Toptec FutureTrac User manual

Assembly Instructions

30 - 40 Wide

40' X 60' w/ 20' MID

40' X 80' w/ 20' MID

40' X 100' w/ 15' MID

40' X 85' w/ 15' MID

40' X 70' w/ 15' MID

40' X 55' w/ 15' MID

40' X 100' w/ 20' MID

Form # 20011001

© 1999 TopTec

TopTec Products, LLC

7601 Highway 221

Moore, SC 29369

Phone: (800) 845-2830

Fax: (800) 921-7750

e-mail: [email protected]

www.TopTecProducts.com

Assembly Instructions

30 - 40 Wide

Form # 20011001

THANK YOU FOR PURCHASING A TOPTEC TENT

If you have questions about the installation, maintenance or disassembly, please call us at (800) 845 - 2830.

Our goal is that you are satisfied with our products. Please read this manual carefully and follow all instructions contained

herein. Please note that the installer is responsible for the site selection, installation and use. Do not erect during inclement

weather and follow all safety procedures during the installation process.

Please contact all utility companies for underground services. In many states, the utilities work together and have formed a

Utility Locating Service. It is your responsibility to locate all underground services, including speaking to the owner about

irrigation, pool and other special services the property owner may have installed.

To provide the quickest possible service, please fill in the information below so that we can efficiently help you should any

problem arise.

FUTURE TRAC SERIES TENT

FRAME SIZE (Width x Length)

END SECTION SERIAL NUMBER

END SECTION SERIAL NUMBER

MID SECTION SERIAL NUMBER

MID SECTION SERIAL NUMBER

MID SECTION SERIAL NUMBER

MID SECTION SERIAL NUMBER

AIFT 30/40

Assembly Instructions

30 - 40 Wide

Form # 20011001

Table of Contents

Limited Warranty .............................................................................................................................. ii

Shipping Damages & Shortages ........................................................................................................... ii

Blackout Material .............................................................................................................................. ii

Site Survey ............................................................................................................................................ ii

Site Plan ............................................................................................................................................ ii

Recommended Tools & Equipment ................................................................................................ iii

Installation Instructions

Frame Lay Out ............................................................................................................................. 1

Building Arch Assembly .............................................................................................................. 2

Raising Arch Assembly .............................................................................................................. 4

Building End Frame ...................................................................................................................... 4

Building Perimeter ...................................................................................................................... 5

Install Hip Pole Braces .............................................................................................................. 6

Adding 10' - 15' Mid Sections ....................................................................................................... 7

Building Final Mid/End Section ................................................................................................ 9

Install Brace Bars ........................................................................................................................ 9

Top Panel Installation .............................................................................................................. 10

Lifting Frame ............................................................................................................................. 11

Leg Installation ............................................................................................................................. 11

Corner Brace Installation .............................................................................................................. 12

Anchoring Tent ............................................................................................................................. 12

Tensioning Top Panels .............................................................................................................. 13

Installed Tent Inspection ...................................................................................................................... 13

Top Removal and Folding ............................................................................................................... 14

Lowering Frame ............................................................................................................................. 15

Disassemble Frame ............................................................................................................................. 15

Jack Assembly ..................................................................................................................................... 16

i

AIFT 30/40

Assembly Instructions

30 - 40 Wide

Form # 20011001

LIMITED WARRANTY

All new TopTec products are warranted to be free from defects in materials and workmanship which may cause failure under

normal usage and service when used for the purpose intended. If you feel that upon the receipt of our products, a possible

defect in material and workmanship exists, contact us immediately. If after examination, TopTec determines that there is a

defect in material and workmanship, TopTec Products, LLC will bear the cost of freight both to and from the factory for

repair. It will be at the factory's discretion to repair or replace the product at no cost to you.

TopTec is not responsible for damages which occur in shipment, weather related damage, damage caused by incorrect use of

the product, damage resulting from not using proper ground cloths nor damage resulting from the use of washing machines.

Any questions in regards to the proper installation procedures should be directed to the installation manual provided with the

product or directly to TopTec Customer Service.

SHIPPING DAMAGES/SHORTAGES

UPS Shipment: The customer is responsible for immediately inspecting merchandise and noting any damage directly with

UPS. UPS will then pickup merchandise for inspection. Do not destroy or throw out shipping container or merchandise. If

UPS determines merchandise was damaged in shipment, they will contact shipper to settle claim. It is important that you

notify shipper of any shipment damage. Credit will be issued as soon as claim is settled.

