Toolots BWD 63 Series Specification sheet

1/ 14

1. GENERAL RULES

1.1 The toll rurret of YAXING design are provided for being

incorporated in numerical controlled turning machines , and they

must be used only for this purpose .The maximum performances

of the turret are shown on the respective Technical data sheets.

Any improper use or alteration of the turret relieves YAXING of any

responsibility for possible injury to persons and damage to

property and will also invalid any obligation for warranty.

1.2 Before installing and commissioning the turret, technician

and the operator must have read carefully this instruction

Manual.

1.3 Commissioning adjustment and repair of the turret must be

carried out by skilled and authorized personnel who must follow

the instructions in this Manual for all necessary steps.

1.4 YAXING declines any responsibility for any accident or injuries

to persons or damages to property due to non observance of the

respective safety rules and to the instruction shown in this

Manual.

2/ 14

2.Application

This turret is a core of economic and advanced NC lathe.It make sure that the

workpiece can be automatically processed from turning internal、external and

turning surface、arc to threading、groove just by once clamping、and widely

used for machine tool、auto、gear、bearing、metallurgy industry etc.

3. Model identification

BWD

4. Technical Date

─

─

Model

Positions

Code

Installing

method

centre H

Order number

When the

turret

indexing the

disc needn’t

in axial

motion

Nr.6.Pos

6

63

standard

Nr.8.Pos

8

F

back

80

01

Other 1

other

front

100

ITEM

PARAMETER

ITEM

PARAMETER

CENTER HIGH

mm

63/80/100

Max Unbalancing torque

Nm

10/12/20

POSITIONS

N

6:8

Repeatability accuracy

mm

<0.005

INDEXING TIME 45°

S

1.8/1.8/2.1

Dividing accuracy

mm

<0.03

INDEXING TIME 180°

S

2.9/2.9/3.2

POWER of the motot

W

90/120/140

Max tangential

KNm

0.8/1.5/3.0

Motor rps

r/min

900/1400/1400

Max axial torque

KNm

0.4/0.6/1.5

Mass(without tooldisc)

Kg

35/50/80

3/ 14

常 州 亚 兴 数 控 设 备 有 限 公 司

Changzhou Yaxing CNCEquipmentCo., Ltd.

