NB tank application with floor drain, typicalFigure 2 NB tank application with condensate pump, typicalFigure 3

Installation

Application — Flue gas condensing boilers, fur-•

naces, and breeching condensate drains only.

DO NOT exhaust flue gases through NB tanks,•

they are not rated for boiler or furnace flue

gases. Operating NB tanks as exhaust vents can

cause injury or death from carbon monoxide.

NB tanks must be installed below all condensate•

traps, boiler, furnace, and breeching condensate

drains.

Gas traps must be installed between the boiler, vent drains, and•

furnace condensate outlet and the inlet of all NB tanks.

Before operating the boiler or furnace, fill the NB tank and traps•

with tap water.

NEVER operate with tubes or P-traps dry.•

Tubes should be recharged yearly, or when pH level moves below 6.•

Obtain neutralizing agent only from JJM Boiler Works.

Failure to comply with these guidelines could result in severe per-•

sonal injury, death or substantial property damage.

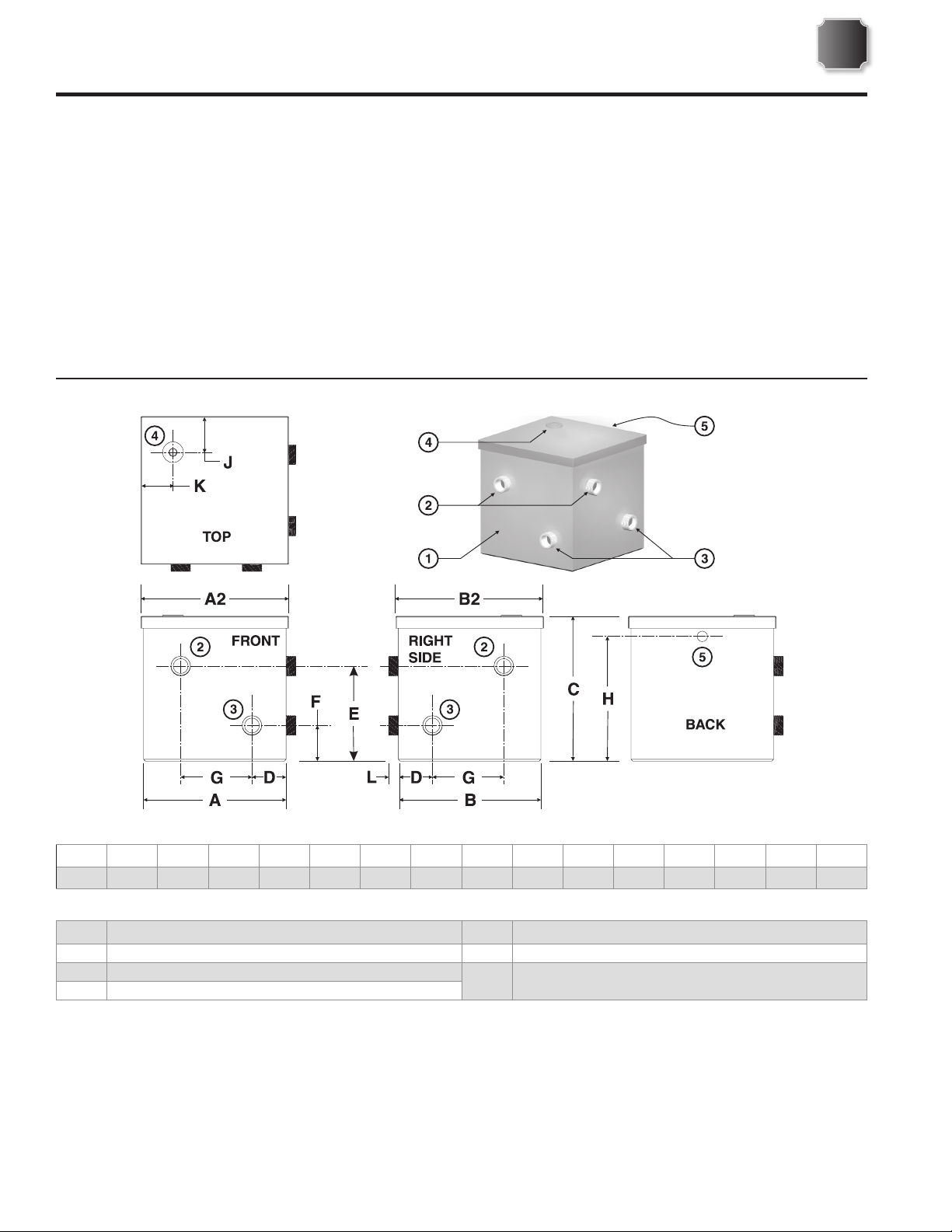

Legend

A Condensing boiler or furnace

B Condensate neutralizing tank

C Boiler/furnace condensate trap connection

D Boiler/furnace vent

E Vent condensate trap, when used — Install a trap as shown.

F Floor drain or sump

G Condensate pump

H Bottom of boiler/furnace condensate outlet — MUST be ABOVE

bottom of NB tube condensate outlet

J Bottom of NB tank condensate outlet

L Mounting pad or structural platform, when required to elevate boiler

condensate drain as needed

P PVC pipe — Include unions in the piping to allow removal of the NB

tank for inspection and service. — Secure pipe in place. — Protect

with a shield if necessary if routed through traffic areas.

Q Secure condensate piping in place with clamps (follow instructions

for securing at condensate pump, when used).

R Elevate the NB tank on a structural base if necessary for the outlet

to be raised.

S Route discharge line from condensate pump assembly per instruc-

tions supplied by pump manufacturer.

T Install ½-inch PVC vent piping to outside from vent tapping on top

of tank where required by codes. (A ½” thread-one-end PVC nipple

is supplied with the optional trim kit.)

U Install a union at each connection to the NB tank to allow discon-

nection for removal and servicing as needed. (Unions are supplied

in the optional trim kit.)

NOTE: Install a 1¼” pipe cap on the unused INLET and

OUTLET tank connections. (Caps are supplied in the

optional trim kit.)

Installation sequence

Before installing boiler or furnace, determine if a mounting pad will1.

be needed to elevate the boiler or furnace so that the condensate con-

nection will be above bottom of the NB tank OUTLET. See Figure 2

or Figure 3. Provide a mounting pad for the NB tank if needed to

obtain the proper elevation relative to a condensate pump reservoir

(when used — see Figure 3).

Place the NB tank in position. Fill the tank to the maximum fill line2.

with neutralizing agent obtained from JJM Boiler Works only.

Connect PVC piping from appliance or breeching drains to P-traps3.

and then from P-trap outlets to either one of the two NB tank

inlets.

Connect the NB tank outlet to house drain or condensate pump.4.

Use Teflon tape on all threaded plastic fittings.5.

NOTE6. — Always consult the local authority regarding any require-

ments concerning flue gas condensate handling codes.

R

Part number NB-001-0110 3

NB

-series Condensate Neutralizing Tanks — Installation, Operation & Maintenance

JJM