Toolshop CSW174 User manual

241-9869

7-1/4 IN. CIRCULAR SAW

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

For questions about this product, please call 1-800-868-7421

Owner’s Manual

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. WARNING

Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

2. WORK AREA

a. Keep your work area clean and well lit. Cluttered benches and dark

areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep bystanders, children and visitors away while operating a power

tool. Distractions can cause you to lose control.

3. ELECTRICAL SAFETY

a. Double insulated tools are equipped with a polarized plug (one prong is

wider than the other). This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation eliminates the need for the

three-wire grounded power cord and grounded power supply system.

b. Avoid body contact with grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if

your body is grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord to carry the tools or pull the

plug from an outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

e. When operating a power tool outside, use an outdoor extension cord

marked “W-A”or “W”. These cords are rated for outdoor use and reduce

the risk of electric shock.

4. PERSONAL SAFETY

a. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use tools while tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b. Dress properly. Do not wear loose clothing or jewelry. Contain long

hair. Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewelry or long hair can be caught in moving parts.

c. Avoid accidental starting. Be sure switch is off before plugging in.

Carrying tools with your finger on the switch or plugging in tools that have

the switch on invites accidents.

d. Remove adjusting keys or switches before turning the tool on. A

wrench or a key that is left attached to a rotating part of the tool may result

in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the tools in unexpected

situation.

f. Use safety equipment. Always wear eye protection. Dust mask, non-skid

safety shoes, hard hat or hearing protection must be used for appropriate

conditions.

2

WARNING!

When using electric tools, machines or equipment, basic safety precautions

should always be followed to reduce the risk of fire, electric shock, and

personal Injury.

IMPORTANT SAFETY INSTRUCTIONS

5. TOOL USE AND CARE

a. Use clamps or other practical ways to secure and support the workpiece

to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

b. Do not force tool. Use the correct tools for your application. The correct

tools will do the job better and safer at the rate for which it is designed.

c. Do not use tools if switch does not turn it on or off. Any tool that can not

be controlled with the switch is dangerous and must be repaired.

d. Disconnect the plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive

safety measures reduce the risk of starting the tools accidentally.

e. Store idle tools out of reach of children and other untrained persons.

Tools are dangerous in the hands of untrained users.

f. Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools with sharp cutting edges are less likely to bind and are easier

to control.

g.Check for misalignment or binding of moving parts, breakage of parts

and any other conditions that may affect the tools operation. If damaged,

have the tools serviced before using. Many accidents are caused by poorly

maintained tools.

h. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

6. SERVICE

a. Tool service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a

risk of injury.

b. When servicing a tool, use only identical replacement parts. Follow

instructions in the maintenance section of the manual. Use of unauthorized

parts or failure to follow maintenance instructions may create a risk of electric

shock or injury.

7. Hold tool by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its owncord.

Contact with a “live” wire will make exposed metal parts of the tool “live” and

shock the operator.

8. Ensure the extension cord you use is of sufficient gauge for its length.

AmpsfromToolNameplate

25’ length

RecommendedMinimumWireGaugeforExtension

50’ length 75’ length

Cords

100’ length

150’ length

200’ length

0-5amps

16ga.

16ga.

16ga.

14ga.

12ga.

12ga.

5.1-8amps

16ga.

16ga.

14ga.

12ga.

10ga.

DoNot Use

8.1-12amps

14ga.

14ga.

12ga.

10ga.

DoNot Use

DoNot Use

12.1-15 amps

12ga.

12ga.

10ga.

10ga.

DoNot Use

DoNot Use

15.1-20 amps

10ga.

10ga.

10ga.

DoNotUse

DoNot Use

DoNot Use

9. STAY ALERT.

Watch what you are doing & use common sense. Don’t operate any tool when

tired.

3

IMPORTANT SAFETY INSTRUCTIONS

1. DANGER! Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle or motor housing. If both hands are holding the saw,

they cannot be cut by the blade. Keep your body positioned to either side of the

saw blade, but not in line with the saw blade. Kickback could cause the saw to

jump backwards. (See Safety Instruction # 10. Causes and Operator Prevention of

Kickback:) Do not reach underneath the work. The guard cannot protect you

from the blade below the work.