EG F

A

H

L B

M

N

1

C

3

2

K

J

I

O P QR2-?S

D

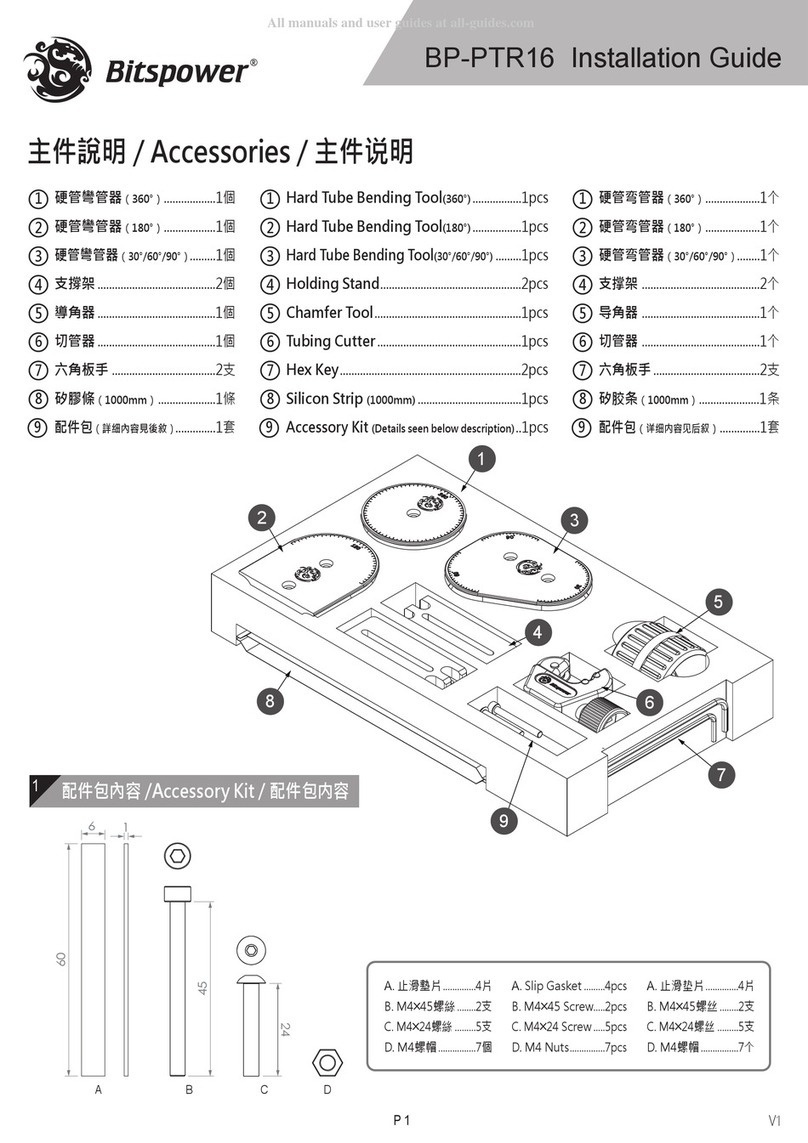

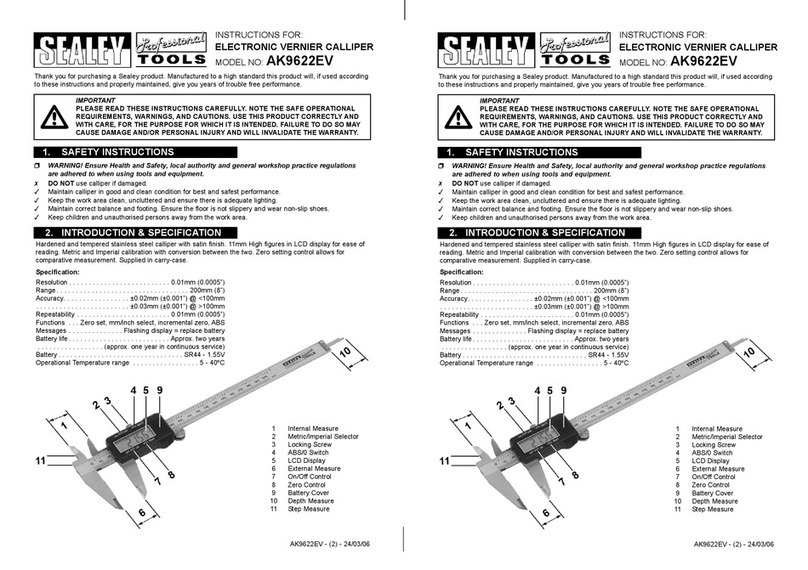

5. Dimension

Note:1.is the coolant input

2.is the oil outlet

3.is the oil input

Note:Can be made according to your demands

H

A

B

C

D

E

F

G

I

J

BWD**-63

63

323

205

20

11

26

145

55

140

40

BWD**-80

80

315

238

25

11

26

149

65

160

40

BWD**-100

100

350

280

32

13

32

172

80

205

50

K

L

M

N

O

P

Q

R

S

T

BWD**-63

190

134

165

185

50

30

30

30

G1/4”

BWD**-80

240

149

190

210

58

32

32

32

11

G3/8”

BWD**-100

305

188

220

250

66

40

30

30

G3/8”

