Toolots ZF-A5645 User manual

ZF-A5645-MANUAL

CONTENT

1, the safety precautions .......................................................................

2, the safety operation precautions .

3. the mechanical specifications .............................................................

4, the mechanical installation ................................................................

5, mechanical debugging and operation ....................................................

6, mechanical adjustment .....................................................................

7, mechanical maintenance.....................................................................

8, troubleshooting ..............................................................................

9, circuit diagram ................................................................................

ZF-A5645-MANUAL

First .the safety precautions:

1,Please read all the related instruction before operating the machine.

2, In order to avoid accidents, please keep the workplace well ventilated, and pay

attention to the damage of packaging which may cause liquid or gas leakage.

3, maintenance person must read the machine maintenance instructions carefully,

before the maintenance work.

4, confirm the power has been cut off, before the maintenance work.

5, during machine running, if any accident occurs, turn off the power at first place,

and then make the appropriate measures.

6, the machine is not suitable for packaging explosives products. In addition, if you

want to package small items or liquid, powder, should first have them packed in

boxes, tanks, bags and other packaging,

7, the machine does not apply to the PVC film, because the PVC material is easy to

damage the machine's knife , if you must use PVC film, the knife must be a special

material. If PVC is used for POF knife, the warranty is automatically invalid.

8, If modify the machine without authorization, the occurrence of any accident

will not be responsible by manufacturer.

9, all air pressure pipes and cylinders can not have oil or water and other

contaminated items, if these pollutants found, the warranty become invalid.

10, if you have any questions, please contact us free.

ZF-A5645-MANUAL

Second, the safety operation precautions

1, None except the operator can operate the machine. When the machine is in

automatic operation, the operator can not place the hand under the sealing knife

or within the range of the electric eye, so as to avoid the accident.

2, When the machine is running, the operator can not stretch out hands to the

front and the rear of conveyor rolling part, in case the hand was jammed or caught

into the machine.

3, When the machine automatically run, should keep the safety door close, to

avoid any contact with the sealing device and cause injury by burns, and other

hazards.

4, When the machine press to the product and alarm, or other failure occurs,

should first press the emergency stop switch, the operation mode should

change from automatic operation to manual operation. After all the failure

being cleared, release of emergency stop switch, turn back to automatic

operation.

5, pay attention to the film sending rubber roller and the needle roller part, when

ZF-A5645-MANUAL

the machine running, must keep the safety door close, do not touch by hand,

in case any damaged caused.

6, if the electronic tape cracked, must be replaced by new one, so as not to affect

the quality of sealing and sealing knife life. When there is film on the knife or

other debris, need to use cotton towel clean the knife. When cleaning, the

emergency stop switch must be pressed and the machine is in manual operation

mode. When doing this cleaning, turn off the main power supply to ensure safety.

ZF-A5645-MANUAL

Third, the mechanical specifications

1、Machine Specification

Machine Model:

ZF-A5645

Machine Size L×W×H(mm):

1795×880×1570mm

Sealing Knife Size mm:

L:565 W:460

Packing Products Size L×W×H

(mm):

(100~450)×(60~350)×(5~120)

Max. Packing Width″:

23″

Production Capacity:

30Pcs/min

Conveyor speed m/min:

26M/min

Packing Material:

POF、PE

Sealing Knife Temperature :

180-230℃

Voltage :

220V/1P

Motor Power :

320W

Heating Power :

2.5KW

Total Power :

3KW

Ross Weight Kg:

330Kg

Gas consumption KG:

6kg/sp.cm

ZF-A5645-MANUAL

1515

750

1795

1570

880

400

C C

2、Machine Size

Unit:mm

ZF-A5645-MANUAL

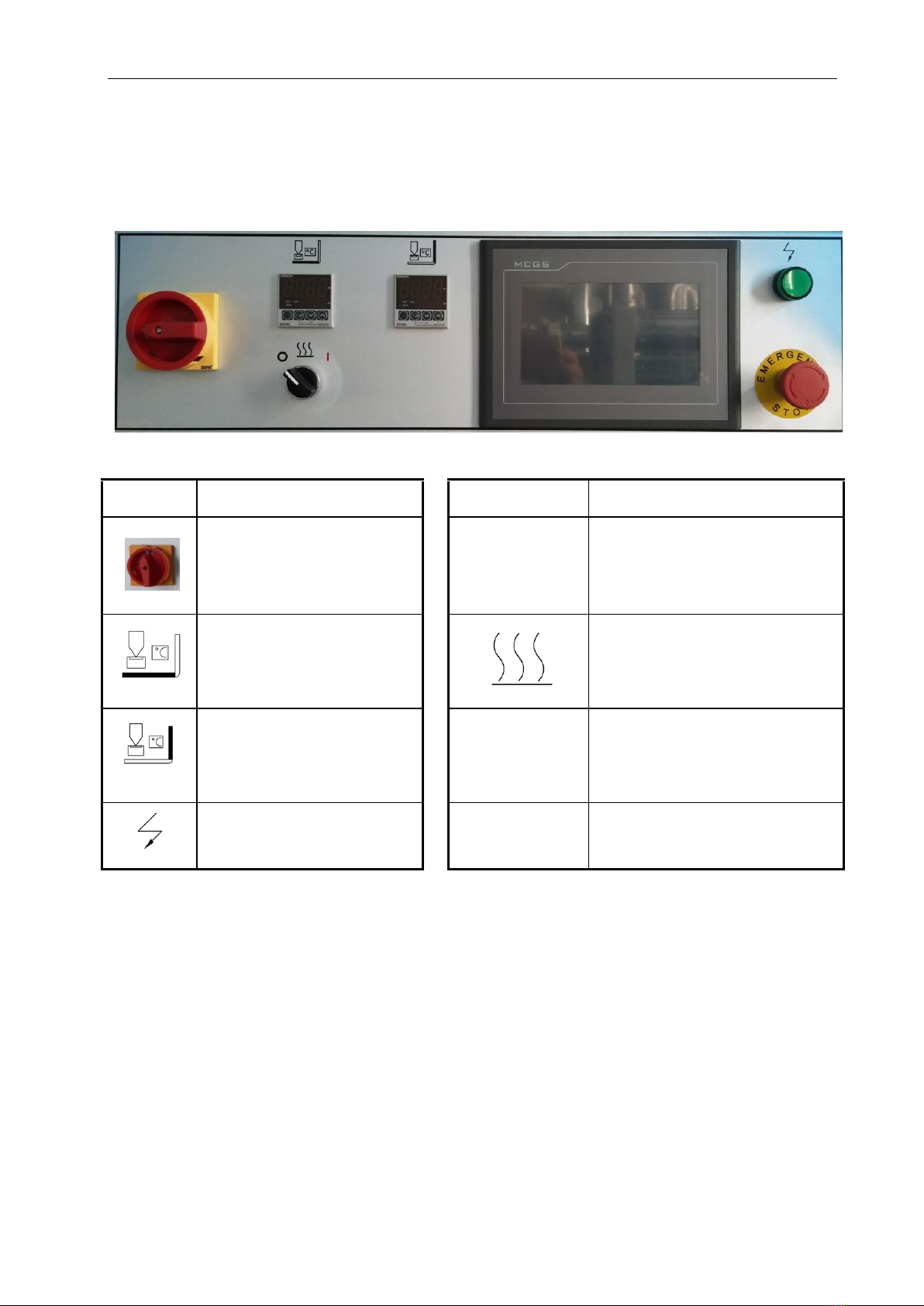

3、Operate Panel

ZF-A5645-MANUAL

Forth: Machine Installation

1, Installation location:

(1) The machine should be installed in a bright, dry place.

(2) The machine should be installed away from environment of dust, explosive

and inflammable, corrosive.

(3) Do not place the machine too close to the ventilation system, which would

case sending of unstable.

2, installation:

(1) After the installation site is selected, move the machine to the intended

location to match the production line.

(2) mechanical height adjustment: use the wrench to loosen the lock nut under

the rack, and then adjust the height adjustment nut, until the required mechanical

height is reached, and finally tighten the lock nut. (Figure 4.1)

(3) Power Connection:

A. Turn the machine power switch to OFF.

B. The main power switch to OFF, confirm the voltage is correct, then have the

sealing machine power connected.

