Top Auto BRK600 User manual

USERMANUAL

MAINTENANCEANDSPAREPARTS

BRAKEBLEEDER

BRK600

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 2

BRK600

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 3

BRK600

1 INTRODUCTION ............................................................................................................................... 5

1.1 PURPOSE OF THE INSTRUCTION MANUAL................................................................................................5

1.2 HOW TO READ AND USE THE INSTRUCTION MANUAL ..............................................................................5

1.3 PRESERVATION OF THE MANUAL.............................................................................................................5

1.4 MANUAL INSTRUCTION UPDATE..............................................................................................................5

1.5 RECIPIENTS .............................................................................................................................................5

1.6 SYMBOLOGY ......................................................................................................................................6

2 GENERAL INFORMATION.......................................................................................................... 6

2.1 MANUFACTURER IDENTIFICATION DATA..................................................................................................6

2.2 MACHINE IDENTIFICATION DATA.............................................................................................................6

2.3 CE MARKING...........................................................................................................................................6

2.4 GENERAL SAFETY RULES ..........................................................................................................................7

2.5 BRAKE FLUIDS - PERSONAL PROTECTIVE EQUIPMENT AND PRECAUTIONS.................................................8

2.5.1 FIRST AID MEASURES .....................................................................................................................................................8

2.5.2 FIRE-FIGHTING MEASURES.............................................................................................................................................8

2.5.3 MEASURES IN THE EVENT OF AN ACCIDENTAL LEAK .....................................................................................................8

2.6 WARRANTY.............................................................................................................................................9

2.7 DURATION OF WARRANTY ......................................................................................................................9

3 MACHINE DESCRIPTION ................................................................................................................. 10

3.1 OPERATING PRINCIPLES.........................................................................................................................10

3.2 MACHINE COMPONENTS.......................................................................................................................10

3.3 TECHNICAL SPECIFICATIONS ..................................................................................................................11

4 OPERATION AND USE..................................................................................................................... 12

4.1 DESCRIPTION OF THE MACHINE OPERATION..........................................................................................12

4.2 MACHINE CYCLES ..................................................................................................................................12

4.3 INTENDED AND UNINTENDED USE.........................................................................................................12

4.4 WORKSTATIONS FOR OPERATORS .........................................................................................................12

5 INSTALLATION ............................................................................................................................... 13

5.1 DELIVERY AND CONTROL.......................................................................................................................13

5.2 MACHINE SETUP ...................................................................................................................................13

6 MACHINE USE................................................................................................................................ 14

6.1 PROBLEMS AND REMEDIES....................................................................................................................17

7 MAINTENANCE .............................................................................................................................. 18

7.1 NATURE AND FREQUENCY OF CHECKS AND MAINTENANCE....................................................................18

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 4

BRK600

7.2 EXHAUSTED OIL TANK EMPTYING ..........................................................................................................18

8 ADDITIONAL INSTRUCTIONS........................................................................................................... 18

8.1 DEACTIVATION AND DISASSEMBLY........................................................................................................18

9 SPARE PARTS ................................................................................................................................. 19

9.1 GENERAL INSTRUCTIONS .......................................................................................................................19

9.2 SPARE PARTS REQUEST FORM ...............................................................................................................19

9.3 SPARE PARTS LIST..................................................................................................................................20

10 ELECTRICAL DIAGRAM.................................................................................................................. 23

11 HYDRAULIC DIAGRAM.................................................................................................................. 24

12 SERVICE-PROGRAM...................................................................................................................... 25

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 5

BRK600

1 INTRODUCTION

1.1 PURPOSE OF THE INSTRUCTION MANUAL

This user and maintenance manual contains data concerning the performance, technical characteristics, use and maintenance

methods for the standard and correct operation of the machine.

The user is recommended to read it carefully and to comply with the rules and procedures contained in it, as they provide important

indications regarding the safety of use.

This will allow to optimize the operation, increase the duration of the machine, and operate safely.

Failure to comply with the suggested rules can cause malfunctions, anomalies, or damages; the machine must therefore be

intended only for the use for which it was expressly designed.

The manufacturing company will not be held responsible for breakages, accidents, or various inconveniences due to the non-

compliance (or in any case non-application) of the requirements contained in this manual. The same applies to the execution of

modifications, variations, and/or the installation of accessories, that were not authorized in advance.

1.2 HOW TO READ AND USE THE INSTRUCTION MANUAL

The machine was manufactured in accordance with all Community rules concerning the free movement of industrial products in

the countries of the European Community (check the Machinery Directive 2006/42/EC).

The machine is then provided complete with all the documentation required by these regulations.

The user manual, maintenance and spare parts is an integral part of it and contains all the information necessary for a good

operation of the machine with particular attention to the safety of the involved personnel.