1/ 14

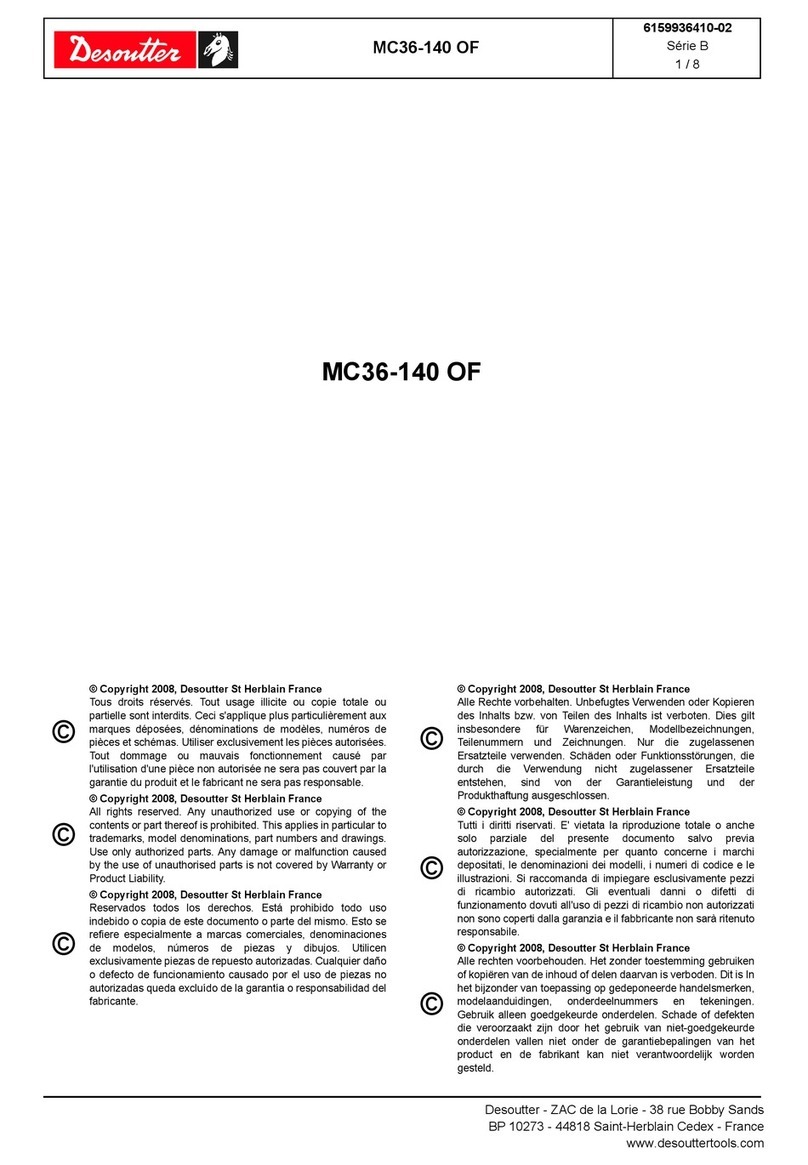

6. Turret indexing sequence

Indexing signal---motor rotating in CW---NC received locating signal from

turret---stoped motor in CW and restarted motor in CCW ---clamping---stoped

motor----detected the clamping signal and response signal----working

7. Sequence diagram

2/ 14

BWD HALL Coder Sequence Diagram

1

0

1

0

1

0

1

0

1

0

1

0

p o s.

1

HA LL c o de r

Se qu en c e

E LE CT R IC

M OT OR

C W

CC W

1

1

0

p os .

2

p o s.

2

p o s.

3

p os .

4

T T

L OC KI N G CO NT R OL

S WI TC H

T1

T2

T3

T4

T8

Hall code

"T "i s th e ti me

f or t he m ot or

c cw a nd lo ck in g,

it is

a bo ut 0 .8 -1 .2 s

T he g ap t im e

b et we en mo to r

c w st opp in g an d

c cw s tar ti ng

d oe s not

e xce ed 5 0m s.

