Toptech MultiLoad II User manual

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

M

Mo

ob

bi

il

le

e

Installation Guide

Version C

April 6, 2012

2

MultiLoad II Mobile Installation Guide: Version C

Electrical Considerations

!

A battery is soldered to the CPU board and provides nonvolatile data storage and time/date retention. This

battery should last between ten and thirteen years and is a factory replaceable part. This battery must be

replaced with Matsushita Electric, model BR2477A only. Use of another battery may present a risk of fire or

explosion.

!

CAUTION: Battery may explode if mistreated. DO NOT RECHARGE, DISASSEMBLE, OR DISPOSE OF IN FIRE.

Copyright Notice

Copyright © 2006 - 2012 Toptech Systems, Inc.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable

for any claims of damage, lost data, or lost time as a result of using its products.

Toptech

Systems, Inc.

A Unit of IDEX Corporation

logo is a registered trademark of Toptech Systems, Inc.

TMS™, TMS5™, TMS6™, RCU II Remote Control Unit™, Toptech MultiLoad II™, MultiLoad II -RCU™, FCM Flow Control Module™

are trademarks of Toptech Systems, Inc.

Copyright © 2007-2012 Toptech Systems, Inc. All Rights Reserved.

3

MultiLoad II Mobile Installation Guide: Version C

Table of Contents

CHAPTER 1General.......................................................................................................................................... 5

1.1Who Should Use This Guide................................................................................................................... 5

1.2Information Alerts:................................................................................................................................... 5

1.2.1Typographical Conventions:.................................................................................................................. 5

1.2.2Receiving and/or Returning Equipment:................................................................................................ 5

1.3Operating Characteristics:...................................................................................................................... 6

1.4Electrostatic Discharge (ESD) Protection:............................................................................................ 7

1.5Recommended Wire Sizes And Torque For All Terminal Blocks....................................................... 8

CHAPTER 2Installing the MultiLoad II Mobile............................................................................................... 9

2.1Tools Required......................................................................................................................................... 9

2.1.1Installation.............................................................................................................................................. 9

2.1.2Servicing and Repair ............................................................................................................................. 9

2.2Mounting the MultiLoad II Mobile Enclosure........................................................................................ 9

2.3Electrical Supply Connections............................................................................................................... 9

2.3.1Cable Entries......................................................................................................................................... 9

2.3.2Attaching vehicle power....................................................................................................................... 10

CHAPTER 3Data Communications Interface............................................................................................... 11

3.1Communications Protocol Selection and Connection:..................................................................... 12

3.1.1RS-422/485:......................................................................................................................................... 12

3.1.2RS-232................................................................................................................................................. 12

3.1.3Ethernet ............................................................................................................................................... 17

CHAPTER 4I/O Configuration ....................................................................................................................... 18

4.1Mass Meter and Solenoid Valve Connections.................................................................................... 20

4.2MultiLoad II Flow Meter and Control Valve Wiring............................................................................. 21

4.3MultiLoad II RTD Temperature Probe Wiring...................................................................................... 22

4.4MultiLoad II 4-20mA Input Wiring......................................................................................................... 23

4.5MultiLoad II 2 Output Air Eliminator Wiring........................................................................................ 24

CHAPTER 5Modem Configuration................................................................................................................ 25

5.1Accessing The Administrative Interface............................................................................................. 25

5.2Configuring Port Forwarding................................................................................................................ 26

Configuring Trusted Networks ......................................................................................................................... 27

CHAPTER 6MultiLoad Configuration........................................................................................................... 28

6.1Overview................................................................................................................................................. 28

6.2Navigating the System:......................................................................................................................... 28

6.2.1Menus and Screens............................................................................................................................. 28

6.2.2Field Modification and Data Entry........................................................................................................ 29

6.3Network Setup........................................................................................................................................ 31

6.4RCU General Setup................................................................................................................................ 33

6.5Suggested Setup for TDS ..................................................................................................................... 34

6.5.1Network Configuration......................................................................................................................... 34

6.5.2RCU General Configuration................................................................................................................. 35

CHAPTER 7Troubleshooting ........................................................................................................................ 36

7.1Modular Design:..................................................................................................................................... 36

7.1.1Operating the Flat Display Cable Connectors:.................................................................................... 37

7.1.2CPU Subassembly Removal and Replacement:................................................................................. 39

7.1.3Display Subassembly Removal and Replacement:............................................................................. 40

7.1.4Keypad Removal and Replacement:................................................................................................... 40

7.1.5Prox Reader Removal and Replacement:........................................................................................... 40

4

MultiLoad II Mobile Installation Guide: Version C

Table of Figures

Figure 1.1MultiLoad II Terminal Block Recommended Wire Size and Screw Torque....................................... 8

Figure 2.1 MultiLoad II Mobile DC Power Supply/Comm Board....................................................................... 10

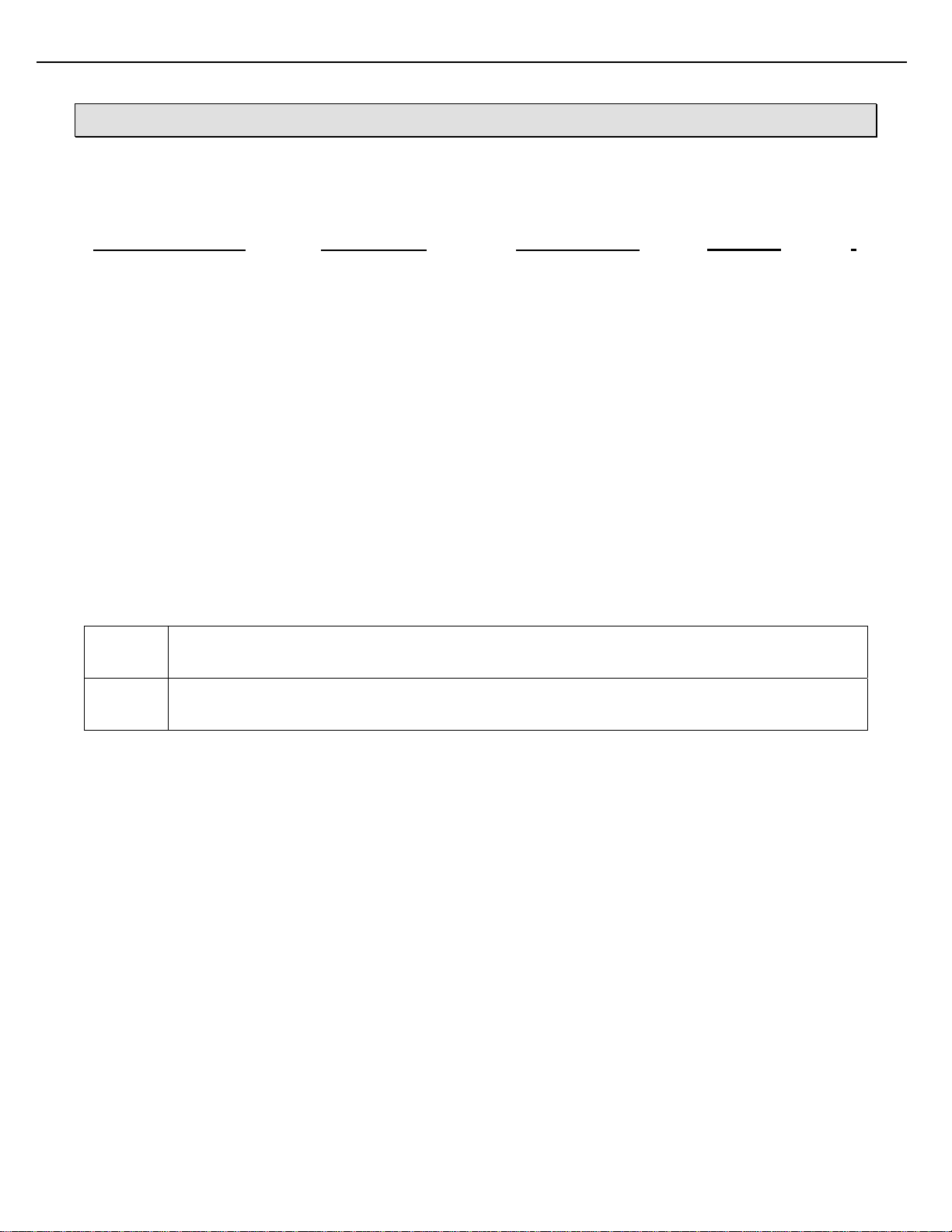

Figure 3.1RS485 4-Wire, Host to a Single MultiLoad II/ RCU II (recommended) ........................................... 13

