Toptech MultiLoad III User manual

MultiLoad III / RCU III

Explosion Proof (EX) Hardware

(Loaded with MultiLoad II+ / RCU II+ Firmware)

Installation Guide

MAY 26, 2023

2MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

TOPTECH SYSTEMS

MultiLoadIII/ RCUIII –ExplosionProof(EX)Hardware

InstallationGuide

(LoadedwithMultiLoadII+/RCUII+Firmware)

1124 Florida Central Parkway

Longwood, FL 32750

USA

Phone +1 (407).332.1774

Copyright Notice

Copyright © 2006 - 2023 Toptech Systems, Inc. All Rights Reserved.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be

liable for any claims of damage, lost data, or lost time as a result of using its products.

3MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

EU Declaration of Conformity

The signatory, representing the manufacturer, declares that the products listed below are in conformity with the essential requirements of

the following EC Directive(s) when installed in accordance with the product installation instructions:

2014/32/EU The Measuring Instruments Directive (and its amending directives)

2014/30/EU The Electromagnetic Compatibility Directive (and its amending directives)

2014/34/EU The Potentially Explosive Atmospheres Directive (and its amending directives)

Product: Operator Interface/Process Control Equipment intended for use in potentially explosive

atmospheres

Model name/number: MultiLoad III EX (MID, YES), RCU III EX (MID, NO)

Protective Systems: Flameproof ‘d’, Intrinsic Safety ‘ib’

Notified Body(ies)

Det Norske Veritas Certification AS, Number 0575

NMi Certin B.V., Number 0122

Veritasveien 1

Hugo de Grootplein 1

1322 Høvik, Norway

3314 EG Dordrecht

The Netherlands

Conformity has been demonstrated with reference to the following documentation:

EC type-examination certificate : Presafe 17 ATEX 9557X

IECEx CoC : IECEx PRE 17.0013X

EC type-examination certificate : TC7311

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

WELMEC guide 8.8 General and Administrative Aspects of the Voluntary System of Modular Evaluation of Measuring

instruments under MID

OIML R117-1:2007(E) Dynamic measuring systems for liquids other than water

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

EN 60079-0: 2012 Electrical apparatus for explosive gas atmospheres—General requirements

EN 60079-1: 2014 Electrical apparatus for explosive gas atmospheres—Flameproof enclosures ‘d’

EN 60079-11: 2012 Electrical apparatus for potentially explosive atmospheres—Intrinsic safety ‘i’

Year of CE Marking: 2023

Name: William J. Porthouse Position: Director of Engineering & Production Date: June 2023

Name Plate

4MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

TableofContents

OVERVIEW..................................................................................................................................... 8

CHAPTER 1 GENERAL INFORMATION & WARNINGS ........................................................ 10

Receiving and/or Returning Equipment ........................................................................................... 10

Safety Warnings.................................................................................................................................. 11

Electrostatic Discharge (ESD) Protection ........................................................................................ 13

FCC Note.............................................................................................................................................. 13

CHAPTER 2 OPERATING CONDITIONS AND COMPONENTS............................................. 14

Product Outline and Dimensions ...................................................................................................... 14

MultiLoad III/RCU III EX Hardware Picture................................................................................... 14

MultiLoad III/RCU III EX Hardware Dimensions ........................................................................... 15

2.1.2.1 Front View ..................................................................................................................................... 15

2.1.2.2 Back View...................................................................................................................................... 16

2.1.2.3 Bottom View.................................................................................................................................. 17

2.1.2.4 Top View ....................................................................................................................................... 18

2.1.2.5 Left Side View ............................................................................................................................... 19

2.1.2.6 Right Side View............................................................................................................................. 20

Operating Characteristics .................................................................................................................. 21

CHAPTER 3 INSTALLING THE MULTILOAD III/RCUIII EX HARDWARE ........................ 22

Tools Required.................................................................................................................................... 22

Installation..................................................................................................................................... 22

Servicing and Repair..................................................................................................................... 22

Cover Closure and Bolt Replacement............................................................................................... 22

Cable Entries ....................................................................................................................................... 23

Mounting the MultiLoad III/RCU III EX Hardware Enclosure........................................................... 23

Metal Plate or Rail......................................................................................................................... 23

Wood............................................................................................................................................. 23

Concrete or Cinder Block Walls .................................................................................................... 23

Mounting Height Considerations................................................................................................... 23

Recommended Wire Sizes and Torque for All Terminal Blocks .................................................... 25

Electrical Supply Connections .......................................................................................................... 25

Cable Gland Entries...................................................................................................................... 25

Mains Supply Connection ............................................................................................................. 26

Equipment Grounding ................................................................................................................... 26

5MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Equipment Battery......................................................................................................................... 27

CHAPTER 4 DATA COMMUNICATIONS INTERFACE ........................................................... 28

Available Communications Protocol Selection and Wire Spec ..................................................... 29

Ethernet......................................................................................................................................... 29

RS-422/485................................................................................................................................... 29

RS-232.......................................................................................................................................... 30

Communication Connection Wiring.................................................................................................. 31

Ethernet –Host/TMS Communications......................................................................................... 31

Serial FCM I/ FCM II Communications, COM 0, RS485............................................................... 32

