Torex VDC Series User manual

VDC

Double dump valve

EN

TO320 - EN Ed. 04.09

UNI EN ISO 9001-2000

Certified Company

All the products described in this catalogue have been manufactured according to the operating

methods dened by the TOREX S.p.A. Quality System

The Company's Quality System, certied in July 2004 in conformity with international standards

ISO 9001:2000 is capable of ensuring that the entire production process, from formulation of the

order to technical assistance after delivery, is done in an appropriate controlled manner to ensure

the quality standard of the product.

This document cancels and replaces all other previous editions or revisions.

The Manufacturer reserves the right to make modications without giving prior notice.

Reproduction, even partial, without authorization is forbidden.

2 1 - Technical Catalogue

VDC

3

TO320 - EN - Ed. 04.09

Sommario

TECHNICAL CATALOGUE

1. INTRODUCTION ......................................................................................................... 2

1.1 Type .................................................................................................................................. 2

1.2 Description ....................................................................................................................... 2

1.3 Application sector ............................................................................................................. 2

1.4 Contraindications .............................................................................................................. 2

1.5 Operating temperatures ................................................................................................... 2

2. GENERAL LAYOUT ................................................................................................... 3

2.1 General layout of VDC with counterweight ....................................................................... 3

2.2 General layout of motor-operated VDC ............................................................................ 4

2.3 General layout of pneumatic VDC .................................................................................... 5

3. TECHNICAL DATA ..................................................................................................... 6

3.1 Solenoid valves technical data (VDC with pneumatic drive) ............................................ 8

3.2 Code key .......................................................................................................................... 9

3.3 Finish .............................................................................................................................. 10

3.4 Shade ..............................................................................................................................11

4. DIMENSIONS ....................................................................................................... 12

4.1 Double dump valve - with counterweight ........................................................................ 12

4.2 Motor-operated double dump valve ................................................................................ 13

4.3 Pneumatic double dump valve ....................................................................................... 14

4.4 Flanges ........................................................................................................................... 15

5. ACCESSORIES......................................................................................................... 16

5.1 Rotation indicator ........................................................................................................... 16

5.2 Dimensions ..................................................................................................................... 16

6. ORDER FORM .......................................................................................................... 17

4 VDC

TO320 - EN - Ed. 04.09

OPERATION AND MAINTENANCE

1. INTRODUCTION ......................................................................................................... 2

1.1 Type .................................................................................................................................. 2

1.2 Description ....................................................................................................................... 2

1.3 Application sector ............................................................................................................. 2

1.4 Contraindications .............................................................................................................. 2

1.5 Operating temperatures ................................................................................................... 2

2. SCOPE AND IMPORTANCE OF THE MANUAL ....................................................... 3

3. WARRANTY CONDITIONS ........................................................................................ 3

4. WARNINGS................................................................................................................. 4

5. PACKING .................................................................................................................... 7

6. UNPACKING ............................................................................................................... 7

7. UNLOADING AND HANDLING .................................................................................. 8

7.1 VDC lifting points .............................................................................................................. 8

7.2 Weights............................................................................................................................. 9

8. STORAGE ................................................................................................................. 10

8.1 Storage prior to installation ............................................................................................. 10

8.2 Prolonged machine shutdown after assembly ................................................................ 10

8.3 Possible reuse after prolonged shutdown ...................................................................... 10

9. OPERATING DIAGRAM ........................................................................................... 11

9.1 Flaps opening sequence .................................................................................................11

9.2 Direction of gear motor crank rotation .............................................................................11

10. INSTALLATION ........................................................................................................ 12

10.1 Mechanical connections ................................................................................................. 12

10.2 Pneumatic connections (VDC with pneumatic drive) ..................................................... 13

10.3 Electrical connections ..................................................................................................... 14

11. SWITCHING ON PROCEDURE................................................................................ 17

11.1 Switching Off procedure ................................................................................................. 17