Motor Freight: TopTec is not responsible for products damaged or lost in transit. The customer is responsible for noting any

damages or shortages with the freight company upon delivery. Ownership of shipment passes to customer after it is loaded

on the truck. The customer must initiate a claim with the freight company and NOTE THE DAMAGE/SHORTAGES ON

THE FREIGHT BILL so customer can protect their right of claim. Concealed damage must be discovered within ten (10)

days and the claims made with the freight carrier. It is your responsibility to count and open all products immediately.

BLACKOUT MATERIAL

The benefits of blackout material has been well emphasized: first the tent's interior is cooler therefore the air conditioning

costs are lower at large events; secondly, stains, dirt, abrasions and patches are less noticeable since light does not pass

through the vinyl. However, blackout material can cause any puncture, hole, tent repair, even box stitching to show up as

starlights in the tops. In most cases these are not holes, only an absence of blackout film which allows the light to pass

through. If these situations occur, we have a self-adhesive Blackout Repair Kit available to solve this problem. Please

contact TopTec Customer Service for assistance.

SITE SURVEY

The major purpose of the site survey is to accomplish the following:

1. To gather all pertinent information regarding the function or event.

2. To ensure that the proper equipment is used to suit the site and function.

3. To organize the information so that it becomes an effective means of communication for all parties involved.

4. To serve as a permanent record of the entire transaction.

5. To serve as a means of ensuring that all codes and regulations are met.

SITE PLAN

The major purpose of the site plan is to accomplish the following:

1. To ensure that the tent and related equipment are installed in the proper manner.

2. To ensure that the layout conforms to local codes.

3. To locate obstructions.

4. To show access to the site.

5. To locate exit areas on tents and sidewalls.

6. To locate areas with specialized anchoring.

ii

AIFT 30/40

Assembly Instructions

30 - 40 Wide

Form # 20011001

RECOMMENDED TOOLS AND EQUIPMENT

Personal Safety

•Gloves - Hard Hat - Steel Toe Shoes - Safety Glasses - Ear Protection

Site Transport

•Hand truck for moving components

Staking Layout

•Two (2) each 100' tape measures (for up to 40' x 60' tents)

•Two (2) each 6" shank screw drivers for staking down tape measures

•Fast dry marking paint (preferably white)

Stake Installation and Removal

•1" capacity rotary hammer for drilling holes in pavement for stakes

•An 8 to 16 pound sledge hammer

•24" pipe wrench for spinning stakes out of wet soil

•Mechanical stake puller

Frame Assembly

•Various wrenches and other types of tools (varies according to tent size)

•Tent jacks for raising frame to install legs (minimum of two (2) for a 40' x 40' and one (1) additional jack

for each 10 ft.,15 ft. or 20 ft. mid section.

•Ladders - Minimum of one (1) 6 ft. step. Two (2) each is best, one (1) 6 ft. and one (1) 8 ft. or 10 ft.

depending on tent size.

Top Installation

•Ground cloths to protect the vinyl from dirt and abrasion.

•Cleaning supplies to remove any marks acquired during installation.

•"Pull Ropes" - Two (2) 75 ft. long by 5/8" diameter and a third smaller rope for a return rope.

Tool Bag

Binder with blueprints and set-up instructions; (2) each - 5/8" x 75 ft. poly rope with carabiner; (1) each -

3/8" x 75 ft. rope with carabiner; Scissors; Utility knife; 8" Cresent Wrench; Flat/Half Round File with

Handle; Pliers; Cats Paw Pry Bar; Punch; Ball Point Pens; Fifty (50) each Quick Pins; One (1) Dozen

