Lintec HX-0020J Series User manual

LN0538E2108D0

Heat Exchanger

Instruction Manual

HX-0020J Series

Safety precautions

Incorrect handling may cause death or injury.

(1) Before connecting with the fittings, check if no damageorproblemsare found on

the fittings. Connectproperly and makesure that leak test is conducted before

actual operation to prevent fluid from leaking into theatmosphere (Hereinafter,

the fluid used is referred as "gas" or "fluid").

(2) DO NOT apply any fluids corrosive to materials exposed to gas. Corrosion

may cause fluid to leak into the atmosphere. Please confirm the physical

properties of fluid before using.

(3) Thisdeviceisnotdesignedasanexplosion-proofstructure.

DONOTuse thisdevice in aplace where explosion-proofstructure are required.

Doing so may cause fireor explosion.

(4) Prepare temperature controller unit when operating Vaporizer/Heat

Exchanger and do not set the temperature over than maximum operating

temperature. Wring temperature setting may cause fire or destruction of the

device. It is recommended to add abnormal overheating detector if

necessary.

(5) This device must be earthed before use. Otherwise, there is the risk of

electric shock.

(6) Thermal switch is equipped in Vaporizer/Heat Exchanger to prevent

overheating. However, the operating temperature of thermal switch would

vary due to operating conditions and ambient temperature.

(7) Attach/remove connector and terminals, please make sure that power supply

turning off. It may cause fire or shock hazard.

Incorrecthandlingcancausemediumor slightinjuryor

maycause damageto,orlossof,facilities orequipment.

(1) Observe the listed in the WARNING (above).

(2) Use out-of-spec power supply will cause electric shock, fire, and

malfunction of device.

(3) This device is not designed to be waterproof. DO NOT locate this device

outdoors or in a place where it may be splashed with water. Doing so may

cause fire, trouble, or malfunction of the device.

(4) DO NOT modify this device. Modification may result in fire or failure of

the device.

(5) A warm-up period of 60 minutes is recommended after reaching the set

temperature. Otherwise, the output gas temperature will be low.

(6) This device is a precious device, please handle it carefully. Dropping down

or handing it carelessly will cause damage. Please use assist instrument

while moving or setting the device.

(7) Please use a screw with depth of 5mm or less from the case surface when

mounting HX by the hole on the surface (M3). It will crush the internal

surface of the product, and lead the break.

(8) The surface of device gets high temperature while heating up. Please wrap

up the device to prevent careless touch. Please be careful to deal with the

device while it is working because of the risk of burning from high

temperature. Please conduct replacement after checking that the device has

cooled down.

1. Introduction

This manual explains basic operation of the HX-0020J Series (Hereinafter

referred as "HX"). Please read through this manual carefully to familiarize

yourself with the features of HX.

.

2. Summary

HX is an ultra-clean high efficiency fluid heat exchanger unit employing Lintec’s

high efficiency liquid vaporization technology with maximum operating

temperature up to 200 °C and maximum heat exchange rate up to 10SLM. This

apparatus is employed over a wide range of applications from semiconductor

industries to other major manufacturing sectors.

3. Features

RoHS compliant.

