Toper TKM-SX 3 User manual

GAS VERSIONS

•TKM-SX 3

•TKM-SX 5

•TKM-SX 10

•TKM-SX 15

•TKM-SX 20

ELECTRIC VERSIONS

•TKM-SX 3 E

•TKM-SX 5 E

1

WARNING

Please read the entire manual completely in order to get the best

results from your roaster and have it as a reference when needed

•Maintenance activities and repairs shall be carried out only by

authorized services or with the written approval of TOPER.

•Improper maintenance may result in equipment damages and/or

injuries.

•Please read carefully the instructions given in this manual before using

the machine and/or carrying out any maintenance or repairs.

•Malfunctions and/or damages that can occur due to mishandling or

improper repairs will be the sole responsibility of the customer.

•Furthermore, such improper usage and/or repairs will lead to the

cancellation of the warranty.

2

CONTROL PANELS DIGITAL 37

MACHINE OPERATION (GAS) 38

OPERATING INSTRUCTIONS OF ROASTER: FOR TOUCH SCREEN CONTROL PANE

L VERSION 43

COMPONENTS OF THE TOUCH SCREEN 45

MANUAL ROASTING WITH TOUCHSCREEN 47

PROFILE ROASTING 49

HOW TO USE THE PROFILE ROASTING SYTEM 51

ABOUT COFFEE

54

THE PROCESS OF ROASTING

58

ROASTING RECORD FORM

59

COLOUR TRACKING TABLE OF ROASTED COFFEE

60

COLOUR TABLE VIS

-A-VIS TASTE OF ROASTED COFFEE 61

ROASTING GRAPH

62

ROASTING RECORD FORM

63

MAINTENANCE & POTECTIVE INSTRUCTIONS

64

THE CORRECT WAY HOW TO OPEN A GREEN COFFEE BAG

65

TROUBLESHOOTING

66 -70

MAINTENANCE OF THE MACHINE

71

PERIODIC MAINTENANCE

72

CLEANING THE CHAFF COLLECTOR & CLEANING THE COOLING SIEVE

73

CLEANING THE COOLER FAN

74 -75

CLEANING THE SIGHT GLASSES

76

CLEANING THE DROP CHUTE

77

CLEANING THE EXHAUST FAN

78 -79

ADJUSTMENT OF THE DRUM

80 -81

CLEANING THE CHAFF IN THE COOLING BIN & Mixer safety setting

82

REPLACEMENT OF GAS NOZZLES

83

CLEANING THE CHAFF DRAWER UNDER THE DRUM

84

LUBRICATION OF FRONT AND REAR BEARINGS OF THE BROILER

85 -89

EMERGENCIES

90

ELEMENT CHANGE IN ELECTRIC ROASTERS

91

ELECTRICAL SCHEMATICS

92 -97

CERTIFICATE OF WARRANTY

98

INDEX

3

COMPONENTS AND FEATURES OF THE MACHINE

4

TKM SX 3 5

TKM SX 5 6

TKM SX 10 7

TKM SX 15 8

TKM SX 20 9

ADDITIONAL EQUIPMENT OPTIONS

10

BEFORE MACHINE SETUP: SAFETY INSTRUCTIONS 11

TRANSPORT OF THE MACHINE 12

ELECTRICAL SAFETY 13

GAS SAFETY 14

IMPORTANT NOTES 15

MACHINE SETUP: INSTRUCTIONS

16

ELECTRICAL CONNECTION 17

GAS CONNECTION 18

FIRE SUPPRESSION SYSTEM 19

ASSEMBLING YOUR ROASTER: INSTRUCTIONS

20

CHAFF COLLECTOR ASSEMBLY 21

CHAFF COLLECTOR ASSEMBLY 22

ASSEMBLING YOUR ROASTER: CHIMNEYS & REQUIRED DISTANCES

23

MATTERS TO BE CONSIDERED DURING THE CHIMNEY SETUP 24

ACCEPTABLE CHIMNEYS (WITHOUT AFTERBURNERS) 25

INSTALLATION AREA 26

ALL ABOUT AFTERBURNERS

27