2. Check lower guard for proper closing before each use. Do not operate saw if

lower guard does not move freely and close instantly. Never clamp or tie the

lower guard into the open position. If saw is accidentally dropped, lower guard

may be bent. With the power to the saw disconnected, raise the lower guard with

the Retracting Handle and make sure it moves freely and does not touch the blade

or any other part, in all angles and depths of cut.

3. Check the operation and condition of the lower guard spring. If the guard and

the spring are not operating properly, they must be serviced before use.

Lower guard may operate sluggishly due to damaged parts, gummy deposits, or a

buildup of debris.

4 L

.ower guard should be retracted manually only for special cuts such as

“Pocket Cuts” and “Compound Cuts.” Raise lower guard by Retracting

Handle. As soon as blade enters the material, lower guard must be released.

For all other sawing, the lower guard should operate automatically.

5. Always observe that the lower guard is covering the blade before placing

saw down on bench or floor. An unprotected, coasting blade will cause the saw

to walk backwards, cutting whatever is in its path. Be aware of the time it takes for

the blade to stop after switch is released.

6. NEVER hold piece being cut in your hands or across your leg. It is important

to support the work properly to minimize body exposure, blade binding, or loss of

control. Use vises, clamps, or other appropriate supports to securely hold the

workpiece.

7. When ripping always use a rip fence or straight edge guide. This improves the

accuracy of cut and reduces the chance for blade binding.

8. Always use blades with correct size and shape (diamond vs. round) arbor

holes. Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

9. Never use damaged or incorrect blade washers or bolts. The blade washers

and bolt were specially designed for your saw, for optimum performance and

safety of operation.

10. Causes and Operator Prevention of Kickback: Kickback is a sudden reaction to

a pinched, bound, or misaligned saw blade, causing an uncontrolled saw to lift up

and out of the workpiece toward the operator. When the blade is pinched or bound

tightly by the kerf closing down, the blade stalls and the motor reaction drives the

unit rapidly back toward the operator. If the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the blade can dig into the top surface of the

wood causing the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below:

Maintain a firm grip on the saw and position your body and arm in a way that

allows you to resist kickback forces. Kickback forces can be controlled by the

operator, if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release the

trigger and hold the saw motionless in the material until the blade comes to a

complete stop. Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may occur. Investigate

and take corrective actions to eliminate the cause of blade binding.

When restarting a saw in the workpiece, center the saw blade in the kerf and

check that teeth are not engaged into the material. If saw blade is binding, it

may walk up or kickback from the workpiece as the saw is restarted.

Support large panels to minimize the risk of blade pinching and kickback.

Large panels tend to sag under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the edge of the panel.

Do not use dull or damaged blade. Unsharpened or improperly set blades

produce narrow kerf causing excessive friction, blade binding, and kickback.

4

SAFETY INSTRUCTIONS FOR CIRCULAR SAWS

Blade depth and bevel adjusting locking levers must be tight and secure

before making cut. If blade adjustment shifts while cutting, it will cause binding

and kickback.

Use extra caution when making a “Pocket Cut” into existing walls or other

blind areas. The protruding blade may cut objects that can cause kickback.

11. Always wear ANSI-approved safety impact eye goggles and heavy work

gloves when using the Circular Saw. Using personal safety devices reduces

the risk of injury.

12. Always connect the Line Cord to a Ground protected electrical outlet.

WARNING! People with pacemakers should consult their physician(s) before

using this product. Electromagnetic fields in close proximity to a heart

pacemaker could cause interference to or failure of the pacemaker. In addition,

people with pacemakers should adhere to the following:

Avoid operating power tools alone.

Don’t use a power tool with the power switch locked on.

Be certain that the tool is properly grounded. A ground fault interrupt (GFCI)

system is also a good precaution. This inexpensive device is a good safety

measure because it prevents a sustained electrical shock.

Properly maintain and inspect all tools before use to avoid electrical shock.