3/8" D-Clasp Pins

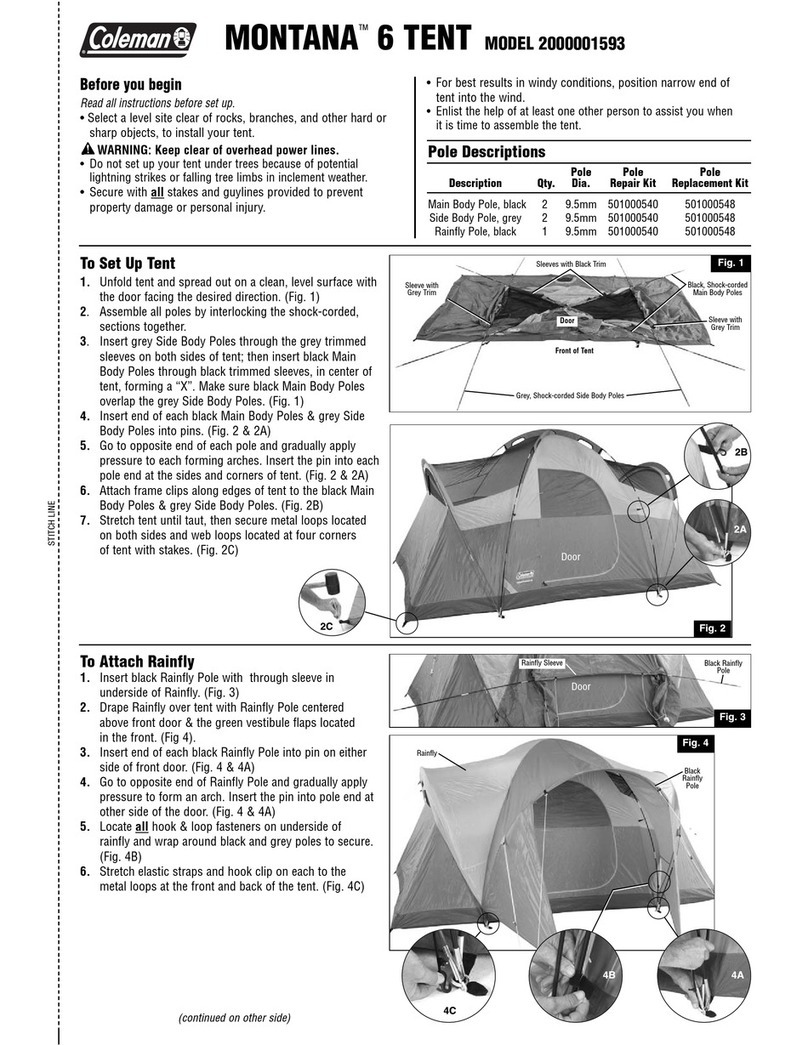

Please read these instructions in advance of assembly. Always be cautious of wind and weather

conditions. Partially assembled tents are large sails in windy conditions. Always tie off frames

before installing the tops.

Check the inventory list to ensure all parts are available prior to assembly. Especially important to

the Future Trac tents are the brace bars and appropriate bolts and pins.

iii

AIFT 30/40

Note: During installation, ensure that all perimeter poles are positioned

so that the opening is towards the crown to match the 26 degree roof

pitch when installed. All poles will have a pin hole drilled through the

score line on the side of the tube. This score line should be facing

upward.

END SECTION

20 FT.

MID SECTION

10 OR 15 FT.

MID SECTION

40 Wide Layout: Position the Future Trac tubes and brackets around the perimeter of the tent as shown in the drawing

above. Please note the difference between the 10/15 ft. mid sections and the 20 ft. mid sections and lay them out

accordingly. There will be a brace bar and cross cable for each crown assembly and they must be installed before raising the

arch assembly.

