22

ROUTER TABLE OPERATION

R9PLUS Dovetail Jig User Guide

Introduction

2000

2090

Your New Leigh R9PLUS Dovetail Jig

for Dovetails and Box Joints

Note: There are two user guides in this book. This user guide is for

Router Table Operation. Flip the book over for Bench Operation.

The R9PLUS Dovetail Jig was designed to overcome the restrictions

of fixed width jigs. Because of its unique “step over” feature, it

is possible to rout Through Dovetails and Box Joints on boards

of ANY width!

The R9PLUS can be used as a template jig with a hand-held router

or as a router table template. In either mode, you will be able

to rout multiple sizes of perfectly fitting through dovetails and

box joints.

Customer Support

If you have any questions that are not answered in this user guide,

please call Leigh Customer Support: 1-800-663-8932 in North

your country of purchase see the Customer Support section of

the Appendix.

Reminder: If at first you don’t succeed, read the instructions!

Important! Inches and Millimeters

Text and illustrations in this English language user guide

indicate dimensions in both inches and millimeters, with

“inches” first, followed by “millimeters” in square brackets, i.e.

1⁄2"x 2"[12x50mm].

Do not be concerned that the inch/millimeter equivalents are

not mathematically “correct.” Just use the dimensions that

apply to your guides and bits.

U.S. Patent No. 8,534,329

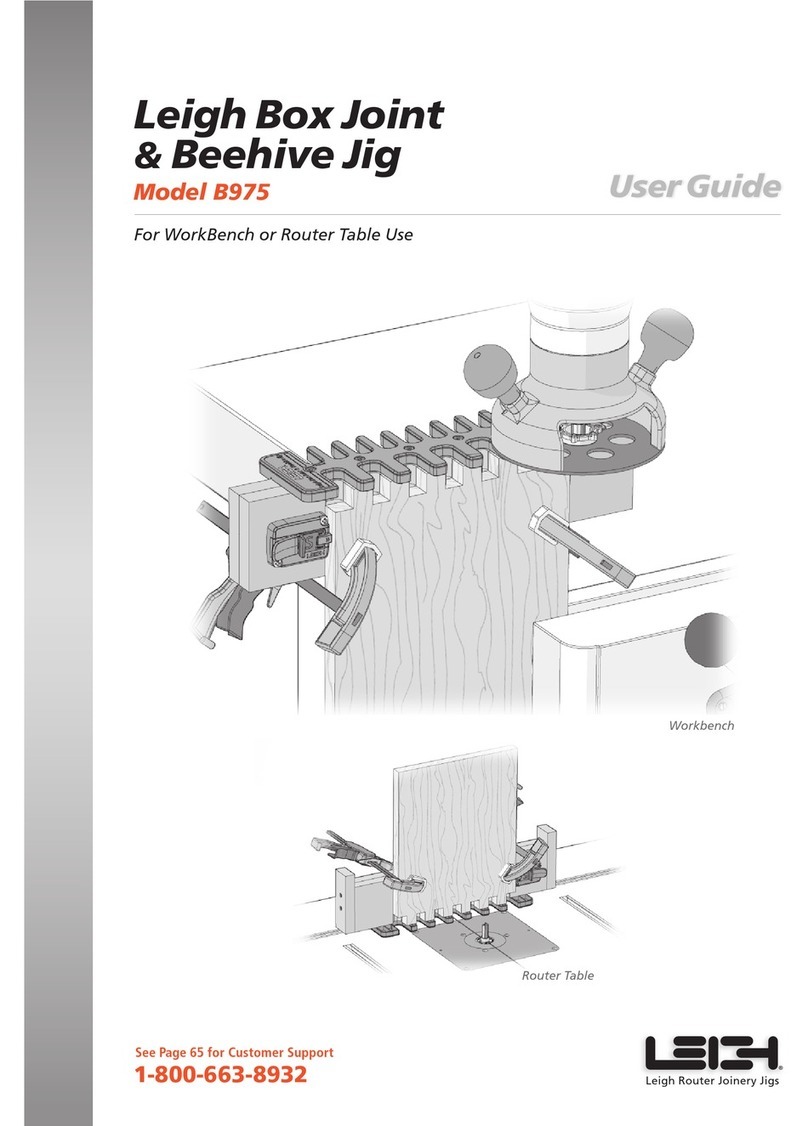

What’s in the Box:

PART NO. QUANTITY PART DESCRIPTION

2000 1 R9PLUS Template

2090 1 User Guide

BAG 1

2030 2 Latches

2040 1 Glide for Router Table

2080 1 Sidestop

BAG 2

2010 3 Pin Plates

BAG 3

2050 2 Beam Assembly Screws, ¼"-20 x 2¾"

2055 2 Beam Assembly Wing Nuts, ¼"-20

2060 2 Latch Screws, Phillips 10-24 x ¾"

2065 2 Latch Nuts, Nyloc

2070 11 Wood Screws, Phillips Flat Head, No.8 x 1¼"

2075 1 Sidestop Screw, Phillips Round Head, No.8 x 1¼"

BAG 4

e10 1 e10 eBush (Guide Bushing)

80-8 1 Dovetail Bit, ½"-8º

160 1 Straight Bit, ½"Two Flute

172-8 1 Collet Reducer, ½"to 8mm

730V 1 Pin Wrench

BAG 5

2020 2 Clamp Locators

9505 2 F-Clamps