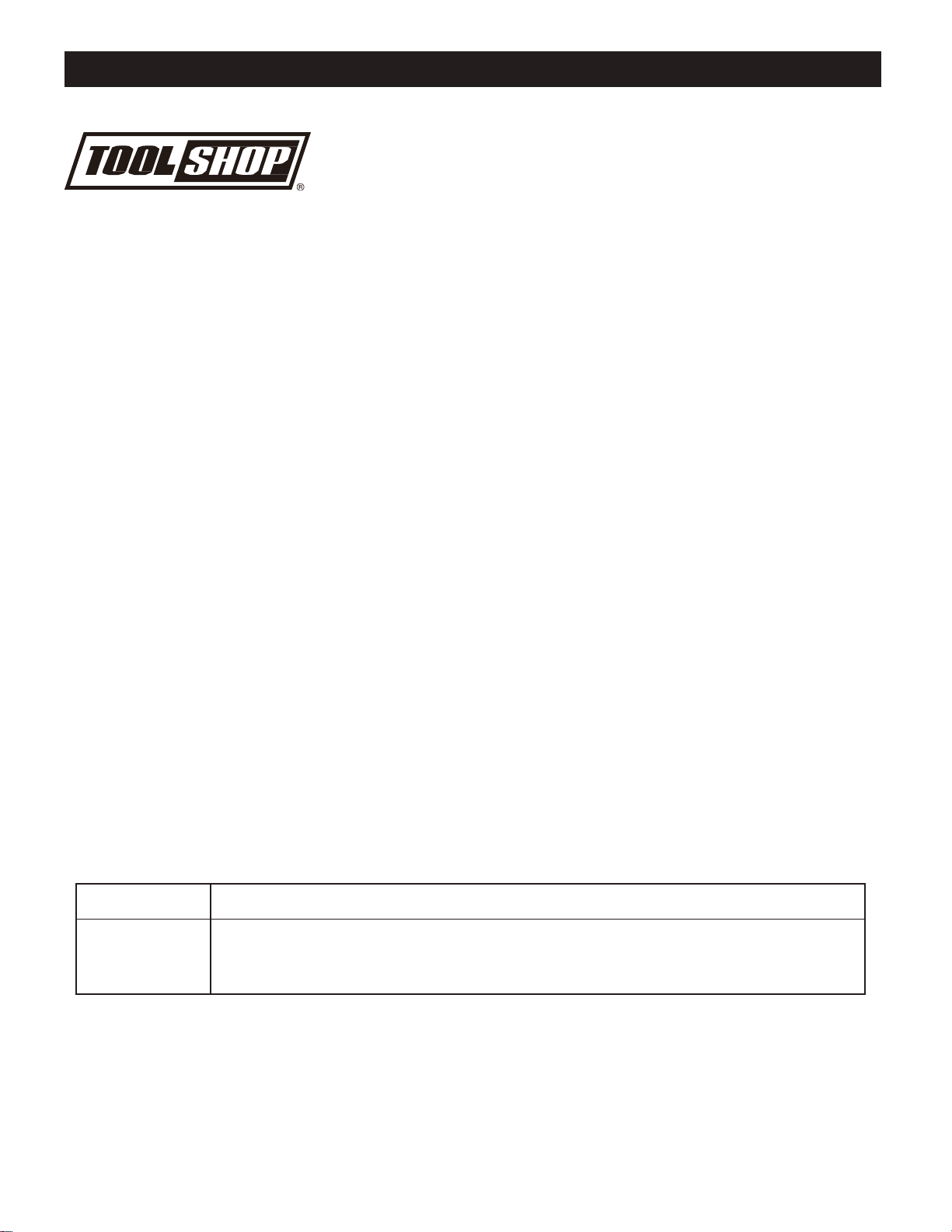

Circular Saw

Rated Input: 10 Amp

No-load Speed: 5800/min

Cutting capacity @ 90°: 2-7/16”

@ 45°1-13/16”

Includes:

1 saw blade

1 wrench

1. Saw Blade

2. Blade Cover

3. Base Plate

4. LowerGuard Lever

5. Dust Extraction Chute

6. BladeGuard

7. RearHandle

8. Front Handle

9. Brush Cap

10. BevelScale Bracket

11. Angle Adjust Wing Nut

12. Hex Screw

13. Lock-Off Button

14. TriggerSwitch

15. DepthGuideBracket

16. DepthLever

17. Spindle Lock

5

KNOWING YOUR CIRCULAR SAW

SPECIFICATIONS

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool or

product. Never remove the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAFETY INSTRUCTIONS FOR CIRCULAR SAWS

17

13

7

6

14

8

5

9

15

16

4

10

11

12

2

1

3

Installing a Saw Blade

1. Use only a 7-1/4 in. (185mm) Saw Blade. The saw blade speed rating must be at

least 5800 RPM. Refer to the following table for saw blade applications and

types.