1.3 PRESERVATION OF THE MANUAL

This instruction manual is an integral part of the machine and must therefore be carefully preserved for any further consultation.

1) It is recommended to use the manual carefully so as not to damage the content and not compromise its functionality.

2) Do not remove, tear or rewrite parts of the manual for any reason.

3) Store the manual in places protected from moisture and heat.

4) The user manual must be stored near the machine so that consultation is facilitated.

5) The place of preservation of the manual must be clearly identifiable and known to all operators authorized to use the machine.

6) Once the consultation has been completed, the manual must be stored in the appropriate place of storage.

7) The manual must be kept for the duration of use of the machine and transmitted to any other user or subsequent owner.

1.4 MANUAL INSTRUCTION UPDATE

The manufacturing company reserves the right to make changes, additions or improvements to the manual itself, without this

being a reason to consider this publication inadequate.

1.5 RECIPIENTS

This documentation is addressed to qualified and appropriately trained technical staff.

Only qualified personnel have the necessary technical knowledge to correctly interpret and apply concretely the safety regulations

and warnings contained in the specific documents.

Knowledge and correct application of safety regulations and warnings are prerequisites for the installation and setup free of

hazards as well as for safety during operation and maintenance of the described product.

"Qualified personnel" means those persons who, by reason of their training, experience, education, knowledge of the relevant

standards, requirements, measures for the prevention of accidents and conditions of service, have been authorized by the person

in charge for the safety concerning machineries to carry out any necessary activities and to be able to recognize and avoid any

possible danger.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 6

BRK600

1.6 SYMBOLOGY

The bold texts, preceded by this symbol, contain very important information/regulation regarding the good operation of the

machine. Failure to comply may result in:

- loss of the contractual warranty

- declination of responsibility by the manufacturing company.

The bold texts preceded by this symbol contain signsof possible dangers and important requirements to safeguard the safety

of the operator. Failure to comply may result in:

- risks to operator’s safety

- declination of responsibility by the manufacturing company.

2 GENERAL INFORMATION

2.1 MANUFACTURER IDENTIFICATION DATA

2.2 MACHINE IDENTIFICATION DATA

The machine is built in accordance with the Machinery Directive 2006/42/ currently in force for use within the European Community

in the safety field. The CE marking tags and related product identification data are affixed to the machine. The serial number must

also be used for the request of intervention or for spare parts.

The identification plate must always be kept legible with regard to all the data contained in it and must be periodically cleaned.

If the license plate deteriorates and/or is no longer legible, even in only one of the information elements reported, it is recom-

mended to request another one from the manufacturer, citing the data contained in this manual, and provide for its replacement.

2.3 CE MARKING

MODEL: Machine Model

SERIAL NUMBER: Machine Serial Number

Top Auto S.r.l.

Viale del Lavoro 40, 37030 Colognola ai colli –Italy

tel. +39 0456170025 - fax. +39 6152493

info@topauto-equipment.com www.topauto-equipment.com

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 7

BRK600

2.4 GENERAL SAFETY RULES

In addition to the rules listed below, the machinery supervisor must comply with the regulation of current legislation on the

safety and health of personnel at workplaces (Directive 2006/42/EC).

Always follow the safety regulations and instructions in this manual.

The manufacturing company disclaims all responsibility resulting from an incorrect use of the machine and the supplied

equipment.

The unit must not operate with liquids other than those for which the machine was built.

The machine must be used by qualified personnel and can be used correctly only after reading this manual containing also

the basic safety rules set out below:

Wear gloves and goggles.

Do not expose the machine to direct sunlight and rain.

Before any operation check on the vehicle use and maintenance manual the type of fluid used by the braking system.

Do not smoke near the machine and during operations.

Do not use the machine in environments without lightning protection.

The equipment is classified in: Group II category 3G II B T3 and must be used in places with classification 2. The environmental

conditions of use of the equipment are as follows:

pressure from 80 kPa (0.8 bar) to 110 kPa (1.1 bar);

temperature from –20°C to + 60°C;

air with normal oxygen content, usually 21 % v/v.

The machine shall not be used in places at risk of explosion and/or fire classified in the following areas:

1. zone 0 –20 / 1 –21;

2. maximum operating temperatures T4, T5 and T6.

Machine storage: the machine, when not used, must be stored in a dedicated place having the following characteristics:

1. There must be no trigger sources, such as heat sources, open flames, sparks of mechanical origin, electrical equipment,

stray electric currents and cathodic corrosion (verify that the electrical distribution system complies with the laws in force); (check

the grounding of the plant's electrical distribution system).

Use the machine away from heat sources, open flames and/or sparks.

Always make sure that when you turn off the engine the vehicle ignition key is brought to the “All Off (OFF)”position.