Serial Host/TMS Communications ................................................................................................ 33

4.2.3.1 COM 1 - RS-485 4-wire - Host/TMS Communications ................................................................. 33

4.2.3.2 COM 1 - RS-485 2-wire - Host/TMS Communications ................................................................. 34

4.2.3.3 COM 1 - RS-232 - Host/TMS Communications ............................................................................ 35

Host Ticket Printer/Data Logger.................................................................................................... 35

4.2.4.1 COM3 –RS232 - Host Ticket Printer/Data Logger....................................................................... 36

4.2.4.2 COM3 –RS232 –PTB Protocol Host Ticket Printer/Data Logger................................................ 37

CHAPTER 5 CONNECTING FIELD DEVICES TO INTERNAL FCMS..................................... 38

CHAPTER 6 CONFIGURATIONS ............................................................................................ 39

Weights and Measures Switch Access Control............................................................................... 39

External Switch Access Control (MultiLoad III Hardware Only).................................................... 39

Field Switch Access Control.......................................................................................................... 40

Keypad ................................................................................................................................................. 41

Menus and Screens ............................................................................................................................ 41

Field Modification and Data Entry..................................................................................................... 42

MultiLoad II+/RCU II+ Firmware Preliminary Configuration............................................................ 44

Verifying Communications with FCMs. ............................................................................................ 48

Using I/O Diagnostics......................................................................................................................... 50

CHAPTER 7 SERVICE AND REPAIR....................................................................................... 51

Overview and Subassemblies............................................................................................................ 51

Main Board Replacement ................................................................................................................... 53

Display Subassembly Replacement.................................................................................................. 54

Keypad Barrier Replacement............................................................................................................. 57

Card Reader Replacement ................................................................................................................. 58

6MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

FCM Power Supply Replacement ...................................................................................................... 59

Keypad Replacement.......................................................................................................................... 60

Mounting Feet Installation.................................................................................................................. 62

Cover Replacement............................................................................................................................. 63

Overview Parts List and Part Numbers............................................................................................. 66

CHAPTER 8 REVISION HISTORY .......................................................................................... 67

Hardware Revision.............................................................................................................................. 67

Manual Revision.................................................................................................................................. 67

7MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

TableofFigures

FIGURE 2.1 MULTILOAD III/RCU III EX HARDWARE 14

FIGURE 2.2 UNIT OUTLINE DRAWING –FRONT VIEW 15

FIGURE 2.3 UNIT OUTLINE DRAWING –BACK VIEW 16

FIGURE 2.4 UNIT OUTLINE DRAWING –BOTTOM VIEW 17

FIGURE 2.5 UNIT OUTLINE DRAWING –LEFT SIDE VIEW 19

FIGURE 2.6 UNIT OUTLINE DRAWING –RIGHT SIDE VIEW 20

FIGURE 3.1 SUGGESTED MOUNTING POSITION 24

FIGURE 3.2 SCREEN VISIBLE AREA 24

FIGURE 3.3 MULTILOAD III/RCU III EX HARDWARE MAIN BOARD POWER CONNECTOR (TB1) 26

FIGURE 3.4 MULTILOAD III/RCU III EX HARDWARE MAIN BOARD BATTERY (BT1) 27

FIGURE 4.1 MULTILOAD III/RCU III EX HARDWARE MAIN BOARD COMMUNICATION CONNECTORS 28

FIGURE 4.2 ETHERNET CONNECTIONS 31

FIGURE 4.3 FCM CONNECTIONS 32

FIGURE 4.4 RS485 4-WIRE, HOST TO A SINGLE MULTILOAD III/RCU III EX HARDWARE (RECOMMENDED) 33

FIGURE 4.5 RS485 4-WIRE, HOST TO MULTIPLE MULTILOAD III/RCU III EX HARDWARE UNITS 33

FIGURE 4.6 RS485 2-WIRE, HOST TO A SINGLE MULTILOAD III/RCU III EX HARDWARE UNIT 34

FIGURE 4.7 RS485 4-WIRE, HOST TO MULTIPLE MULTILOAD III/RCU III EX HARDWARE UNITS 34

FIGURE 4.8 RS232, HOST TO A SINGLE MULTILOAD III/RCU III EX HARDWARE UNIT 35

FIGURE 4.9 RS232, HOST TO MULTIPLE MULTILOAD III/RCU III EX HARDWARE UNITS 35

FIGURE 4.10 TICKET PRINTER / DATA LOGGER CONNECTIONS WITH HANDSHAKE 36

FIGURE 4.11 TICKET PRINTER / DATA LOGGER CONNECTIONS WITHOUT HANDSHAKE 36

FIGURE 4.12 PTB PRINTER CONNECTION WITH HANDSHAKE 37

FIGURE 4.13 PTB PRINTER CONFIGURATION 37

FIGURE 6.1 W&M BOLT SWITCH 40

FIGURE 7.1 MULTILOAD III / RCU III EX HARDWARE UNIT 51

FIGURE 7.2 SUBASSEMBLY IDENTIFICATION 52

FIGURE 7.3 MAIN BOARD ASSEMBLY REMOVAL 53

FIGURE 7.4 DISPLAY ASSEMBLY REMOVED FROM THE MOUNTING BRACKET 55

FIGURE 7.5 REMOVAL OF KEYPAD BARRIER 57

FIGURE 7.6 EXPLODED VIEW OF CARD READER 58

FIGURE 7.7 REMOVAL OF FCM POWER SUPPLY 59

FIGURE 7.8 KEYPAD ASSEMBLY INSTALLATION PREP 61

FIGURE 7.9 MOUNTING FEET ASSEMBLY 62

FIGURE 7.10 DISCONNECT DISPLAY AND KEYPAD CABLES 63

FIGURE 7.11 INSTALL TOP RIGHT SCREW AND REMOVE LOWER HINGE KNUCKLE. 64

FIGURE 7.12 REMOVE TOP RIGHT SCREW AND LIFT COVER OFF. 65

8MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Overview

This document is designed to guide individuals installing MultiLoad III/RCU III EX Hardware equipment,

engineering firms developing site electrical drawings, and users troubleshooting system operations such as

managers, system administrators, technicians, andmeter proving personnel.

The following table provides an informative summary of the material available in this guide:

Chapter

Topics Covered

1.General Information and Warnings

This chapter reviews safety and compliance information, as well as

instructions for receiving and returning products.

2.Operating Conditions & Components

This chapter covers product outlineand dimensions, as well as

operating characteristics of the unit.

3.Installing the MultiLoad III/RCU III EX

Hardware

This chapter covers installation considerations and instructions for

the MultiLoad III/RCU III EX Hardware.

4.Data Communication Interface

This chapter reviews hardware connections andcommunication

processes.

5.Connecting Field Devices to the

Internal I/O Board

This chapter covers the available I/O points per board, the

terminal arrangements per board, and then describes in detail

how to connect different field devices to the internal I/O Board.

6. Configurations

This chapter describes how to navigate the system, select field

values, perform data entry, and toggle options on and off.

7. Service and Repair

This chapter describes how to service and repair the MultiLoad

III/ RCU III EX Hardware subassemblies and parts.

8. Hardware Revision History &

Compatibility

This chapter provides changes, modifications,and updates to the

hardware.

9. Revision History

This chapter provides further hardware revisions as well as revisions

made to this document.

9MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

The following keys allow the user to locate information needed in this guide:

ICON KEY

Important information to enhance understanding and make better use of the product.

Indicates potential damage to hardware or loss of data.

Potential for property damage or that personal injury may occur. Pay close attention and

follow instructions when this symbol is displayed.

Typographical Conventions:

Boldface: Indicates what is pressed on the keypad. Example: Key in 00000.

Italics: Emphasizes a key product or industry term.

Example: the display features a pick-list style of item selection.

This guide covers RCU III/MultiLoad III EX Hardware installation information only. For information about

base MultiLoad firmware, please consult the MultiLoad II+ Firmware User Guide. For information about base

RCU firmware, please consult the RCU II+ Firmware User Guide. For information about wiring other models,

please consult the respective installation guides. For information about the MultiLoad register interface and

Modbus communication, please reference the MultiLoad II Communication Guide. Updated versions of all

manuals, including this one, are available on our website at http://www.toptech.com.

CHAPTER 1–GENERAL INFORMATION & WARNINGS

10 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Chapter 1 General Information & Warnings

Receiving and/or Returning Equipment

At receipt, the MultiLoad III/ RCU III EX Hardware should be immediately inspected after opening the

packaging case. If any damage is visible, notify the carrier at once to establish liability.

Contact Toptech’s Return Materials Department to initiate timely repair or replacement of the unit.

A Return Materials Authorization (RMA) will be for the purpose of returning the product or parts

requiring repair. Do not return any material to Toptech without an RMA.

Contact Information for Americas:

Return Materials Department

Toptech Systems, Inc.

1124 Florida Central Pkwy

Longwood, FL 32750 USA

+1 (407) 332-1774

Contact Information for EMEA and Asia:

Return Materials Department

Toptech System NVs

Nieuwe weg 1- haven 1053

2070 Zwijndrecht, BELGIUM

+32 (0)3 250 60 60

Chapter

1

CHAPTER 1–GENERAL INFORMATION & WARNINGS

11 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Safety Warnings

NORTH AMERICAN INSTALLATIONS:

▲This equipment is suitable for use in Class I, Division 1, Groups C and D locations, OR non-

hazardous locations.

▲WARNING: TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES,

conduit runs must have a sealing fitting connected within 18 inches of the enclosure.

▲WARNING: TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES,

disconnect from the supply circuit before opening enclosure. Keep tightly closed when

circuits are live.

▲WARNING: Substitution of components may impair intrinsic safety.

▲WARNING: Do not open when an explosive gas atmosphere is present.

▲WARNING: All unused conduit entries must be sealed with a conduit plug which

satisfies the flameproof “d” method of protection.

▲CAUTION: Battery may explode if mistreated. DO NOT RECHARGE, DISASSEMBLE, OR

DISPOSE OF IN FIRE.

▲CAUTION: Field wiring must have a temperature rating of +75 °C or greater. Use copper

wire only.

▲Consult installation manual for required cable entry size and thread.

▲A battery is installed into the main board for retention of time and date only. This battery should

last more than ten years. This battery can be replaced by the end user but must be

replaced with Matsushita Electric, model BR2032 only. Use of another battery may

present a risk of fire or explosion.

