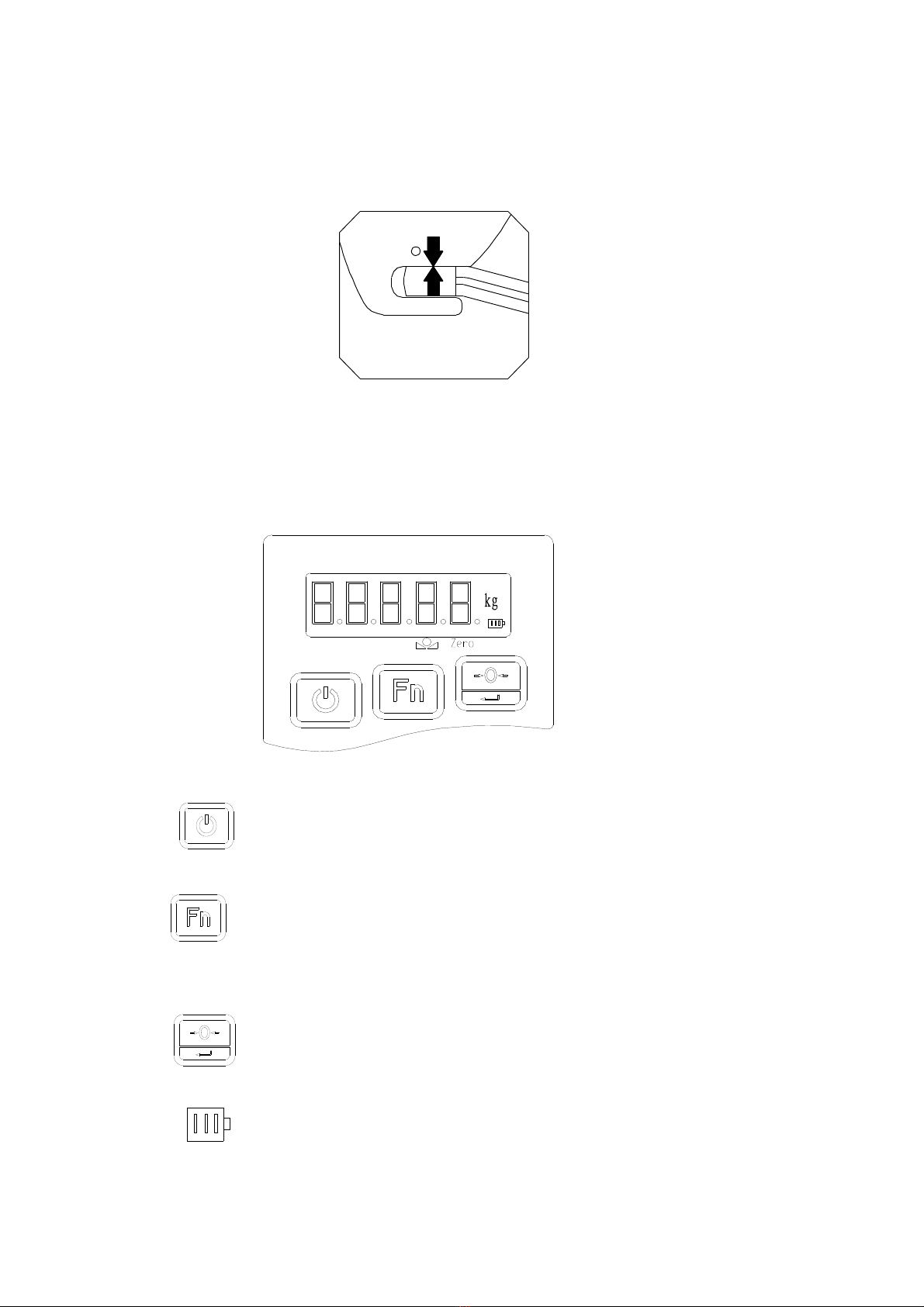

3.2 See fig 1, pull out the pin roll 1, and then pull out pin roll 2。

3.3 Insert the hand grip 3 to place A. Couple the hand grip 3 and pump body 4 with pin roll 2。

3.4 See fig 2. Put the chain 5of hand grip get across the middle hole of pin roll 2.

3.5 Take screw nut which is at the end of chain 5 and hitch the groove of lever board 6. See fig

2 and fig 4

3.6 Then get the spring pin 1 through pin roll 2 and fix it。