Keep connection pipes away from moving or rotating objects/elements.

Keep connection pipes away from hot objects/elements.

Always make sure that the liquid tank is at the correct level.

Before connecting the machinewith the power grid, check that the voltage and the frequency of the power supply corresponds

to the values indicated in the CE marking.

Always check that the exhausted fluid tank is not full before starting each operation

Throw the extracted liquid in the appropriate containers for exhausted oils.

Check frequently that the two filters on the device are not obstructed.

Use only the liquids recommended by the manufacturer.

Failure to comply with each of the above safety rules results in the decay of any form of warranty on the machine.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 8

BRK600

2.5 BRAKE FLUIDS - PERSONAL PROTECTIVE EQUIPMENT AND PRECAUTIONS

The operator must wear appropriate protections such as goggles, gloves, and clothing suitable for work.

2.5.1 FIRST AID MEASURES

Inhalation

If inhaled, go quickly to the open air. If symptoms appear ask for medical assistance. In case of

inhalation of decomposed products in a fire, symptoms may be delayed. It is possible that the ex-

posed person shall be kept under medical supervision for 48 hours.

Contact with the

skin

Skin degreasing. It can cause dryness and skin irritation.

Eye contact

Not classified as eye irritant. Based on the documentation available for this or other similar materials.

Ingestion

Diethylene glycol: ingestion of diethylene glycol can cause metabolic acidosis, kidney damage, cen-

tral nervous system depression and convulsions. The estimated lethal dose for an adult is circa 100

ml.

Main symptoms and

effects, both acute

and delayed

Overexposure to inhalation of drops in the air or aerosols can cause irritation of the respiratory tract.

Ingestion of large amounts can cause nausea and diarrhea.

Prolonged or repeated contact with the skin may over-degrease the skin and cause irritation and/or

dermatitis.

Potential risk of burning or temporary redness in case of accidental eye contact.

2.5.2 FIRE-FIGHTING MEASURES

Usable means for

extinguishing a fire

In case of fire, use sprays or fire extinguishers based on foam, anhydrous chemicals, or carbon

dioxide.

Special hazards

arising from the

substance or the

mixture

Exposure to flames can cause the container to break or explode.

Dangerous combustion products: in the event of fire, the following products may result by thermal

decomposition:

Carbon monoxide, carbon dioxide, nitrogen monoxide, nitrogen dioxide

Recommendations

for people in charge

of fire extinguishing

No action should be taken involving any personal risk or without appropriate training. Promptly isolate

the area by moving all people away from the accident area in the event of a fire.

Special protective

equipment for fire-

fighters

Firefighters must wear protective equipment and a self-contained breathing apparatus (SCBA) with

full face mask on the face operating at positive pressure. Clothing for firefighters (including helmets,

protective boots, and gloves) that comply with the EN 469 European standard will ensure basic level

protection for chemical accidents.

2.5.3 MEASURES IN THE EVENT OF AN ACCIDENTAL LEAK

Small leak

Stop the leakage if there is no risk. Move containers away from the leakage area. Absorb with an

inert material and put the spilled product in a special recovery container. Dispose of waste through

an authorized company for waste disposal.

Big leak

Stop the leakage if there is no risk. Move containers away from the leakage area. Prevent the leak-

age in sewer systems, waterways, bases, or limited areas. Circumscribe and collect any leak with

non-combustible absorbent material, such as sand, soil, vermiculite, diatomite and dispose of the

product in a container in accordance with the current legislation. Dispose of waste through an au-

thorized company for waste disposal.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 9

BRK600

Environmental pre-

cautions

Avoid dispersion and outflow of any spilled material and contact with waterways, drains and sew-

ers. Inform the relevant authorities if the product has caused environmental pollution (sewers, wa-

terways, land or air).

2.6 WARRANTY

The terms and conditions of the warranty are established as follows unless otherwise specified in the Order Confirmation:

Subject of the Warranty

The manufacturing company guarantees the good quality and good construction of the machine it builds, forcing itself, during

the specified warranty period, to repair or replace free of charge the parts whose premature breakage or wear are due to poor

quality of the materials used, defect in processing or imperfect assembly.

The warranty of those parts whose breakage or wear are due to:

Failure to comply with the instructions contained in the User and Maintenance Manual.

Lacking or incorrect maintenance.

Lacking or incorrect cleaning of all the components of the machine that need to be cleaned regularly.

User’s negligence related to level control, filters cleaning, auxiliary services, power supply.

Use of tools not suitable to perform ordinary and extraordinary maintenance.

Modifications or tampering carried out by the user or carried out by third parties, without specific approval by the manufac-

turing company.

Use of non-original spare parts.