Figure 3.2RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs..................................................................... 13

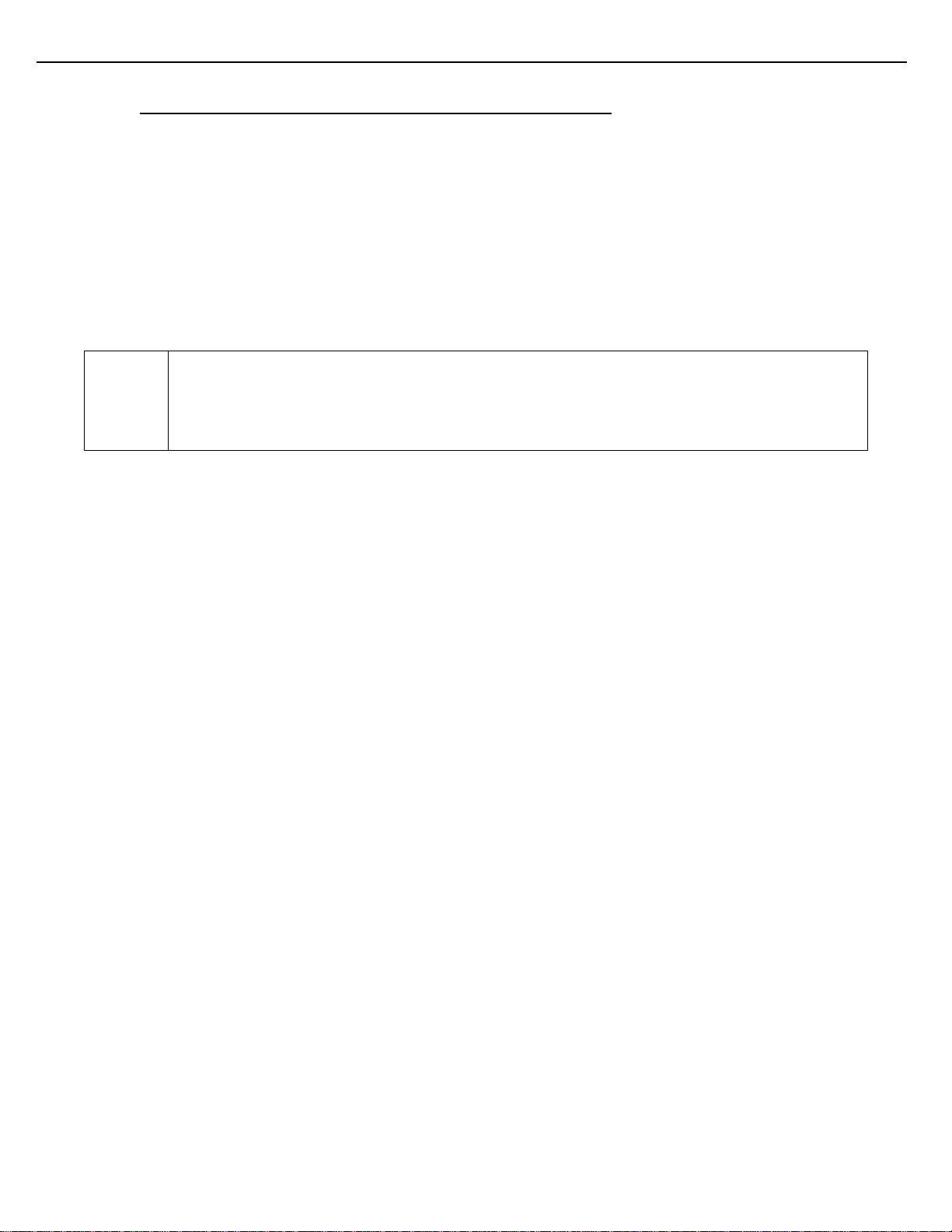

Figure 3.3RS485 2-Wire, Host to a Single MultiLoad II/ RCU II...................................................................... 14

Figure 3.4RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs..................................................................... 14

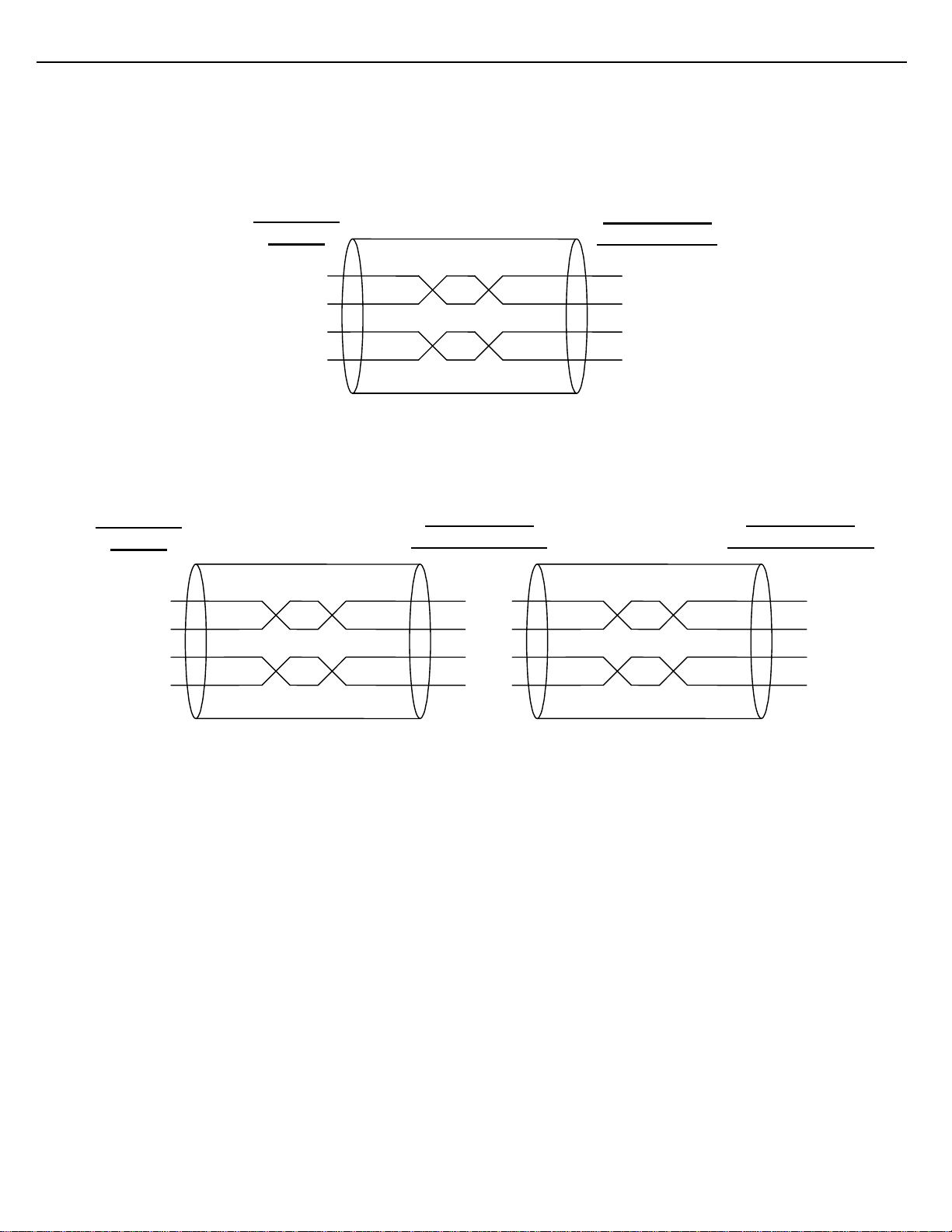

Figure 3.5RS232, Host to a Single MultiLoad II/ RCU II.................................................................................. 15

