Topwisdom TL-403 User manual

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

Copyright Statement

Shenzhen Topwisdom Technology Co., Ltd.

All rights reserved.

Shenzhen Topwisdom Technology Co., Ltd. (Topwisdom Technology hereinafter)

reserves the rights of final interpretation and modification for this manual and

declaration. Topwisdom Technology owns the patents, copyright and other intellectual

property rights for its product and software. Without authorization, no one is allowed to

copy, excerpt, reproduce, process, disseminate and use this product and its relative

parts directly or indirectly.

Disclaimer

Topwisdom Technology reserves the right to modify the content described in this

manual without advance notice. Topwisdom Technology is not responsible to any direct,

indirect, or consequential damage or liability caused by improper use of this manual or

the product. Machinery in motion can be dangerous! It is the responsibility of the user

to design effective error handling and safety protection as part of the machinery.

Topwisdom Technology shall not be liable or responsible for any incidental or

consequential damages.

Technical Support

To get our technical support and after-sale service:

Tel: +86-0755-82057902

Fax: +86-0755-82057892

Website: http://www.topwisdom.com.cn

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

I

Content

Part 1 Overview ............................................................................................................... 1

1.1 System Overview ............................................................................................... 1

1.2 Notes and Warning............................................................................................. 2

1.3 Work Environment.............................................................................................. 2

1.4 Power Supply and Grounding............................................................................ 2

1.4.1 Power supply requirements ..................................................................... 2

1.4.2 Grounding requirements .......................................................................... 2

1.5 Accessory List .................................................................................................... 3

Part 2 Wiring Installation Instruction................................................................................ 5

2.1 System Wiring Diagram ..................................................................................... 5

2.2 Installation Dimension ........................................................................................ 6

2.2.1 Panel ........................................................................................................ 6

2.2.2 Mainboard ................................................................................................ 7

2.3 Wiring Instruction................................................................................................ 9

2.3.1 Interface Broad ........................................................................................ 9

2.3.2 Wiring Diagram ........................................................................................ 9

2.4 Interface Instruction.......................................................................................... 13

2.4.1 Power Signal .......................................................................................... 13

2.4.2 U-DISK Port ........................................................................................... 14

2.4.3 PC Connection Port ............................................................................... 14

2.4.4 NETWORK Port ..................................................................................... 14

2.4.5 Output..................................................................................................... 14

2.4.6 Laser Power Interface............................................................................ 16

2.4.7 Input ....................................................................................................... 17

2.4.8 Input Signal Diagram ............................................................................. 19

Part 3 Software Installation............................................................................................ 20

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

II

3.1 Installing CoreDRAW Direct Output................................................................. 20

3.1.1 Manual Install ......................................................................................... 21

3.1.2 Auto install .............................................................................................. 22

3.2 Uninstalling CorelDRAW Direct Output ........................................................... 23

3.3 Installing CAD Direct Output ............................................................................ 23

3.4 Uninstalling CAD Direct Output ....................................................................... 25

3.5 USB Driver Installation ..................................................................................... 26

3.6 USB Port Setting .............................................................................................. 29

3.6.1 View the assigned COM Port by Computer .......................................... 29

3.6.2 Change the Assigned COM port by Computer ..................................... 32

3.7 IP Setting .......................................................................................................... 33

Part 4 Software Operation Guide .................................................................................. 37

4.1 CorelDRAW Direct Output Software Operation .............................................. 37

4.1.1 Layer Parameter Setting........................................................................ 38

4.1.2 Coordinate Setting ................................................................................. 42

4.1.3 Track Setting .......................................................................................... 43

4.1.4 Single Axis Operation ............................................................................ 44

4.1.5 Output Engrave...................................................................................... 45

4.2 The Equipment Management .......................................................................... 49

4.2.1 Toolbar.................................................................................................... 50

4.2.2 Parameter Setting .................................................................................. 50

4.2.3 Embroidery Import ................................................................................. 55

4.2.4 Import bitmap ......................................................................................... 56

4.2.5 Curve Precision...................................................................................... 57

4.3 CAD Direct Output Software Operation........................................................... 57

4.4 CAD Direct Output Software Supplementary Description .............................. 58

4.4.1 The Support of AutoCAD Direct Output Annotation Text ...................... 58

4.4.2 Carving Gradient Sketch Map ............................................................... 60

4.4.3 Coordinate System ................................................................................ 60

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

III

4.4.4 Supplementary Description of Carving ................................................. 61

4.4.5 Supplementary Description of Software and CAD Direct Output......... 62

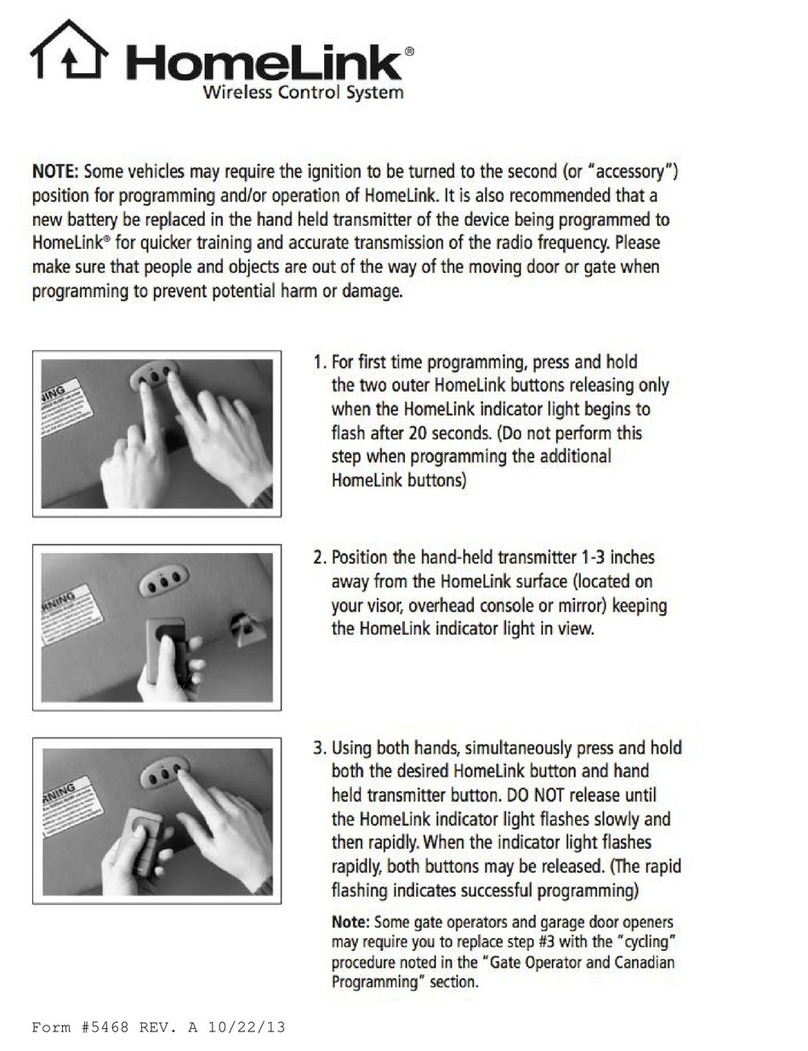

Part 5 The Operation Panel........................................................................................... 66

5.1 The Panel Operation and Buttons Function Introduction................................ 66

5.1.1 The Panel............................................................................................... 66

5.1.2 Buttons Function Introduction................................................................ 66

5.2 The Main Interface Introduction ....................................................................... 69

5.2.1 Power Interface...................................................................................... 69

5.2.2 Standby Interface ................................................................................... 69

5.2.3 Speed Setting Interface ......................................................................... 71

5.2.4 Power Light Intensity Interface .............................................................. 71

5.2.5 Range Preview Interface ....................................................................... 72

5.2.6 Single Axis Movement Interface............................................................ 73

5.2.7 File Selection Interface .......................................................................... 73

5.2.8 U disk File Interface ............................................................................... 74

5.2.9 The Main Menu Setting.......................................................................... 75

5.3 File Setting........................................................................................................ 76

5.4 The Integrate Settings ...................................................................................... 77

5.4.1 Laser Set ................................................................................................ 77

5.4.2 Equipment Set ....................................................................................... 78

5.4.3 Axis Set .................................................................................................. 80

5.4.4 Back Set ................................................................................................. 83

5.4.5 User Set ................................................................................................. 85

5.5 System Information .......................................................................................... 87

5.5.1 The Password Setting............................................................................ 88

5.6 System Test ...................................................................................................... 89

Part 6 the Frequently Asked Question Help.................................................................. 91

6.1 Power-on Reset Question................................................................................ 91

6.2 The Laser Light Question................................................................................. 92

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

1

Part 1 Overview

1.1 System Overview

Thank you very much for using laser engraving control system of our company!

This system can be used with various types of laser engraving cutting machine, meets

your different requirements for processing.

Use High-Performance 32-Bit CPU with Single-Precision Floating-Point Unit (FPU),

the main frequency is up to 150MH. Setting device parameter out of PC completely.

All coupler completely isolated from outside interference, the system is reliable.

Support USB2.0 port, U disk reading and writing, support U disk system upgrade;

Support network , PC-communication is more convenient, safe, and reliable.

With 64MB storage, work independently form PC, which is useful for the quantities

of engraving and cutting production.

Support 5 axises motion control(X Y Z U V, XY is for laser cutting control, Z is

feeding axis, U is lift axis, V is for the second laser cutting head).

Support double laser head cutting, support leftover cutting. Each laser power is

able to be control independently.

Support feeding, lifting, rotating engraving, metal cutting, scale cutting, automatic

blowing, automatic focusing, foot switch, cover protect, power-off cutting

restoration, system lock, device management.

S-shape acceleration and deceleration and adjustable velocity profile, meet the

demand of smooth cutting and high speed working.

Before using, please read our manual carefully, ensure to operate our system

correctly.

Please keep the manual well, and it’s convenient for your future references.

Because of different configuration, some devices have not some of the

functions listed in the manual, the details subject to appropriate operation

functions.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

2

1.2 Notes and Warning

Prohibit the non-professionals to maintenance and debug the electrical system, if

not, this will reduce device’s safety performance, and expand failure, even cause

accident and property loss.

Please do not piles up debris on the control box, and in the course of using,

regularly remove the dust of the control box surface and filters, to keep good

ventilation.

When users have to open the cover of the control box, must cut off the power after

5minutes and under the professionals’guidance, only can be allowed to touch the

components in the electrical control box!

Prohibit touching any motion parts or opening the control equipments when the

machine is working, or it maybe bring about the accident and machine can’t work.

Prohibit using the electrical equipment in the damp, dust, corrosive gas, flammable

gas area, or it maybe cause the electrical shock or fire!

1.3 Work Environment

Ventilation, sanitation, and less dust

Storage temperature: 0-50℃

Work temperature: 5-40℃

Work relative humidity: 30%-90%(no condensation)

1.4 Power Supply and Grounding

1.4.1 Power supply requirements

Core power supply: DC 5V, 3A; External power supply: DC 5V, 3A

According to different machine configurations, power consumption is between

0.1-0.2KW

1.4.2 Grounding requirements

In order to prevent electrical equipment due to leakage, over-voltage, insulation etc

causes of the electrical shock or fire, please make the electrical control reliable

grounding.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

3

Grounding resistance is less than 100 ohms; the length of wire cable is within the

20meters, the cross-sectional area of the wire cable is larger than 1.0 mm2.

1.5 Accessory List

The Laser Engraving Control System-TL-403 contained the accessories as below:

Name

Qty

Introduction

Photo

Operation

Panel

1

For user

operation

Controller

1

The Motion

Control Card

Connection

cable

3

1.Panel

Connection

cable for

connecting

controller and

panel.

2.USB

communication

cable for

connecting

controller and

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

4

PC

3.USB

communication

extended cable

Crossover

Ethernet

Cable

2

1.Crossover

Ethernet Cable

2.Network

communication

extended cable

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

5

Part 2 Wiring Installation Instruction

2.1 System Wiring Diagram

PC

U-DISK

EX5V

EX5V

XGND

IN-5

XGND

OUT6

OUT5

OUT2

OUT1

EX5V

IN-2

IN-3

IN-4

XGND

EX5V

EX5V

PWM4

DIR4

XGND

IN 6

GND

+5V

EX5V

PWM3

DIR3

XGND

IN 1

LASER-2 LASER-1

EX5V

XGND

IN10

IN-7

IN-8

IN-9

EX5V

XGND

IN11

IN12

IN13

EXV+

EXV-

OUT7

OUT8

EX5V

XGND

PWM6

DIR6

EX5V

XGND

PWM5

DIR5

EX5V

XGND

PWM2

DIR2

EX5V

XGND

PWM1

DIR1

X-DRIVERY-DRIVERZ-DRIVERV-DRIVER

DIR

PUL

EX5V

TL-403C

HANDSET

NETWORK

Air Control

Pen Control

5V Relay

5V Relay

EX5V

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

Axis V Driver

(Laser head2 motor)

Axis Z Driver

(Feeding motor)

Axis Y Driver

(Y motor)

Axis X Driver

(X motor)

U-DRIVER

V Origin Limit

Z Origin Limit

U Origin Limit

Cover Protect

Foot Switch

X Origin Limit

Y Origin Limit

PWM

DIR

PWM

DIR

- - + +

Mechanical

Switch

DC 5V/3A

DC 5V/3A

Water Protect

Water Protect

TH

TL

WP

G

IN

5V

Two way

switch

RP100R

CO2

Laser

power

1

TL

G

IN

CO2

Laser

power

2

Axis U Driver

(Lifting motor)

Control

damper

Control

damper

Auto Manual

Y Up Limit

X Up Limit

5V o0V Optoelectronic

Switch

Fig. 2-1

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

6

2.2 Installation Dimension

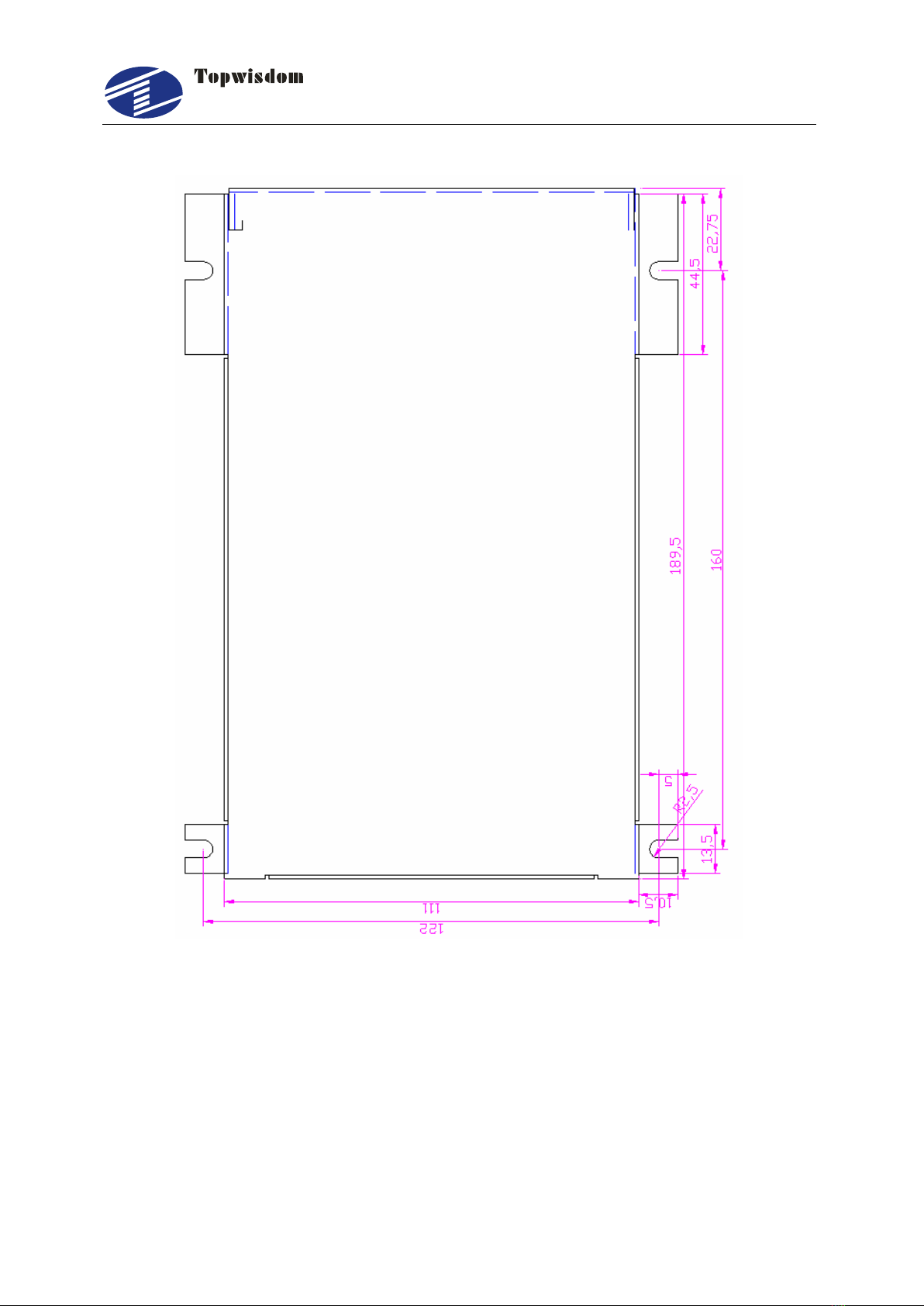

2.2.1 Panel

The installation dimension of operation panel (the unit is MM):

Face:

Fig. 2-2

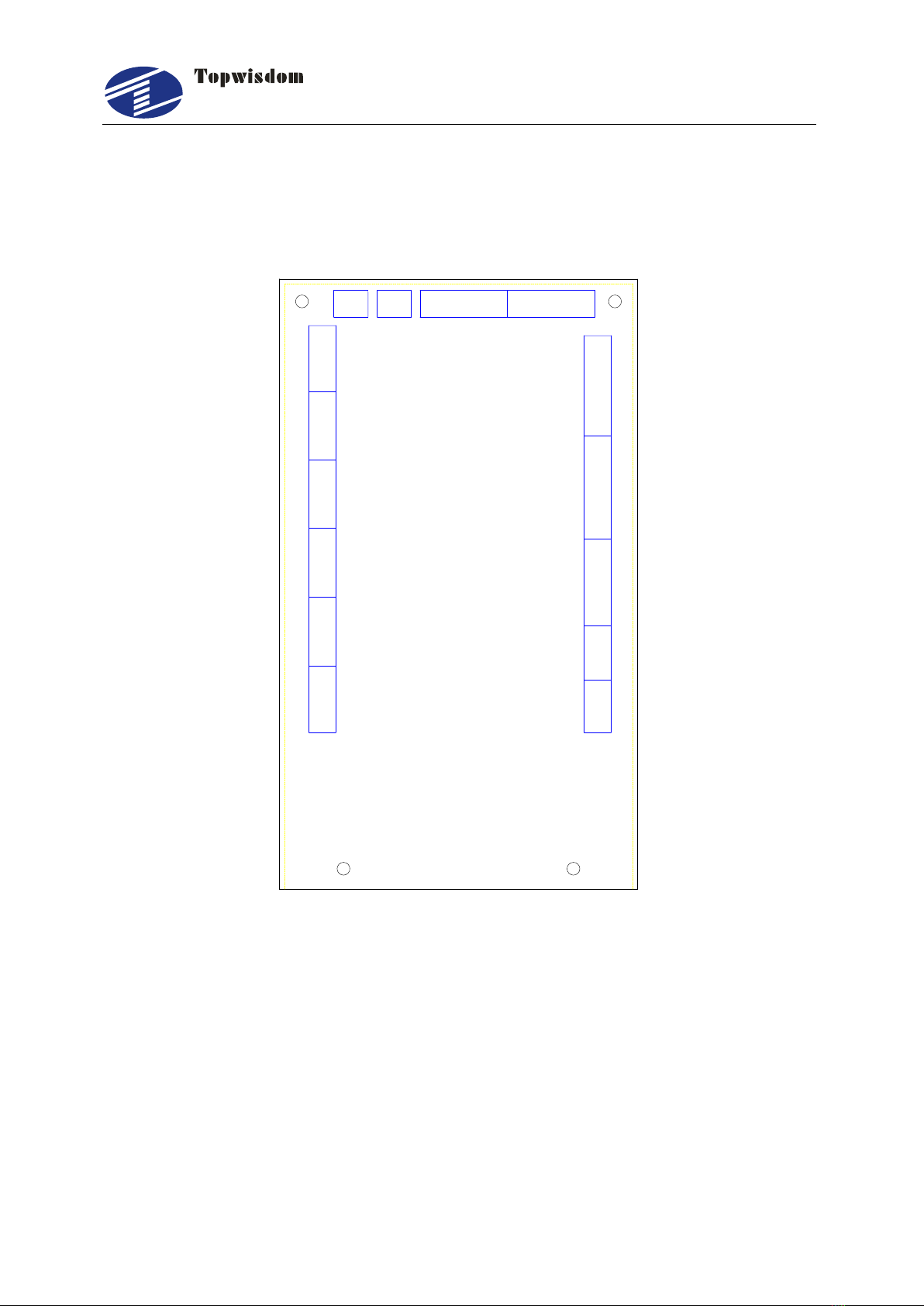

Bottom:

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

7

Fig. 2-3

2.2.2 Mainboard

The installation dimension of mainboard (the unit is MM):

Fig.2-4

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

8

Fig.2-5

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

9

2.3 Wiring Instruction

2.3.1 Interface Broad

PC

U-DISK

EX5V

EX5V

XGND

IN-5

XGND

OUT6

OUT5

OUT2

OUT1

EX5V

IN-2

IN-3

IN-4

XGND

EX5V

EX5V

PWM4

DIR4

XGND

IN 6

GND

+5V

EX5V

PWM3

DIR3

XGND

IN 1

LASER-2 LASER-1

EX5V

XGND

IN10

IN-7

IN-8

IN-9

EX5V

XGND

IN11

IN12

IN13

EXV+

EXV-

OUT7

OUT8

EX5V

XGND

PWM6

DIR6

EX5V

XGND

PWM5

DIR5

EX5V

XGND

PWM2

DIR2

EX5V

XGND

PWM1

DIR1

X-DRIVERY-DRIVERZ-DRIVERV-DRIVER

DIR

PUL

EX5V

TL-403C

HANDSET

NETWORK

U-DRIVER

Fig. 2-6

2.3.2 Wiring Diagram

2.3.2.1 Motor Wiring

The following is X axis motor wiring, other axis are similar.

1. Step Motor Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

10

PUL+

PUL-

DIR+

DIR-

ENA+

ENA-

GND

DIR1

PWM1

+5V

GND

U

V

W

Vdc

36V-

To

Motor

36V+

J20 X Driver

Fig. 2-7

2. Panasonic Servo Wiring

PULS1

PULS2

SIGN1

SIGN2

GND

DIR1

PWM1

+5V

COM-

U

V

W

COM+

24V-

To

Motor

24V+

J20 Panasonic servo

3

6

5

4

41

7

Fig. 2-8

2.3.2.2 Laser Power Supply Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

11

1. CO2 Laser Power Supply Wiring

TTL-H TTL-L WP GND DAC

1 3 4 5 62

Water Potect

EX5V PWM3 DIR3 IN-1 XGND

J2

Laser

Power

Supply

Active low

Fig. 2-9

2.RF Laser Wiring

Power

Water Protect

EX5V PWM3 DIR3 IN-1 XGND

J2

Laser

Power

Supply

GND

Fig. 2-10

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

12

The wiring of laser 2 is similar.

Note:When “RF1 or RF2”is selected, please set the PWM Frequency according

to the data sheet of the laser. Generally, PWM Frequency is 5000Hz. And set the

Laser Max parameter not larger than 95%, especially not to set as 100%,

otherwise it works improperly.

2.3.2.3 Blowing Air Signal Wiring

EXV-

OUT8

OUT7

EXV+

J9 5V/24V Relay

5V+/24V+

Fig. 2-11

2.3.2.4 Pen UP/Down Signal Wiring

EXV-

OUT8

OUT7

EXV+

J9 5V/24V Relay

5V+/24V+

Fig. 2-12

2.3.2.5 Limit Switch Signal Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

13

XGND

IN-5

IN-4

IN-3

IN-2

EX5V

0V

OUT

5V

J3 Photoelectric limit switch

X Origin limit switch

Fig. 2-13

Other limit switch wirings are similar.

2.4 Interface Instruction

2.4.1 Power Signal

The system is dual 5V power supply

The system internal 5V power interface J24 (switching power interface)

Pin

Definition

1

+5V Internal 5V power source positive (input)

2

GND Internal 5V power source grounding (input)

The system external power interface J23 (switching power interface)

Pin

Definition

1

EX5V External 5V power source positive (output)

2

XGND External 5V power source grounding (output)

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

14

2.4.2 U-DISK Port

Label U-DISK, can directly insert the U disk to read and write.

2.4.3 PC Connection Port

Label PC connection port, can connect PC to read and write with USB.

2.4.4 NETWORK Port

Label NETWORK, can connect PC to read and write by network.

2.4.5 Output

The driver interface

X axis interface J20

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM1 Step pulse (output) PUL-

3

DIR1 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

Y axis interface J18

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM2 Step pulse (output) PUL-

3

DIR2 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

Z axis interface J21

Pin

Definition

Table of contents

Other Topwisdom Control System manuals