TRANSPORT & INSTALLATION 28

ASSEMBLY: ON TOP OF CHAFF COLLECTOR OR BESIDE CHAFF COLLECTOR 29

FINAL CONNECTIONS 30

ELECTRICAL CONNECTIONS 31

TYPICAL GAS TRAIN CONNECTION 32

ACCEPTABLE CHIMNEY CONNECTIONS AND TYPES OF CHIMNEYS FOR

AFTERBURNERS 33

START UP & MAINTENANCE 35

OPERATING INSTRUCTIONS OF ROASTER: DIGITAL FUNCTIONS

36

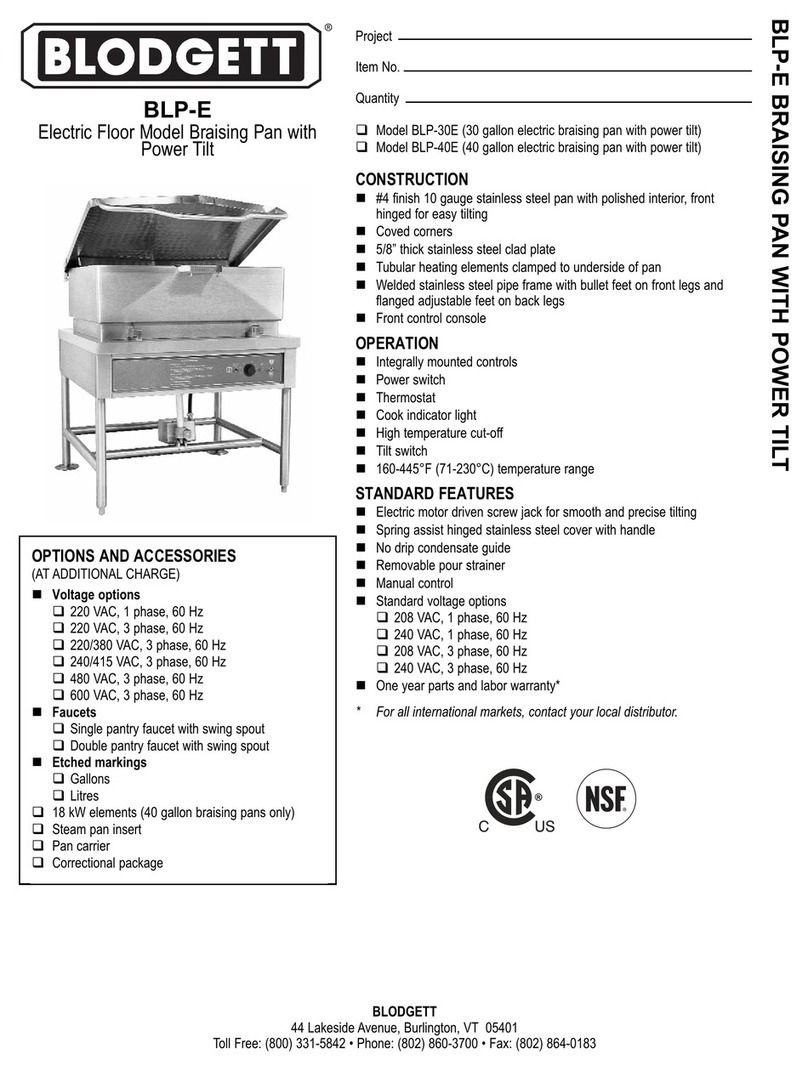

COMPONENTS AND FEATURES OF THE MACHINE

Green Coffee

Hopper

Chaff Collector

Control Board

Smoke Chimney

Cooling Chimney (s)

Smoke Fan &

Motor

Cooling Fan &

Motor

Cooling Bin

Roasted Coffee

Discharge Door

(Drum)

Chaff Garbage Bin

Anti Fire System

Roasted Coffee

Discharge Door

(Cooling Bin)

Sampler & Sight

Window

Figure 1

Cooling Bin

Protective Screen

Burner Sight

Window

4

TKM SX 3

5

TKM SX 5

6

TKM SX 10

7

TKM SX 15

8

TKM SX 20

9

ADDITIONAL EQUIPMENT OPTIONS

1

3

2

1. AFTER BURNER: Exhaust gas eliminator. Versions: TAB 5, TAB 10, TAB 15

2. DESTONER: Destoner. Versions: TDS 15

3. PNEUMATIC LOADER: Pneumatic green coffee loader. Versions: TPL 15

Figure 2

10

BEFORE MACHINE SETUP: SAFETY INSTRUCTIONS

11

TRANSPORT OF THE MACHINE

1. Lift and transport the machine from points A and B. Please refer to Figure 3

2. Protect the machine from external impacts during transport.

3. Take the machine out of its crate & packaging.

4. Check whether there is any damages on the machine. If the machine is

damaged, never operate the machine. Inform your dealer or technical

service about this issue.

5. For insurance, have your dealer apply to the insurance company.

6. After taking the machine out of its packaging, place it on a flat surface.

7. Do not use your machine in environments where there is a high-level of

humidity or wet surfaces.

8. Make sure that the environment where your roaster will be placed is not wet

and humid, even if the roaster is in its original packaging.

A B

Figure 3

For transport, always lift the machine from points A

and B and always use a Jigger/Pallet Jack

12

ELECTRICAL SAFETY

1. In order to ensure that your machine works efficiently and safely, your electrical installation shall not worned out, preferably new.

2. When assembling the electrical system:

1. Be very careful if your electrical installation is in ‘‘Single or Three Phase’’.

2. Motors in ‘‘Three-Phase’’ can rotate in both directions.

3. The motors MUST rotate in the direction of the OK mark taped on the fans.

4. If the motors rotate in the opposite direction, inform your electrician.

5. The power line to be used for the machine shall have a ground line.

3. Check the cable section of the electrical line, through which the machine will be operated. The amperage in the cable section shall

correspond to the ampere rating on the machine.