C. Check all the machine part in normal condition, turn the machine power switch

Height Adjustment Nut

Air Pressure

Lock nut

Intake Valve

Figure 4.1

Figure 4.2

ZF-A5645-MANUAL

to ON, then the machine into the operating state.

(4) Pneumatic device: As shown in Figure 4.2, the air pressure throat connected to

the machine's air pipe, open the intake valve, and then rotate the air adjustment

device, so that the air pressure maintained at 6kg / cm2 or more.

ZF-A5645-MANUAL

Fifth, mechanical debugging and operation

1、Machine Installation

(1)Sealing Machine Control Function Explanation

Diagrams

Application Function

Diagram

Application Function

Power Supply on/off

MCGS

Touch Screen, for operation

and parameter adjustment, the

center control system.

Set the temperature of heating

tube for the side sealing knife,

to control the sealing

performance.

When select 1 or ON,the sealing

knife hearing tubes start working,

will heating to the set temperature.

Set the temperature of heating

tube for the front sealing knife,

to control the sealing

performance.

EMERGENCY

Click it down, the machine will stop

working immediately. To start the

machine again, should loose the

button.

Power supply indicator

ZF-A5645-MANUAL

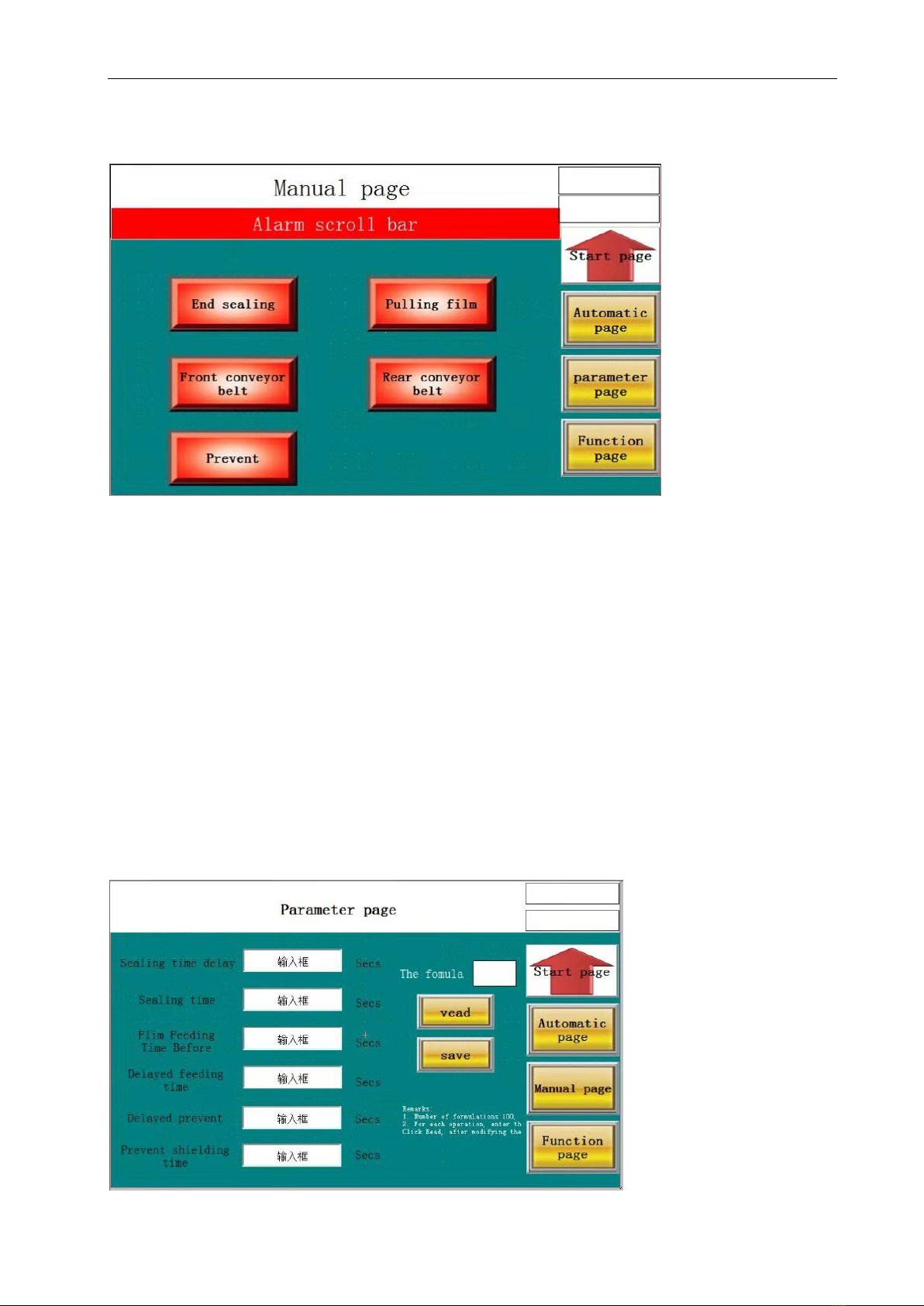

2, touch screen operation and its function explanation

(1) to open the main power switch, touch screen display the home page as shown

Select the “automatic page” and the submenu appears as shown in Figure 5.3

A. Run: click the "Run" button, and then the device enters the running state

B. Stop: click the “stop”button, and the device stops

C. Reset: when the device alarm, click the "reset" button to clear the alarm and the

device enters the normal preparation state.

D. Manual sealing: click it to manual seal

5.2

ZF-A5645-MANUAL

Select the “manual page” option and the submenu appears as shown in Figure 5.4

A. Manual sealing: click it once to manual seal once

B. Synchronous film pulling: when click” pulling film”, the action of sending film

and

pulling film goes; when release, the action stop.

C. Front conveyor: click "front conveyor" and enter manual operation

D. Rear conveyor: click "front conveyor" and enter manual operation

Select the parameter page and the submenu appears as shown in Figure 5.5

ZF-A5645-MANUAL

A. Sealing time delay: set the time of the film feeding length

B. Sealing time: the residence time of sealing and cutting film

C. Film feeding time before: each time of sealing time, the time of film pre-feeding

length

D. Delay pulling time: the time of detect electric eye to see the delayed time of

pulling.