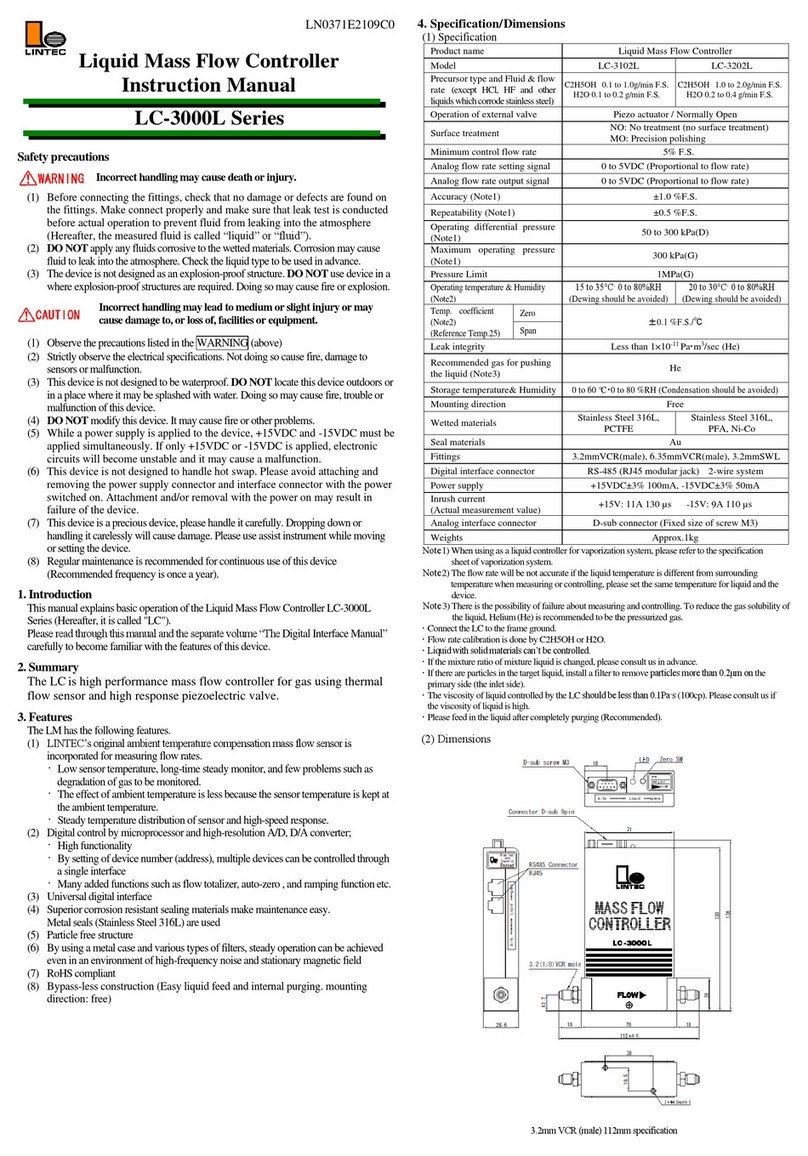

4. Specification/ Dimensions

(1) Specification

Product name

Heat Exchanger

Model

HX-0020J Series

Flow rate (N2)

10SLM

Pressure loss(N2)

24kPa (10SLM, 200°C)

Withstand pressure

(Gauge pressure)

1 MPa(G)

Leak integrity

Less than 1×10-11Pa·m3/sec (He)

Operating condition

Continuous operation

Operating temperature

15 to 50ºC (Without dew condensation)

Maximum operating

temperature

200ºC

Recommended temperature

control method

PID control

Material exposed to gas

Stainless steel 316L / Stainless steel 316L(EP)

Fitting

Inlet: 6.35mm (1/4”)VCR type female

Outlet: 6.35mm (1/4”)VCR type male

Heater

120V 100W

(100V 69.4W)

240V 100W

(200V 69.4W)

Power source

AC100 to 120V

AC200 to 240V

Thermocouple

K type 1pc

ThermalswitchSpecification

(Note1)

Over 230±10ºC OPEN

Return operating temperature 200±15ºC CLOSE

Electrical rating (With resistance load)

DC42V/200mA, Min:10mA

Mounting position

Free,

Except Upright with the connectors on the top

Weight

Approx.1kg

Standard accessories

None

Note1) In actual operation, there may be a difference between the temperature at the

temperature control point and the temperature at which the thermal switch operates.