11.2 Description of work sequence ........................................................................................ 17

12. MAINTENANCE ........................................................................................................ 19

12.1 VDC with counterweight ................................................................................................. 19

VDC

5

TO320 - EN - Ed. 04.09

12.2 Motor-operated VDC ...................................................................................................... 20

12.3 Pneumatic VDC .............................................................................................................. 21

12.4 Valve body ...................................................................................................................... 23

12.5 Motor-operated VDC ...................................................................................................... 24

12.6 Pneumatic VDC .............................................................................................................. 27

12.7 Valve body ...................................................................................................................... 33

12.8 Maintenance ................................................................................................................... 35

13. CLEANING ................................................................................................................ 36

14. NOISE........................................................................................................................ 37

15. SCRAPPING THE MACHINE ................................................................................... 37

16. POSSIbLE PRObLEMS ........................................................................................... 38

17. CHECK-LIST IN CASE OF FAULT .......................................................................... 39

18. RESIDUAL RISKS .................................................................................................... 40

18.1 Mechanical hazards ....................................................................................................... 40

18.2 Risks due to Electricity ................................................................................................... 40

18.3 Risks due to high temperatures ...................................................................................... 40

18.4 Noise, Vibrations. ........................................................................................................... 41

18.5 Emissions of hazardous matter/substances ................................................................... 41

SPARE PARTS CATALOGUE

1. PLATE 1 - bODY ........................................................................................................ 2

1.1 VDC 200 ........................................................................................................................... 3

1.2 VDC 250 ........................................................................................................................... 4

1.3 VDC 315 ........................................................................................................................... 5

1.4 VDC 400 ........................................................................................................................... 6

1.5 VDC 500 ........................................................................................................................... 7

1.6 “Code” reference Table ..................................................................................................... 8

2. PLATE 2 - COUNTERWEIGHT................................................................................. 10

2.1 VDC 200 ..........................................................................................................................11

2.2 VDC 250 ..........................................................................................................................11

2.3 VDC 315 ..........................................................................................................................11

2.4 VDC 400 ..........................................................................................................................11

2.5 VDC 500 ..........................................................................................................................11

6 VDC

TO320 - EN - Ed. 04.09

3. PLATE 3 - DRIVE UNIT ............................................................................................ 12

3.1 VDC 200 ......................................................................................................................... 13

3.2 VDC 250 ......................................................................................................................... 14

3.3 VDC 315 ......................................................................................................................... 15

3.4 VDC 400 ......................................................................................................................... 16

3.5 VDC 500 ......................................................................................................................... 17

3.6 Spares Kit Tables............................................................................................................ 18

4. PLATE 4 - PNEUMATICS ......................................................................................... 19

4.1 VDC 200 ......................................................................................................................... 20

4.2 VDC 250 ......................................................................................................................... 21

4.3 VDC 315 ......................................................................................................................... 22

4.4 VDC 400 ......................................................................................................................... 23

4.5 VDC 500 ......................................................................................................................... 24

4.6 Cylinders Kit Table .......................................................................................................... 25

5. PLATE 5 - ROTATION INDICATOR ......................................................................... 26

5.1 VDC 200 ......................................................................................................................... 27

5.2 VDC 250 ......................................................................................................................... 27

5.3 VDC 315 ......................................................................................................................... 28

5.4 VDC 400 ......................................................................................................................... 28

5.5 VDC 500 ......................................................................................................................... 29

TECHNICAL CATALOGUE

TO320 T - EN Ed. 04.09

1

VDC

Double dump valve

EN

2 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

INTRODUCTION1.

Type1.1

VDC

Description1.2

Double dump valve

Application sector1.3

The double dump valves are ideal for controlled unloading of powder or granular materials; they are mostly

suitable for de-dusting and for heavy-duty applications in all industrial sectors. Designed for operating require-

ments such as: high temperatures, highly abrasive materials and /or materials with large grain size. They are

also suitable for systems that do not require continuous ow of material.