▲The installation of this product must be in conformity with NFPA 70 (US National Electric Code)

or CSA C22.1 (Canadian Electrical Code) as appropriate.

INSTALLATIONS NORD-AMÉRICAINES (FRANÇAIS)

▲Cet équipement est compatible pour une installation en Classe I, Division 1, Groupes C & D ou

les emplacements non dangereux.

▲AVERTISSEMENT: RISQUE D'EXPLOSION Les scellements des conduits doit être

installé à moins de 18 pouces du boîtier.

▲AVERTISSEMENT: RISQUE D'EXPLOSION Couper le courant avant d'enlever le

couvercle. Garder le couvercle bien fermé tant que les circuits sont sous tension.

▲AVERTISSEMENT: La substitution de composants peut compromettre la sécurité

intrinsèque.

▲AVERTISSEMENT: Ne pas ouvrir si une atmosphère explosive peut être présente.

▲AVERTISSEMENT: Toutes les entrées du boîtier inutilisées doivent être scellées avec un

bouchon de conduit.

▲PRUDENCE: La pile peut exploser si elle est maltraitée. NE PAS RECHARGER, NE PAS

DÉMONTER, ET NE PAS JETER DANS LE FEU.

▲PRUDENCE: Câblage de terrain doit avoir un classement de température de +75 °C ou

plus. Utilisez uniquement du fil de cuivre.

▲Consultez le manuel d'installation pour le filetage de forme et la taille du presse-étoupe.

Suite à la page suivante

CHAPTER 1–GENERAL INFORMATION & WARNINGS

12 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

INSTALLATIONS NORD-AMÉRICAINES (FRANÇAIS, suite de la page précédente)

▲Une batterie est installée dans la carte principale pour la conservation de l'heure et de la date

uniquement. Cette batterie devrait durer plus de dix ans. Cette batterie peut être remplacée

par l'utilisateur final mais doit être remplacée par Matsushita Electric, modèle BR2032

uniquement. L'utilisation d'une autre batterie peut présenter un risque d'incendie ou

d'explosion.

▲L’installation de ce produit doit se conformer avec NFPA 70 ou CSA C22.1 comme appropriée.

ATEX AND IECEX INSTALLATIONS:

▲This equipment is suitable for use in Ex Zone I Group IIB locations or non-hazardous locations.

THE LETTER “X” TO THE RIGHT OF THE CERTIFICATE NUMBER INDICATES THE

FOLLOWING SPECIAL CONDITIONS FOR SAFE USE:

▲CERTAIN FLAMEPROOF JOINTS ARE OTHER THAN THE MINIMUM OR MAXIMUM

DIMENSIONS GIVEN IN IEC/EN/BR 60079-1, CLAUSE 5. PLEASE CONSULT TOPTECH

SYSTEMS IF DIMENSIONAL INFORMATION IS REQUIRED.

▲MAXIMUM SPECIFIED GAP OF FLANGE JOINT IS 0.08mm.

▲AMBIENT TEMPERATURE RANGE IS BETWEEN -40°C AND +60°C.

▲CAUTION: COVER BOLTS MUST HAVE A YIELD STRESS OF AT LEAST 700 N/mm².

▲WARNING: TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES,

disconnect from the supply circuit before opening enclosure. Keep tightly closed when

circuits are live.

▲WARNING: Substitution of components may impair intrinsic safety.

▲WARNING: Do not open when an explosive gas atmosphere is present.

▲WARNING: All unused conduit entries must be sealed with a conduit plug which

satisfies the flameproof “d” method of protection. Blanking elements must be removable

with the aid of a tool, ATEX certified, suitable for Gas Group IIB and suitable for an

ambient temperature range of -40 C to +60 C.

▲CAUTION: Battery may explode if mistreated. DO NOT RECHARGE, DISASSEMBLE, OR

DISPOSE OF IN FIRE.

▲CAUTION: Field wiring must have a temperature rating of +75 °C or greater. It must also

have a temperature rating for the lowest expected minimum ambient temperature. Use

copper wire only.

▲Consult installation manual for required cable entry size and thread.

▲A battery is installed into the main board for retention of time and date only. This battery should

last more than ten years. This battery can be replaced by the end user but must be

replaced with Matsushita Electric, model BR2032 only. Use of another battery may

present a risk of fire or explosion.

▲The installation of this product must be in conformity with IEC/EN/BR 60079-14.

CHAPTER 1–GENERAL INFORMATION & WARNINGS

13 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Electrostatic Discharge (ESD) Protection

The MultiLoad III/ RCU III EX Hardware contains electronic components and assemblies subject to

damage by ESD. The MultiLoad III/ RCU III EX Hardware was designed to protect against ESD while

the unit is closed and in normal operation. Proper handling procedures must be observed during the

removal, installation, repair and other handling of printed circuit board assemblies, electronic devices,

and components. This includes:

1) Service to be performed by authorized personnel only.

2) The person performing the service must be grounded by an ESD grounding strap and

connected to ground.

3) While performing maintenance or repair, touch an unpainted metal of the MultiLoad III/RCU

III EX Hardware surface prior to touching or handling any printed circuit boards or electronic

components.

