Toray NHPA Series User manual

“NHPA Series C type”

[050-1C, 100-1C,

150-1C, 2C, 3C and 4C]

Instruction

Manual

Instruction

Manual

Toray MBR

Last updated August 2022

06-G-MB2-NHPAC-220801

Instruction Manual

Toray MBR

06-G-MB2-NHPAC-220801

Notice

The data and information contained in this document are based upon rigorous technical

testing by Toray, and is to the best of our knowledge reliable. Toray cannot control design

and operating conditions, and consequently Toray does not assume any liability for results

obtained or damage incurred through the application of the information provided herein.

No liability, warranty or guarantee of nal product performance by Toray is implied by the

information provided in this document.

This manual supersedes all previous versions. Technical modication of products or

production technology may necessitate changes to information in this manual without prior

notice. Please verify that your version of the manual is the latest version available by either

contacting Toray, or checking online at www.water.toray.

Terms and Conditions of Use

When using this document, please read the Terms and Conditions of Use below thoroughly and agree to them before using

this document. By using this document, you agree to all of the Terms and Conditions of Use outlined here. The Terms and

Conditions of Use are subject to change without prior notice, so please check with Toray for the latest Terms and Conditions

of Use before using the document.

1. Intellectual Property Rights

The content in this document is protected by copyright laws in respective countries and relevant treaties. Accordingly,

the document's information may not be reproduced, altered, or distributed without permission in writing from Toray. We

permit downloading this document through Toray's website as a PDF le, stored on a personal computer, and printed

out for customers' personal use. However, we prohibit transferring this document to any other websites or printed media.

The material contained in this document may not be used without permission from the copyright holder for any other

purpose that exceeds the scope permitted under copyright law.

2. Trademarks

The "TORAY" company name used in this document is a trade name, and the names of products manufactured by

Toray are trademarks or registered trademarks. Toray's trade names and trademarks are protected under the Japanese

Trademark Law, the Unfair Competition Prevention Law, and other legislation. The trade name and trademarks may not

be used or reproduced without express permission from Toray.

3. Disclaimer

Toray takes all reasonable care in updating the information in this document. However, Toray makes no representation

and warranty of any kind, either express or implied, including without limitation, any implied warranties concerning the

accuracy, usefulness, suitability, or tness for a particular purpose of the information in the document.

Toray shall not be responsible or liable for any losses or damage incurred due to the use of the information in this

document. The information in this document is subject to change without prior notice, and Toray reserves the right to

suspend or discontinue the publication of this document.

4. Availability of Goods and Services

The goods and services contained in this document are not available in all countries and regions. Goods and services

may also be supplied under dierent trademarks in dierent countries. We ask that you contact your nearest Toray

representative oce if you wish to use the goods and services shown or implied in this document.

5. Proper Law and Court of Jurisdiction

This Terms and Conditions of Use shall be governed by and construed according to the laws of Japan. Any and all

disputes arising out of or relating to this document shall be brought to the Tokyo District Court Tokyo, Japan.

Instruction Manual

Toray MBR

06-G-MB2-NHPAC-220801

Contact Information

Toray Industries, Inc. — UF & MBR Membrane Products Department (Global Headquarters)

Nihonbashi Mitsui Tower, 1-1, Nihonbashi-Muromachi 2 chome, Chuo-ku, Tokyo, 103-8666

Japan

Tel: +81-3-3245-4542 Fax: +81-3-3245-4913

Toray Membrane USA, Inc. (TMUS)

13435 Danielson Street, Poway, California 92064 USA

Tel: +1-858-218-2360 Fax: +1-858-218-2380

Toray Membrane Europe AG (TMEU)

Grabenackerstrasse 8b, Muenchenstein 1 CH-4142, Switzerland

Tel: +41-61-415-8710 Fax: +41-61-415-8720 E-mail: info.tmeu.mb@mail.toray

Toray Asia Pte. Ltd. (TAS)

111 Somerset Road, #14-22 - #14-27, Singapore 238164, Republic of Singapore

Tel: +65-6226-0525 Fax: +65-6226-0509

Toray BlueStar Membrane Co., Ltd. (TBMC)

Zone B, Tianzhu Airport Industrial Zone, Beijing 101318, China

Tel: +86-10-8048-5216 Fax: +86-10-8048-5217

Toray Membrane Middle East LLC (TMME)

PO Box 20279, Dammam 31952, Kingdom of Saudi Arabia

Tel: +966-13-568-0091 Fax: +966-13-568-0093

Toray Advanced Materials Korea Inc. (TAK)

Korea Toray R&D Center 7, Magokdonng-ro 10-gil, Gangseo-gu, Seoul 07790, Republic of

Korea

Tel: +82-22-3279-7389 Fax: +82-2-3279-7088

website: www.water.toray

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

TABLE OF CONTENTS

I. INTRODUCTION ..................................................................................................................... 1

1. Features of MBR ................................................................................................................... 1

2. Outline of “NHPA Series” ...................................................................................................... 2

II. FOR SAFE OPERATION OF “NHPA SERIES”...................................................................... 5

1. Safety Instruction for Unpacking and Installation.................................................................. 5

2. Safety Instruction for Operation and Maintenance................................................................ 6

3. Safety Instruction for Chemical Cleaning of Element ........................................................... 8

III. SPECIFICATIONS AND PERFORMANCE OF “NHPA SERIES” ........................................ 10

1. Specifications of Element.................................................................................................... 10

2. Specifications of Filtrate Tube Assembly ............................................................................ 10

3. Specifications and Performance of “NHPA Series” Module................................................ 10

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “NHPA SERIES”............................. 15

1. Standard Time Chart ........................................................................................................... 15

2. Flow Diagram of Membrane Filtration................................................................................. 16

3. Layout of “NHPA Series” Modules in Membrane Tank....................................................... 21

4. Piping................................................................................................................................... 24

V. INSTALLATION OF “NHPA SERIES”................................................................................... 28

1. Preparatory Procedure ........................................................................................................ 28

2. Unloading/Lifting Products .................................................................................................. 28

3. Checking Products .............................................................................................................. 29

4. Storing Products .................................................................................................................. 29

5. Installing Products ............................................................................................................... 30

VI. START OF OPERATION ...................................................................................................... 33

1. Clean Water Operation........................................................................................................ 33

2. Seeding Sludge Injection..................................................................................................... 34

3. Actual Filtration Operation................................................................................................... 35

VII. OPERATION CONTROL ...................................................................................................... 36

1. Standard Operating Conditions........................................................................................... 36

2. Operating Parameters ......................................................................................................... 38

3. Basic Control Philosophy .................................................................................................... 38

4. Daily Inspection ................................................................................................................... 40

VIII. MAINTENANCE OF “NHPA SERIES”.................................................................................. 43

1. Maintenance Items and Maintenance Frequency............................................................... 43

2. Air Diffuser Cleaning............................................................................................................ 44

3. Chemical Cleaning of Element............................................................................................ 46

4. Chemical Agents Available for Chemical Cleaning............................................................. 46

5. Handling of Chemical Agents.............................................................................................. 47

6. Chemical Cleaning Procedure............................................................................................. 50

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

7. Lifting Procedure ................................................................................................................. 55

8. Storing Products after Use .................................................................................................. 56

9. Disposing Procedure ........................................................................................................... 57

IX. REPLACEMENT PARTS LIST ............................................................................................. 58

X. TROUBLESHOOTING.......................................................................................................... 59

XI. WARRANTY POLICY ........................................................................................................... 60

XII. REFERENCE ...................................................................................................................... 61

Symbols used in this manual

This symbol is used to indicate an imminent hazardous situation

which, if not avoided, will result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, can result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, may result in injury or property damage.

“Prohibited”

This symbol indicates a prohibited action or procedure.

“Instruction”

This symbol indicates an important action or procedure which has

to be taken without fail.

DANGER

!

WARNING

!

CAUTION

!

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

1 of 61

I. INTRODUCTION

Toray MBR is the submerged membrane module suitable for the membrane bioreactor

(MBR) that has been developed based on the polymer science and the membrane

fabrication technologies accumulated for a long time in Toray Industries, Inc.

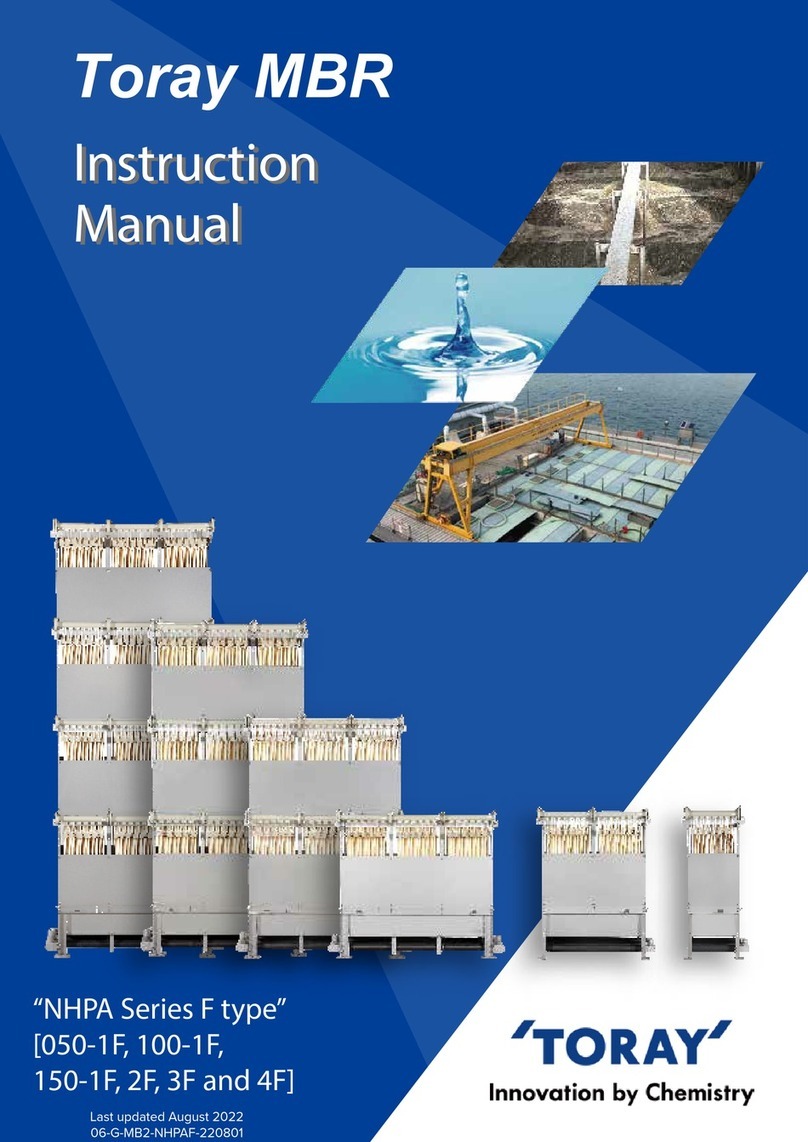

"NHPA Series" is a new model of NHP-MBR module equipped with thin membrane elements

having higher packing density, while reliable performance of Toray PVDF membrane has

been kept unchanged.

This manual explains MBR's features and describes the specifications of "NHPA Series" and

its safe operations including installation, operation, maintenance procedures and peripheral

equipment. Operators should thoroughly read this manual to ensure stable operation.

1. Features of MBR

The process flow of the conventional activated sludge system (CAS) and MBR are shown in

Fig.I-1 and Fig.I-2, respectively.

MBR provides the following advantages:

(1) Small Footprint

Unlike CAS, MBR separates sludge within an aeration tank using membranes, thus

eliminating the space for the sedimentation tank. Also with membrane, MBR can hold higher

concentration of activated sludge in the aeration tank, so its volume can be reduced. As a

result, MBR requires a smaller footprint compared to CAS.

(2) High Quality of Treated Water

MBR removes suspended solids (SS) from the sludge liquid with membrane much more

certainly than the conventional sedimentation process. MBR also rejects microorganisms

such as Escherichia coli and Cryptosporidium efficiently.

Sedimentation Tank

Wastewater

Aeration Tank

Discharge

Wastewater

Discharge or Reuse

Reuse

RO

membrane

Submerged Membrane

Module

Membrane

Tank

Fig. I-1 CAS Flow

Fig. I-2 MBR Flow

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

2 of 61

2. Outline of “NHPA Series”

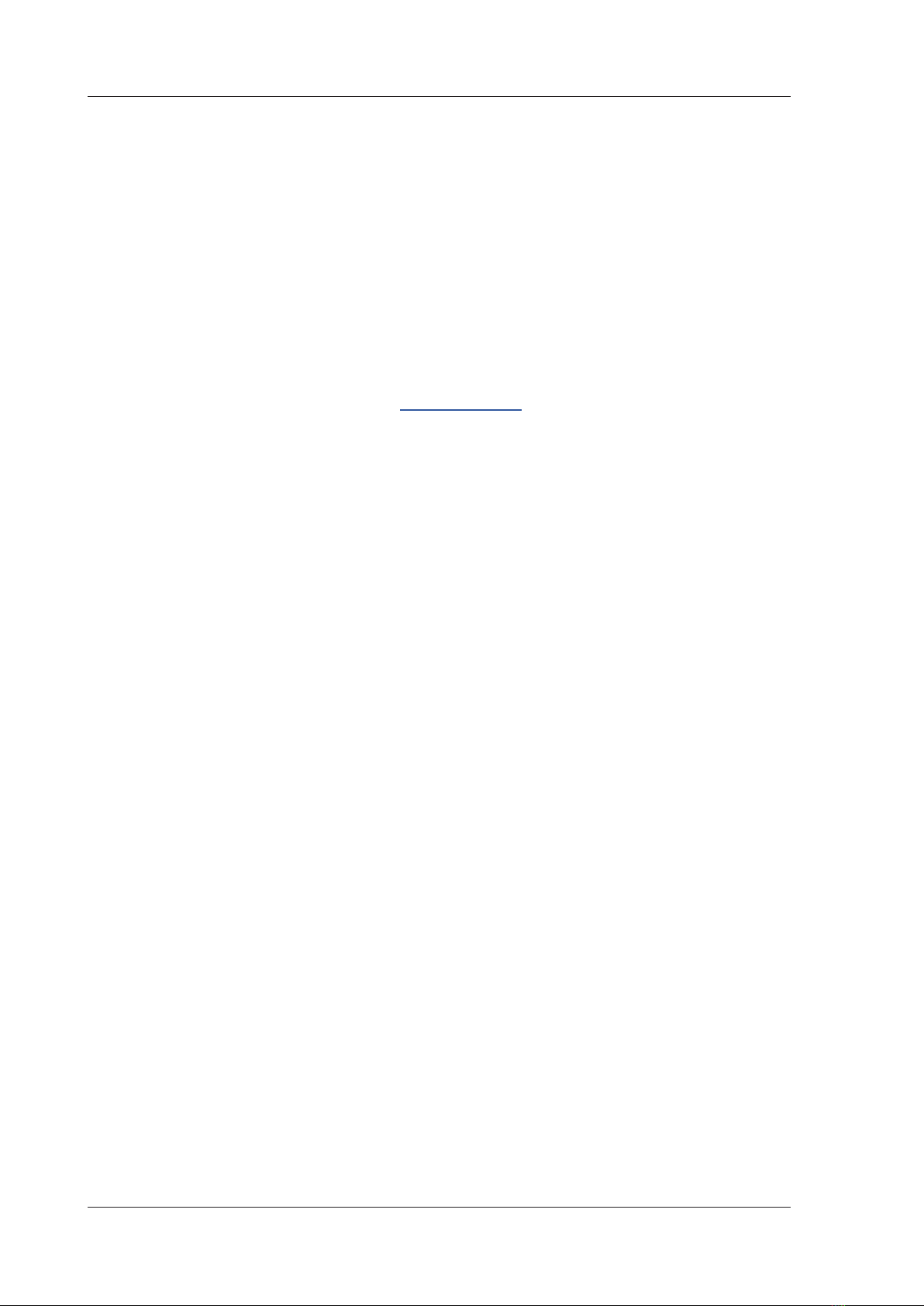

“NHPA Series” is the membrane module composed of the element block and the aeration

block. The element block contains several cassettes, and in the cassette the membrane

elements, each of which consists of two flat membrane sheets, are arranged at a constant

clearance. Each element is connected via plastic tube to the filtrated water manifold. For this

-C model, the aeration block consists of coarse-bubble air diffusers to supply scouring air

(see Fig.I-3).

This module is used submerged in sludge liquid.

The following shows the features of “NHPA Series”.

Fig. I-3 Components and Appearance of “NHPA150-1C”

Nozzle

Filtrate water manifold

Tubes

Module

Frame

Cassette

Element

50 sheets

Element

block

Aeration

block

Coarse

bubble

diffuser

3 pcs

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

3 of 61

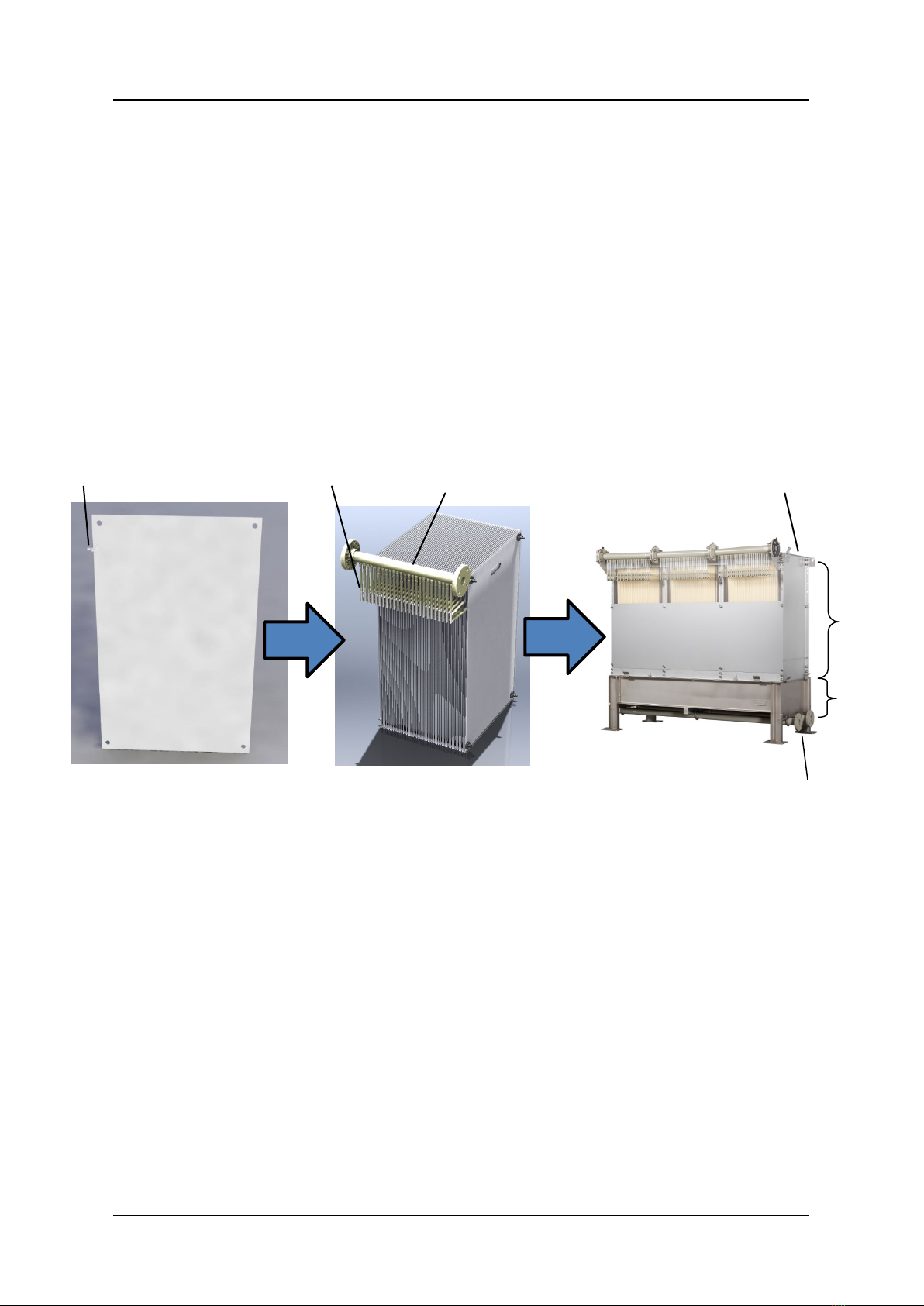

(1) Shape of Element

The membrane element is a flat sheet type as shown in Fig.I-4. At the normal filtration

operation, the sludge accumulated on the membrane surface is cleaned up effectively with

upward water stream generated with the scouring air supplied from the air diffusers installed

at the bottom side (Fig.I-5). This mechanism ensures the stable filtration since the membrane

does not easily admit of sludge adherence to its surface.

In addition, thin membrane element which consists of two membrane sheets and spacers in

between makes it possible to have higher membrane packing density in the module similar to

that of a hollow fiber membrane, and also the vibration of elements by scouring air improves

membrane cleaning efficiency.

Fig. I-4 Structure of Element

Fig. I-5 Filtration Principle of Activated Sludge

Air

Element

Filtrated water

Activated sludge

Membrane

Air

480

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

4 of 61

3.0 micrometer

Fig. I-6 Membrane Surface

(photo)

Fig. I-7 Pore Size Distribution

(2) Membrane Structure

The flat sheet membrane consists of a PVDF (Polyvinylidene Fluoride) functional layer and a

base layer of PET (polyester) non-woven fabric. This structure gives the membrane superior

physical strength and high chemical resistance.

(3) Membrane Pore Size

Numerous small-size pores are distributed evenly over the membrane surface with a sharp

pore-size distribution. This structure gives an outstanding high treated water quality and

excellent water permeability, making the membrane highly resistant to clogging (see Fig.I-6

and Fig.I-7) compared to other membranes. The average pore size is 0.08 micrometer.

(4) Cassette Replacement

Membranes can be taken out and exchanged by cassette. It is possible to replace only a

cassette which contains a damaged membrane.

Pore size (micrometer)

0

0.5

1.0

1.5

0.2

0.4

0.6

0.8

0

Number of pore (10

12

/m

2

)

0.08 micrometer

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

5 of 61

II. FOR SAFE OPERATION OF “NHPA SERIES”

Before using “NHPA Series”, please thoroughly read this Instruction Manual and follow the

instructions described in this manual, especially the safety precautions shown below. The

details of each precaution are described in the relevant chapter

1. Safety Instruction for Unpacking and Installation

Attach chains or slings to the lifting lugs when lifting element-deck, an

element block or aeration block of “NHPA Series”. Slowly raise the module

straight up. Avoid sudden changes in movement to minimize shaking the

module. Never allow personnel to stand under the “NHPA Series

” during

lifting.

Never lift or operate the module with worn or damaged parts. Use chains or

slings rated for the weight being lifted. Check the condition of each part

before lifting.

Do not lift upper element block and lower element block at once as one unit

when lifting NHPA150-3C or 4C

. Lift the upper and lower element block

separately.

Make provisions, in advance, to access the upper portions of the membrane

module via a scaffold or ladder when installing “NHPA Series” module. Do

not climb on the module structure. Never step on the air diffuser and filtrate

water manifold. Use protective equipment to ensure the safety of workers.

Wear the appropriate personal protective equipment (e.g. safety gloves) in

order not to cut one’s hand on the edge of the module frame.

During transportation, storage, and installation, take appropriate measures

to protect "NHPA Series" or associated components from damage. Do not

put any heavy objects directly on the module. Store the module in an area

that will minimize the risk of damage from moving equipment like forklifts etc.

Exposing the “NHPA Series” and membrane elements to temperatures

above 40 deg C or direct sunlight

should be avoided. Exposure to direct

sunlight/UV radiation will cause the polypropylene

air diffuser and filtrate

water manifold to deteriorate.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

6 of 61

Take adequate measures, during the installation process, to protect the

“NHPA Series” from: sparks emitted from welding equipment, fusion cutting,

or grinding.

Protect “NHPA Series” from freezing at all the time.

Avoid pressurizing the filtrate side of "NHPA Series”.

Install the screen with openings of 3.0 mm or under before the membrane

tank. Mesh type screen is recommended. Overflow or waste carryover must

be avoided at all the time.

Connect the flanges of air diffuser and filtrate water manifold to the piping

with the tightening torque of 20 N.m, in order to avoid distortion, leakage, or

breakage of the air diffuser and filtrate water manifold.

Consider piping materials

and regulate the load to the flange connection

points at less than 20 kg per flange in order to avoid distortion, leakage, or

breakage of the air diffuser and filtrate water manifold. If the load exceeds

the limit shown above, put some supports on the piping to reduce the load.

2. Safety Instruction for Operation and Maintenance

Filtrated water is not for potable uses. Do not drink the MBR filtrate.

Before discharging the treated water to the environment or reusing it, make

sure to analyze its quality and confirm that the water quality

meets the

intended purpose.

Do not burn the membranes without appropriate facilities since harmful

Hydrogen fluoride (HF) gas will be generated. H

ire a professional solid

waste disposal company to perform the task when

disposing of the

membrane elements.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

7 of 61

Make certain the air discharge valve is in the open position to assure any

accumulated air is released when first filling the membrane tank with clean

water or sludge. After the tank is filled with clean water,

close the air

discharge valve.

Do not use ground water for the initial filling of the membrane tank. Ground

water may contain considerable concentrations of iron, manganese, calcium,

or silica

. Naturally occurring compounds of these elements can clog the

membrane pores.

White foaming may occur in the membrane tank during clean water

operation. The foaming is caused by the leaching of residual biodegradable

hydrophilic components contained in the membrane after the manufacturing

process. Foaming is normal and does not adversely

affect the membrane

filtration process but if you want to remove this, do not use silicone-based

anti-foaming agent which may cause choking of membrane pores.

Do not operate the membranes longer than necessary to purge the system

of entrained air when using clean water in the MBR tank. Prolonged clean

water operation can clog the membrane pores.

Keep the membranes wet once they get wet. If the membranes are allowed

to dry out, the permeability of the membranes may be permanently reduced.

B

e sure to pass the seeding sludge through a screen to remove large

foreign materials when feeding the seeding sludge. It is recommended that

the screen mesh be 3 mm or smaller.

Make certain sufficient air is being

supplied to the membrane module air

diffuser before operating in the filtration mode. Failure to do so will result in

the membrane becoming clogged.

Do not allow chemicals, toxic agents, oils, or any other substances into the

MBR tank that may adversely affect the condition of the activated sludge.

If anti-

foaming agents are to be added to the membrane tank, use only

alcohol based anti-foaming products. Do not use silicone-based anti-foaming

agent which may cause choking of membrane pores.

Avoid abrupt changes to especially pH, temperature, and suction pressure,

when operating in the filtration mode, e

ven if these changes are within

acceptable operating guidelines.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

8 of 61

When it is obvious that a module part is worn and potential for failure is high,

promptly replace that part with approved replacement parts.

Never expose the “NHPA Series” to freezing temperatures at any time.

Take measures to keep the membrane elements wet

when removing the

“NHPA Series” module from the activated sludge for inspection or

maintenance

. Allowing the membrane elements to dry out will adversely

affect the membrane’s permeability.

The air scour should be stopped when the filtration process is suspended.

There are two exceptions:

1) Do not stop the air scour during the normal relaxation period.

2) Do not stop the air scour if the activated sludge requires air for normal

metabolic processes. However, under t

hese conditions the amount of air

flow directed to the diffuser should be reduced to just the amount required to

maintain sludge viability.

Once a filtrate tube has been removed or disconnected from either the

element nozzle or filtrate manifold,

it should be replaced with a Toray

approved replacement part. Old filtrate tubes lose their elasticity,

and the

integrity of the seal can be compromised.

Never use a pressure washer machine when

washing the membrane

module and element which c

an cause fatal delamination of membrane

element edge.

3. Safety Instruction for Chemical Cleaning of Element

Chemical agents used for chemical cleaning can be harmful to one’s health.

Wear protective goggles, protective gloves, and other safety gear when

handling chemicals. Make sure to check the details of its material safety

data sheet (SDS) beforehand.

If chemicals come in contact with your skin or clothes, immediately wash the

contacted area with a large volume of running water.

If chemicals splash into your eyes, immediately flush with large volumes of

running water and contact a doctor.

Immediately stop the

chemical cleaning operation if any of the associated

cleaning equipment appears to be malfunctioning.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

9 of 61

Do not inject any chemical into the membrane directly from the chemical

pump discharge. Excessive membrane element internal pre

ssure will

damage the element. Be sure to inject chemicals at a pressure less than 10

kPa (100 mbar).

Before starting injecting chemical to elements, confirm that the membrane

tank liquid level is more than 500 mm above the top of the module.

Store chemicals in a dark, cold place free from direct sunlight.

Use chemical storage tanks constructed of chemically compatible materials

to prevent corrosion.

Never mix sodium hypochlorite with heavy metals or acids.

The resulting

chemical reaction will generate toxic chlorine gas.

To avoid scattering of chemical solution turn off the air scour during a chemical

cleaning.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

10 of 61

III. SPECIFICATIONS AND PERFORMANCE OF “NHPA SERIES”

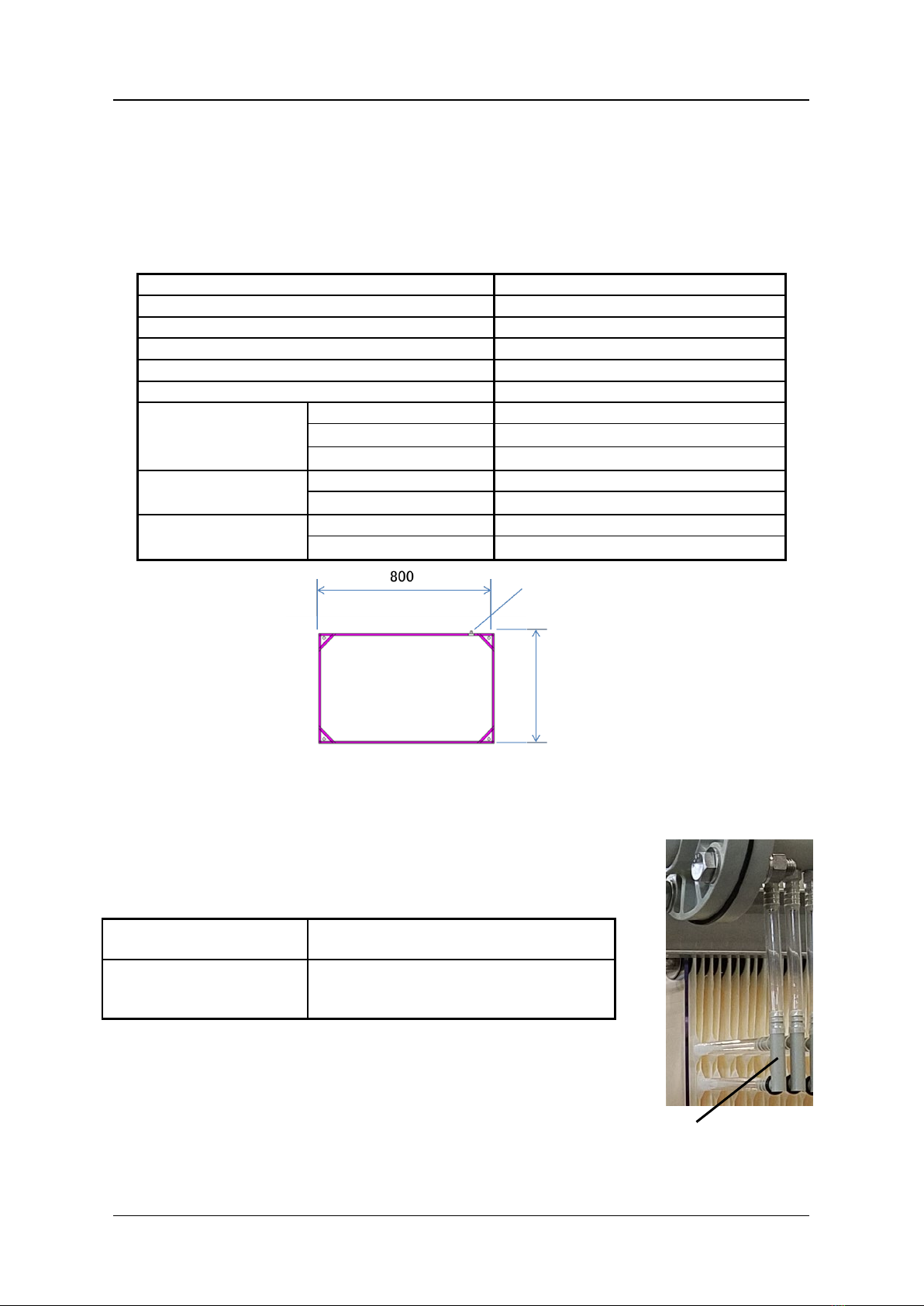

1. Specifications of Element

TableIII-1 and Fig.III-1 show the specifications and the physical dimensions for the NHPA

Series element.

Table III-1 Specifications of Element (TSP-50080)

Model name

TSP-50080

Membrane configuration

Flat sheet

Application

Filtration of activated sludge

Filtration method

Suction filtration

Nominal pore diameter (

µ

m)

0.08

Effective membrane area (m2)

0.7

Dimensions (mm)

Total width

480

Total height

800

Thickness

1.8

Weight (kg)

Dry

0.25

Wet (Reference)

0.5

Main material

Membrane

PVDF and PET non-woven fiber

Nozzle

PE

Fig.III-1 Element Appearance (mm)

2. Specifications of Filtrate Tube Assembly

Table III-2 and Fig. III-2 show the specifications and appearance of

Tube Assembly.

Table III-2 Specifications of Filtrate Tube Assembly

Material

Thermoplastic polyether-polyurethane (tube)

Polypropylene (connector)

Tube Inside diameter (mm)

Tube outside diameter (mm)

Dimensions (mm)

8

10

Approx. 125 x 155

Fig.III-2 Tube Assembly Appearance

*Two elements are connected to one manifold nozzle via tubes and connector

Nozzle

480

Connector

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

11 of 61

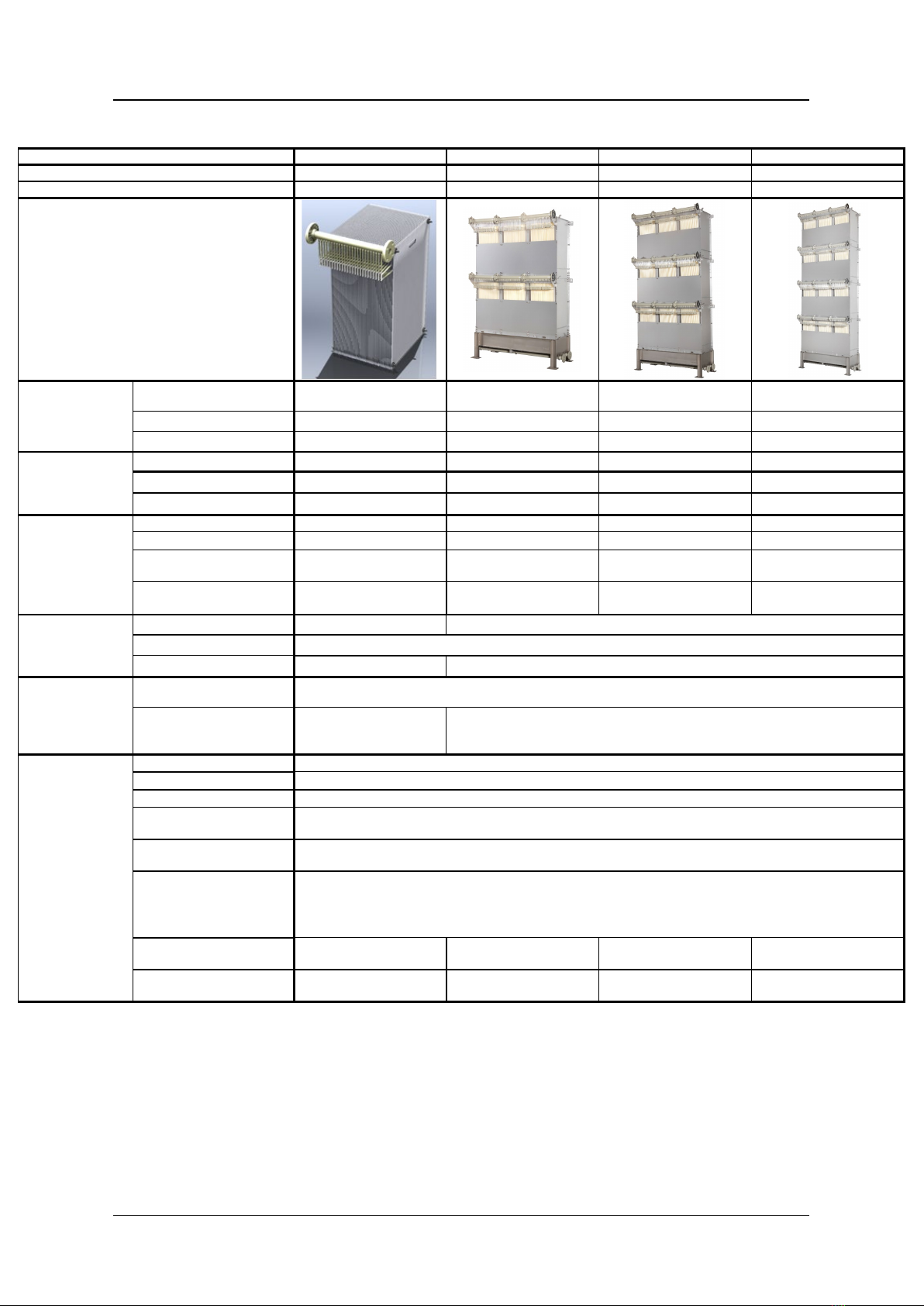

3. Specifications and Performance of “NHPA Series” Module

Figure III-3 shows the cassette arrangement of “NHPA Series” modules shown in this

Instruction Manual. Table III-3a shows the specifications of NHPA050-1C, 100-1C and

150-1C cassette and modules. Table III-3b shows the specifications of NHPA-150-2C, -3C,

and -4C cassette and modules.

Note that NHP210-300S and -600D are described in the separate Instruction Manual.

Contact Toray in case of replacing existing Toray MBR “TMR Series” or “NHP210 Series”

with “NHPA Series”.

Fig. III-3 Cassette Arrangement of the NHPA Modules Shown in This Manual

EBL050

EBL100

Cassette “ECS035”

ABL050-C

ABL100-C

ABL150-C

EBL150

EBL150

EBL150

+

+

+

⇩

⇩

⇩

Bolts/nuts

EBL150

+

+

EBL150

EBL150

Bolts/nuts

+

+

EBL150

EBL150

Bolts/nuts

+

+

EBL150

EBL150

Bolts/nuts

+

+

ABL150-C

ABL150-C

ABL150-C

+

+

+

NHPA050-1C

NHPA100-1C

NHPA150-1C

NHPA150-4C

NHPA150-3C

NHPA150-2C

⇩

⇩

⇩

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

12 of 61

Table III-3a Specifications of Cassette and Module (NHPA050-1C, 100-1C and 150-1C)

Model name

ECS035 (Cassette)

NHPA050-1C

NHPA100-1C

NHPA150-1C

Number of membrane elements

50

50

100

150

Cassette structure

-

1 cassette x 1 deck

2 cassettes x 1 deck

3 cassettes x 1 deck

Appearance

Overall

dimensions (mm)

Width

485

(excluding nozzle&hose)

738 738 763

Length

440

660

1,130

1,617

Height

820

1,404

1,404

1,404

Dimensions

excluding filtrate header

pipes and air diffuser

pipe

(mm)

Width

-

565

565

565

Length

-

501

986

1,460

Height

-

1,320

1,320

1,320

Weight

(kg)

Module (dry)

N/A

70

110

170

Aeration block (dry)

N/A

20

30

55

Cassette/Element block

(dry)

17 50 80 115

Cassette/Element block

(sludge clogging)

*1

145 175 340 500

Material

Frame

-

304SS (316LSS is available as option)

Filtrate water manifold

Polypropylene

Air diffuser

-

304SS (316LSS is available as option)

Polypropylene

Connection

Manifold

ANSI 1 1/2 inch flange using M12 bolts/nuts

One flange per module

Air diffuser -

ANSI 1 1/4 inch flange

Using M12 bolts/nuts

Two flanges per Aeration block

ANSI 1 1/2 inch flange

Using M12 bolts/nuts

Two flanges per Aeration

block.

Operating range*3

Temperature

5-40 deg C

pH*2 of liquid

5-10

MLSS

Not higher than 18,000 mg/L

Trans-membrane

pressure

Not higher than 20 kPa (200 mbar)

Cleaning chemicals feed

pressure

Not higher than 10 kPa (100 mbar)

Cleaning chemicals and

chemicals concentration

Sodium hypochlorite (effective chlorine concentration)

:2,000-6,000 mg/L(10<pH<12)

Oxalic acid :0.5-1.0wt%

Citric acid

:

1.0-3.0wt%

Scouring Air Flow rate

(NL/min/Module)

*4

-*5 330 - 670 670 - 1,340 1,000 - 2,000

Scouring Air Flow rate

(Cubic feet/min/Module)

*4

-*5 12 - 24 24 – 48 35 – 71

*1 The weight assumed in the case of sludge clogging between elements.

*2 Except when the chemical cleaning with the designated chemical agents.

*3 For the standard operating condition refer to the Instruction Manual.

*4 Air volume as being 0 deg C and 101.325 kPa (1 atm).

*5 MBR operation only by Cassette is not assumed.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

13 of 61

Table III-3b Specifications of Cassette and Module (NHPA150-2C, 3C and 4C)

Model name

ECS035 (Cassette)

NHPA150-2C

NHPA150-3C

NHPA150-4C

Number of membrane elements

50

300

450

600

Cassette structure

-

3 cassettes x 2 decks

3 cassettes x 3 decks

3 cassettes x 4 decks

Appearance

Overall

dimensions (mm)

Width

485

(excluding nozzle&hose)

763 763 763

Length

440

1,617

1,617

1,617

Height

820

2,304 *6

3,204

4,104*6

Dimensions

excluding filtrate header

pipes and air diffuser

pipe

(mm)

Width

-

565

565

565

Length

-

1,460

1,460

1,460

Height

-

2,220

3,120

4,020

Weight

(kg)

Module (dry)

N/A

285

400

515

Aeration block (dry)

N/A

55

55

55

Cassette/Element block

(dry)

17 230 345 460

Cassette/Element block

(sludge clogging)

*1

145 1,000 1,500 2,000

Material

Frame

-

304SS (316LSS is available as option)

Filtrate water manifold

Polypropylene

Air diffuser

-

Polypropylene

Connection

Manifold

ANSI 1 1/2 inch flange using M12 bolts/nuts

One flange per each deck (2C: 2 pcs per module, 3C: 3 pcs per module, 4C: 4 pcs per module)

Air diffuser -

ANSI 1 1/2 inch flange

Using M12 bolts/nuts

Two flanges per Aeration block.

Operating range*3

Temperature

5-40 deg C

pH*2 of liquid

5-10

MLSS

Not higher than 18,000 mg/L

Trans-membrane

pressure

Not higher than 20 kPa (200 mbar)

Cleaning chemicals feed

pressure

Not higher than 10 kPa (100 mbar)

Cleaning chemicals and

chemicals concentration

Sodium hypochlorite (effective chlorine concentration)

:2,000-6,000 mg/L(10<pH<12)

Oxalic acid :0.5-1.0wt%

Citric acid

:

1.0-3.0wt%

Scouring Air Flow rate

(NL/min/Module)

*4

-*5 1,000 - 2,000 1,300 - 2,000 1,300 - 2,000

Scouring Air Flow rate

(Cubic feet/min/Module)

*4

-*5 35 - 71 46 - 71 46 - 71

*1 The weight assumed in the case of sludge clogging between elements.

*2 Except when the chemical cleaning with the designated chemical agents.

*3 For the standard operating condition refer to the Instruction Manual.

*4 Air volume as being 0 deg C and 101.325 kPa (1 atm).

*5 MBR operation only by Cassette is not assumed.

*6 Check tank height and piping condition when using this module for replacement of existing Toray MBR

TMR140-100S or NHP210-300S/600D since NHPA is a little taller than existing modules.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

14 of 61

Table III-4 and III-5 shows the performance of ”NHPA Series” modules.

Table III-4 Filtrate water quality (Reference value)

Model name All models

Filtrate

water

quality*1

TSS (mg/L) *2 Not higher than 3.0

Turbidity (NTU) *3 Not higher than 1.0

*1 This value can be attained when operated under the standard operating conditions as specified in this

Instruction Manual and Operation and Maintenance guideline during a period specified separately by

Toray.

*2 Measuring method of TSS is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2540D, Total Suspended Solids Dried at 103-105 deg C or ISO 11923.

*3 Measuring method of NTU is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2130, Turbidity or ISO 7027.

Table III-5 Flow capacity (Reference value)

Model name NHPA050-1C NHPA100-1C NHPA150-1C

Filtration

Flow (m3/d)

*4

Sewage 3-25 7-50 10-75

Industrial wastewater 3-17 7-33 10-50

Model name NHPA150-2C NHPA150-3C NHPA150-4C

Filtration

Flow (m3/d)

*4

Sewage 20 - 150 30-225 40 - 300

Industrial wastewater 20 - 100 30-150 40 - 200

*4 This value is just a reference value and not a guaranteed value of Toray. Sustainable operating filtration

flow capacity varies among the plant depending on the type of wastewater, total process design, and

operating condition. In case of industrial wastewater application, it is strongly recommended to conduct

a pilot test before membrane tank designing.

TORAY MBR

Instruction Manual 06-G-MB2-NHPAC-220801

15 of 61

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “NHPA SERIES”

This section will address the following for the Toray “NHPA Series”: Standard sequence of

operation/time chart, illustrated piping, flow schema, and module(s) layout in the membrane

tank.

1. Standard Time Chart

Usually intermittent filtration (filtration with relaxation) is recommended. The most common

mode of filtration operation is nine (9) minutes of filtration followed by one (1) minute

of suspended membrane filtration (membrane relaxation) with continued air scour, as

shown in Fig.IV-1. This period of relaxation, with no filtration, allows the continued air scour

to be more effective at removing solids that may have accumulated on the surface of the

membrane. Intermittent filtration followed by a relaxation period is recommended for stable

and efficient membrane filtration.

The air scour should be suspended when the filtration process is stopped except for the

following conditions:

1) During normal membrane relaxation periods.

2) During suspended filtration operation unless aeration is required for mixing or biological

demand requirements. For the latter the air flow should be reduced to minimum flow

rates to prevent membrane damage.

* During low wastewater supply period, basically all modules should be in operation at lower

flux rate, considering maintaining viable activated sludge. In case operation of some or all

modules will be shut down, the air scour for those modules should be suspended or applied

intermittently following the above description. For long-term shutdown, refer to the following

Section 9, chapter VIII “Storage Products after Use”.

Fig.IV-1 Recommended Time Chart for Intermittent Filtration

Filtration

Air diffusion

Continuous Operation

Filtration: 9 min.

Relaxation: 1 min.

Cycle of 10 minutes

F1: Average flow rate for treatment capacity

and membrane area calculation

F2: Filtration flow rate for suction pump

capacity calculation

F1

F2

Other manuals for NHPA Series

1

This manual suits for next models

6

Table of contents

Other Toray Industrial Equipment manuals