2.7 DURATION OF WARRANTY

For warranty terms, reference is made to what is contractually agreed.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 10

BRK600

3 MACHINE DESCRIPTION

3.1 OPERATING PRINCIPLES

The machine referred to in this manual was designed and built to bleed the braking system in a single series of operations, with-

out any dispersion into the environment of brake fluids present in the vehicle braking system.

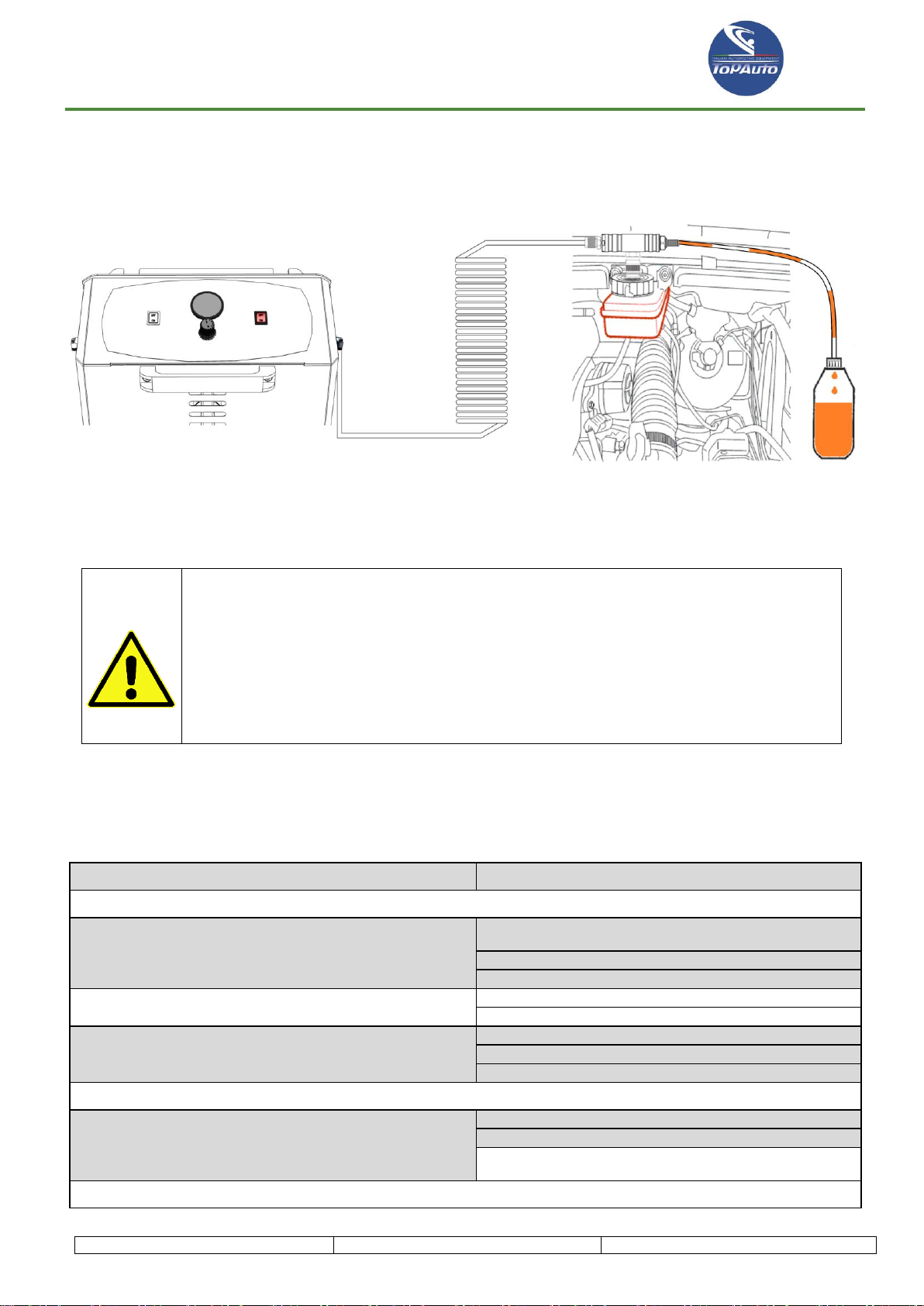

3.2 MACHINE COMPONENTS

1 –Carrying handle 8 –Polysnap module

2 –EXTRACTION PUMP ON / OFF button 9 –Connection for the extraction pipe

3 –Pressure regulator 10 –Clamp for charging pipe at rest

4 –Pressure gauge 11 –Clamp for extraction pipe at rest

5 –CHARGING PUMP ON / OFF button 12 –Extracted exhausted fluid tank

6 –Connection for the charging pipe 13 –Tank

7 –Handling wheels 14 –Space for accessories briefcase

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 11

BRK600

3.3 TECHNICAL SPECIFICATIONS

Compatible fluid types

Pre-DOT –DOT2 –DOT3 –DOT4 –DOT5 –

DOT5.1 –DOT6 –DOT6.1 - LHM

Exhausted fluid tank capacity

5 l

New fluid tank capacity

5 l standard (predisposition for tanks up to 25 lt)

