2

EVERY MACHINE IS THOROUGHLY TESTED BEFORE LEAVING THE FACTORY. EACH MA-

CHINE IS SUPPLIED WITH A COPY OF THIS MANUAL. OPERATORS OF THIS EQUIPMENT

MUST READ AND BE FAMILIAR WITH THE SAFETY WARNINGS. FAILURE TO OBEY WARN-

INGS MAY RESULT IN INJURY OR DEATH. FOLLOW INSTRUCTIONS STRICTLY TO ENSURE

LONG SERVICE IN NORMAL OPERATION.

CONTENTS

Symbol Definitions............................................................................................................................... 3 - 6

Decal Descriptions and Locations ....................................................................................................... 7

Safety Warnings - DOs & DO NOTs .................................................................................................... 8 - 9

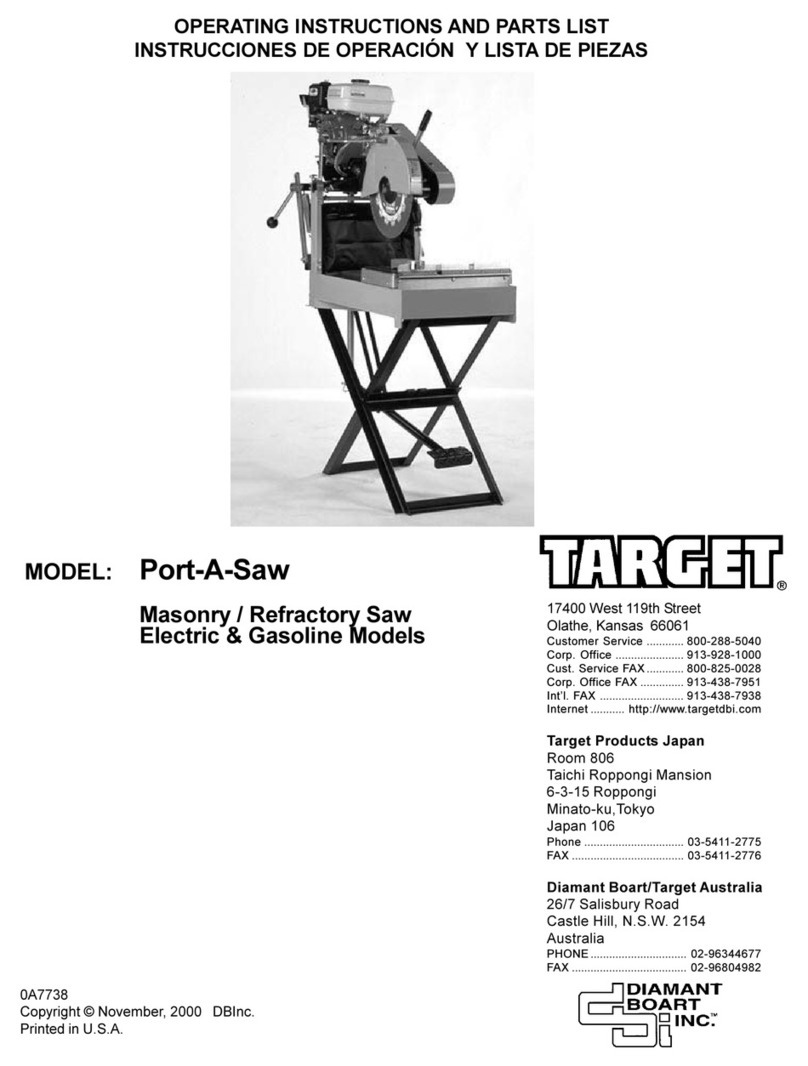

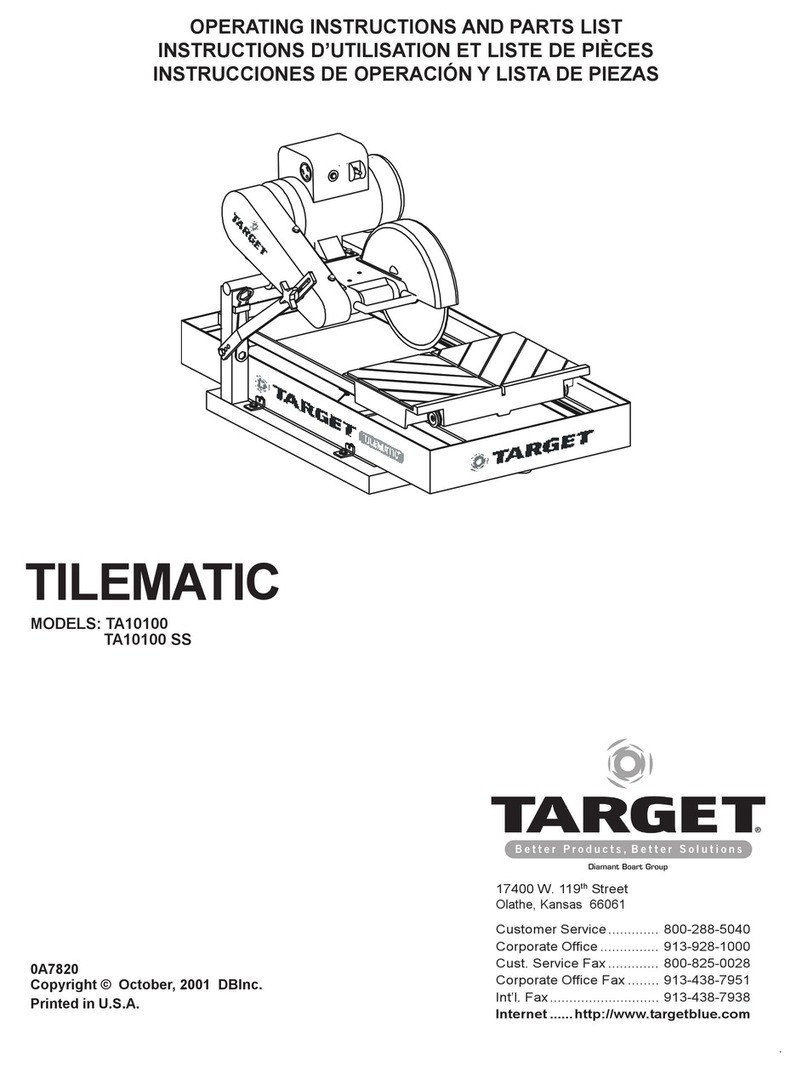

Reference Figure ................................................................................................................................ 10

Instructions:

1. Features................................................................................................................................11

2. Benefits ................................................................................................................................. 11

3. Machine Set-Up .................................................................................................................... 11 - 13

4. Operating Procedures ........................................................................................................... 13

5. Manual Thermal Overload .................................................................................................... 13

6. Extension Cords ................................................................................................................... 13

7. Alignment Procedures ..........................................................................................................14

8. Profile Wheel Set-Up ............................................................................................................14 - 15

9. Maintenance ......................................................................................................................... 15

10. Water Pump, Trouble Shooting Procedure ........................................................................... 15

11. Repairs ................................................................................................................................. 15

12. Spare Parts ........................................................................................................................... 15

13. Accessories .......................................................................................................................... 16

Diagrams and Spare Parts .................................................................................................................. 28 - 29

Wiring Diagrams ................................................................................................................................. 30 - 32

Warranty ....................................................................................................................................... ..... 33

ANTES DE SALIR DE NUESTRA FÁBRICA, CADA MÁQUINA ES SOMETIDA A PUREBAS

DETENIDAS. CADA MÁQUINA DE CORTE ES ENTREGADA CON UNA CIPIA DE ESTE

MANUAL. LOS OPERARIOS DE ESTOS EQUIPOS DEBEN LEER Y FAMILIARIZARSE CON

LAS INSTRUCCIONES DE SEGURIDAD. EL NO PRESTAR ATENCIÓN A ESTAS

ADVERTENCIAS PUEDE OCASIONAR GRAVES LESIONE. SIGA ESTRICAMENTE NUESTRAS

INSTRUCCIONES Y SU MÁQUINA LE VA A PRESTAR LARGOS AÑOS DE SERVICIO EN

CONDICIONES NORMALES DE UTILIZACIÓN.

CONTENIDO

Definición De Los Simbolos ................................................................................................................3 - 6

Descripción De Calcamonias Y Ubicaciones .....................................................................................7

Advertencias De Seguridad HACER & NO HACER ............................................................................18 - 19

Figura De Referencia .......................................................................................................................... 20

Instrucciones:

1. Caracteristica ......................................................................................................................21

2. Beneficio ............................................................................................................................. 21

3. Instalacíon De La Cortadora ............................................................................................... 22

4. Instrucciones De Operación ................................................................................................ 23 - 24

5. Protector Térmico - Rearmado Manual ...............................................................................24

6. Cables De Extensión........................................................................................................... 24

7. Procedimientos de Alineacion ............................................................................................. 24

8. Armado y Uso de la Rueda Perfiladora ...............................................................................24 - 25

9. Instrucciones De Mantenimiento ......................................................................................... 25

10. EnCaso De Problemas Con La Bomba De Agua ................................................................25

11. Reparaciones ......................................................................................................................26

12. Piezas De Recambio ...........................................................................................................26

13. Accesorios .......................................................................................................................... 27

Diagrame y Piezas De Recambio .......................................................................................................28 - 29

Diagrame De Cablado Eléctrico ..........................................................................................................30 - 32

Garantía .......33