Contents

1. Foreword............................................................................................................................................... 1

2. Warranty Information......................................................................................................................... 1

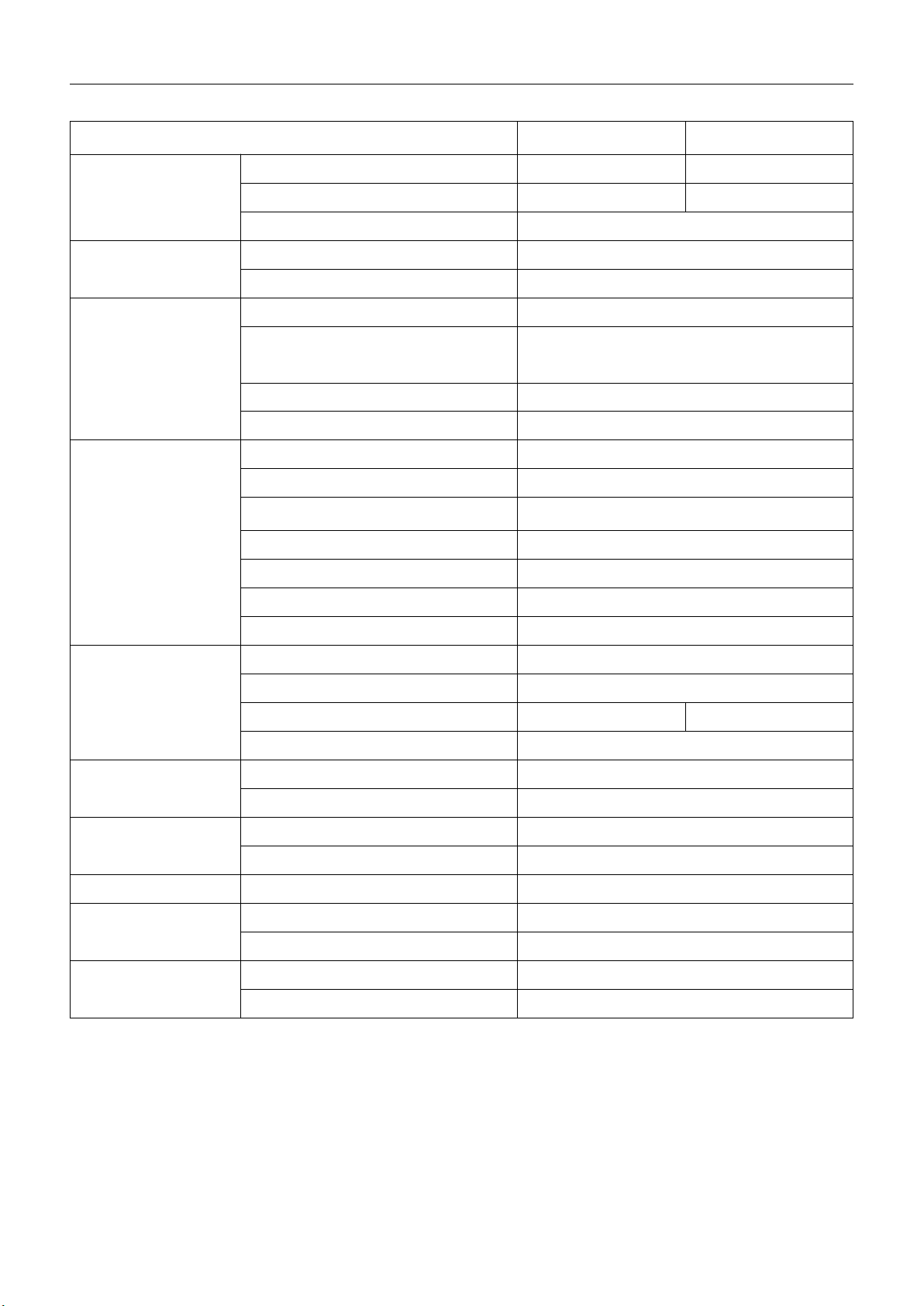

3. Machine Description.......................................................................................................................... 2

3.1 Technical Parameters................................................................................................................. 2

3.2 Feature Identification...................................................................................................................5

3.3 Optional Equipment..................................................................................................................... 5

3.4 Intended Use................................................................................................................................ 6

3.5 Electrical Power Requirements................................................................................................. 6