APPLICATION

BLADE

DESCRIPTION

NO. OF TEETH TYPE OF CUT

Fine Trim Molding

Precision Trim

Carbide

60~100

Very smooth,

splinter free

Trim, Framing,

Pressure Treated

Decking

Combination,

multi-purpose

24~60

Smooth, fast cut

Aluminum

Non-ferrous metal

cutting

60~80 ….

2. Unplug the circular saw from the electrical outlet.

3. Raise the Blade Guard as far as possible. See photo on the right.

4. Hold the Blade Guard up and press the Spindle Lock Button with one hand.

Rotate the Saw Blade until the Spindle Lock catches and the blade stops.

Blade pressure plate spindle lock

Blade cover

5. Using the supplied Saw Blade Hex Key in the other hand, loosen (counterclockwise)

the left-hand threaded Hex Screw. Remove the Saw Blade Hex Screw, Blade

Pressure Plate, then the Saw Blade.

6. Clean out Blade Cover of any debris.

7. Place the new Saw Blade over the Spindle hole. The Saw Blade teeth at the

bottom of the saw blade should be pointing toward the back of the Circular Saw.

8. Place the Blade Pressure Plate over the Spindle hole, then insert the Hex

Screw.

9. Press the Spindle Lock Button with one hand and tighten the Blade Screw

(clockwise) using the Hex Key with the other hand.