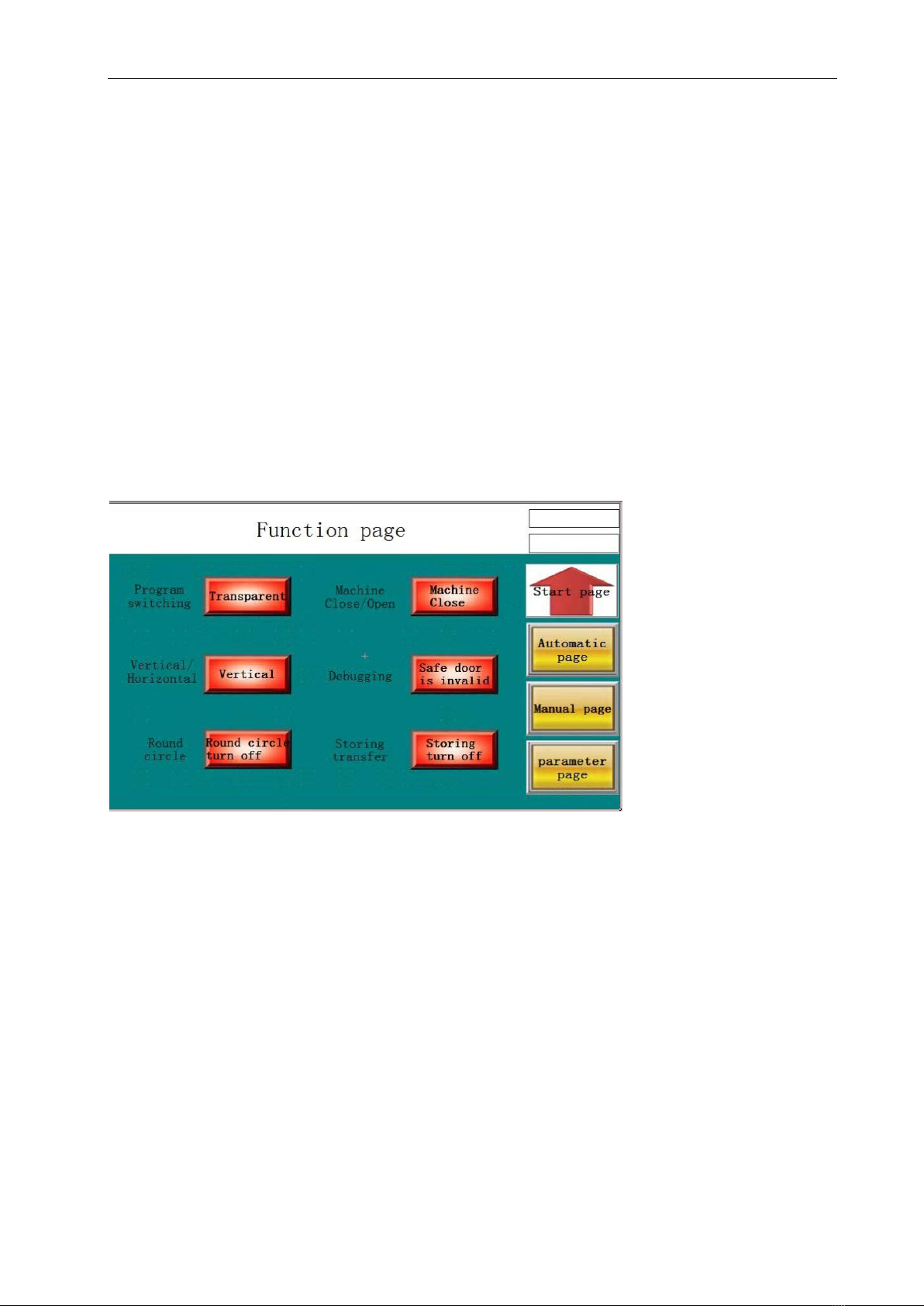

Select the function page and the submenu appears as shown in Figure 5.6

A.Program switching: click it to make switch between" hollow products" and

"solid products".

B. Machine close/open: once click it, the equipment can start automatically.

C. Vertical / horizontal: click it to make switch between horizontal detection and

vertical detection.

D. Debugging: to switch the safe door between valid and invalid

E. Connecting conveyor belt: click it to make switch between the start -stop

ZF-A5645-MANUAL

mode and the continuous mode.

2、Function debugging

(1) When the machine is running, switch the operation mode to (STARTUP), check

whether the belt is running normally, whether the conveyor surface is in the

middle of the wheel, if there is deviation, please refer to the next chapter

conveyor belt adjustment, Switch to manual mode.

(2) The width of the package mentioned in this manual is expressed in W, the

height is expressed by H, and the length is in L, as shown in Figure 5.1.

(3) shrink film width calculation method: shrink film width = package width W +

package high H + 4-6 inches.

(4) tripod and conveyor belt adjustment

A. Tripod height adjustment: Figure 5.2, turn the hand wheel to adjust the

height of the tripod, about (high H + 5-10mm packaging).

B. Guide rod height adjustment: loosen the screws on the fixed block, you

can adjust the height of the guide rod up and down according to the