4. In the event of a fire in the electrical equipment for any reason, first disconnect all power connections. Then extinguish the fire using the

appropriate type of fire extinguishers (Fire Extinguisher with Halon Gas).

5. In case of a malfunction in the electrical system, cut off the electricity from the main breaker and pull out the plug.

6. Ensure that it is serviced by an authorized electrician.

THE MAIN ELECTRICAL SUPPLY LINE TO THE MACHINE HAS TO BE INSTALLED BY A QUALIFIED ELECTRICIAN.

13

GAS SAFETY

1. Gas installation shall be done by an expert and qualified person.

2. Check for gas leakage with appropriate equipment; never perform the gas leakage verifications near an open flame close by.

3. Gas burners lose their function over time, and they must be replaced with a new ones. (Refer to Periodic Maintenance)

4. Have the annual maintenance of the gas installation done on time every year.

5. If you operate your machine with natural gas, please note that the gas does not have an odour.

IF THERE IS A GAS LEAKAGE IN THE MACHINE:

1. Turn of entire gas supply.

2. Ventilate the environment by opening doors and windows.

3. If the gas leak is severe, please do 1 & 2 and leave the scene of leakage and warn other people around.

4. If any stoves or flames are on, turn them off immediately.

5. Do not use push buttons, electrical devices and phone.

6. If the leakage is from the machine, please inform Toper services

7. If it is on the main supply line, please inform the necessary institutions.

14

Important Notes

1. Chimney installation must be done by the authorized chimney installation experts.

2. The burners and the drum of this machine consumes oxygen. Install the necessary system (windows, fresh

air intake fan, etc.) to ensure sufficient fresh air intake are around where the machine operates.

3. Before cleaning and doing maintenance activities on your machine and if any operations are to be done on

the inside of the machine, stop the machine and cut off the electricity supply.

4. In case of any malfunction, contact your authorised service dealer. Never try to fix the malfunction on your

own.

5. Quick and simple interventions that the user can make are explained at the end of this instruction manual.

15

MACHINE SETUP: INSTRUCTIONS

16

ELECTRICAL CONNECTION

•Make sure that electrical wiring is installed by experienced

electricians.

•Check whether your Machine is suitable for wiring that has

been installed by your electrician.

•There are many different voltage and Hertz options that vary

according to different regions in the world (Such as

208/220/240/380-volts, 50-60 Hz, single or three phase). Toper

exports to 132 different countries around the world. The

electrical system of the machine is produced according to the

characteristics of the country to which it will be exported.

Please check the electrical specifications of the machine.

Connect properly to the electrical system.

•Your roaster have been factory tested. Thus, ready for use, it

should be Connect/Plug & Go!

•Check the ground line of the machine.

•Have the ground line coming to your machine checked; if it is

decided that it is insufficient, have the ground line installed to

the point shown in the ‘‘Figure 4’’.

•For electrical machines: The total power of your roaster is

between 8.300 –10.000 W. The amperage shall in accordance

with this power. The roaster shall be connected to a 32 A

automatic breaker. While the operating is operating, a second

appliance with a power of 2000 W or more connected to the

same breaker with pop the breaker and stop both the roaster

and the other appliance.

17

Figure 4

GAS CONNECTION

•Make sure that the gas connection is made by a gas plumber.

•Make sure that a suitable regulator is installed according to the

gas characteristics and capacity used by the machine.

•If the type of gas used as burner fuel is changed, have this change

done by the technical service (from LPG to natural gas and from

natural gas to LPG).

•Attention: The type of gas nozzle used for LPG is written on the

burner of the machine.

•Gas nozzles can be converted to natural gas on request. If you do

not know which gas the machine uses, get help by contacting our

technical service.

•If LPG is used, check whether the regulators in the system are

suitable for the capacity of the machine.

•Insufficient gas flow as a result of using the wrong regulator and

unsuitable regulators may cause unnecessary energy

consumption by prolonging the roasting time of the machine.

•NOTE: Our company will always install on your roaster a gas

regulator with the correct capacity for that roaster. If the gas

pressure and capacity of the natural gas line are suitable for the

machine, remove that regulator.

•Nozzles for both types of gases are delivered with your roaster.

Use them if changing types of gas

18

Burner

Manometer

Gas valve

Manometer

Honeywell

Ball valve

Regulator

Figure 5

FIRE SUPPRESSION SYSTEM

19

The Toper Fire Protection system built into the chaff

collector for all our roasters; the system monitors the

temperature in the cyclone and if it exceeds the set level

due to a fire open the valve, it will spray water into the

chaff collector and extinguishes the fire

ASSEMBLING YOUR ROASTER: INSTRUCTIONS

20

All Toper TKM SX 3 to 20 kg are first assembled, then tested and finally shipped. Some parts must be disassembled before shipping. Chaff collector, connecting pipes and

green coffee hopper are shipped disassembled. You need to assemble the chaff collector parts with the self-locking clamps provided together with pipes and displayed in

figure 6. Do not forget to fasten the cotter pin in the clamp after mounting.

This manual suits for next models

6

Table of contents