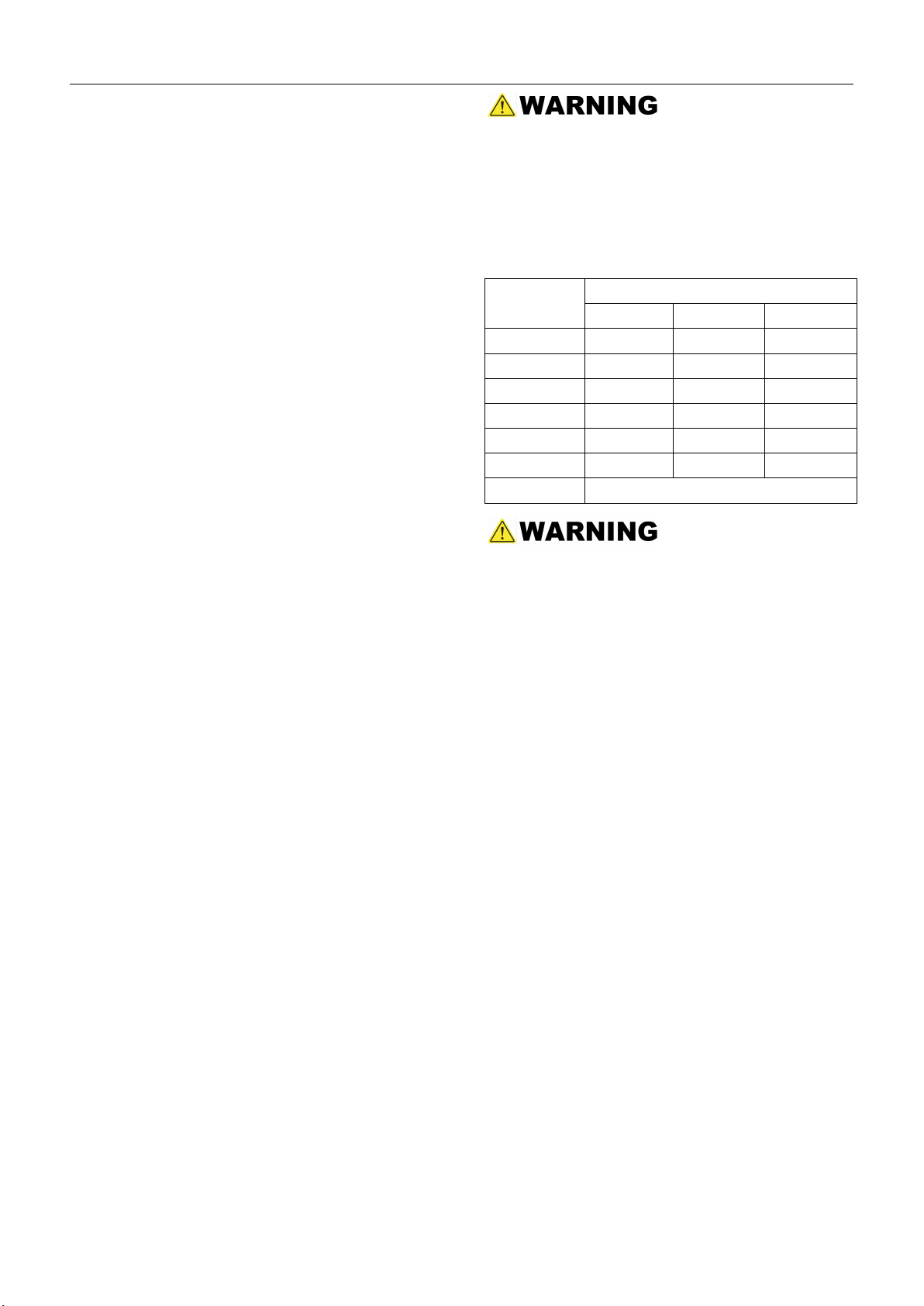

4. Safety Regulations............................................................................................................................. 7

4.1. General Safety Instructions.......................................................................................................7

4.2. Table Saw Safety Instructions.................................................................................................. 7

4.3. Residual Risks............................................................................................................................ 8

4.4. Safety Eequipment..................................................................................................................... 8

5. Installation of the Machine............................................................................................................... 9

5.1 Transportation of Machines........................................................................................................9

5.2 Unpacking..................................................................................................................................... 9

5.3 Contents...................................................................................................................................... 10

5.4 Installation...................................................................................................................................12

6. Adjustment......................................................................................................................................... 17

6.1 Adjusting the Rip Fence........................................................................................................... 17

6.2 Aligning the Table T-slot Parallel with the Blade.................................................................. 17