Operating pressure

0 –4 bar

Extraction pump power

30 W (1 l/min)

Charging pump power

30 W (1 l/min)

Charging/extraction pipe length

7,5 m

Power supply

230/50-60 Volt/Hz

Machine size

67x54x90H cm

Pack size

Unladen weight

Noise

< 70 dB (A)

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 12

BRK600

4 OPERATION AND USE

4.1 DESCRIPTION OF THE MACHINE OPERATION

The machine referred to in this manual has been designed and built for the replacement and discharge of brake fluid from brake

and car clutch systems. The liquid is constantly pumped into the brake liquid tank with a pressure of 0 to 4 bar. The liquid to be

replaced can therefore be discharged through the individual bleeding valves of brake calipers until the new liquid comes out. This

technique avoids the formation of air bubbles in the system and avoids the typical annoying pouring operations.

4.2 MACHINE CYCLES

1) Extraction

The pump extracts the exhausted brake fluid from the specific pan in the engine compartment until completely emptied.

2) Connection

The adapter ca be found in the specific kit and connects to the pan instead of the original cap.

3) Charging new liquid

The pan is filled up to the expected level.

4) Bleeding old liquid

The exhausted liquid is extracted from the system through the bleeding valves.

5) Disconnection

The pressure is bled by the specific valve and the adapter is disconnected by putting the original cap back on the pan.

4.3 INTENDED AND UNINTENDED USE

The machine in question has been designed and built for the above use. The machine must not be used for uses other than those

specified here.

It is forbidden to:

Use the machine with a different liquid than the indicated one in this manual.

Modify the operation principle of the machine in any way by adding or removing components to it.

Use the machine in explosive and/or fire-risk environments.

Plug in the machine to energy sources other than those envisaged by the manufacturer

Use commercial devices for a purpose other than the manufacturer intended.

ATTENTION It is the obligation of the employer (or safety officer) to ensure that the machine is not used improperly,

endangering the health of the operator and exposed persons. It is the worker's obligation to inform the employer (or the

safety officer) if there is a danger of improper use of the machine because, as an educated person, the worker is respon-

sible for the machinery use he is going to carry on.

4.4 WORKSTATIONS FOR OPERATORS

The machine is designed to work in the presence of an operator. The presence of an operator is provided for the connection

and disconnection of the machine to the vehicle as well as to setup and switch off the cycle.

The dismantling of the protective casings and the consequent access inside the machine is provided only for maintenance and

cleaning operations.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 13

BRK600

5 INSTALLATION

5.1 DELIVERY AND CONTROL

Once the machine leaves the production plant of the Manufacturing company, any damage to it is attributable to the carrier, be

it a courier or a means of the buyer, unless otherwise specified in the Order Confirmation.

In case of damage to the machine, please inform the Manufacturing company as soon as possible.

At the time of delivery it is therefore necessary to check:

The match between packing list and the actual contents of the packaging.

The integrity of the packaging in all its parts, in order to identify any obvious damage attributable to the carrier.

Any damage reported by the machine as a result of incorrect execution of the carrier.

Contents of the packaging:

1 unit for the replacement of brake fluids

1 spiral charging pipe L= 7.5 m

1 spiral extraction pipe with filter L= 7.5 m

1 T-coupling to connect to adapters.

1 transparent pipe with rubber seal for bleeding valves connection L= 1 m

2 tanks (2 lt) for exhausted liquid bleeding

1 tank (10 lt) for extracted exhausted liquid.

1 tank (10 lt) for new liquid

5 adapters of various sizes

1 universal adapter

1 power cord

5.2 MACHINE SETUP

The machine is supplied fully assembled and tested. Before use, it is necessary to proceed with the preparation of the machine:

1) Connection of the charging pipe

Connect the spiral charging pipe with the

T-coupling to the right connector of the machine

2) Connection of the extraction pipe

Connect the spiral extraction pipe with the filter

to the left connector of the machine

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 14

BRK600

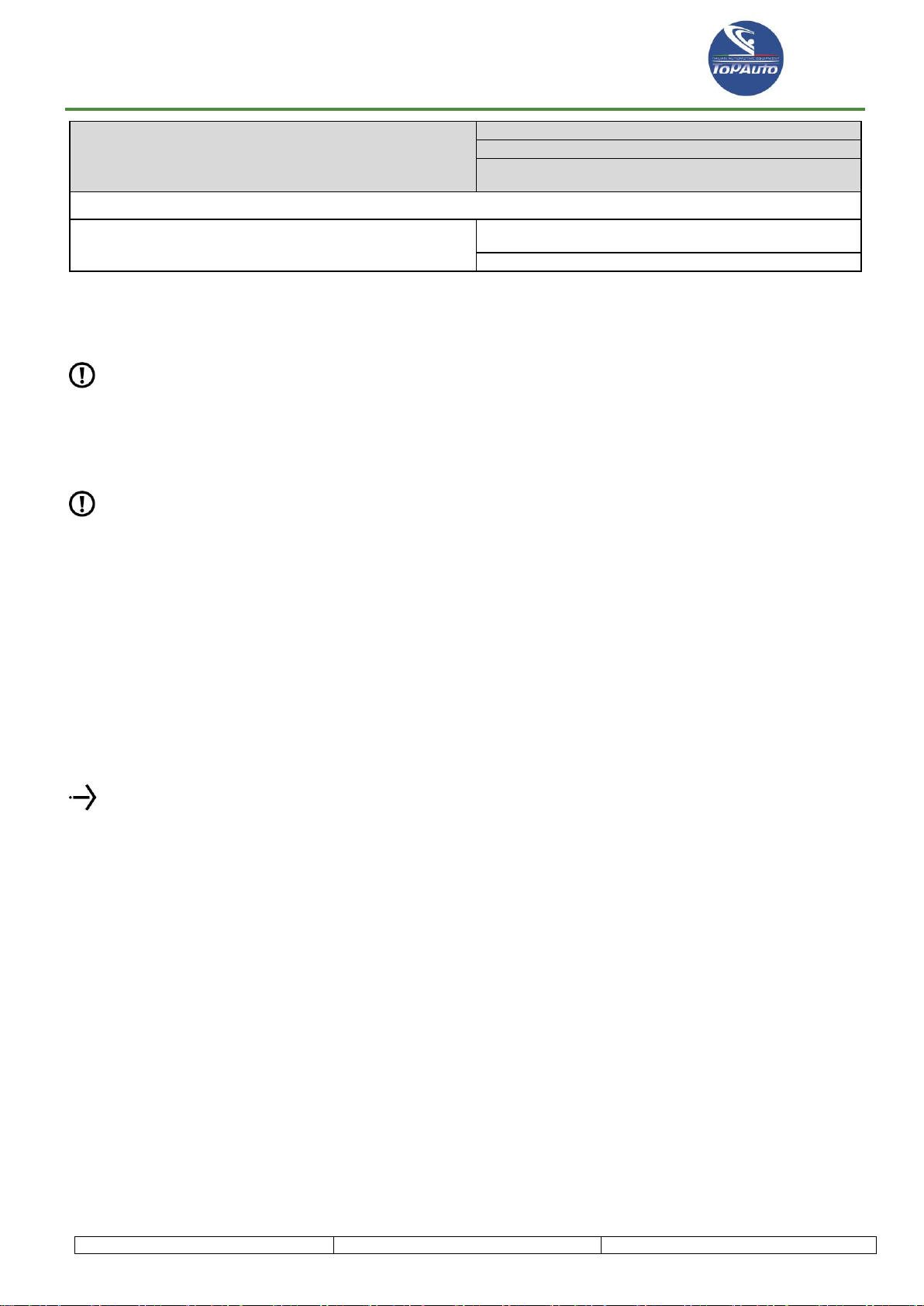

6 MACHINE USE

1. Identify the brake liquid pan 2. Remove the pan cap.

located in the motor engine.

3. Insert the extraction pipe into the pan and press the ON button to start the pump and extract all the exhausted liquid.

Stop the pump by pressing the OFF button when you start extracting air.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 15

BRK600

4. Identify the specific adapter and connect it to the pan making sure it is fixed correctly to avoid leakage during subse-

quent operations.

5. Connect the charging pipe to the adapter and press the ON button to start charging the new liquid.

Through the pressure regulator set the working pressure (usually 1.5 –2 bar)