4) Printed circuit board assemblies must be placed in and transported in conductive bags or

other conductive containers.

5) Printed circuit boards must not be removed from the conductive container until time of use.

6) All other “best” practices for protecting devices from ESD must be observed.

FCC Note

This equipment complies with the limits for a Class A Digital Device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the

interference at their expense.

Modifications not approved by the manufacturer could void the user's authority to operate the

equipment under FCC rules.

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

14 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

Chapter 2 Operating Conditions and Components

Product Outline and Dimensions

MultiLoad III/RCU III EX Hardware Picture

Figure 2.1 MultiLoad III/RCU III Ex Hardware

Chapter

2

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

15 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

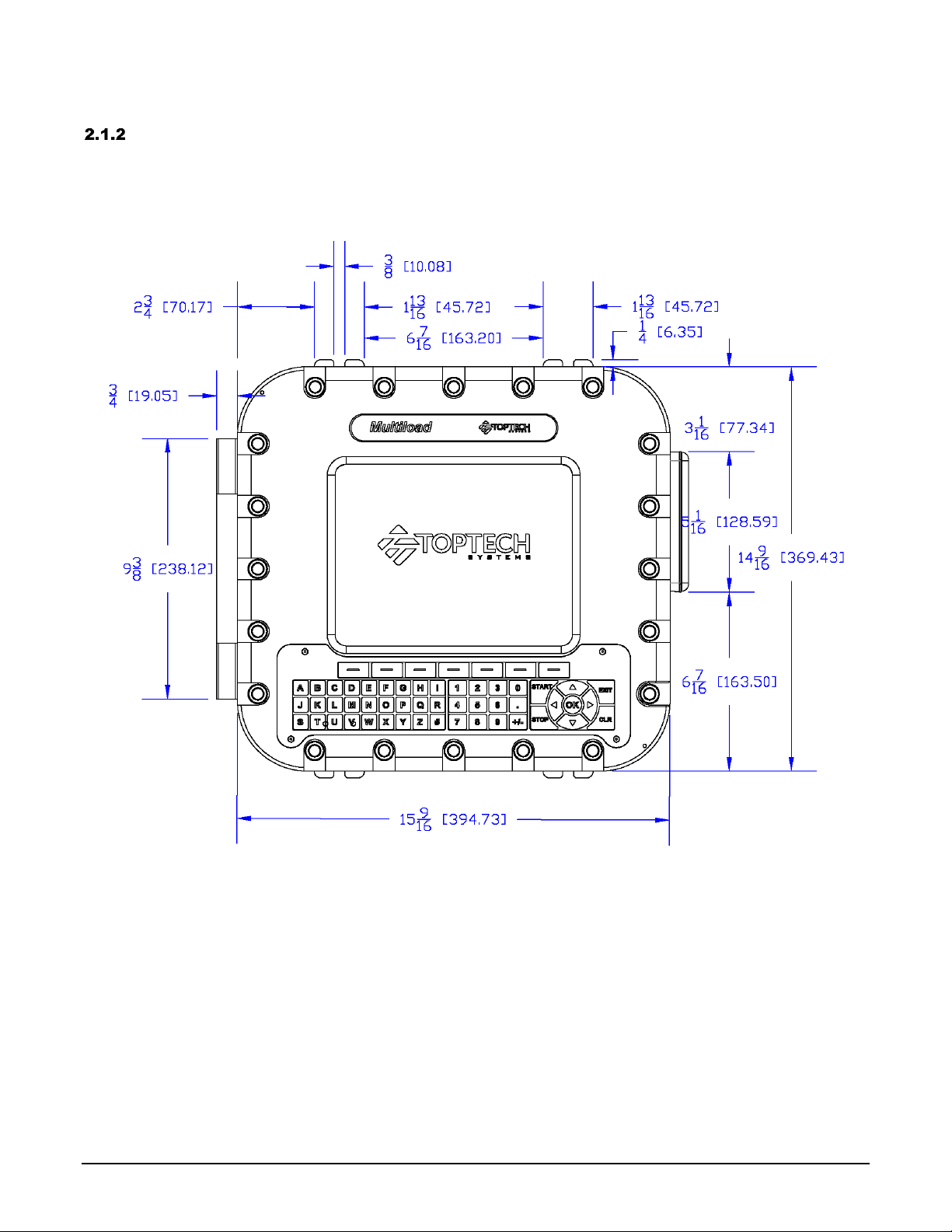

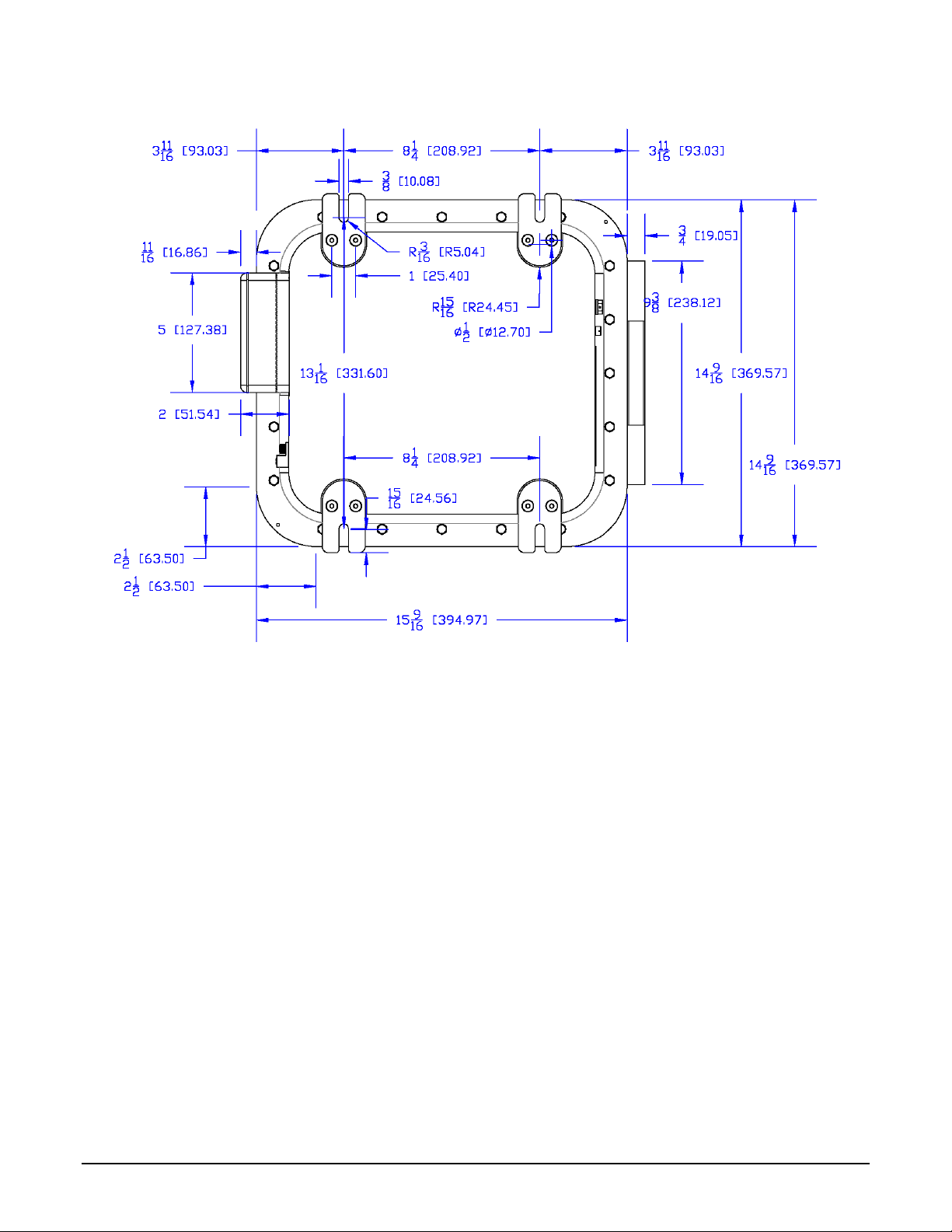

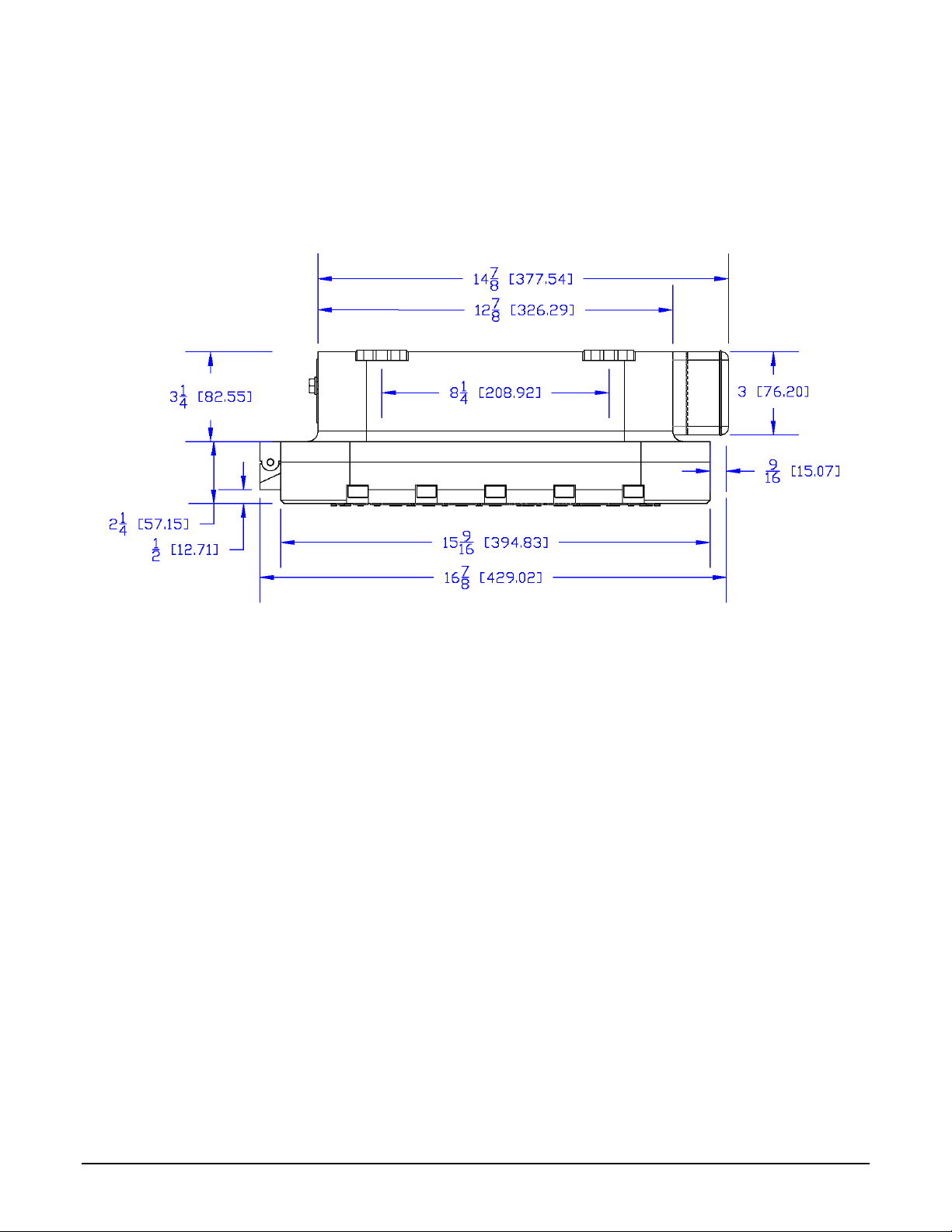

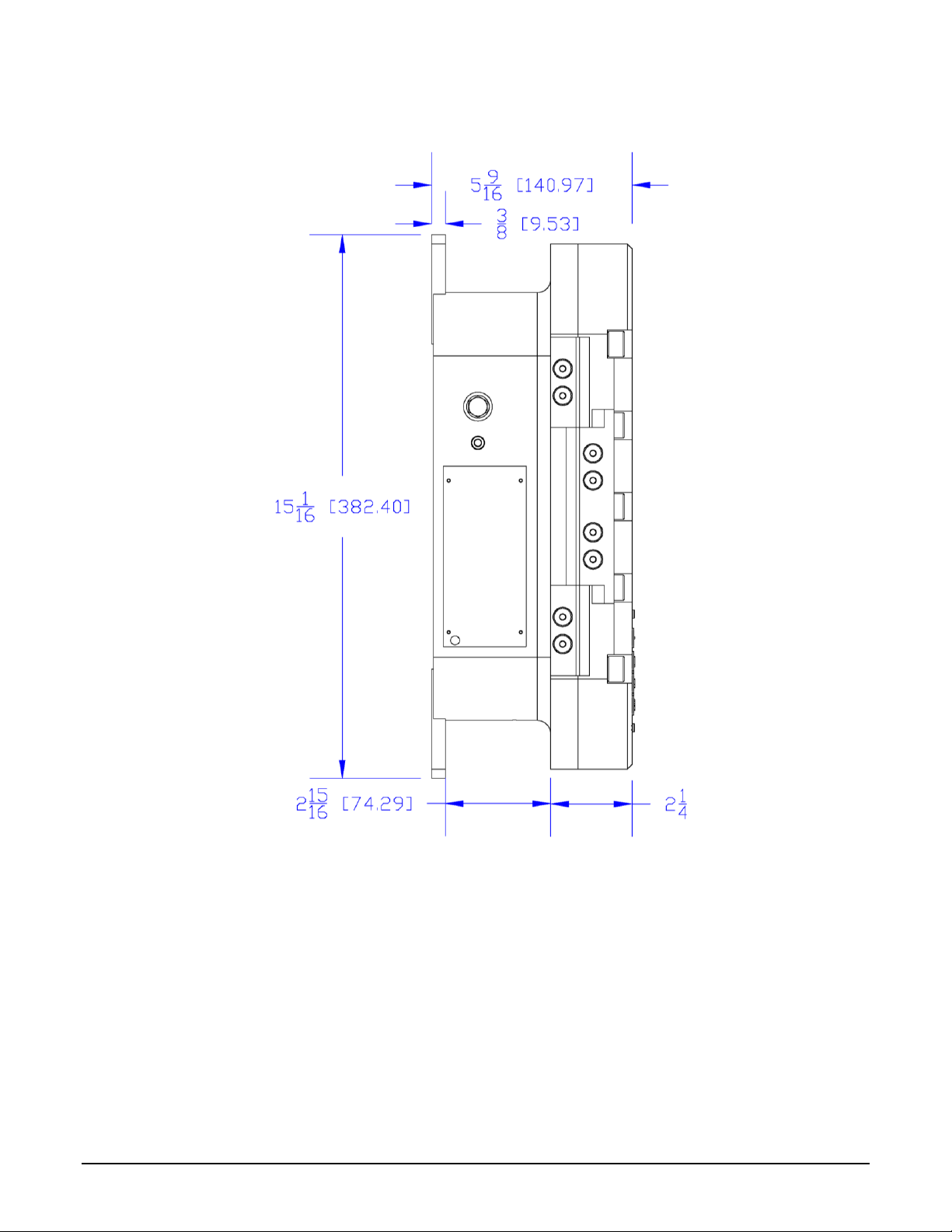

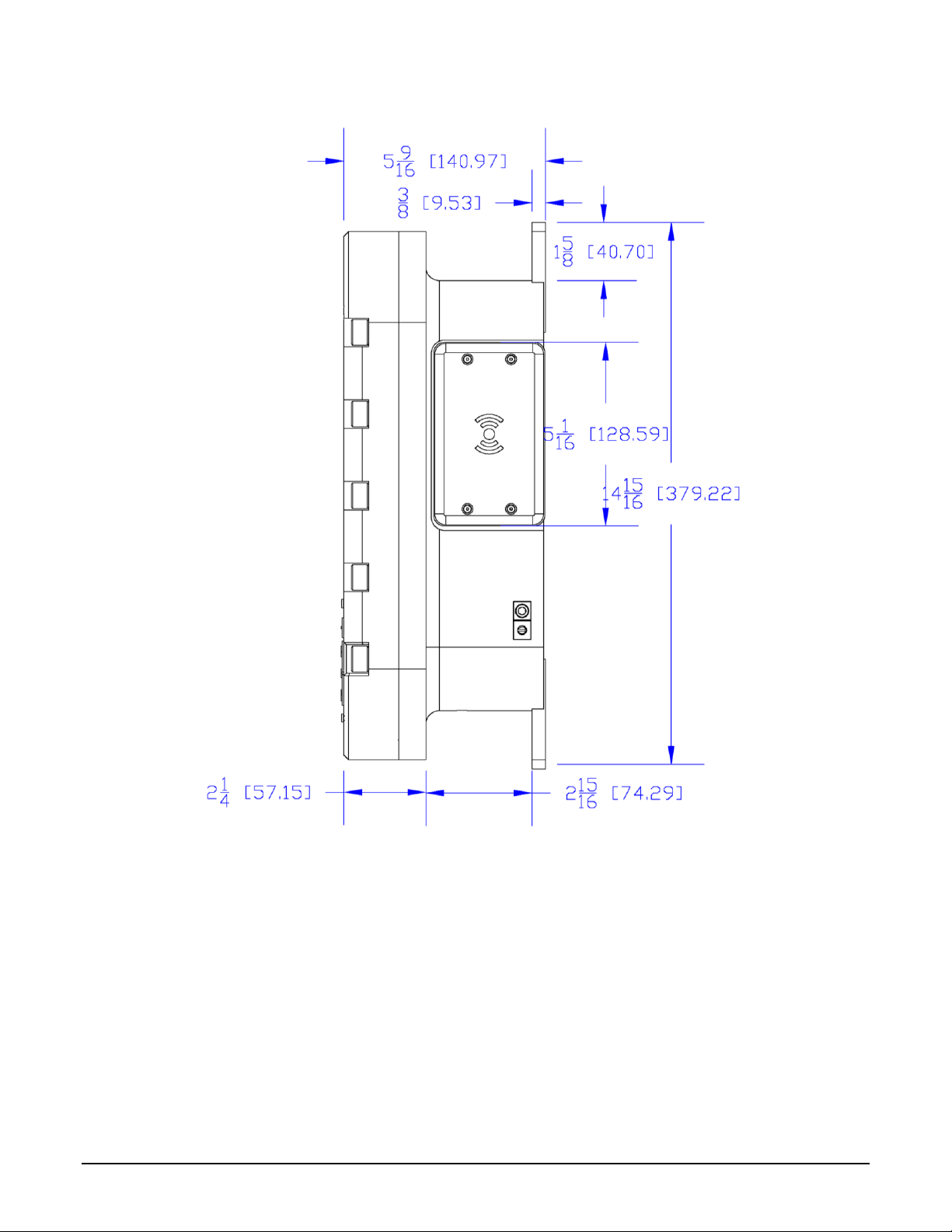

MultiLoad III/RCU III EX Hardware Dimensions

The dimensions in this section are indicated in inches and millimeters (in parenthesis).

2.1.2.1 Front View

Figure 2.2 Unit Outline Drawing –Front View

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

16 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

2.1.2.2 Back View

Figure 2.3 Unit Outline Drawing –Back View

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

17 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

2.1.2.3 Bottom View

Figure 2.4 Unit Outline Drawing –Bottom View

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

18 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

2.1.2.4 Top View

Unit Outline Drawing –Top View

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

19 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

2.1.2.5 Left Side View

Figure 2.5 Unit Outline Drawing –Left Side View

CHAPTER 2–OPERATING CONDITIONS AND COMPONENTS

20 MultiLoad III/RCU III Hardware - Explosion Proof (EX) Installation Guide

2.1.2.6 Right Side View

Figure 2.6 Unit Outline Drawing –Right Side View

Other manuals for MultiLoad III

1

This manual suits for next models

1

Table of contents

Other Toptech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Bosch

Bosch Rexroth MTA 200 Planning Manual

Aerotech

Aerotech PRO190LM Hardware manual

KMT

KMT STREAMLINE SL-V SRP 100 Operation and maintenance manual

Conductix-Wampfler

Conductix-Wampfler Safe-Lec 2 manual

Dustcontrol

Dustcontrol S 11000 EX Translation of the original instructions

LNS

LNS Alpha ST320 S2 instruction manual