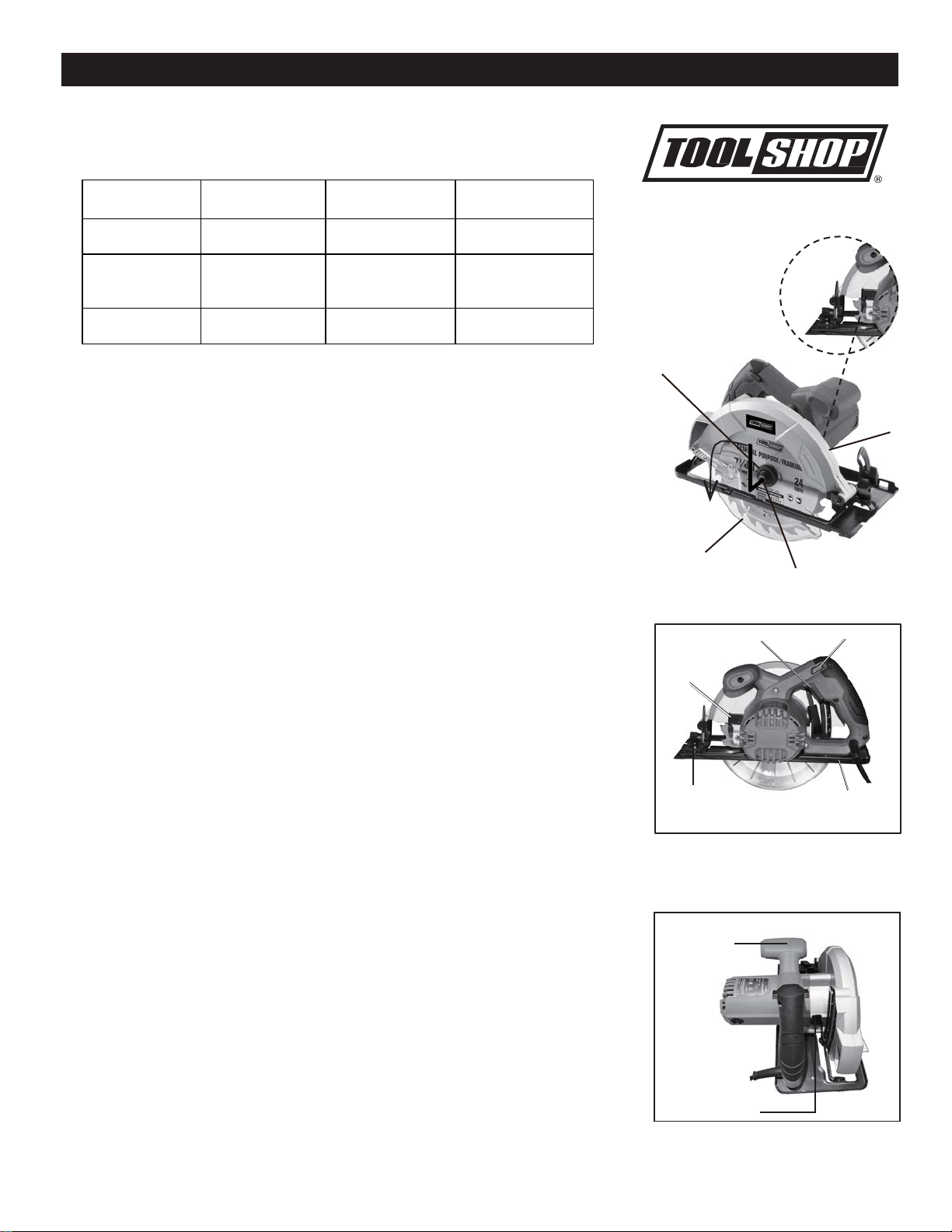

Adjusting the Saw Prior to Cutting

CAUTION: Always make sure the Power Cord is unplugged from its electrical

outlet prior to making any adjustments to the tool.

1. To adjust the angle of blade from 0 to 45 degrees, loosen wing nut and move

base plate down, observing the degrees indicated on the Angle Bracket.

counter-

clockwise

Blade guard

Hex screw

Tighten wing nut. (Fig. A)

2. To adjust the depth of the cut, lift depth lever and move base plate down

(or up) while observing the amount of saw blade exposed under base plate. Push

Down on the depth lever to lock in new depth setting. (Fig. B)

Prepare Material Before Cutting (Fig. C)

1. Support large panels to minimize risk of blade pinching and saw kickback.

2. Use the supplied guide fence when ripping material by sliding it into the base

plate, and tightening screw.

3. Securely clamp material to be cut to work bench.

4. Ensure the circular saw does not cut into supports or workbench.

5. Use the appropriate type of blade for the material you are cutting.

General Cutting

Caution: Verify that Saw Blade is securely tightened and both angle and

height adjusting nuts and levers are tight. Read and understand all safety

precautions listed in this instruction manual.

1. Hold the circular saw by both handles. Always keep hands and fingers away from

the saw blade.

2. Push in and hold the lock-off button, then squeeze the trigger switch with

the index finger. Do this before the saw blade touches the material.

3. With the saw at full speed, move the saw slowly forward to complete the cut.

4. When the cut is complete, release the trigger switch. Do not set the saw down until

the blade stops turning.

Fig. A

Fig. B

6

ASSEMBLY AND OPERATION

Handle Grip

Depth Lever

Triggerswitch

Lock-offButton

spindlelock

AngleAdjust

WingNut

BasePlate

Fig. C

Pocket Cuts

1. Tilt the saw forward with the cutting guide notch of the base plate on the line drawn

for the cut.

2. Raise the blade guard with the blade guard lever.

3. With the saw blade just above the material to be cut, start the saw and allow the

saw blade to come to full speed.

4. Gradually lower the saw blade onto the stock using the front end of the base plate

as a pivot point.

5. When the cutting begins, release the blade guard.

6. When the base plate is resting flat on the stock being cut, proceed cutting in a

forward direction to the end of the cut.

7. When the cut is complete, release the trigger switch and wait for the saw blade to

come to a stop before lifting the saw out of the cut.

8. If necessary, complete the cut from the opposite direction in the same manner

described above.

Caution: Never pull the saw backwards since the saw blade will climb out of the

cut and kickback will occur.

Before each use, inspect the general condition of the circular saw. Check for

loose screws, misalignment or binding of moving parts, cracked or broken parts,

damaged electrical wiring, and any other condition that may affect its safe

operation. If abnormal noise or vibration occurs, have the problem corrected before

further use.

Before remounting the saw blade, remove all sawdust that has accumulated

around the safety guard.

Regularly inspect and tighten all mounting screws and knobs.

Keep saw blade clean and sharp. Sharp blades minimize stalling and kickback.

Keep guards in good working order.

Keep motor air vent clean of dust and debris. Vacuum periodically.

If the tool is not operating normally, making unusual noises, or appears defective,

stop using it immediately and get it repaired.

Clean tool with a damp cloth and light detergent. Do not use solvents as they can

damage and crack the plastic parts.

7

WARNING!

Make sure the Power Switch of the Circular Saw is in its “OFF” position, and that

the tool is unplugged from its electrical outlet, before performing any inspection,

maintenance, or cleaning procedures.

MAINTENANCE

ASSEMBLY AND OPERATION

Blade guard

lever

Blade guard

8

TROUBLESHOOTING

Symptom

Possible

Remedy

Saw does not start when trigger is

pulled.

1.No power to line cord.

1.Check electrical outlet for power.