needs of the packaging, adjust and then lock the screws. Adjust the

height to 1/2 height of the product.

C. Conveyor belt horizontal position adjustment: hold down the handle,

connecting rod jacking-up the locking block, then drag the handle to

Figure 5.1

W

H

L

ZF-A5645-MANUAL

adjust the front conveyor belt position. After dragging to the

appropriate position, release the handle and lock the block to lock the

front conveyor. The adjustment is complete. The distance from the

guide rod to the product is 1 / 3-1 / 2 of the Product height.

(5) Load shrink film to the film fixing roller.

A. As shown in Figure 5.3, the shrink film is placed on the film feed roller.

Note: that the opening side of the shrink film must face the side of the

positioning of rod B.

B. There are 8 positioning-lines on the front film roller, the spacing between

Locking block

Hand-whe

el

Tripod

Handle

Guide rod

1

Locking

block

Figure 5.2

SP-line

Conne

cting

rod

Guide

Rod

Connecting

rod

Guide Rod

ZF-A5645-MANUAL

each positioning-lines is 10mm; if the height of the packing product is

20mm or less, the left side of the film should be placed on the rightmost

position. If the packing height is more than 20mm, the higher the

packaging, the more left should the film be loaded. (Every 10mm higher

of the packing product, the film should be moved 5mm in the direction

of the positioning rod.)