Figure 3.6RS232, Host to Multiple MultiLoad II/ RCU IIs................................................................................. 15

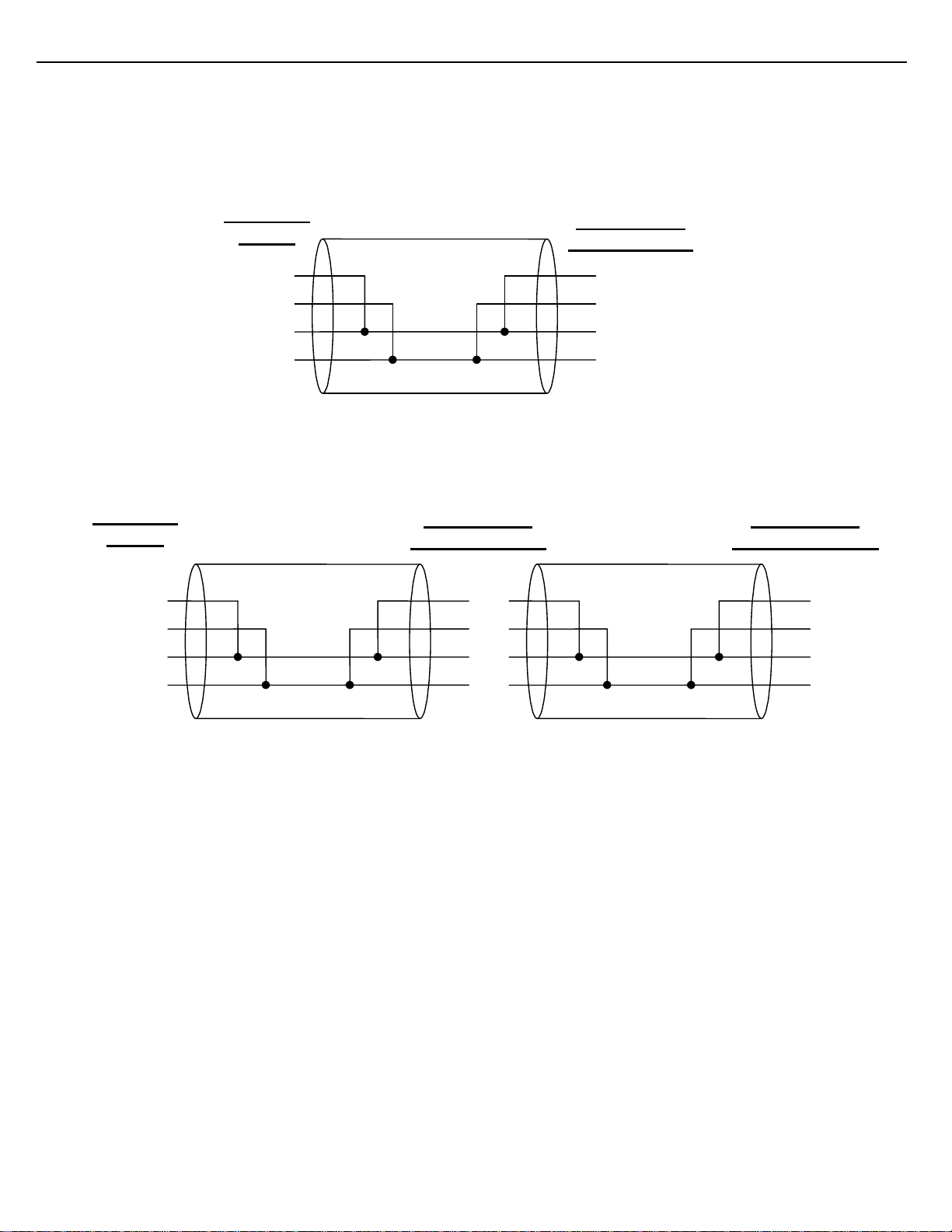

Figure 3.7Ticket Printer / Data Logger Connections with Handshake............................................................. 16

Figure 3.8Ticket Printer / Data Logger Connections without Handshake........................................................ 16

Figure 3.9Ethernet Connections...................................................................................................................... 17

Figure 4.1 I/O Board Terminal Block Assignments........................................................................................... 19

Figure 4.2I/O Board Field Wiring: Flow Meter and Control Valve.................................................................... 20

Figure 4.3MultiLoad II Digital/ Analog I/O Board Field Wiring: Flow Meter and Control Valve........................ 21

Figure 4.4MultiLoad II Digital/ Analog I/O Board Field Wiring: RTD................................................................ 22

Figure 4.5MultiLoad II Digital/ Analog I/O Board Field Wiring: 4-20mA Input.................................................. 23

Figure 4.6MultiLoad II Digital/ Analog I/O Board Field Wiring: 2 Output Air Eliminator................................... 24

Figure 5.1Status screen................................................................................................................................... 25

Figure 5.2Port forwarding configuration........................................................................................................... 26

Figure 5.3Trusted IP range configuration ........................................................................................................ 27

Figure 7-1Cam lock in the Open (Up) position................................................................................................. 37

Figure 7-2Display Cable Insertion.................................................................................................................... 38

Figure 7-3Cam lock in the closed (down) position........................................................................................... 38

Figure 7.4Microprocessor Board...................................................................................................................... 41

Figure 7.5Power Supply Board........................................................................................................................ 41

Figure 7.6I/O Board.......................................................................................................................................... 42

Figure 7.7Power Supply / Comm Board & I/O Board Chassis ........................................................................ 43

Chapter 1 – General 5

MultiLoad II Mobile Installation Guide: Version C

!

CHAPTER 1 GENERAL

1.1 WHO SHOULD USE THIS GUIDE

This guide is intended for individuals installing MultiLoad II equipment, engineering firms developing site electrical

drawings, and users troubleshooting system operation such as managers, system administrators, technicians,

and meter proving personnel.

1.2 INFORMATION ALERTS:

Important information to enhance understanding and make better use of the product.

Indicates potential damage to hardware or loss of data.

Potential for property damage or that personal injury may occur. Pay close attention and follow

instructions when you see this symbol.

1.2.1 TYPOGRAPHICAL CONVENTIONS:

Boldface: Indicates what you are to press on the keypad. Example: Key in 00000.

Italics: Emphasizes a key product or industry term.

Example: the display features a pick list style of item selection.

1.2.2 RECEIVING AND/OR RETURNING EQUIPMENT:

The MultiLoad II should be immediately inspected after opening the packaging case. If any damage is visible

notify the carrier at once to establish liability. Contact Toptech Account Management to initiate timely repair or

replacement of the unit.

Account Management will issue a Return Materials Authorization (RMA) to return the product or parts requiring

repair. Do not return any material to Toptech without an RMA.

Account Management contact information:

Account Management

Toptech Systems

1124 Florida Central Pkwy

Longwood, FL

(407) 332-1774

Prior to installation the MultiLoad II should be stored in its packing case and be protected from damage due to

handling and adverse weather conditions.

Chapter 1 – General 6

MultiLoad II Mobile Installation Guide: Version C

1.3 OPERATING CHARACTERISTICS:

Operating voltage: 9-30Vdc, 1.2A

Operating temperature: -22°F to 140°F (-25°C to 60°C).

with Optional Heater: -40°F to 140°F (-40°C to 60°C).