2.Switch lock button not pushed in

while pulling trigger.

2.Press in button while pulling trigger.

3.Defectiveswitch.

3.Replaceswitch.

4.Carbon brushes dirty or worn down.

4.Clean or replace carbon brushes.

While cutting, saw slows down.

Carbon brushes dirty or worndown.

Clean or replace carbon brushes.

Saw blade slips while cutting.

Hexscrew loose.

Securely tighten hex screw

Blade guard sticks or does not open

easily.

Debris buildup in the blade cover

Remove saw blade and clean out

blade cover.

Wood burns or smokes while being

Saw blade dull.

Sharpen or replace saw blade.

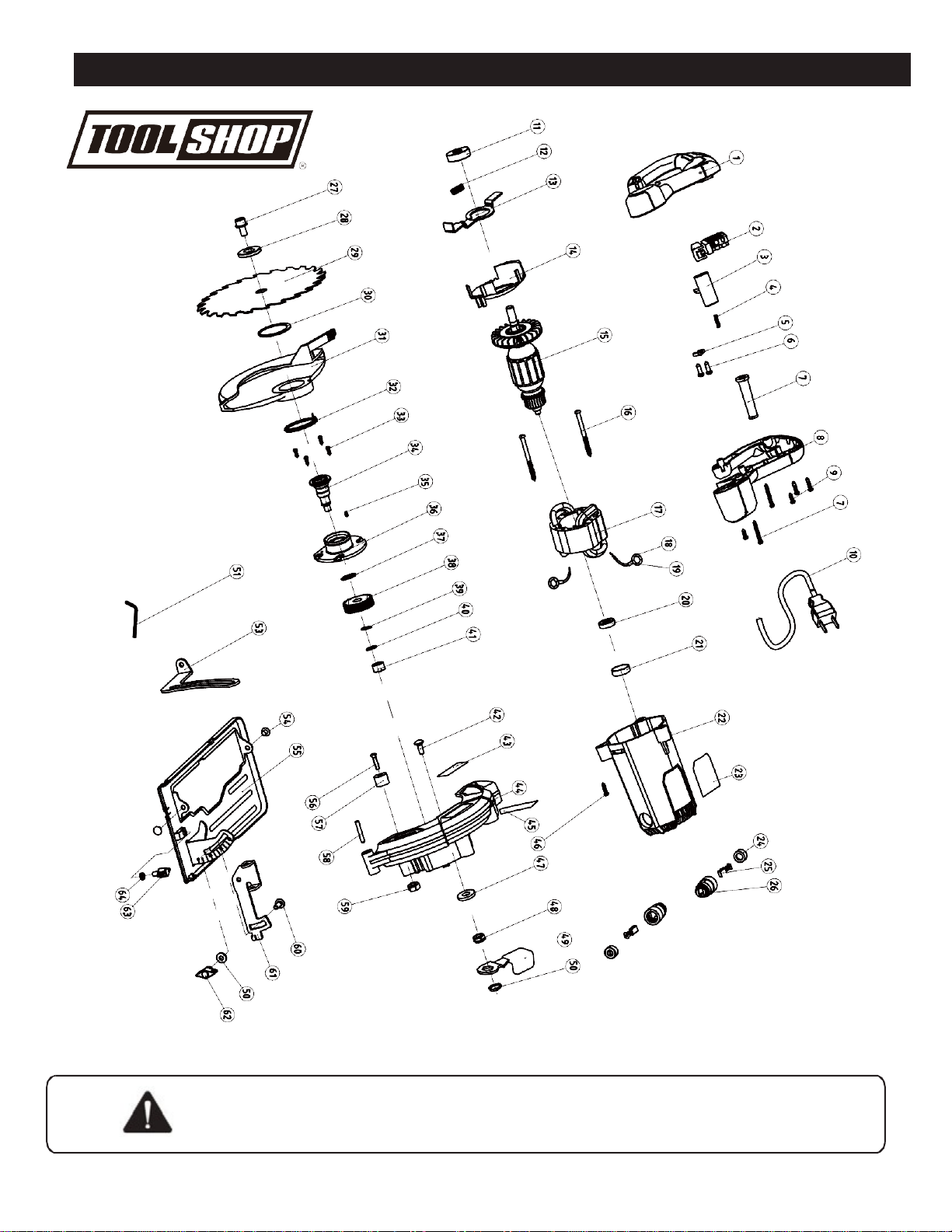

Part No.

Description

Qty

Part No.

Description

Qty

1

Right handle

1

33

Self-tapping screw ST4.2×14

4

2

Switch 120V

1

34

Spindle

1

3

Lock off lever

1

35

Woodruff key 3X10X3.7

1

4

Spring for lock off lever

1

36

Front cover

1

5

Power cord clamp

1

37

Circlip for shaft 17

1

6

Self-tapping screw ST4.2×14

6

38

Gear

1

7

Power cord sleeve

1

39

Washer 12

1

8

Left handle

1

40

Circlip for shaft 12

1

9

Self-tapping screw ST4.8×55

2

41

Oil bearing

1

10

Power cord

1

42

Square neck bolt M6×16

1

11

Bearing 6000-2Z

1

43

Brand label

1

12

Spring for spindle lock

1

44

Upper guard

1

13

Spindle lock plate

1

45

Depth scale label

1

14

Fan guide

1

46

Self-tapping screw ST4.8×30

1

15

Rotor 120V

1

47

Washerφ6Xφ14X1.5

1

16

Self-tapping screw ST4.2×50

2

48

Nut M6

1

17

Stator 120V

1

49

Depth locking lever

1

18

Tension spring for carbon brush hold

2

50

Circlip for shaft 10

1

19

H buckle

2

51

Allen key

1

20

Bearing 607-2Z

1

53

Depth scale bracket

1

21

Sleeve for bearing

1

54

Thin flat head socket shank rivet 6×7

2

22

Motor housing

1

55

Baseplate

1

23

Nameplate

1

56

Countersink philips screw M6×25

1

24

Carbon brush cover

2

57

Rubber block for lower guard

1

25

Carbon brush

(

120V)

2

58

Cylindrical spring pin 6X40

1

26

Carbon brush holder

(

120V)

2

59

Hexagon nut M6

1

27

Hexagonal screws M8X16

1

60

Square neck bolt M6×12

1

28

Outer flange

1

61

Bevel scale bracket

1

29

Blade

1

62

Bevel locking knob

1

30

Baffle

1

63

Parallel guide locking knob

1

31

Lower guard

1

64

Spring for parallel guide locking knob

1

32

Spring for lower guard

1

PARTS LIST

MAINTENANCE

9

WARNING!

Repairs should be made by an authorized repair center. Do not open or

disassemble this power tool.

EXPLODED VIEW

TOOL SHOP

®

10A 7-1/4" CIRCULAR SAW WARRANTY

1-YEAR LIMITED WARRANTY:

This TOOL SHOP®brand power tool carries a 1-Year Limited Warranty to the original

purchaser. If the tool fails within one (1) year from the date of purchase, simply bring this tool

with your original sales receipt back to your nearest MENARDS® retail store. At its discretion,

TOOL SHOP® agrees to have the tool replaced with the same or similar TOOL SHOP®

product free of charge, within the stated warranty period, when returned by the original

purchaser with original sales receipt. Notwithstanding the foregoing, this limited warranty does

not cover any damage that has resulted from abuse or misuse of the Merchandise. This

warranty: (1) excludes expendable parts including but not limited to blades, belts, bits, light

bulbs, and/ or batteries; (2) shall be void if this tool is used for commercial and/or rental

purposes; and (3) does not cover any losses, injuries to persons/property or costs. This

warranty does give you specific legal rights and you may have other rights, which vary from

state to state. Be careful, tools are dangerous if improperly used or maintained. Seller’s

employees are not qualified to advise you on the use of this Merchandise. Any oral

representation(s) made will not be binding on seller or its employees. The rights under this

limited warranty are to the original purchaser of the Merchandise and may not be transferred

to any subsequent owner. This limited warranty is in lieu of all warranties, expressed or

implied including warranties or merchantability and fitness for a particular purpose. Seller shall

not be liable for any special, incidental, or consequential damages. The sole exclusive remedy

against the seller will be for the replacement of any defects as provided herein, as long as the

seller is willing or able to replace this product or is willing to refund the purchase price as

provided above. For insurance purposes, seller is not allowed to demonstrate any of these

power tools for you.

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-800-868-7421 (M-F 8am – 5pm EST)

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.

Distributed by: Menard, Inc., Eau Claire, WI 54703 Rev. 1.1 2018/05/02

This manual suits for next models

1

Table of contents

Other Toolshop Saw manuals