The truth table of Hall coder

position

1

2

3

4

5

6

7

8

T1

1

0

0

0

0

0

0

0

T2

0

1

0

0

0

0

0

0

T3

0

0

1

0

0

0

0

0

T4

0

0

0

1

0

0

0

0

T8

0

0

0

0

0

0

0

1

3/ 14

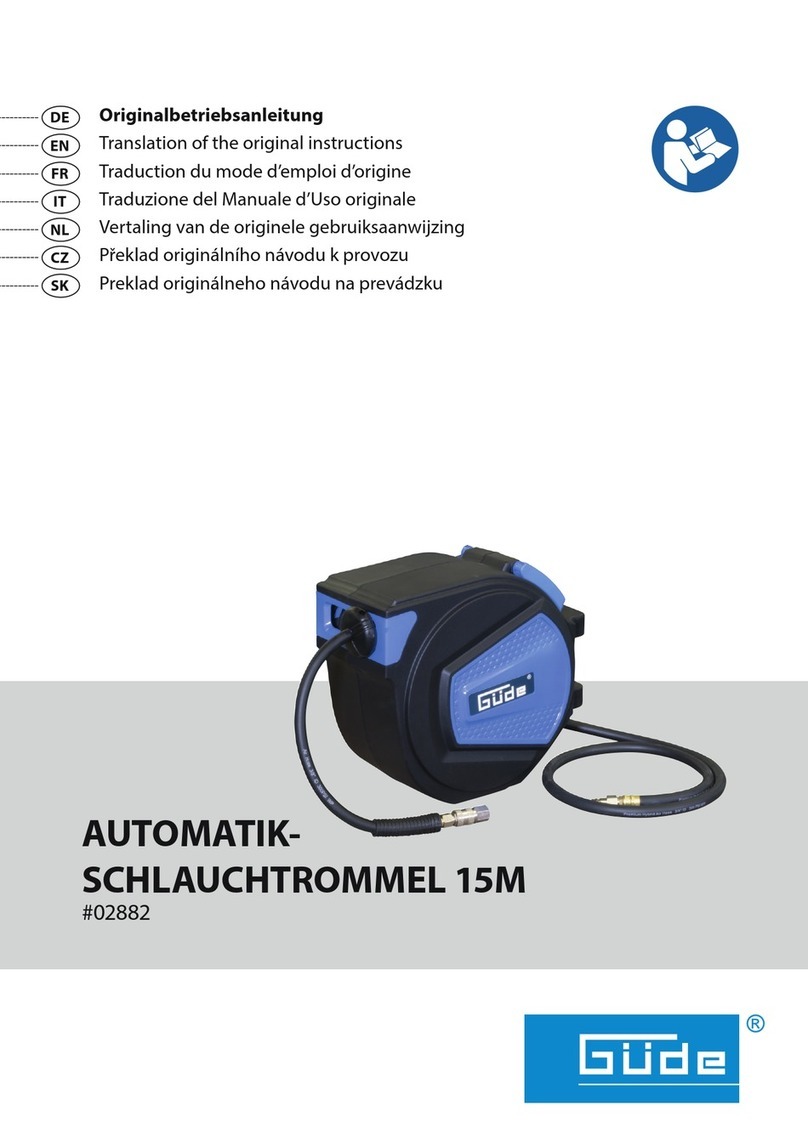

BWD 8421 Coder Sequence Diagram

1

0

1

0

1

0

1

0

1

0

1

0

p os .

1

8421 coder

S e qu en ce

EL E CT RI C

MO T OR

C W

C CW

1

1

0

po s .

2

p os .

2

p os .

3

po s .

4

T T

LO C KI NG C O NT RO L

SW I TC H

2

0

8 421 co de

" T" is t he t im e

f or t he m ot or

c cw a nd l oc ki ng ,

it i s

a bo ut 0 .8 -1 . 2 s

Th e ga p ti me

be tw ee n m ot or

c w st op pi ng a nd

c cw s ta rt in g

d oe s no t

e xc ee d 50 ms .