Enclosure: Type 4

Weight: 24 lbs (11 kg)

Display: Color 5.7” Diagonal VGA

Prox Card Reader: Captive or Non-captive

Optional Lockable External Switches: Program Access, Weights & Measures Parameter Access

Keypad: 47 Key Alpha/ Numeric Capacitive Keypad

Communications:

3 serial ports (1 RS-232, 1 RS-485, 1 User Selectable RS-232 or RS-485)

1 Ethernet port 10/100 Mbps

Internal I/O: The quantity and electrical ratings of the I/O are described in the table below.

TYPE I/O QUANTITY,LOCATION ELECTRICAL RATING

DC Outputs: 7 (TB1, TB2) 0 - 30Vdc, 1.0A (per point)

DC Inputs: 6 (TB6, TB7)

(2 High Speed) 5 – 30Vdc

Dual Channel flow meter inputs (1-5000Hz)

Miscellaneous signal inputs

12Vdc Source: 167mA Max Load (TB5) Isolated Power Supply

Power for flow meter pulsers or preamps

RTD Input: 1 (TB3) 100ohm platinum, four wire

Coefficient 0.00385Ohm/Ohm/°C

Analog Input 1 (TB4 pins 1 &.2) 4 – 20mA, 1.5V maximum burden

Analog Output 1 (TB4 pins 3 - 6) 4 – 20mA, Requires 12Vdc – 30Vdc Supply

Chapter 1 – General 7

MultiLoad II Mobile Installation Guide: Version C

1.4 ELECTROSTATIC DISCHARGE (ESD) PROTECTION:

The MultiLoad II contains electronic components and assemblies subject to damage by ESD. The MultiLoad II

was designed to protect against ESD while the unit is closed and in normal operation. Proper handling

procedures must be observed during the removal, installation, repair and other handling of printed circuit board

assemblies, electronic devices and components to include:

1) Service to be performed by authorized personnel only.

2) The person performing the service must be grounded by an ESD grounding strap and connected to

ground.

3) While performing maintenance or repair, touch an unpainted metal of the MultiLoad II surface prior to

touching or handling any printed circuit boards or electronic components.

4) Printed circuit board assemblies must be placed in and transported in conductive bags or other

conductive containers.

5) Printed circuit boards must not be removed from the conductive container until time of use.

6) All other “best” practices for protecting devices from ESD must be observed.