Assembly Instructions

30 - 40 Wide

Form # 20011001

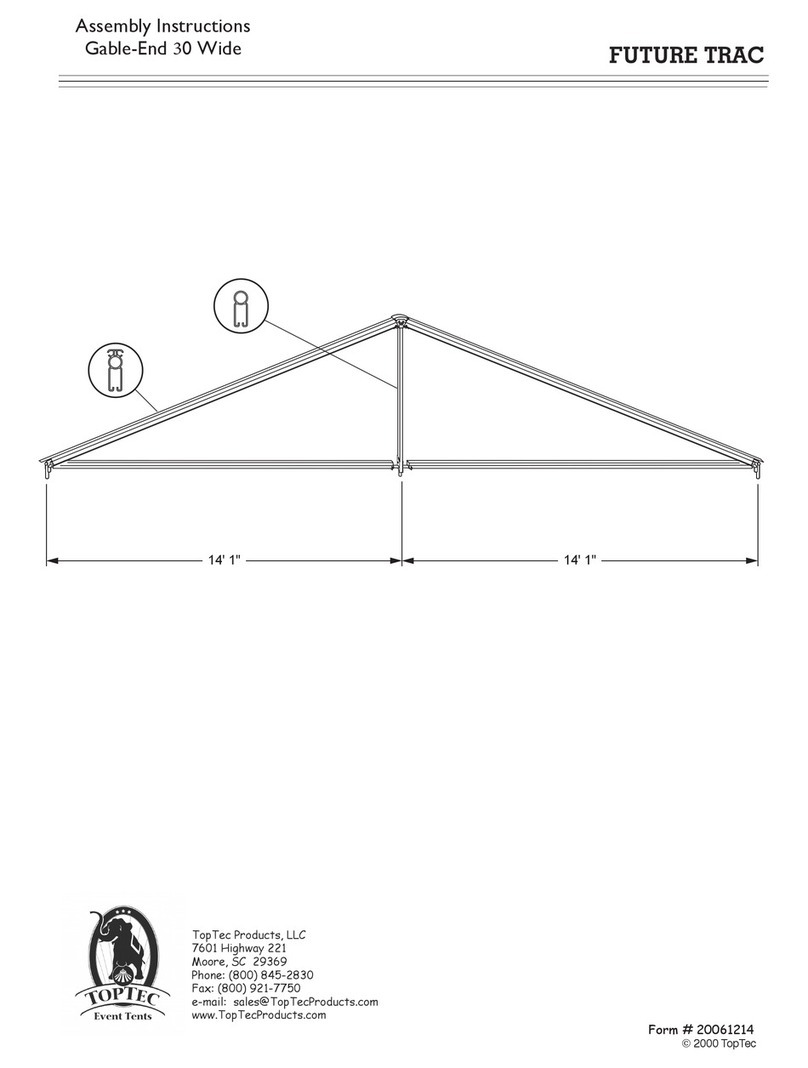

30 Wide Layout: Position the Future Trac tubes and brackets around the perimeter of the tent as shown in the drawing

above. There will be a brace bar for each crown assembly and they must be installed before raising the arch assembly.

END SECTION

20 FT.

MID SECTION

10 OR 15 FT.

MID SECTION

( 1 ) AIFT 30/40

Form # 20011001

Next, attach an intermediate bracket with a

3/8" D-clasp pin as shown in the drawing

above.

Begin the assembly process, by attaching

the crown assembly to the Keder rafter as

shown using a 3/8" D-clasp pin.

Attach the opposite side Keder rafter to the

crown in the same manner as in the previous

step.

Repeat this procedure on the opposite side

intermediate bracket with a 3/8" D-clasp pin

as shown.

Step 1 Step 2

Step 3 Step 4

Important: Install the brace bar at the top of each arch. Slip

flat eye end into function slot of Keder rafter and pin with 3/8"

D-Clasp pin. Repeat prodedure for opposite side. It may be

necessary to move the rafter in or out to locate and pin this side.

Note: 30 Wide Future Trac tents will have a longer brace bar and

will be mounted lower on the Keder rafter however the installation

procedures will be the same.

Step 5

Cable - Straight (optional)

(Attaching Cable on Left Side)

Once the brace bar has been installed, connect one side of the cross cable with the clevis pin as show. Be sure that the pin is

installed so that it can be easily removed (if necessary). Attach opposite side using the same procedure as shown above. It

will require pulling the frame inward to install the clevis pin. This is a designed pre-load.

Step 6

Assembly Instructions

30 - 40 Wide

( 2 )

Building Arch Assembly

Cable Installation - 40 Wide Only

AIFT 30/40

Form # 20011001

AB

C

Insert Quick Pin

on A,B, and C

from top side QUICK PIN

The next step, prior to raising the arch assembly, is to install any accessory attachments to the frame while it is on

the ground. Connect both hip rafters A & B ( on 40' wide attach only the upper halves) with quick pin as shown,

then connect the end rafter (C) to the rotating spigot with the quick pin as shown in the call out above.

Step 7

Assembly Instructions

30 - 40 Wide

( 3 )

Once the brace bar has been installed, connect both of the long ends of the scissors truss cables with the clevis pin (as shown)

to the intermediate brackets. Next, pull the frame inward from each intermediate bracket and use 3/8" D-Clasp Pins to pin

the short ends of the scissors truss cables to the Keder rafters at the holes below the brace bar. This is a designed pre-load.

Step 6 - Scissors Truss Cable Installation (40 Wide Only)

Tip: Place clevis pins that fasten the scissors truss cable

to the intermediate bracket on the opposite side of where

the hip pole brace bars fasten. This will eliminate the

interference of the D-Clasp pin when installing the hip

pole brace bars.

Note: 30 wide Future Trac hip rafters (A & B) are single piece 21' 10" poles. These can be attached in the same

manner as above or the arch assembly can be raised as described in the next step and then attached.

AIFT 30/40

Scissors Truss Cable

(Attaching Scissors Truss

Cable on Left Side)

Note: The mounting hole for the scissors truss

cable is the first hole below the rafter brace bar.

Form # 20011001

A

B

C

Rotating the arch assembly into its upright position is easiest when there is a crew of three (3) or more. Place the completed

arch with the intermediate brackets at the desired finish location and pick up the arch, as shown above, and rotate it to the

upright position. The person on the end rafter (C) pulls while the other two (2) lift the arch near the middle and work their

way out as the arch rotates into position.

CAUTION! Once the arch is upright,

one (1) person needs to steady it

(reference C) until the next steps

are complete.

AB C

Build the hip rafters out by installing the 4-way hip splices into upper rafters (A & B)

and quick pin. Then slip on the lower half of the hip rafter and quick pin as shown.

Tighten wing nuts to secure connectors to hip pole. Repeat this procedue on both

sides of this end frame assembly

Assembly Instructions

30 - 40 Wide

( 4 )

Raising Arch Assembly

Building End Frame

Step 8

Step 9

Step 10

Note: 30 Wide Future Trac tents do not have 4-way hip splices. The hip rafters are

single piece 21' 10" poles and once in place will steady the tent.

AIFT 30/40

Form # 20011001

Install Quick Pin

on Perimeter Pole

Perimeter Pole

Cable

Next, assemble the perimeter of the frame, starting at an

intermediate on one side of the raised arch assembly.

Install Corner Hip Pole

Connect corner bracket by placing perimeter tube and hip

rafter tube together into the corner bracket and quick pin;

then install perimeter tube to end intermediate on corner

and quick pin.

Connect end rafter to intermediate bracket and quick pin,

then connect perimeter tubes to intermediate bracket and

quick pin. The frame should stand by itself at this point.

Assembly Instructions

30 - 40 Wide

( 5 )

Step 11 Step 12

Intermediate and End Rafter

Step 13

Install Corner Hip Pole

Connect remaining corner bracket by placing perimeter

tube from end rafter and hip rafter tube together into the

corner bracket and quick pin; then install the remaining

perimeter tube to corner bracket and quick pin. Note:

Frame may require squaring up to make this connection.

Lift corner to make final connection easier, then quick

pin.

Step 14

Install Quick Pin

on Perimeter Pole

Perimeter Pole

Cable

Step 15

Next, connect the perimeter tube to the arch and quick

pin (as shown).

AIFT 30/40

Form # 20011001

Next, connect the hip pole brace tube to the Intermediate

bracket as shown with a 3/8" D-clasp pin. Hold pole

firmly so that it wil not drop. This could damage the eye

end.

Connect remaining end of hip pole brace to the hip pole

connector as show. Please note that it may be necessary to

push up on hip pole to locate D-clasp pin to lock hip pole

into place. Repeat procedure for the remaining hip pole

braces.

View of completed frame with hip pole brace bars in place.

Now is the time to check that frame is square with installation

site. Shift as necessary to properly align before completing

frame assembly. As you add components frame becomes

heavier and more rigid making it difficult to move around.

Keder Rafter

Intermediate

Bracket

D-Clasp Pin

D-Clasp Brace Bar

to Connector

Step 17

Step 16

Assembly Instructions

30 - 40 Wide

View of completed end frame prior to installation of hip pole brace bars (40 Wide). This would be a completed end frame

on a 30 Wide tent. Please note that 30 Wide Future Trac tents do not use cross or scissors truss cables.

Note: 30 Wide Future Trac frame tents

do not have hip pole brace kits and

these steps are eliminated.

( 6 )

AIFT 30/40

Form # 20011001

To add mid section to end frame, connect the two perimeter poles to the

completed half of the end frame. This will establish the location for

alignment of the next arch assembly.

Build arch assembly in the same method as in Steps 2, 3, and 4. Brace

bar and/or scissors truss or cross cable must be installed in the same

methods as outlined in Steps 5 and 6.

QUICK PIN

QUICK PIN

Assembly Instructions

30 - 40 Wide

Step 18

Step 19

Step 20

Install ridge rafter as shown. Pivot man, as in illustration below, will

stay with this pole until it is raised and installed onto the crown cluster

and quick pinned.

Step 21

( 7 ) AIFT 30/40

Form # 20011001

Use step ladder (as shown) to attach ridge rafter. This step must be

completed prior to attaching the perimeter poles from the completed

end section to the arch assembly.

QUICK PIN

ARCH ASSEMBLY

IN UPRIGHT POSITION

Step 22

Step 23

QUICK PIN

QUICK PIN

Assembly Instructions

30 - 40 Wide

Quick pin the perimeter poles to the completed arch assembly (as shown).

Additional mid sections should be installed in the same manner as above.

( 8 )

AIFT 30/40

Form # 20011001

QUICK PIN

QUICK PIN

QUICK PIN

Step 24

To build mid section and end frame, connect the two perimeter poles to the

completed half of the end frame. This will establish the location for alignment

of the last arch assembly.

Build arch assembly and raise in the same manner as in steps 1 - 9. Attach ridge

rafter as shown, using step ladder. Once ridge rafter is installed, attach

intermediates to perimeter poles as shown in the step above.

Build out the hip rafters as in step 10. Next, assemble the perimeter of the frame

starting at the intermediate bracket on one side of the remaining arch assembly. Attach

corner bracket as in step 12 and continue to attach the remaining components as in

steps 13 - 18.

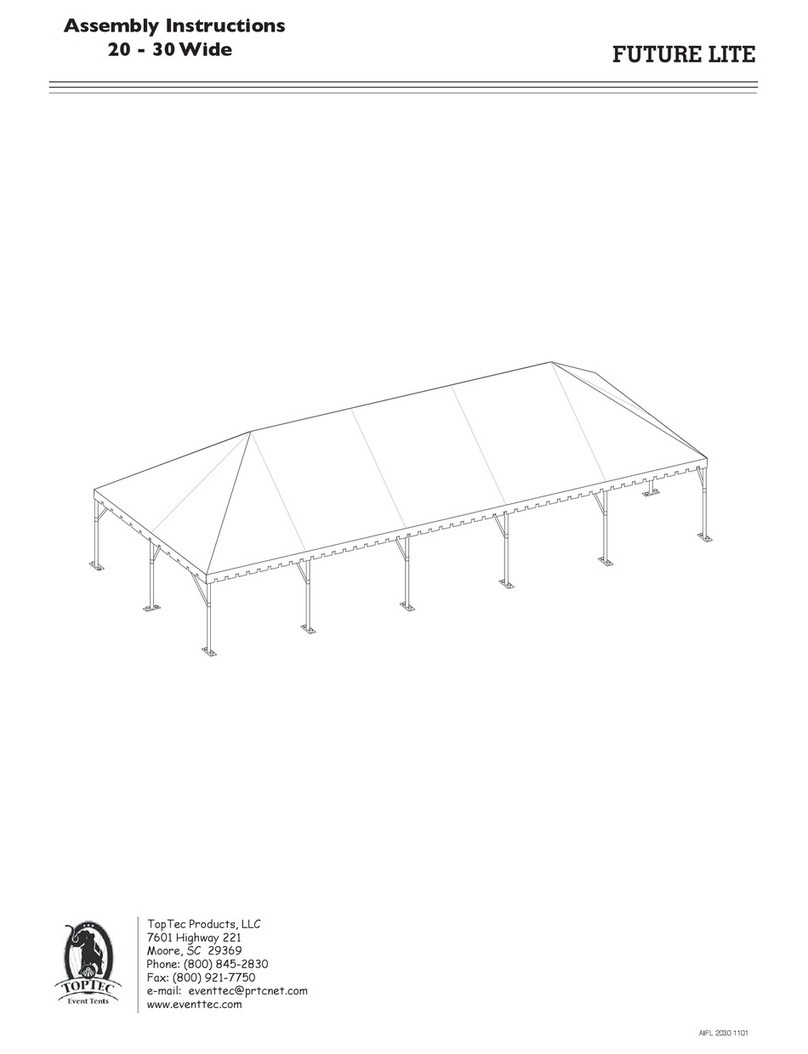

View of completed frame, sitting on the ground, prior to

installation of tent tops or raising the frame onto it's legs.

D-CLASP PIN

Step 25

Step 26

Note: Leg brace bars have been

installed to reduce ladder work

during the nal installation process.

Check all connections and fittings to be sure that the frame is ready to raise or to receive the tent top. All quick pins and D-

Clasp pins must be facing the same direction to prevent the fabric from catching on the pins when pulling the tops onto the

frame assembly.

( 9 ) AIFT 30/40

Assembly Instructions

30 - 40Wide

font: Geo Slabserif

Form # 20011001

Top Panel Installation

Preparation is important. Layout ground covers at eave line of tent to protect the fabric and keep it from becoming soiled in

the installation process. Prior to installing the top panels, be sure to check all connections and fittings to ensure that the frame

is ready to receive the top. All quick pins and D-Clasp pins must be facing the same direction to ensure that when the top

panels are installed, they will not catch on the pins.

Place the tent top panel on the ground cover and roll out along the length of the tent frame section. Place pull ropes over the

top of the frame and tie loose end to the frame (to prevent the rope from pulling off the frame). Connect the carabiners to the

web loops on the end of the Keder edge of the top (see illustration below). Two (2) people working as a team will man the

ropes on the loose end, while two (2) other people guide the top panels into the "Keder" track in the rafter tube.

A ssem bly I nstr uctions

30 - 40 W ide

KEDER RAIL

VINYL TOP

Tip: Always rebuckle (as shown) the buckle

straps on the leading edge of the top panel. This

will greatly reduce the chance of the buckles

getting caught in the ridge rafters as the tops are

being installed.

Standing out approximately four (4) feet from the frame, use the pull ropes and begin pulling the tops slowly and evenly over

the crown and down to the other eave.

Caution! If top panels catch, stop and back the top out. Check

Keder tracks and connectors, then pull again.

As soon as the panel is pulled into place, fasten the eave straps at the

perimeter. Note: If this connection is not made, the wind could cause

the panel to slide out of the frame.

Repeat this procedure for the remaining panels and when all panels are in place, connect just enough straps to hold them in

place. Before raising the frame, connect a ratchet strap to the webbing loop on each panel connection on the perimeter line

and the corner. Note: Tops can be installed in the same manner with frame already raised and the legs installed.

( 10 )

AIFT 30/40

Form # 20011001

Lifting Frame

Preparation is important at this time. Install anchoring points prior to raising the tent. At a minimum, install one anchor point

at each corner of the tent. Drive a stake out about four (4) feet from the frame location and attach a tie down strap or rope

between the frame and the stake. Pre-assemble legs to base plates and distribute to needed points prior to raising the tent.

A ssem bly I nstr uctions

30 - 40 W ide

Place jacks at or near connection points (as shown). Put slings around the perimeter eave tubes and operate winch until the

slack is taken up on all jacks. One jack per section is required.

Caution! Wind conditions can and will lift the entire tent. Proceed with

extreme caution and always lift with the top surface in the wind stream.

RATCHET STRAPS

BRACE BAR

BASE PLATE

LIFT

LIFT

LIFT

Working as a team, crank jacks to raise the tent side evenly and lift frame until it is above leg height, then install the leg with

base plates to the eave fitting and pin immediately with a 3/8" D-Clasp pin. Attach brace bar from rafter to leg (as shown

below), then lower tent jackslowly until the full weight of the tent is on its legs. Fasten top tie to leg bases (as shown).

Leg Installation

Installation of leg brace (prior to lowering jack). Fasten top tie-downs to leg

( 11 ) AIFT 30/40

Form # 20011001

A ssem bly Instr uctions

30 - 40 W ide

Caution! If Keder sidewalls are to be installed, it is necessary that all legs are

straight and in alignment along the side of the tent. Legs must be spaced evenly

apart to allow for installation of these sidewalls. To assure proper alignment, a

tape measure must be used.

Note: Corner brace connector slides over the perimeter tube with

opening facing toward the crown. Place bolt from the top side down

and tighten after locating and aligning with the leg assembly. Leg

brace bar may be installed on either side of the corner leg. Location

will be determined by site conditions as to the proper direction.

Important At This Point! With the first side raised, connect as

many of the perimeter buckles as possible to keep the top from

pulling out during the final assembly process.

Loosen slings and lower the tent jacks. Move all jacks to the opposite side of the tent and place jacks at or near corners and

connection points. Place the slings around the perimeter tubes and operate winch until slack is taken up on all the jacks.

Working as a team, raise the tent until the legs can be slipped on. Immediately pin legs with a 3/8" D-Clasp pin and install

the leg to rafter braces (leg brace bars). Lower jacks to set the tent onto its legs. Remove slings and place jacks in delivery

truck.

Install legs into the end of the tent. Starting with the leg inside of

the tent at an angle (as shown), push up and out until the leg slips

onto the connector. Pin leg in typical manner and install the leg

brace bar. Finish connecting all the perimeter buckles. When

tensioning buckle straps, pull until the sidewall rope appears at the

bottom of the perimeter tube. The final goal is to have the top

evenly and squarely affixed to the frame. Be sure that all tie down

tension straps are in place at the seams and corners.

The tent must be anchored properly for safe tent installation. On 30

and 40 ft tents, two (2) each 1" x 40" double head stakes per base

plate are recommended. Additonal guys and stakes may be required

depending on soil and/or wind conditions.

* In cases such as tents anchored ot concrete or other situations that

deem staking unreasonable, it is permissible to anchor with a concrete

anchor that is capable of equivalent holding power.