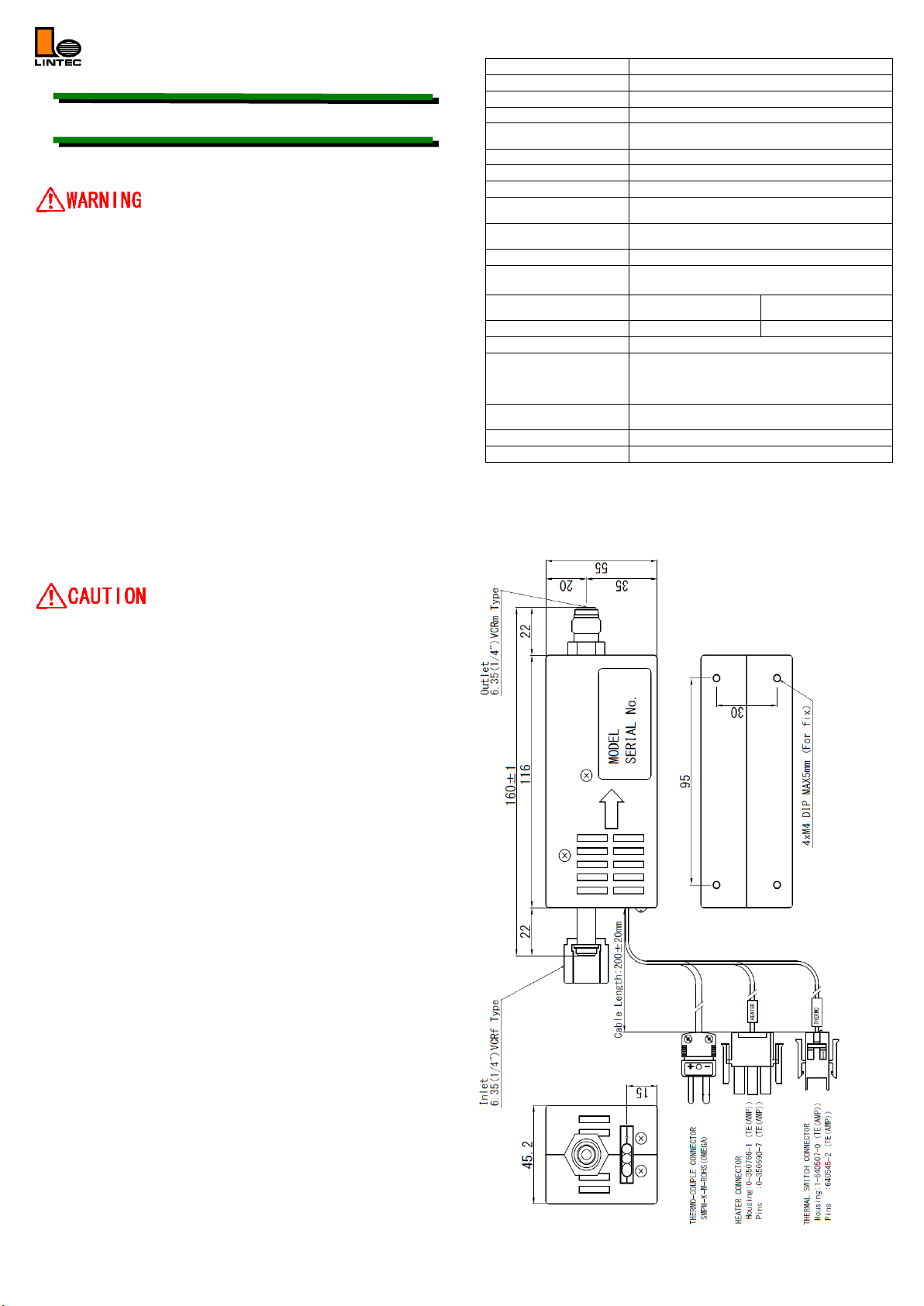

(2) Dimensions

5. Ordering information

HX-0020J-44 TK3 N L03 T23 NNN

[1] [2] [3] [4] [5] [6] [7]

[1] Series Model:

HX: Heat Exchanger Series

[2] Fitting size

44: IN 6.35mm (1/4in), OUT 6.35mm (1/4in)

[3] Fitting type

TK3: VCR type [IN female, OUT male]

[4] Internal treatment

N: No polishing (※Standard Specification)

E: Electrical polishing (※Option)

[5] Heater type

L03: AC120V 100W

L04: AC240V 100W

[6] Thermal switch

T23: 230 ±10 ºC

[7] Option

NNN: Standard specification

※Notation other than NNN means customer options. The specification will be

different from this specification sheet, please refer to specific specification sheet

please notice that the pin assignment may be different as well.

6. Connection

(1) Heater Connectors

Housing : 0-350766-1 (TE(AMP))

Pin : 0-350690-7 (TE(AMP))

Pin No.

Signal name

1

L03:120V 100W

L04:240V 100W

2

3

Case Gnd.

(2) Thermal switch Connectors

Housing : 1-640507-0 (TE(AMP))

Pin : 640545-2 (TE(AMP))

Pin No.

Signal name

1

Thermal switch

2

(3) Thermocouple Connectors

Equipped Connector : SMPW-K-M-ROHS (OMEGA)

Applicable Connector : SMPW-K-F-ROHS (OMEGA)

Pin No.

Signal name

K

K Type Thermocouple (-)

+

K Type Thermocouple (+)

7. Preparation and Operational Procedure

(1) Please prepare temperature control unit.120V100W(240V100W) heaters is

used. Please take care with respect to the heater capacities. In addition,

temperature control unit with built-in safety mechanisms is recommended

for temperature control point. As the built-in thermocouple is K type, please

select unit which is compatible with this type of thermocouple.

(2) Please be sure to use safety devices such as circuit breakers to prevent surge

currents and short circuits.

(3) Please be careful to attach this device in the direction of the gas flow. In

order to prevent a decrease in the gas temperature after heat exchange has

taken place, please heat the piping between the gas outlet and the next piece

of machinery.

(4) Please carry out connections according to the connector table. This device

has a built-in 230ºC thermal switch.

(5) The heater can be affected by humidity during storage. Ensure that

insulation resistance is above 20M ohm. If the insulation resistance drops

below 20M ohm, dry the HX and ensure that insulation resistance is above

20M ohm.

(6) Supply power, set the temperature to the desired value using the

temperature control units and allow 60 minutes for the device to stabilize

after the set temperature has been reached. Even though the temperature

control unit display temperature may be stable the temperature of the body

of the device is not. In order to achieve good heat exchange efficiency

please allow this device to stabilize before use.

(7) Estimated gas temperatures can be found from the graphs in the upper right.

However, this data is for nitrogen gas and should not be applied as is to

gases other than nitrogen. Please use this data only as a guide.

8. Product reference data

Since this data is for nitrogen, it cannot be applied directly to gases other than

nitrogen. Please use as a guide.

(1) Heat exchanger outlet gas temperature

< Measurement conditions >

·Heat exchanger set temperature: 50, 100, 150, 200°C

·Gas used: N2

·Measuring room temperature: 25°C

·Secondary line temperature control: None

(No heat insulating material, open to atmosphere)

·Secondary pressure: atmospheric pressure

(2) Pressure loss data

< Measurement conditions >

·Heat exchanger set temperature: 100, 150, 200°C

·Gas used: N2

·Measuring room temperature: 25°C

·Secondary pressure: atmospheric pressure

9. Product Warranty

(1) Period

This product is guaranteed for 1 year from the date of shipment.

Defects are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other damage caused

by this product is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty:

1) Failure caused by product of gas or liquid used.

2) Failurecausedbymisuse(includingcarelessoperation),incorrectrepairormodification.

3) Failure cause by falling or dropping after purchase.

4) Failure caused by fire,earthquake, flood,lightning,orother naturaldisasters.

Even if the warranty period is still in effect, repair service may not be provided

in the following cases.

1) When the kind of fluid used in the product is unclear.

2) Theproductisreturnedwithfluid remaininginside, and safetycannotbeconfirmed.

This instruction manual is subject to revision without notice.

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23Sekinotsu,OtsuCity,ShigaPref.520-2277,Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo160-0004,Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

Other Lintec Industrial Equipment manuals