6.3 Adjusting the 45°and 90°Positive Stops................................................................................ 17

6.4 Aligning Riving Knife with the Blade....................................................................................... 18

7. Operations.......................................................................................................................................... 19

7.1 Electrical Operation................................................................................................................... 19

7.2 Blade Elevation and Tilting Adjustment................................................................................. 19

7.3 Crosscutting................................................................................................................................19

7.4 Ripping........................................................................................................................................ 20

8. Maintenance....................................................................................................................................... 20

9. Trouble Shooting.............................................................................................................................. 21

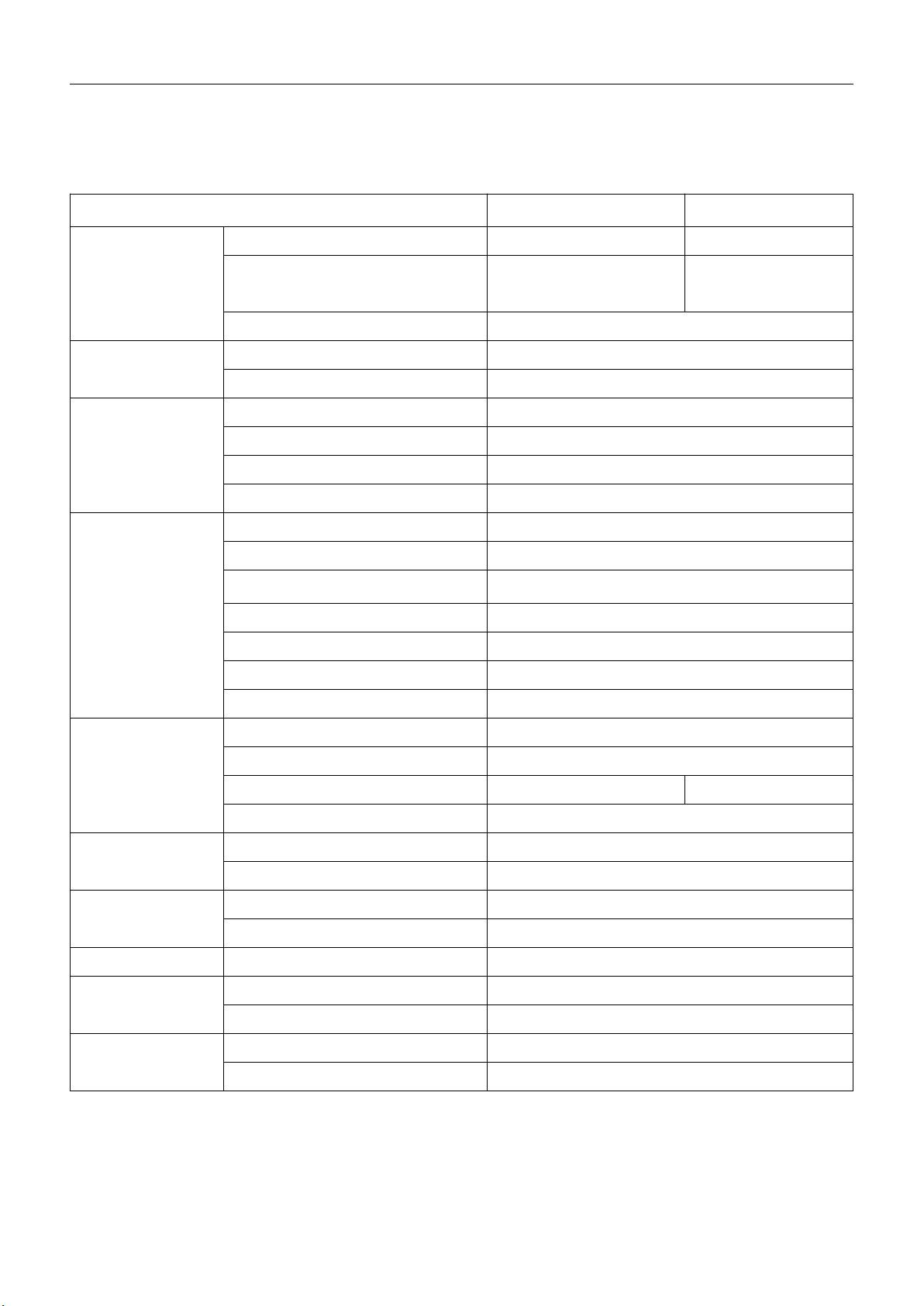

10. Exploded View and Parts List..................................................................................................... 22