BASE PLATE

DOUBLE-HEADED

STA KE

( 12 )

AIFT 30/40

font: Geo Slabserif

Form # 20011001

A ssem bly I nstr uctions

30 - 40 W ide

Top Panel Tensioning

Once all legs have been anchored properly, it is time to tension the top using the

ratchet straps. Begin the tensioning process on the eave line (where the end section

and the mid section meet) on one side of the tent. Using ratchet, tighten tops until the

Keder is just beginning to show outside of the Keder rafter. Both Keders should be

fairly even. If not, it will be necessary to loosen and retighten the buckle bands

accordingly to straighten out the top panel. Repeat this procedure on the opposite

side, then at each mid section until the top is tensioned. Next, move to the end leg

(middle leg) and tighten top until it is snug. The final step will be the corners. Use

caution at this location as the tightening process is just enough to allow the curtain

rope to be pulled down over the corner. Fold all straps into ratchet cover and Velcro

over to give a finished look.

Installed Tent Inspection

1. Staking - Check all stakes for signs of movement.

2. Tensioning - Check all ropes for proper tension and make sure that the tent top is set for proper drainage.

3. Poles - Check that all poles are properly aligned, securely tied and structurally sound.

4. Sidewalls - Check that they are properly secured as needed.

5. Special Considerations - Make sure that the installation is in compliance with all local building, fire and public safety

codes.

During inclement weather, particularly when the tent is in use, experienced

tent personnel should be present to ensure the security of the equipment and

those using it. All parties must be aware of the limitations for safe occupancy

of the tent. The tent renter must retain the right to declare the tent for unsafe

occupancy. Always follow manufacturer's instructions and warnings as they

take precedence over any conflicting information contained in this manual.

RATCHET STRAPS

BRACE BAR

BASE PLATE

( 13 ) AIFT 30/40

Form # 20011001

Assembly Instructions

30 - 40 Wide

Top Removal and Folding

To remove the top panels, unbuckle all buckles, disconnect the ratchet straps, check all pins and clips to ensure that they will

not cut or snag the top panels. Always remove the top panels in the same direction as the installation process.

Tip # 1 Always re-buckle (as shown) the buckle straps on the trailing

edge of the top panel. This will greatly reduce the chance of the

buckles getting caught in the ridge rafters as the tops are being

removed.

Tip # 2 Fold valance back on top panel leading edge. This will ensure that the curtain rope is not caught on the quick pins.

Tip # 3 Always use ground covers when removing top panels. This will prevent the tops from becoming soiled during the

removal process.

Stand back away from the tent (approximately four feet),

then grab the top panel and pull it towards you as shown

in the diagram. Pull gently but firmly on the top panel.

Pull panel sufficiently to allow a three to four foot overlap

to accordion fold the top. Continue this process until the

top panel is folded. Roll top panel and place in storage

bag. Continue this process until the remaining panels

have been removed.

Tip # 4 Pulling gently, but firmly will lay the top down in a manageable fashion. If it is pulled too hard, it will fall quickly

off the frame and prevent you from getting a nice smooth, even fold.

DROP CLOTH

ACCORDION

FOLDED TOP

GROUND COVER

( 14 )

AIFT 30/40

Form # 20011001

A ssem bly I nstr uctions

30 - 40 W ide

Caution! Safety first when lowering frames. Make sure that all loose

objects are out of the work area. Maintain control of the jacks by keeping a

firm grip on the crank handles.

Lowering Frame

Prepare to lower the frame using jacks placed about one (1) foot away from the frame. Place all jacks at or near all corner

connections or intermediate connections. Remove the legs from the center of the end frame first, then, reverse the installation

process to lower frames to the ground. Lower one side at a time and start disassembly of the frame starting at one end and

working towards the other.

Disassemble Frame

Tip # 5 Frame disassembly will be faster and easier if you start at one of the corners after removal of the hip pole brace bars

(40 wide only). Remove quick pins from the perimeter poles and hip poles first.

Remove hip pole lower halves and connectors first, then remove perimeter poles to the first arch assembly. The next step is to

remove quick pins on perimeter poles to the next arch assembly, then with sufficient personnel use a ladder to remove ridge

rafter from the second arch assembly. Move backward until it clears the crown cluster. then lower ridge rafter to the ground.

Once off the ladder and it is move out of the way, pick up ridge rafter and lower arch slowly to the ground. Remove poles and

cables as in the installation process. Repeat this procedure with the remaining sections.

Note: The disassembly process is a reversal of the installation process.

( 15 ) AIFT 30/40

Other manuals for FutureTrac

1

Table of contents

Other Toptec Tent manuals