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 16

BRK600

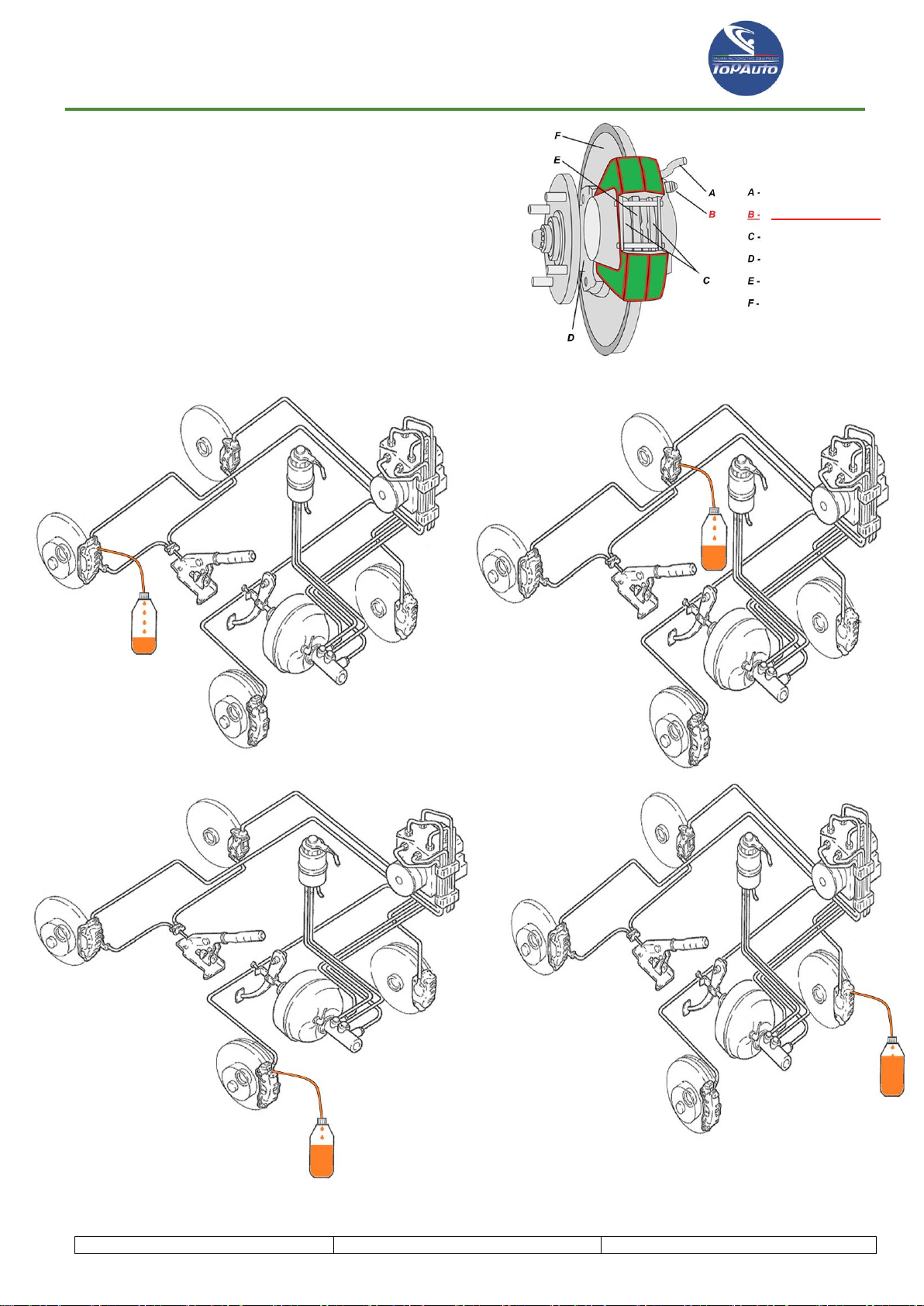

6. Use the pipette with the transparent tube and the 5l tank

supplied to connect to the valve.

Use a wrench to open the bleeding valve until you

see that the exhausted liquid comes out.

Bleeding is considered finished when new liquid comes out

from the transparent pipe. Then close the bleeding valve and

switch to the next brake caliper.

Carry out the bleeding operation on all 4 brake calipers.

Brake fluid pipe

BLEEDING VALVE

Piston

Hub

Brake pad

Disk

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 17

BRK600

7. Once the bleeding operation is finished, turn off the machine via the OFF button.

8. Connect the pipette with the transparent pipe and the 5l tank to the T-coupling bleeding valve to bleed the pressure in

the charging pipe before disconnecting it.

9. Make sure the liquid inside the pan is at the correct level.

10. Disconnect the adapter and screw the original pan cap again.

ATTENTION!!!

When performing the brake bleeding operation on cars that are over 5 years old or that

still show signs of wear, it is absolutely advisable to replace the hoses that take the oil

to the brake calipers. In fact, maintenance on the braking system involves a restoration

of the original pressure. This pressure may be excessive for the old hoses, which may

break causing the liquid to spill and consequent malfunction of the braking system

with serious danger while driving.

6.1 PROBLEMS AND REMEDIES

The search for faults and the eventual repairing operations require compliance with ALL SAFETY PRECAUTIONS indicated in

Chapter 2.