Chapter 1 – General 8

MultiLoad II Mobile Installation Guide: Version C

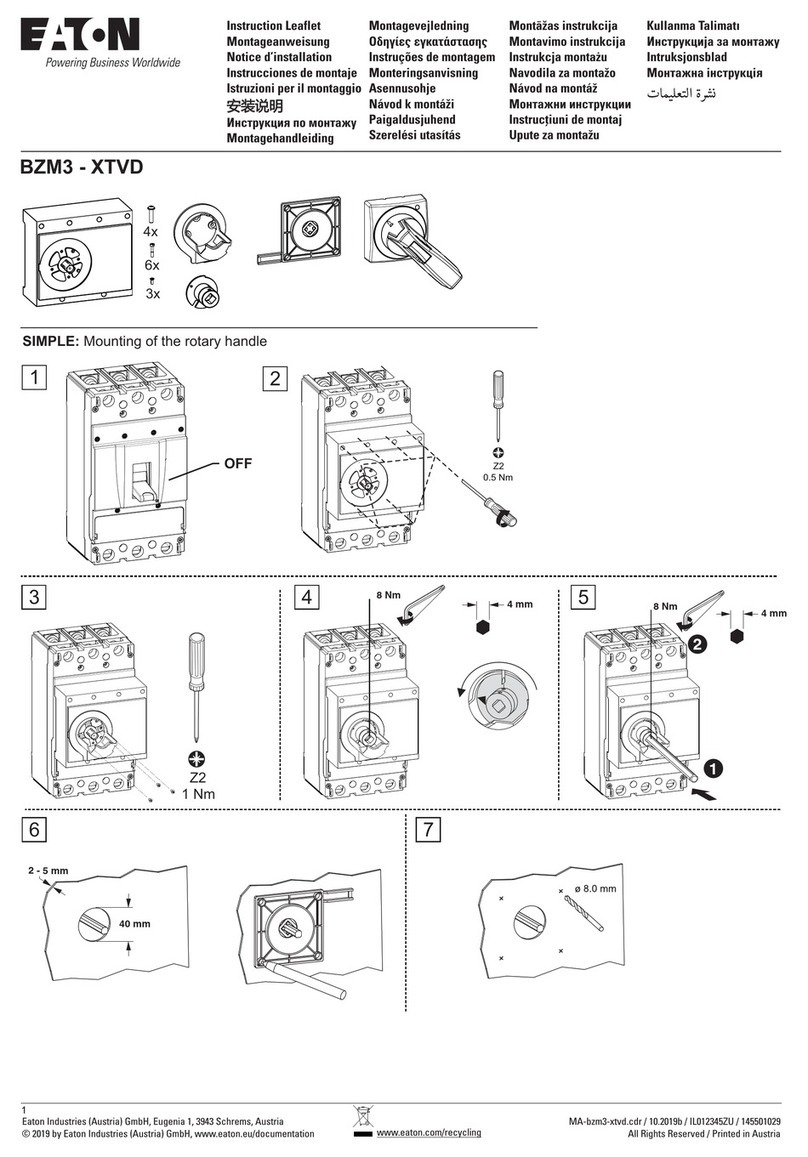

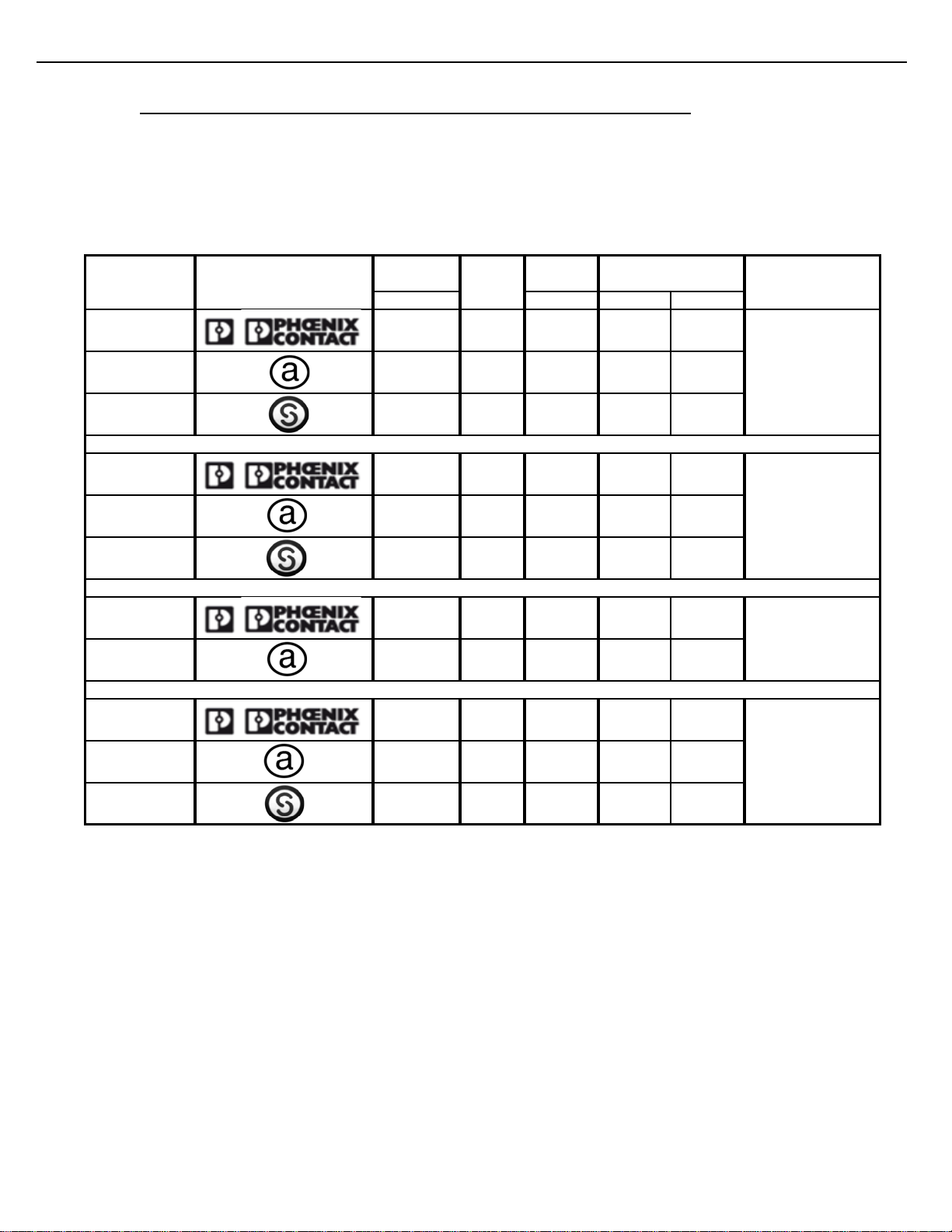

1.5 RECOMMENDED WIRE SIZES AND TORQUE FOR ALL TERMINAL BLOCKS

Three sizes of terminal blocks are used in the MultiLoad II products: 7.62 mm pitch (supply power), 5.08 mm pitch

(line voltage switching), and 3.81 mm pitch (serial communication, analog or dc voltages). All sizes, orientations,

and manufacturer brands have different torque and wire size specifications. Please follow the recommendations

in Figure 2.1 below. The manufacturer may be determined by looking for the logo molded into the terminal block,

usually on the side.

[mm] [AWG] [Nm] [LB in]

Phoenix 7.62 Straight 30 - 12 .6 - .8 5 - 7

On-Shore

Technology 7.62 Straight 24 - 12 0.40 3.5

Sauro 7.62 Straight 30 - 12 0.8 7

Phoenix 5.08 Straight 30 - 12 .6 - .8 5 - 7

On-Shore

Technology 5.08 Straight 24 - 12 0.40 3.5

Sauro 5.08 Straight 30 - 12 0.8 7

Phoenix 3.81 Straight 30 - 14 0.5 4

On-Shore

Technology 3.81 Straight 28 - 16 0.19 1.7

Phoenix 3.81 90° 30 - 14 0.2 - 0.5 2 - 4

On-Shore

Technology 3.81 90° 26 - 16 0.3 3

Sauro 3.81 90° 30 - 14 0.31 2.7

TB2A, TB2B, I/O

Board

Manufacturer Orienta-

tion

Logo Recommended

Screw Torque Location

TB1, Power Supply

Board

TB1, I/O Board

Terminal

Block Pitch

A

llowable

Wire Size

TB2 - TB5, Power

Supply Board; TB3

-

TB6, I/O Board

Figure 1.1 MultiLoad II Terminal Block Recommended Wire Size and Screw Torque

Chapter 2 – Installing the MultiLoad II Mobile 9

MultiLoad II Mobile Installation Guide: Version C

CHAPTER 2 INSTALLING THE MULTILOAD II MOBILE

2.1 TOOLS REQUIRED

2.1.1 INSTALLATION

- ¼” Flat Head screw driver is required for tightening cover screws

2.1.2 SERVICING AND REPAIR

- #2 Philips screwdriver for circuit board removal

- ¼” socket wrench for CPU circuit board removal, 5/16” socket wrench for display board removal

- #2 Philips screwdriver for removal of keypad plat screws

2.2 MOUNTING THE MULTILOAD II MOBILE ENCLOSURE

The MultiLoad II Mobile is designed with a standard 100mm VESA pattern. This enables it to attach to a variety

of vehicle mounting hardware.

2.3 ELECTRICAL SUPPLY CONNECTIONS

2.3.1 CABLE ENTRIES

A variety of cable entries are provided:

Five ½” NPT glands on the right side (use these for power entry, and truck mounted control devices)

Two PG16 glands on the bottom side (use these for modem and GPS connection)

Two ½” NPT glands on the bottom side (use these for in cab mounted devices)

Three ½” NPT glands on the back side (use these for power entry, and truck mounted control devices).

Using the supplied rubber sealing washer a recommended torque of 192 inch-ounces (1 ft-lb.) should be

used on glands or hole plugs as specified by the manufacture.

Note that RJ45 latching plugs can be inserted through the PG16 glands. A service loop is recommended

for all wires and cables entering the enclosure.

Do not allow service loop cables to overlap the circuit boards. Coil any cable length in the

bottom of the enclosure. Keep AC wiring separated from all other wiring in the enclosure by use of

the supplied partitions (see wire partition instructions below.

Chapter 2 – Installing the MultiLoad II Mobile 10

MultiLoad II Mobile Installation Guide: Version C

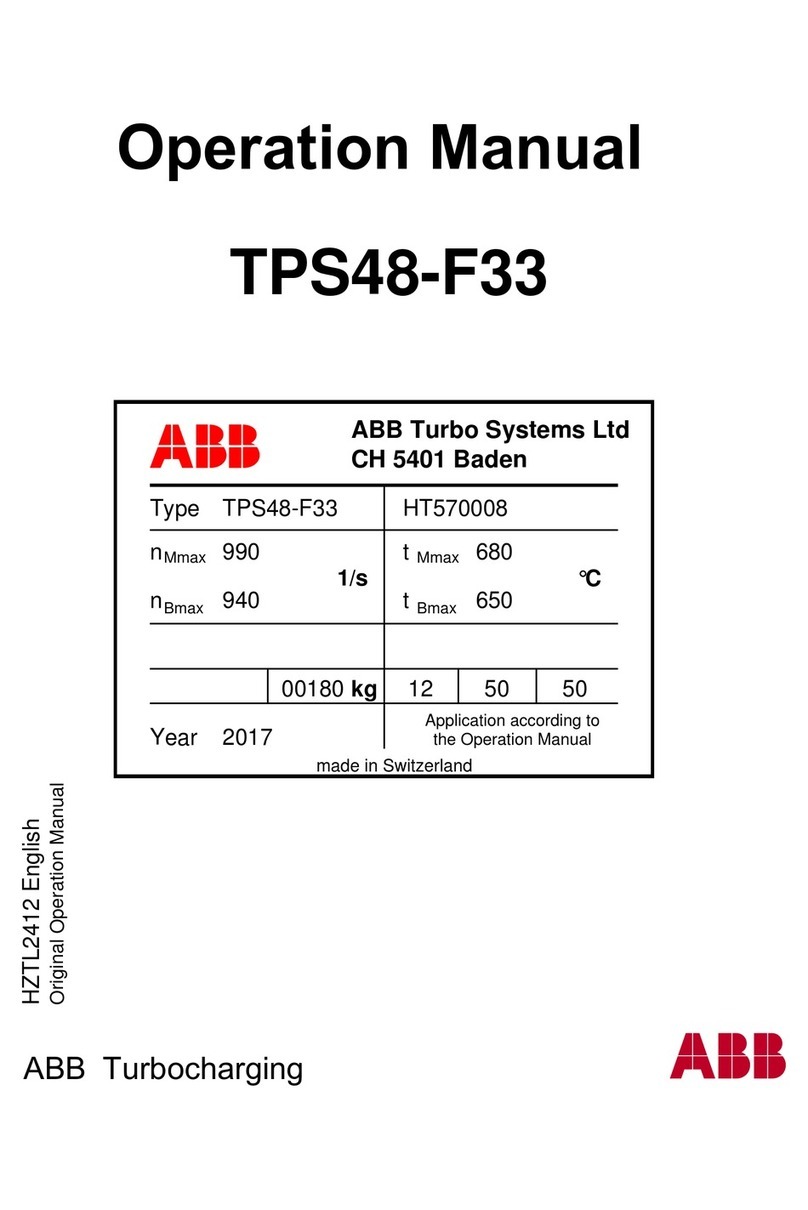

2.3.2 ATTACHING VEHICLE POWER.

Connect red and black wire pairs to the left and center pins of TB1 respectively. This terminal block is located on

the power supply board shown. Connection of the red wire to the accessory voltage is recommended over wiring

to the battery in order to prevent battery drain while the vehicle is not running.