2

1

2

2

2

3

TP

The truth table of 8421 coder

position

1

2

3

4

5

6

7

8

9

10

11

12

20

1

0

1

0

1

0

1

0

1

0

1

0

21

0

1

1

0

0

1

1

0

0

1

1

0

22

0

0

0

1

1

1

1

0

0

0

0

1

23

0

0

0

0

0

0

0

1

1

1

1

1

TP

1

1

1

1

1

1

1

1

1

1

1

1

4/ 14

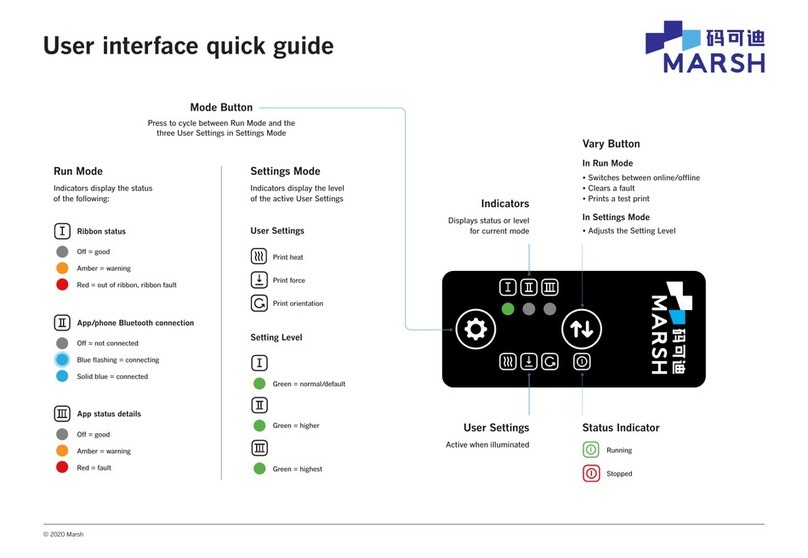

8.ELECTRICAL CONNECTION

8.1 Motor connection

Lea

1

2

3

fun

U

V

W

8.2 The connection of the coder and proximity switch

The signaling device composed of Hall coder and optical coder

8.2.1 The connection of the Hall coder

BRO RED ORA YEL GRE BLU VIO BLA BLU BLA BRO

WHI

8 STATIONS TURRET

LEA

1

2

3

4

5

6

7

8

9

10

11

12

FUN

T1

T2

T3

T4

T5

T6

T7

T8

0V

clamp

VCC

P r o x i m a t o

CODER

5/ 14

YEL ORA BLU WHI BLA VIO BLU BLA BRO

RED

6 STATIONS TURRET

8.2.2 The connection of the 8421 coder

YEL BLU VIO GRE WHI BLU BLA BRO

BLA

RED

8.2.3.1 The clamping signal is from the clamping proximate of the turret

and the clamping proximate is the NC PNP switch and it is high lever

effective and it,s output current is 200mA.

8.2.3.2 Hall coder:It is composed ofA 1104 BiCMOS Hall-effect switches

and lower lever effective.

LEA

1

2

3

4

5

6

7

8

9

10

11

12

FUN

T1

T2

T3

T4

T5

T6

0V

clamp

VCC

LEA

1

2

3

4

5

6

7

8

9

10

11

12

FUN

8

4

2

1

TP

0V

clamp

VCC

CODER

P r o x i m a t o

CODER

P r o x i m a t o

6/ 14

8.2.3.3 Signaling disc:There are two signaling disc in our company one is

the high lever effective signaling disc and it is used for high lever effective

CNC system and other is the lower lever effective signaling disc and it is

used for lower lever effective CNC system.

8.2.3.4 8421 coder:It is NO PNP output device and it is used 24 VDC

power and it,s output current is 25 mA.

8.2.4 NOTE:

8.2.4.1 Do not with the signaling output terminal or proximate output

terminal or proximate output terminal and electrode of the power

short-circuiting.

8.2.4.2 It is must be close the power switch when you connecting the

coder terminal and the proximate output terminal.

8.2.4.3 Because the output device is used CMOS device so when you

connected from turret to CNC system the ground connecting of the electric

iron must be good.

8.2.4.4 15T diagram

HA L L HA L L HA L L H A L L

R ES P O NS SE N S OR

+V C

C ND

T 1

T 8

RE S P ON S SE N SO R

J 1 J 2

J 2 J 1 J 1

J 2

A C3 8 0

C W C C W

C

N

C

TURRET

7/ 14

9Installing and adjusting

9.1 Installing

When the turret is installing at frist the assemblies must be coating oil and

the driving system must be lubrication.

Make sure the fixing surface is clean and squared to ensure a proper tool

alignment. Align the front surface of the disc in order to have it

perpendicular to the spindle axis.

9.2 Adjusting

The electric connection must be carried out according to the 15T

diagram,The connection cable must be provided with fittings and gasket in

order to penetration of water into the turret.When the turret can not

indexing at this frist must be cutoff the power switch and detected phase of

the motor and then restarted ,when the turret indexing the turret must be

agile and no abnormal sound.

10 Use and maintenance

10.1 The back cap do not removed and every assembly do not changed.

10.2 Indexing frequency <6 cycle min

10.3 The CCW clamping time is equal to 0.8-1.0s.

10.4 Maintenance

10.4.1every day must be lubricating the mechanical part of the turret ,and

after tree month must be changed lubricate and coating the oil for the tool

disc.

8/ 14

11. FAULT,FINDING LIST, CORRECTION

Note:when adjusting the relative position of the .Hall unit and magnet the

Carrier must be locked and the position of .Hall unit must be 1/3 ahead

magnet steel.

FAULT

FINDING LIST

CORRECTION

1.motor can not start or

upper body can’t

rotation

1.phase inversion votage

is too low

cut off the power at once

adjust the phase and

voltage of the motor then

start agan.

2.upper body rotating

continually and can’t

stop.

1.signalling disc bad

contact .

2.signalling disc fault.

3.Hall unit is broken or

short.

4.pole of magnet steel is

inversion.

5.the position of the

magnet steel and .Hall

unit is relative departure.

6.the Hall unit or magnet

is bad.

Unload cover,checking

signalling disc and

supply ,adjust the

position of the magnet

and Hall unit .or replace

Hall unit .

3.after having

correctly perfomed

the indexing cycle

the disk stil unloked

1.the time of the CCW

so short.

2.bad contact.

3.with the locking

signal cut off the

CCW rotating signal.

Adjusting the time of

CCW,checking wire pf

the turret .can not with

the locking signal foe

the motor in CCW.

4.the disc goes on

rotating without

stopping or over.

the position of the

magnet and Hall unit

no good. Delay

between the CW and

CCW is no long.

Adjust the position of

the magnet and .Hall

unit and delay time

between the CW and

the CCW.

5.the face of the

workpice present

some ripple.

1.the turret is not

clamping.

2.fault of the

mechanical system.

Adjusted clamping time

(must be according to

the instruction of the

turret)

9/ 14

12. Assembly drawing

12.1 Assembly drawing

12.2Note:

12.2.1 When you dismantling the turret must be marked relatively position

of the assembly and do not attained sealed ring of the turret.

12.2.2 When you reassembling the turret it is must be make sure the fixing

surface is clean and have not dust or other material.

12.2.3 When you adjused coder at frist must be lock the turret at any

position and set an approximate positioning by rotating the unit to get the

corresponding position code or the signal passes from 1 to 0 and mark this

new position and tighten the screws of the fixing pieces.

10 / 14

Assembly drawing BWD**-63/80/100

This manual suits for next models

2

Table of contents

Other Toolots Tools manuals