3.7 See fig 3, turn the hand grip to the level position, pull out pin 7 and save pin 7 with care for

next use

4. Test of hand pallet truck

图十

上升

空档

下降

Fig1

Fig2

Fig3

Fig5

Fig5

Drop position

Free position

Lift position

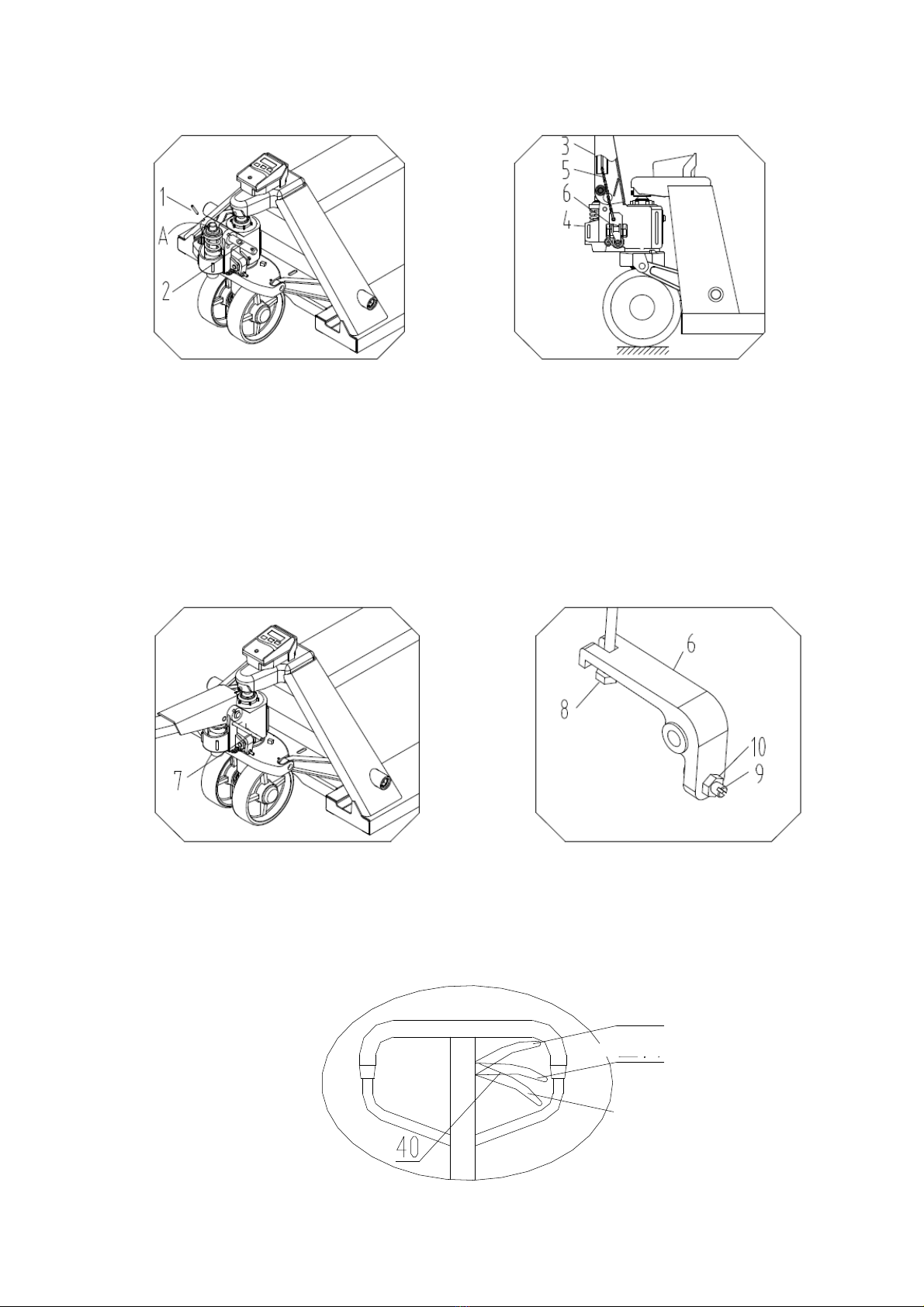

4.1 After the truck is assembled, try to rock the hand grip and operate different positions of

control handle knob 40 to examine the lifting, free position and dropping and check that

whether the different positions are normal or not. See fig 5.