C. After adjusting the film position, move the positioning rod on both sides,

adjust it to both ends of the film, and then lock the nut to fix.

(6) Turn on the heating switch to 1 (select ), and set the front and side

seals to the appropriate temperature (select & ). (See Table 5.2 for

temperature adjustment)

Film

Needed Temperature

Film

Needed Temperature

PE Film

200℃~240℃

POF

180℃~220℃

Figure 5.3

Positioning rod A

Tripod

Positioning

Rod B

Open side

Positioning

Line

ZF-A5645-MANUAL

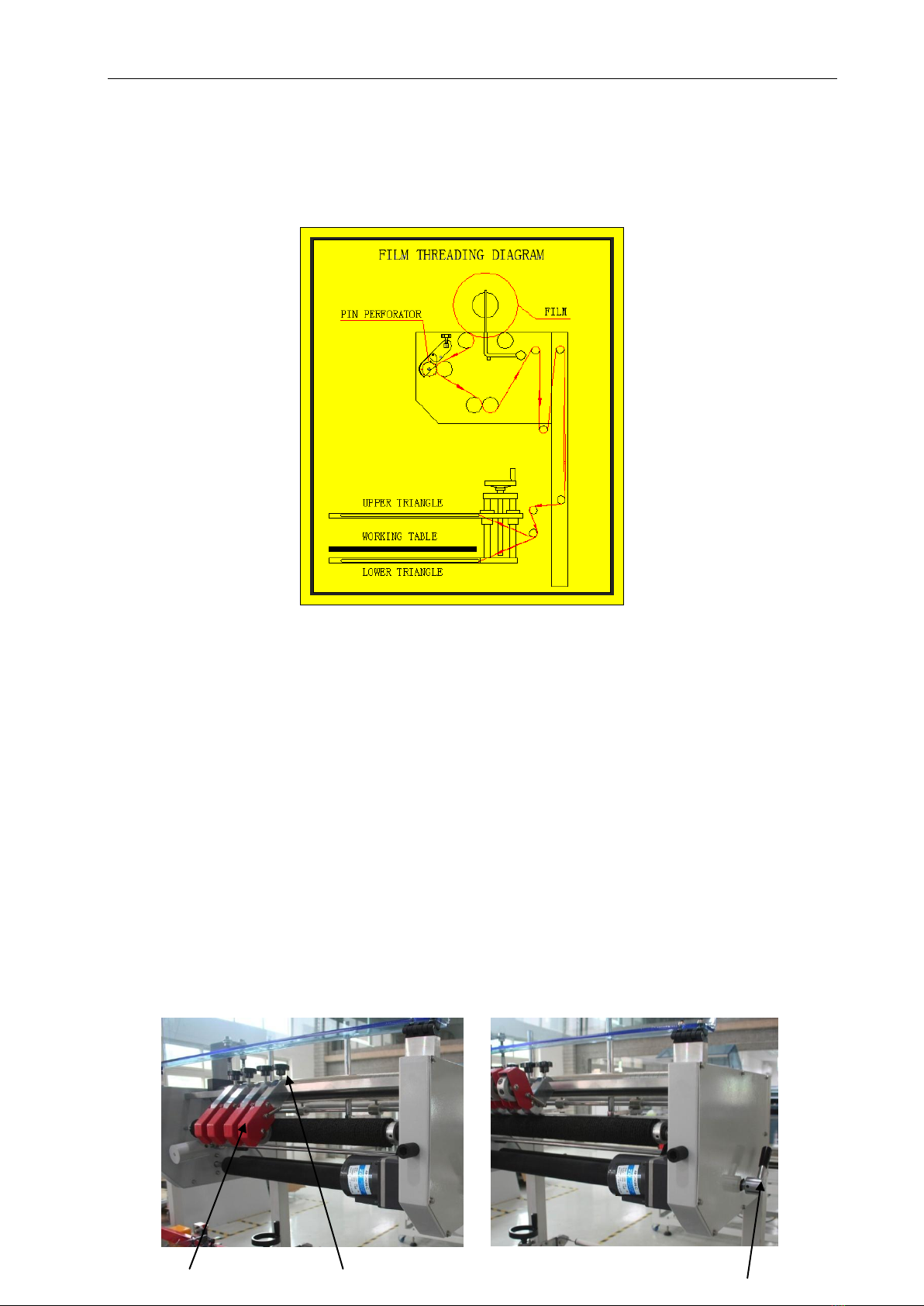

(7)Method for loading the film(Figure 5.4)

(8)Film Threading:

A.As shown in the right figure of Figure 5.5, pull the handle rearward so that the

two rubber wheels are separated and the roller device is turned up and then

spread through the film as in the diagram of 5.4, then reset the handle and pin

roller. Depending on the packaging, the number of needle(pin) roller is different.

Loosen the fixing hand-wheel to slide the roller device and increase or decrease

the number of needle roller as needed.

Figure5.4

Figure5.5

Hand

Wheel

Needle Roller

Fixing

Handwheel

ZF-A5645-MANUAL

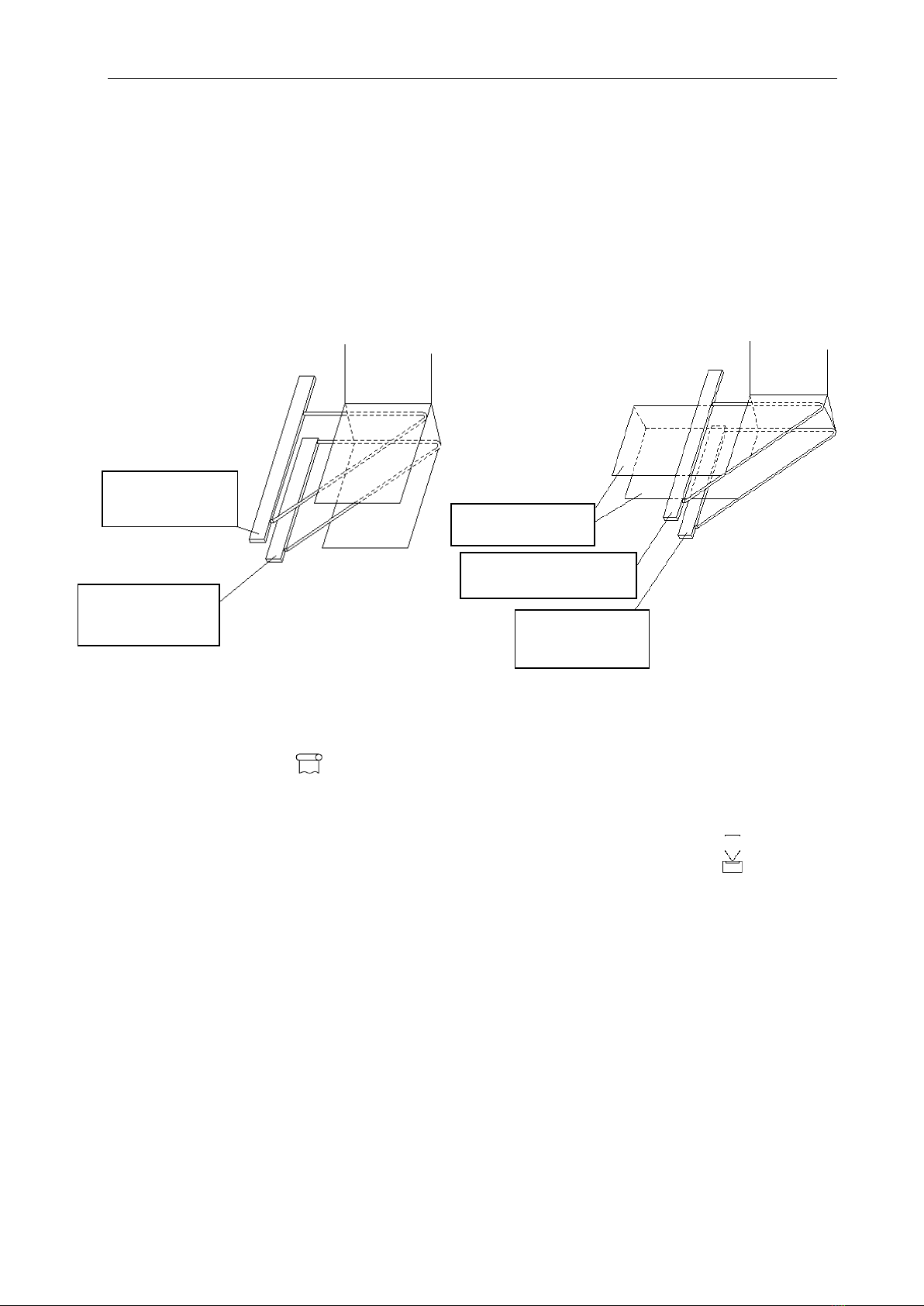

Figure5.6

B. After threading the shrink film to the rollers, then lead to the upper and lower

triangular plate. The upper and lower triangular plates are shown in Figure 5.6.

C. Finally, pull the shrink film to the middle of clamp-roller and pull-material -belt

to clamp it.

(10) When the temperature reaches the default degree, press the manual feeding

film switch ( ) once, then the pull device will pull the shrink film, if the

film is not pulled, please check the film is placed correctly or not.

(11) If the above action is normal, press the manual sealing switch ( ) once, at

that time the sealing knife will carry out the sealing action, and complete

the sealing and cutting of the shrink film.

(12) Repeat the operation several times as described in (10, 11), until the shrink

film scrap can coiled on the scrap-winding roller for 2-3 turns, then the

sealing machine can be operated automatically.

(13) Switch the machine to automatic mode (press STARTUP key) and place the

product to be packed on the conveyor.

Note: Both hands should be completely away from the conveyor surface to avoid

Upper Triangular

plate

Lower Triangular

plate

Upper Triangular plate

Lower Triangular

plate

Two layers of film

ZF-A5645-MANUAL

Figure5.7

danger.

(14) adjust the seal to the best condition

A. Adjust the pre-sending (feeding) film: pre-feeding film length is best 1 / 3H,

then the best shrink effect. (Figure 5.7 size A)

Adjustment method:

a. When the length of the reserved film is too long, the distance

between the electric eye and the sealing knife L1 (Fig. 5.8) can be

adjusted closer.

b. If the L1 length is too short, you can adjust the pre-feeding film time

to change the length of the film (select ), set the longer time,

the longer the length of the pre-feeding film.

B. Adjust the extension of the sealing method: to extend the length of the

seal according to the electric eye pattern. If the eye contact mode is in

standard mode, extend sealing length would be the size of Figure 5.7 B;

if the electric eye sensor mode is of view-compensation-mode,

extended seal length would be the size of(B + L). However, regardless of

which mode adopted adjust the size of B to 1 / 2H can get the best

shrink performance. (The extend length of the seal is related to the way

and principle of the electric eye sensing, please refer to P13.)

Packed

product

Feeding

Direction

Sealing Line

ZF-A5645-MANUAL

Figure5.8

Adjustment method: choose the extend the sealing time switch ( ), the

time up and down, longer the time, longer the length of the extend seal

until get the appropriate length.

C. Different shrink film requires a different sealing time, generally about

0.3-0.6 seconds, depending on the sealing situation. Sealing lines should

be cut off and no holes, if the cutting off is uneven, may caused by

temperature overheating, could adjust the sealing time or sealing

temperature. ( )

(15) If the sealing line is satisfied, the sealing machine debugging is completed.

2, the machine features

(1) The machine has a safety protection function and alarm device.

(2) sealing system can carry out the sealing action continuously.

(3) simple operation and can be used with different sizes of packaging products.

(4) The machine adopts PLC and electric eye control.

(5) electric eye devices including the horizontal eye (PH1, PH2) and vertical

electric eye (PH3) two kinds. General products packaging use the horizontal

electric eye, thin products packaging use vertical electric eye. In addition,

Down Knife

Seat

Front Seal Knife

Packed product

Photoelectric

Table of contents

Popular Food Saver manuals by other brands

Primus

Primus PRI20001 User manual and product specifications

Rx Systems

Rx Systems AutoSealer 1002 user guide

Euronda

Euronda Euroseal instruction manual

Insta

Insta 228 Operation and maintenance manual

Van Der Stahl

Van Der Stahl FAS-402-CH Series operating instructions

Sheffield

Sheffield PLA1405 instruction manual