Contraindications1.4

VDC valves are not suitable for conveying materials that are not owable in compliance with the

required quality standards.

VDC valves are not designed for operating in hazardous conditions or with hazardous materials.

Hazardous materials are those that are:

• Explosive;

• Toxic;

• Harmful;

• Inammable

Operating temperatures1.5

External temperatures -10°C to +50°C

Max. temperature of conveyed material 500°C.

1 - Technical Catalogue

3

TO320 T - EN - Ed. 04.09

GENERAL LAYOUT2.

General layout of VDC with counterweight2.1

In VDC with counterweight, the opening of the plate depends on the weight of the material.

The force of the material on the plate must overcome the force exerted by the weight on the lever.

The working is not regular over time.

General layout of VDC with counterweight

Pos. Qty. Description

12 Body

2 2 Shaft

3 2 Flap

4 2 Cover

54 Bearing

6 2

Lever for counterweight

7 2 Counterweight

8 2 Hopper

1

2

4

5

3

6

7

8

4 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

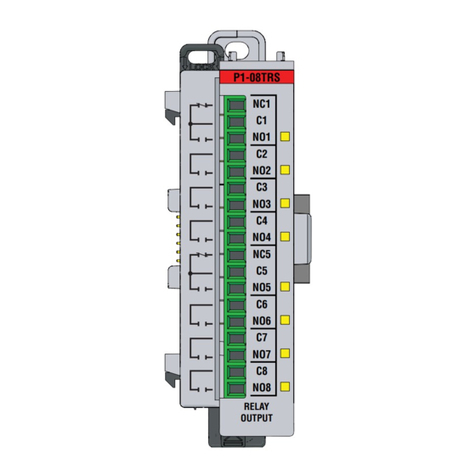

General layout of motor-operated VDC2.2

The activation of the closure plates is brought about by means of the gear motor, and they are opened

by means of a spring. This system (as compared to the gravity system) makes it possible to maintain

regular operation also with variable product loads.

General layout of motor-operated VDC

Position Quantity Description

12 Body

2 2 Shaft

3 2 Flap

4 2 Cover

54 Bearing

61Guard

71Reduction gear

81Motor

9 2 Lever

10 1 Reduction gear crank wheel

11 2 Hopper

12 1 Spring

A

A

A-A

4

23

7

659

10

9

11

1

8

12

1 - Technical Catalogue

5

TO320 T - EN - Ed. 04.09

General layout of pneumatic VDC

Position Quantity Description

12 Body

2 2 Shaft

3 2 Flap

4 2 Cover

54 Bearing

61Guard

71Pneumatic control unit

81 Junction box

9 4 Flow regulator

10 4 Magnetic limit switch

11 2 Lever

12 2 Cylinder

13 2 Hopper

General layout of pneumatic VDC2.3

The opening and closure of the plates is brought about by means of cylinders. The opening/closure

duration can be preset according to one's requirements. Like the motor-operated VDC, it is possible

to maintain regular operation also with variable product loads.

A

SEZIONE A-A

A

1

2 3

4

5

67

8

9

10

11

12

13

6 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

TECHNICAL DATA3.

Type

Ambient

Temp.

(°C)

Process

Temp.

(°C)

Differential

pressure

(bar)

Wt. of VDC

with counter-

weight (kg)

Wt. of mo-

tor-operated

VDC (kg)

Wt. of

pneumatic

VDC (kg)

Maximum

pc. size

(Ø mm)

200 -10/ +50 Max.500 0.05 115 140 120 68

250 -10/ +50 Max.500 0.05 160 190 170 75

315 -10/ +50 Max.500 0.05 205 240 220 90

400 -10/ +50 Max.500 0.05 380 420 400 110

500 -10/ +50 Max.500 0.05 490 570 550 140

Type Hopper capacity

(dm3)

Filling

coefcient

Theoretical throughput*

(dm3/h)

200 40.5 1200

250 70.5 2100

315 14 0.5 4500

400 31 0.5 9300

500 59 0.5 17700

* Calculated for 600 activation cycles/hour

Volume conveyed at each cycle according to the lling coefcient

0

10

20

30

40

50

60

0,20,4 0,60,8 11,2

VDC200

VDC250

VDC315

VDC400

VDC500

VOLUME CONVEYED (dm3)

FILLING COEFFICIENT

1 - Technical Catalogue

7

TO320 T - EN - Ed. 04.09

The lling coefcient varies according to the owability of material, the preset ow rate and the type

of conveyor upline of the VDC.

Materials available

Standard Available

Body Steel AISI304 AI-

SI316

Hopper Steel AISI304 AI-

SI316 Fe with polyurethane Hardox

Flap Steel AISI304 AI-

SI316 Fe with polyurethane Hardox

Drive unit

Type

Electric drive unit

Motor Reduction gear Drives

Type Power (kW) RPM Cycles/h

200 71B B5 0.37 1400 600

250 71B B5 0.37 1400 600

315 71B B5 0.37 1400 600

400 80B B5 0.55 1400 600

500 80B B5 0.55 1400 600

VDC with gear motor or pneumatic drive, 600 cycles/h

Volumetric capacity

Drive speed: the drive speed of the VDC with counterweight is determined by the fall of the mate-

rial.

0

5000

10000

15000

20000

25000

30000

35000

00,2 0,40,6 0,811,2

VDC200

VDC250

VDC315

VDC400

VDC500

FILLING COEFFICIENT

HOURLY THROUGHPUT (dm3/h)

8 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

Solenoid valves technical data (VDC with pneumatic drive)3.1

Type: ..............................................................................................5/2 monostable with spring return

Protection degree: .......................................................................................................................IP65

Operating pressure: ............................................................................................................2.5 - 8 bar

Nominal ow rate: ...................................................................................................620 NI/min (6bar)

Connections: ....................................................................................................................1/8” ISO228

Operating environment temperature: ..............................................................................-10°C +50°C

Operating uid temperature: .............................................................................................5°C + 50°C

Solenoid valves supply voltage and power: ..................................................................24V AC (8VA)

Solenoid valves diagram

Pos. Description

1Power supply

2Use

3Discharge

4Use

5Discharge

12 Mechanical spring

14 Line driver

14

513

12

42

1 - Technical Catalogue

9

TO320 T - EN - Ed. 04.09

VDC 250 10 1 1 0

1 Fe ap

2 AISI 304 ap

3 AISI 316 ap

4

Fe ap covered with wear-proof rubber

5 HARDOX ap

VDC Double dump valve

1Hopper made of carbon steel

2 Hopper made of AISI 304

2 Hopper made of AISI 316

4 Hopper made of Fe covered with

wear-proof rubber

5 Hardox hopper

200

250

315

400

500

1 Iron Body

2 AISI 304 body

3 AISI 316 body

10 Motor-operated 10 RPM

CP Counterweight

PN Pneumatic

SM Without Motor

1

0 Seals with Teon-coated packing

gland

Code key3.2

10 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

* Recommended shades

1) See Tab. X page T.11

2) See Tab. Y page T.11

The shades in Tables X and Y must be specied in the order.

Rust-proof shade = red-brown.

3 P D

1)

2)

STANDARD

P D

Paint

3

P

INTERNAL

Powder paint

Finish

**

* Attention: the internal and external shades must be the same.

80 µm

P

D

*

Finish3.3

P

EXTERNAL

Powder paint

80 µm

P

SHADE

O none

A Caterpillar yellow*

B RAL 1013 pearl white

C RAL 1015 light ivory

D RAL 5010 gentian blue*

E RAL 5015 sky blue

F RAL 6011 reseda green

G RAL 7035 light grey*

H RAL 7032 pebble grey

I RAL 7001 silver grey

L RAL 9001 creamy white

M RAL 9002 grey white

N RAL 9010 pure white

P Aluminium

X Ecological shades

Y Non environment-friendly shades

Z as per specication

1 - Technical Catalogue

11

TO320 T - EN - Ed. 04.09

X - “ENVIRONMENT-FRIENDLY” RAL SHADES WITHOUT CHROMIUM AND LEAD

1000 1001 1002 1011 1014 1019

3005 3007 3009 3027

4001 4004 4005 4006 4007 4008

5000 5001 5002 5003 5004 5005 5507 5008 5009 5011 5012 5013 5014 5017

6000 6003 6004 6006 6012 6013 6015 6016 6019 6020 6021 6022 6025 6026 6027 6028 6033 6034 6034

7000 7002 7003 7004 7005 7006 7007 7008 7009 7010 7011 7012 7013 7015 7016 7021 7022 7023 7023

7024 7025 7026 7030 7031 7033 7034 7036 7037 7038 7039 7040 7042 7043 7044

8000 8001 8002 8004 8011 8015 8016 8017 8019 8022 8024 8025 8028

9003 9004 9005 9011 9016 9017 9018

Y - “NON ENVIRONMENT-FRIENDLY” RAL SHADES CONTAINING CHROMIUM-LEAD

RAL 1006 Corn yellow

RAL 1007 Chrome yellow

RAL 1018 Zinc yellow

RAL 2008 Orange light red

RAL 6017 May green

RAL 6018 Yellow green

Shade3.4

12 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

DIMENSIONS4.

Double dump valve - with counterweight4.1

Type A A1 A2 B B1 B2 C D D1 D2 E E1 E2 F G

200 315 157,5 157,5 315 157,5 157,5 410 545 228 317 573 158 415 720 12

250 375 187,5 187,5 375 187,5 187,5 440 585 255 330 603 188 415 720 16

315 460 230 230 460 230 230 500 656 294 362 660 230 430 920 16

400 545 272,5 272,5 545 272,5 272,5 615 795 351 444 903 273 630 1074 20

500 655 327,5 327,5 655 327,5 327,5 720 915 400 515 1098 328 770 1224 20

E

FG

A

D

E1 E2 D1 D2

A2

A1

B1 B2

B

C

1 - Technical Catalogue

13

TO320 T - EN - Ed. 04.09

Motor-operated double dump valve4.2

Type A A1 A2 B B1 B2 C D D1 D2 E E1 E2 F G

200 315 157,5 157,5 315 157,5 157,5 410 734 227 507 600 215,5 384,5 720 12

250 375 187,5 187,5 375 187,5 187,5 440 785 255 530 600 215,5 384,5 720 16

315 460 230 230 460 230 230 500 857 293,5 563,5 665 197 468 920 16

400 545 272,5 272,5 545 272,5 272,5 615 1018 351 667 763 223 540 1074 20

500 655 327,5 327,5 655 327,5 327,5 720 1116 400 716 825 172 655 1224 20

F

D

E

G

A

B

C

B1 B2

A2A1

D1 D2

E1 E2

14 1 - Technical Catalogue

TO320 T - EN - Ed. 04.09

Pneumatic double dump valve4.3

Type A A1 A2 B B1 B2 C D D1 D2 E E1 E2 F G

200 315 157,5 157,5 315 157,5 157,5 410 864 227 637 623 238 385 720 12

250 375 187,5 187,5 375 187,5 187,5 440 915 255 660 653 268 385 720 16

315 460 230 230 460 230 230 500 988 294 694 778 310 468 920 16

400 545 272,5 272,5 545 272,5 272,5 615 1148 351 797 893 353 540 1074 20

500 655 327,5 327,5 655 327,5 327,5 720 1246 400 846 1063 408 655 1224 20

A

B

C

B1 B2

A2A1

D1 D2

D

E1 E2

E

G

F

This manual suits for next models

5

Table of contents

Other Torex Control Unit manuals