4.2 The screw 9 in fig 4 is used to adjust the truck situation. When the truck body drops

immediately after it is lifted, you should turn the screw 9 a little counter-clockwise.

And then try the truck again until truck body could lift normally. If the truck body couldn’t

drop after it is lifted, you should turn the screw 9 a little clockwise. And then try to operate

truck again until the truck body could drop normally. The external hexagon nut 8 at screw

9

Plays the locking function in the truck. So you should undo the external hexagon nut 10 before

adjustment. And screw down the nut 10 after you finish the adjustment.。

5. Operation instruction

5.1 Before operation of the hand pallet truck please make sure that whether the cargo weight

exceeds the rated load or not.

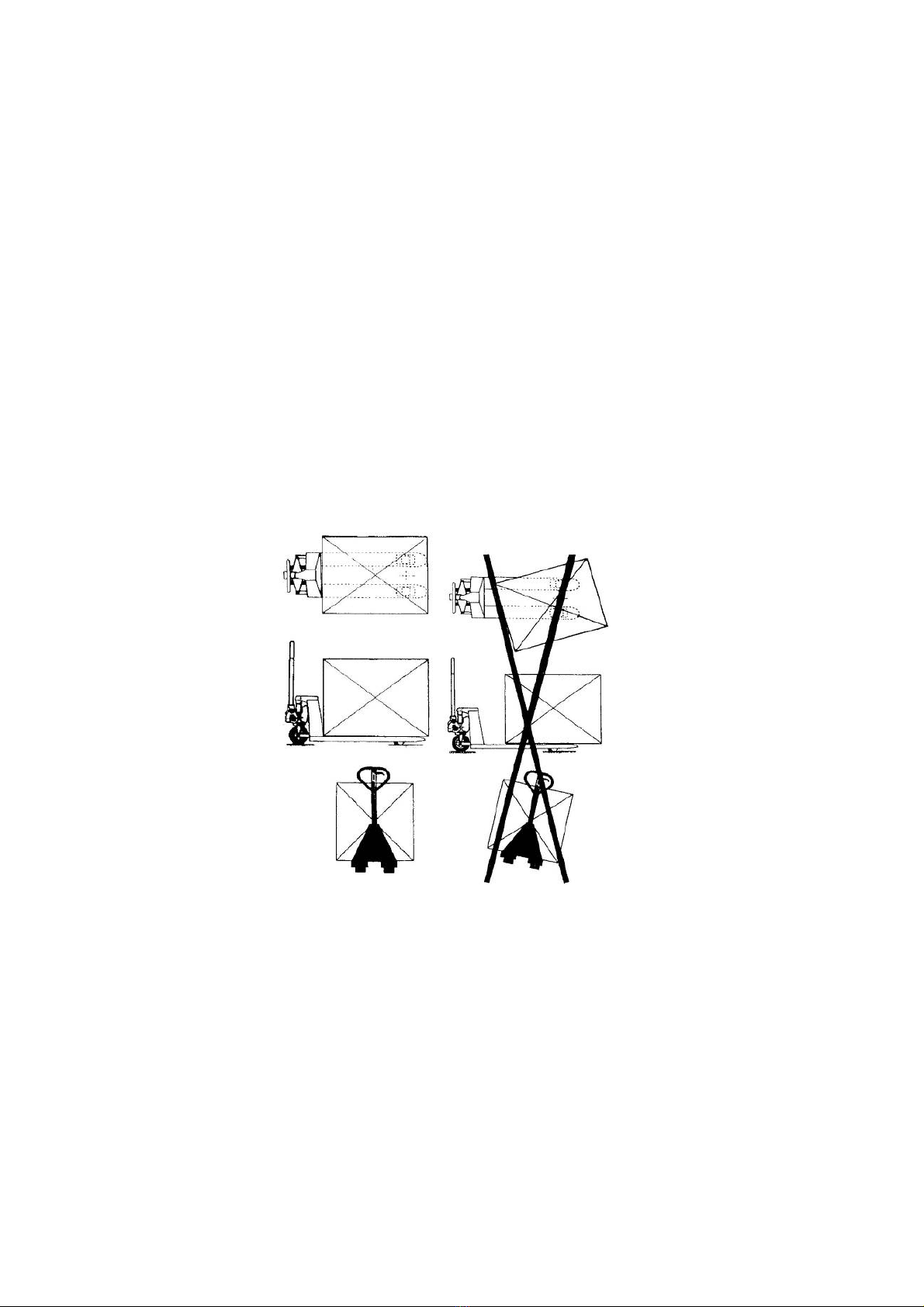

5.2 The cargo loading type is shown as fig 6

5.3 See fig 5, when hand knob 40 is placed on the lift position, the truck will be in a state of lift.

At this time, if you rock the hand grip, the truck will be lifted.。

5.4 See fig 5, when hand knob 40 is placed on the free position, the truck will travel. At this time,

if you rock the hand grip, the truck will neither lift nor drop. Then, you can use the truck to

move the cargo.

5.5 See fig 5, when the hand knob 40 is placed on

The drop position, truck forks will drop. At this time, the truck forks will drop automatically.

5.6 Should make the pallet off ground when weighting

fig 6

Chart 8

5.6 See figure 7, figure 8.Each frame of indicating instrument means 50kg. Pointer aims at six

frames in figure 7.which means the weight of goods is 300 kg. Pointer aims at 13.6 frames in

figure 8.which means the weight of goods is 680 kg。

6. Display instrument operation introduction

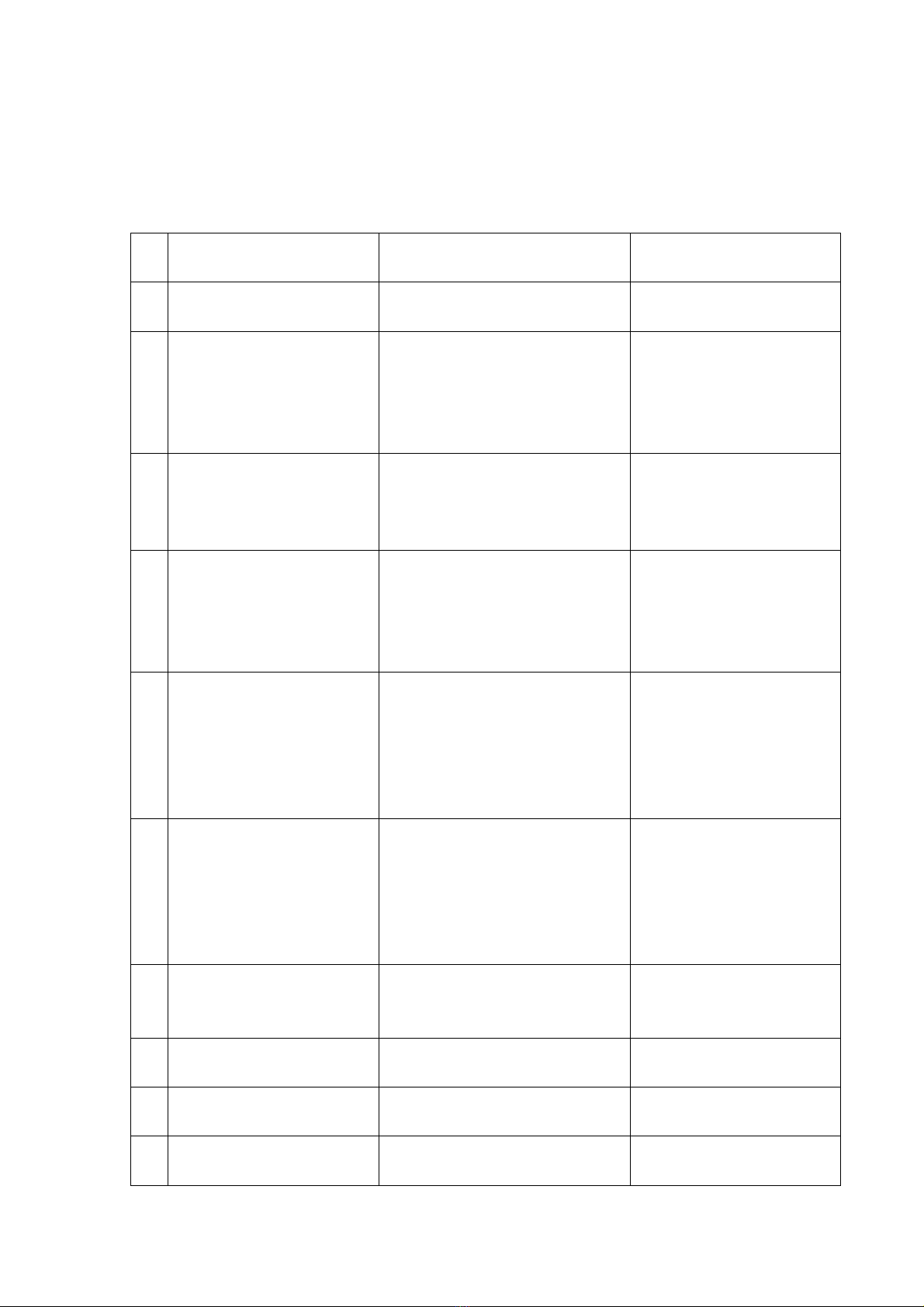

6.1 display instrument operation as figure eight.

6.2 is Startup & Shutdown button。Short press will start up, long press will

shutdown.

6.3 is function keys。In the normal load condition by 2 seconds press, into the

instrument parameter set state; enter the parameter setting, click this button to exit the

Settings

6.4 is reset button 。"Reset" function and enter the parameter setting, "confirmed"

function。

6.5 is the symbol of power display 。

fig 8

fig 7

7. Points for attention and safety norms

7.1 The operators must put on the work clothes, safety shoes and gloves during the operation。

7.2 The trucks should be locked in order to prevent moving。

7.3 When the truck is used for the motor vehicle, the truck must be moved slowly to ensure

safety

7.4 Do not park the truck on the slope or in emergency passageway

7.5 Should make operation carefully when used on the slope and make sure to operate on the

top of the slope.

7.6 Put the forks to the lowest place when parking。

7.7 Not allow to park in a place which block traffic or influence on working.。

7.8 Not allow to use in a rainy circumstance。

7.9 It is forbidden for the operator to sit or stand on the hand pallet truck to operate the truck

6.10 Not allow to turn on slope.

7.10 Not allow to turn on slope

7.11 Do not pile the cargo too high in order to prevent the goods from falling down or

overturning of the truck。

7.12 Do not use the hand pallet truck to carry people。

7.13 Untrained personnel are not allowed to stand around the operation area in order to avoid

injury caused by sudden malfunction。

7.14 Before the hand pallet truck is pushed into the elevator, the operator shall make sure that

the elevator can bear the total load of hand pallet truck and cargo as well as the total weight of

the operator and other personnel in the elevator. When entering the elevator, people should let

the load enter first but not operator. When the load or hand pallet truck enters or leaves the

elevator, other personnel should not stay in the elevator.

7.15 The hand pallet truck should be stored in dry and ventilated environment.

8. Check up before using

If the hand pallet truck is not used for a long time, air may get into the hydraulic system. Due to

this, the trouble can be eliminated by the following method:

Set the handle to the lower position. Shake the handle four to six times then let go. May

repeat above procedures for several times if necessary。

9. Loading type and rated weight

The ideal loading type is that the gravity center of the cargo is just in the middle of the truck

forks. The rated weight must be reduced when the cargo gravity center is not in the middle of

the truck forks. The rated weight is shown as the label.。

10.Oil

The oil capacity which oil pump needs is about 250ml(or 0.25kg).According to the ISO oil

criterion ,the choice of oil is 32# when the environment temperature during-5~40℃。

11. Care and Maintenance

Normal check everyday and getting rid of unusual phenomenon. Don’t use faulted trucks

in order to increase the service life. Should ask the professional person to repair if has faults.

The parts should be provided by manufacturers if need to change. Each rotational joints should

beaded motor oil once in every three months .Pay attention to the wheel and axle can not be

wrapped by sundries. To keep the wheel lightly in order to fit with the safety requirement.。

12. Possible faults and trouble shooting

No

.

Faults

Causes

Trouble shooting

1

The forks can’t be lifted to

the maximum lift height

Hydraulic oil is not enough.

Add appropriate filtrated

working oil.

2

The forks can’t return to the

lowest position.

1. Too much hydraulic oil.

2. The rotary parts are deformed

or blocked.

3. The trunk piston and guides

bushing are blocked.

1.Take out appropriate

working oil

2. Replace the parts.

3

The forks can’t drop after

lifted.

1. There is something abnormal in

the unloading device.

2. The parts are deformed and

damaged.

1. Readjust the unloading

device, see item 4.2.

2. Replace the deformed

and damaged parts.

4

Hydraulic oil leakage

1. The oil seal is unavailable.

2. The surface of some parts is

damaged or worn.

3. The coupled places become

loosened.

1. Replace the oil seal.

2. Replace the damaged

parts.

3. Fasten the loosened place

again.

5

The fork can’t be lifted.

1. The viscosity of the working oil

is too high, or there is no

working oil.

2. There is impurity in the oil.

3. There is something abnormal in

the unloading device.

1. Replace the working oil.

2.Clear up the impurity and

add new working oil

3. Readjust the unloading

device, see item 4.2.

6

When the handle is rocked,

the forks drop immediately

after they are lifted; the

handle returns or the forks

drop markedly after they are

lifted.

The valve of oil pump is blocked

by abnormal matter.

Open the valve and take out

the parts. Then re-install the

parts after they are cleaned.

7

indicated weights has big

deviation

truck is out of shape or abrasion

wil lead to meter has big

weight deviation

recalibration meter

8

meter display Err01

out of the scope of reset

Remove the goods and press

the reset button

9

meter display Err03

weight overload, or poor contact or

sensors

Remove the goos or

recalibration the instrument

10

meter display Err04

weight is not stable when demacrate

Demarcate again after put the

goods stability

11

meter display Err05

does not meet the conditions of

calibration loaded weight is less

than 20kg

Adjust the loaded weight

13.Disposal of waste oil

The waste hydraulic oil shall be disposed in terms of relative laws. And it is forbidden to pouring

out anywhere。

14.Warning !

14. 1 Please read the operation instruction carefully before you operate the hand pallet truck

and learn about all the features of this type of hand pallet truck.。

14. 2 if you want to let the truck down by controlling the hand knob, you should better lift the

hand knob a little at first, and then let the truck down slowly. It is forbidden to pull the handle

knob with great force, because rapid dropping could cause some damages to both the hand

pallet truck and cargo

14. 3 don’t rock the hand grip at a high speed and in a high frequency!

14. 4 don’t load the cargo at a high speed!

14. 5 do not overload the forks. Overloading could keep the hand pallet truck from working

normally.

14. 6 the gravity center of cargo should be in the middle of truck forks. The offset of cargo

could make hand pallet truck out of balance!

14. 7 don’t load loose or unstable goods!

14. 8 don’t put the goods on the truck fork for a long time!

14. 9 when the truck does not work, make sure that the truck forks are on the lowest position

and the power should be cut off!

14. 10 it is forbidden to load people and let them stand on the forks to slide. Don’t put any part

of body below the cargo.

14. 11 do not operate the unnamed position!

14.12 The truck shall be used, serviced and repaired according to the manufacturer’s

requirements and shall not be modified or have attachments fitted without ensuring that

the truck is still safe.

14.13 Do not use the hand pallet truck at an insufficiently illuminated place!

14.14 Do not park the hand pallet truck by turning the hand grip to the right!

14.15 Do not use the hand pallet truck as bumper jack!

14.16 The extremity of fork arms shall not be used as a lever to lift a load!

14.17 It is forbidden to use the truck at places where a risk of unintentional movement exists.

14.18 It is forbidden to contact the truck with goods or cargo directly!

14.19 Do not use the hand pallet truck in a potentially explosive atmosphere!

14.20 During the operation of the hand pallet truck, the operator should pay more attention to

the feet and any body part so as to avoid the risk of being crushed!

14.21 The truck shall be used, serviced and repaired according to the manufacturer’s

requirements

Table of contents