The required power is 9 -30Vdc, 1.2A.

Figure 2.1 MultiLoad II Mobile DC Power Supply/Comm Board

Chapter 3 – Data Communications Interface 11

MultiLoad II Mobile Installation Guide: Version C

CHAPTER 3 DATA COMMUNICATIONS INTERFACE

The MultiLoad II Mobile has four communications ports (see Figure 2.1) each with a specific purpose. The

following section provides the information required to select and make the wiring connections to the ports.

Communication Port Interface Type Typical Function Terminal (Figure 2.1)

Comm. Port 0 RS-485 Internal I/O board /

FCM I / FCM II / PCM

Communication

TB2

Comm. Port 1 RS-232 or RS-485 Host Communication

(TMS) TB3 RS-232

TB4 RS-485

Comm. Port 2 RS-232 Ticket Printer/Data

Logger TB5

Ethernet 10/100MBPS Host Communication

(TMS) J3

Cat 5 Cable

If a service loop is used, the maximum wire length in the service loop should not exceed 3 inches

[75mm].

Separate AC and DC wiring by at least 3 inches [75mm]. Do not allow excess wire in the service

loop to overhang printed circuit board.

Chapter 3 – Data Communications Interface 12

MultiLoad II Mobile Installation Guide: Version C

3.1 COMMUNICATIONS PROTOCOL SELECTION AND CONNECTION:

3.1.1 RS-422/485:

RS-422/485 communications protocol is designed for multi-point (i.e. computer to multiple devices, also called

multi-dropped) communications up to 4,000 feet (1,220 Meters).

RS-422 requires 4-wires (2 twisted pair) for full duplex communications and utilizes a transmit pair of wires (TDA

& TDB) and a receive pair of wires (RDA & RDB).

RS-485 requires 2-wires (1 twisted pair) for half duplex communications and utilizes a single pair of wires

(TDA/RDA & TDB/RDB) for transmit and receive.

This manual will typically refer to both RS-422 and RS-485 as simply RS485 2 wire or RS485 4 wire.

Although a ground wire is not required, the common mode voltage between the MultiLoad II/ RCU

II and the field device must be within -7Vdc to 12Vdc. To correct situations where this is not the

case, the DC common is available on COM 0 and COM 1 by using TB2, pin five (revision 1.1

Power Supply/Comm boards only) and TB 3, pin three. Connect the MultiLoad II/ RCU II DC

common to the signal ground of the field device.

Wire used must meet the following characteristics:

24 AWG stranded.

4-wire, two twisted pair with overall shield.

2-wire, one twisted pair with overall shield.

30pF maximum between conductors.

1,000 ohm impedance.

Maximum length: 4,000 feet (1,220 Meters)

Maximum stub length: 15 feet.

All exposed shields must be properly insulated to prevent short circuits.

All shields must be continuous, soldered, and properly insulated.

3.1.2 RS-232

RS-232 protocol is designed for point-to-point (i.e., computer to a single device) communications limited to 50 feet

requiring a minimum of 3 wires – transmit, receive and ground. Additional wires are required for hardware

handshaking when using printers and data loggers.

Wire used must meet the following characteristics:

24 AWG.

3 conductor with overall shield (data only) or 8 conductor with overall shield (full handshaking).

30 pF maximum between conductors.

Chapter 3 – Data Communications Interface 13

MultiLoad II Mobile Installation Guide: Version C

Host/TMS Communications (COM 1 - RS-485 4-wire)

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II via RS485 4-wire on COM 1.

The TD and RD pairs are swapped at the Host/TMS.

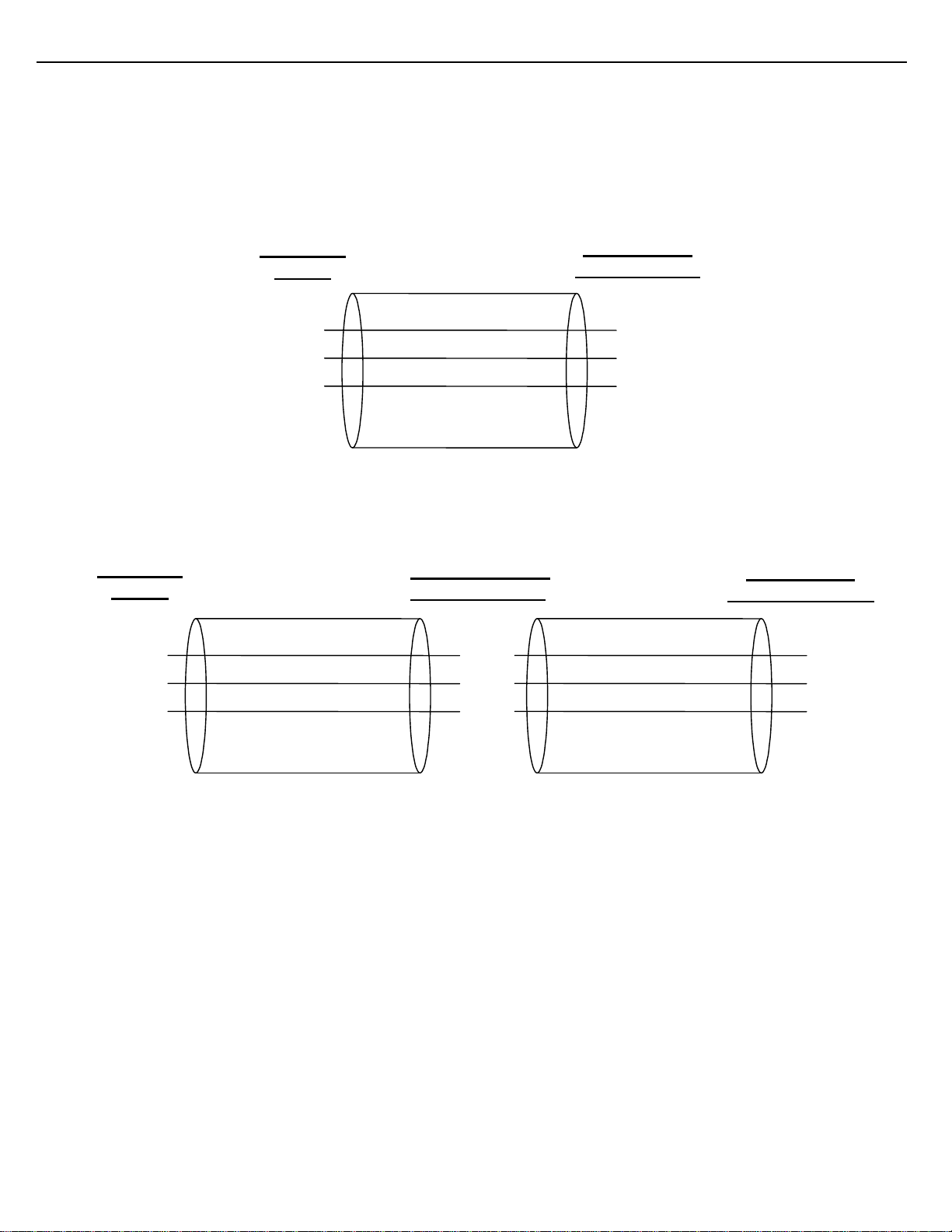

Figure 3.1 RS485 4-Wire, Host to a Single MultiLoad II/ RCU II (recommended)

Figure 3.2 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

RDA

RDB

TDA

TDB

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

Host/TMS

RS485

MultiLoad II/

RCU II #1 COM

Host/TMS

RS485 MultiLoad II/

RCU II #n COM 1

MultiLoad II/

RCU II COM 1

Chapter 3 – Data Communications Interface 14

MultiLoad II Mobile Installation Guide: Version C

Host/TMS Communications (COM 1 - RS-485 2-wire)

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II via RS485 2-wire on COM 1.

The TD and RD pairs tied together at the Host/TMS and all MultiLoad II/ RCU IIs.

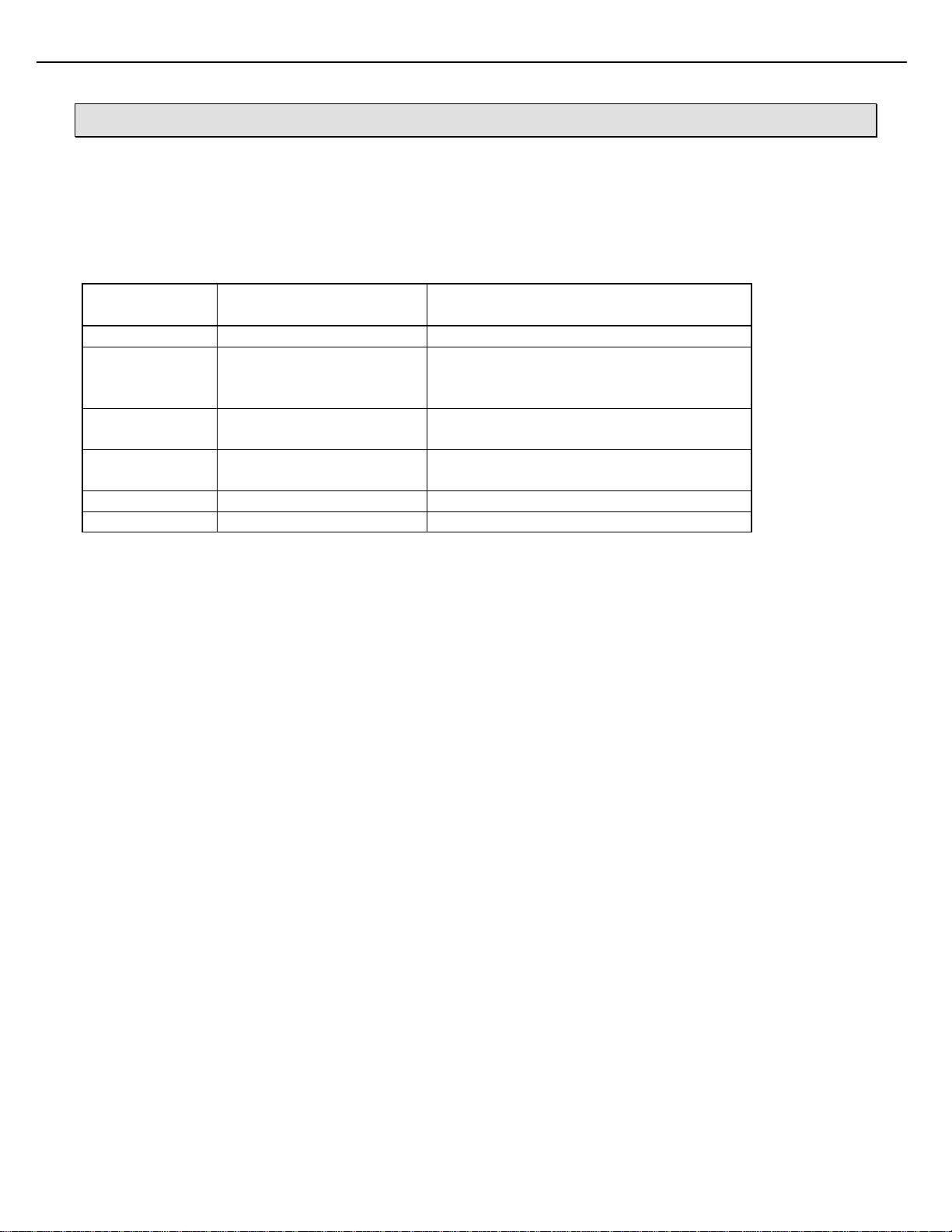

Figure 3.3 RS485 2-Wire, Host to a Single MultiLoad II/ RCU II

Figure 3.4 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

RDA

RDB

TDA

TDB

TDA

TDB

RDA

RDB

RDA

RDB TDA

TDB

MultiLoad II/

RCU II COM 1

Host/TMS

RS485

MultiLoad II/

RCU II #1 COM

Host/TMS

RS485 MultiLoad II/

RCU II #n COM 1

Chapter 3 – Data Communications Interface 15

MultiLoad II Mobile Installation Guide: Version C

Host/TMS Communications (COM 1 - RS-232)

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II via RS232 on COM 1.

The TX and RX are swapped at the Host/TMS.

MultiLoad II/ RCU II has the ability to multi-drop onto a RS232 line.

Figure 3.5 RS232, Host to a Single MultiLoad II/ RCU II

Figure 3.6 RS232, Host to Multiple MultiLoad II/ RCU IIs

TX

RX RX

TX

GND GND

RX

TX

GND

TX

RX RX

TX

GND GND

MultiLoad II/

RCU II COM 1

Host/TMS

RS232

MultiLoad II

/

RCU II #1 COM

Host/TMS

RS232 MultiLoad II/

RCU II #n COM 1

Chapter 3 – Data Communications Interface 16

MultiLoad II Mobile Installation Guide: Version C

Host Ticket Printer/Data Logger (COM 2 - RS-232)

A Ticket Printer or Data Logger can be connected to the MultiLoad II/ RCU II via RS232 on COM 2.

The TX and RX are swapped at the MultiLoad II/ RCU II.

Handshake lines MUST be connected or terminated or a Printer Error will be reported.

MultiLoad II/ RCU II will monitor CTS, DSR and DCD for active signals.

Figure 3.7 Ticket Printer / Data Logger Connections with Handshake

Figure 3.8 Ticket Printer / Data Logger Connections without Handshake

MultiLoad II/

RCU II COM 2 Printer Logger RS232

DB25 Connector

RX

CTS

TX

GND

DSR

DCD

RTS

DTR

MultiLoad II/

RCU II COM 2 Printer Logger RS232

DB25 Connector

RX

CTS

TX

GND

DSR

DCD

RTS

DTR

2 - TX

20 - DTR

3 - RX

7 – GND

4 – RTS

5 – CTS

6 – DSR

8 - DCD

Chapter 3 – Data Communications Interface 17

MultiLoad II Mobile Installation Guide: Version C

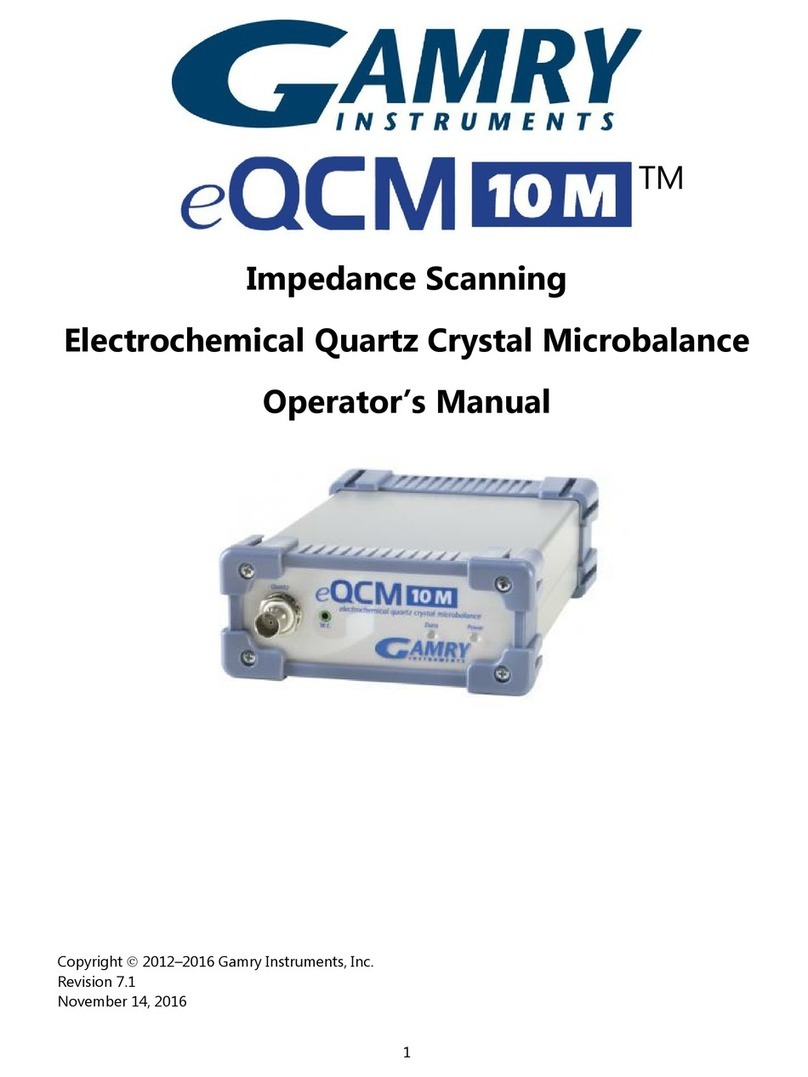

3.1.3 ETHERNET

Ethernet wiring standard T568B - Cat5 cable (or greater).

Figure 3.9 illustrates the required connections for Ethernet.

The Ethernet controller on revision 2.0 CPU boards uses HP Auto-MDIX technology. By automatically detecting

the signaling on the connected device, the transceiver will configure the port settings automatically. Thus, the

choice of a straight through or cross over cable no longer has to be made—either will work.

1 White/org 1

7 White/Brown

6 Green

5 White/Blue

4 Blue

3 White/Grn

2 Org

8 Brown

6

7

8

5

4

3

2

Twisted Pairs

Figure 3.9 Ethernet Connections

8 - DCD

Chapter 4 – I/O Configuration 18

MultiLoad II Mobile Installation Guide: Version C

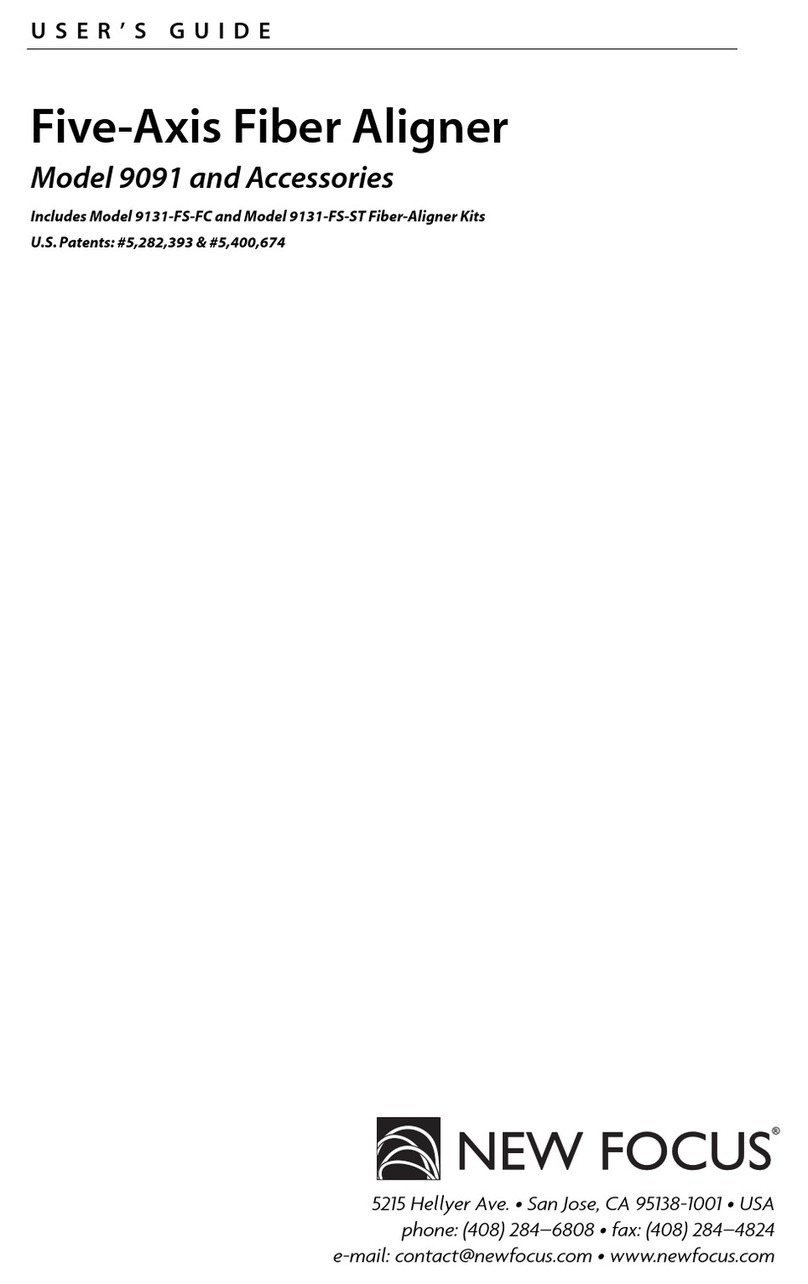

CHAPTER 4 I/O CONFIGURATION

The I/O board is mounted above the Power Supply/Comm board. The I/O board is connected to the Power

Supply/Comm board at J4 & J5. Corresponding connections are on bottom side of the I/O board.

The following defines the electrical ratings of Inputs and Outputs supported by the I/O board:

TYPE I/O QUANTITY,LOCATION ELECTRICAL RATING

DC Outputs: 7 (TB1, TB2) 0 - 30Vdc, 1.0A (per point)

DC Inputs: 6 (TB6, TB7)

(2 High Speed) 5 – 30Vdc

Dual Channel flow meter inputs (1-5000Hz)

Miscellaneous signal inputs

12Vdc Source: 167mA Max Load (TB5) Isolated Power Supply

Power for flow meter pulsers or preamps

RTD Input: 1 (TB3) 100ohm platinum, four wire

Coefficient 0.00385Ohm/Ohm/°C

Analog Input 1 (TB4 pins 1 &.2) 4 – 20mA, 1.5V maximum burden

Analog Output 1 (TB4 pins 3 - 6) 4 – 20mA, Requires 12Vdc – 30Vdc Supply

Chapter 4 – I/O Configuration 19

MultiLoad II Mobile Installation Guide: Version C

Figure 4.1 I/O Board Terminal Block Assignments

7 DC Outputs

0 – 30Vdc

0.6A

No orientation on pins.

RTD.

Analog Input

Analog Output

12Vdc, 2W supply

Available for pulsers

6 DC Inputs:

5-30Vdc

Chapter 4 – I/O Configuration 20

MultiLoad II Mobile Installation Guide: Version C

4.1 MASS METER AND SOLENOID VALVE CONNECTIONS

MASS

METER

Pulse

1

6

Terminal

Number

Pulse GND

Density +

Density -

1

6

Terminal

Number

I+ 1

I- 2

V+ 3

GND 4

I5

6

TB4

4-20

mA IN

4-20

mA

OUT

+-

12/24Vdc

DCCom

In

6

Out

5

In

4

Out

3

In

2

Out

1

Port 0

Port 1

Port 2

TB2

Note: For Density and pulse

wiring, use a 24AWG twisted

pair shielded for each pair.

+

1

-

2

+

3

-

4

+

5

-

6

Port 4

Port 5

Port 6

TB6

Note: Largest wire that TB1 – TB7 can accommodate is 16AWG.

Terminal

Number

1

6

+

-

+

-

12Vdc Coil

(Air Valve)

TO CHASSIS

12/24Vdc (J1.3 PS)

12Vdc Coil

(Interposing

Relay

Figure 4.2 I/O Board Field Wiring: Flow Meter and Control Valve

Other manuals for MultiLoad II

1

Table of contents

Other Toptech Industrial Equipment manuals