PROBLEM

REMEDY

General problems

The machine does not work, the two ON/OFF switches do not

light up

Check the 2 line fuses (those mounted in the polysnap mod-

ule)

Check the power cord

Check the connection of the two ON/OFF buttons

When turned on, only one of the two ON/OFF buttons lights up

Check the connection of the not working button

Replace the not working button

The machine works but the pumps do not start

Check pump connection

Check the connection of thermal protectors

Replace pumps *

Problems with exhausted liquid extraction

The pump starts but extracts very slowly

Clean the filter on the extraction pipe

Check the correct operation of the non-return valve

Check that there is no narrowing on the pipes inside the ma-

chine

Problems with the new liquid charge

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 18

BRK600

The pump starts but struggles to charge the new liquid

Clean the filter on the pipe that goes into the new liquid tank

Check the correct operation of the non-return valve

Check that there is no narrowing on the pipes inside the ma-

chine

Problems with pressure regulation

The machine does not reach the set pressure

Check that the adapter on the pan is connected correctly and

that there are no leaks

Replace pressure regulator *

* CONTACT THE MANUFACTURER'S SUPPORT SERVICE.

7 MAINTENANCE

ALL MAINTENANCE OPERATIONS MUST BE CARRIED OUT WHEN THE MACHINE IS STATIONARY.

7.1 NATURE AND FREQUENCY OF CHECKS AND MAINTENANCE

To keep the unit in full efficiency, you must follow the stated maintenance timelines.

FAILURE TO COMPLY WITH THE ABOVE STATEMENTS EXEMPTS THE MANUFACTURER FROM ANY RESPONSI-

BILITY TO THE EFFECTS OF THE WARRANTY.

AFTER 1 WEEK after the setup, you must check:

The correct tightening of the screws;

The correct tightening of the pipes;

The absence of leaks in the machine.

EVERY 6 MONTHS you must check:

The correct tightening of the screws;

The correct tightening of the pipes;

The integrity of the connection pipes;

The cleaning of the two filters;

The absence of leaks in the machine.

ATTENTION! The brake fluid must not be discharged in the environment; it is a special waste and as such it must

be disposed of in accordance with the rules in force.

7.2 EXHAUSTED OIL TANK EMPTYING

When the level of the exhausted liquid in the tank exceeds half, it must be emptied in order to avoid leaks. Remove the tank with

the exhausted liquid very carefully. Unscrew the cap and empty the tank into another tank for exhausted oils. Screw the tank cap

again and place it in its location.

8 ADDITIONAL INSTRUCTIONS

8.1 DEACTIVATION AND DISASSEMBLY

According to Directive 2012/19/EU, the machine cannot be disposed of through municipal waste, but is required to be delivered

to a specialised centre for the separate collection and disposal of Waste Electrical and Electronic Equipment (WEEE), or it can

be returned to the retailer in case of purchase of a new machine. The law provides for sanctions for those who release WEEE into

the environment. WEEE, if released into the environment or misused, can release substances that are dangerous to the environ-

ment itself and to human health.

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 19

BRK600

9 SPARE PARTS

9.1 GENERAL INSTRUCTIONS

For the replacement of spare parts use only ORIGINAL SPARE PARTS.

The use of non-original spare parts entails the immediate suspension of the warranty; in addition, the manufacturing company

disclaims all responsibility concerning the machinery safety in case of accidents.

The manufacturing company put its technicians in its factory at customers’ disposal, to solve any problems regarding the use

and maintenance of the machine.

To order a spare part, it is advisable to use the attached form below, which must be completed in all its parts.

The following is a list of the individual pieces, the number corresponding to the position occupied in the attached drawings, the

code and the description.

Orders (which must be sent by fax or e-mail) must be addressed to:

9.2 SPARE PARTS REQUEST FORM

The next page shows the form to be used to order spare parts.

In the case of a request for spare parts or a request for a quote for spare parts, it is advisable to photocopy the form and fill it out

in all its parts.

The detailed compilation is decisive to receive a prompt response from the Technical Assistance Support of the Manufacturing

company.

DRAWING NO.

POS

CODE - DESCRIPTION

QUANTITY

SPARE PARTS REQUEST FORM

CUSTOMER:

MACHINE:

SERIAL NUMBER:

YEAR OF MANUFACTURE:

SHIPPING ADDRESS:

TELEPHONE:

FAX:

Top Auto S.r.l.

Viale dell'Artigianato 4, 37042- Caldiero (VR) –Italy

tel. +39 0456170025 - fax. +39 0456152493

info@topauto-equipment.com www.topauto-equipment.com

USER MANUAL, MAINTENANCE AND SPARE PARTS

Rev. 01-2020

PAGE. 20

BRK600

9.3 SPARE PARTS LIST

Table of contents

Other Top Auto Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction