Torin BIG RED TR9010 User manual

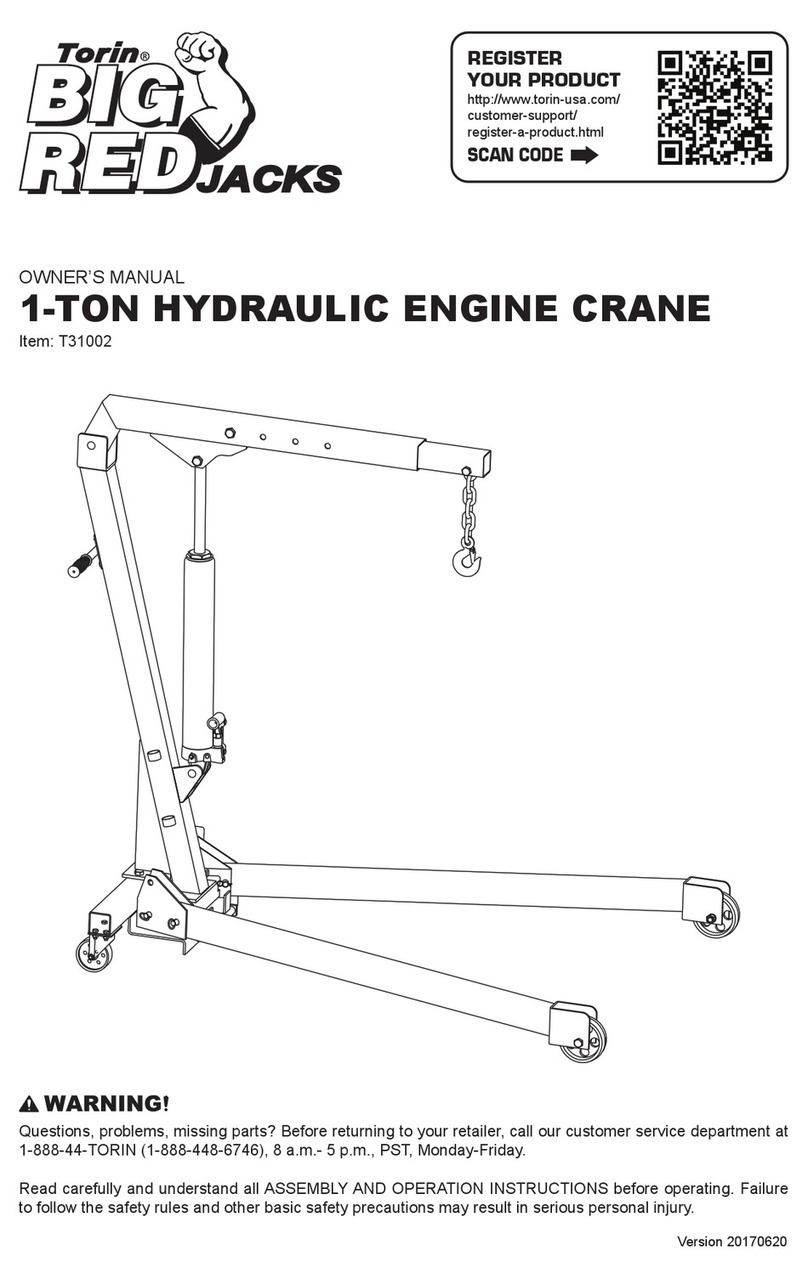

OWNER’S MANUAL

CHAIN BLOCK

Item: TR9010 TR9020 TR9030 TR9050

Questions, problems, missing parts? Before returning to your retailer, call our customer service department at

1-888-44-TORIN (1-888-448-6746), 8 a.m.- 5 p.m., PST, Monday-Friday.

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure

to follow the safety rules and other basic safety precautions may result in serious personal injury.

Version 20180314

REGISTER

YOUR PRODUCT

http://www.torin-usa.com/

customer-support/

register-a-product.html

SCAN CODE

IMPORTANT

OWNER / USER RESPONSIBILITY

INTENDED USE

TECHNICAL SPECIFICATIONS

Before You Begin Register This Product.

For future reference, record the model name, model number, date of manufacture and purchase date of this

product. You can nd this information on the product.

Model Name ________________________

Model Number ________________________

Date of Manufacture _______________________

Date of Purchase ________________________

DO NOT OPERATE OR REPAIR THIS PRODUCT WITHOUT READING THIS MANUAL.

Read and follow the safety instructions. Keep Instructions readily available for operators. Make certain all

operators are properly trained and understand how to safely and correctly operate the product. By proceeding

you agree that you fully understand and comprehend the full contents of this manual. Failure to operate this

product as intended may cause injury or death. The manufacturer is not responsible for any damages or injury

caused by improper use or neglect. Allow product operation only with all parts in place and operating safely.

Use only genuine replacement parts. Service and maintain the product only with authorized or approved

replacement parts; negligence will make the product unsafe for use and will void the warranty. Carefully

inspect the product on a regular basis and perform all maintenance as required. Store these instructions

in a protected dry location. Keep all decals on the product clean and visible. Do not modify and/or use for

any application other than that for which this product was designed. If you have any questions relative to a

particular application, DO NOT use the product until you have rst contacted the distributor or manufacturer to

determine if it can or should be performed on the product.

For technical questions please call 1-888-448-6746.

The CHAIN BLOCK is a portable lifting device easily operated by hand chain. It is suitable for use in factories,

mines, farms, construction sites, wharves, docks and warehouses for installation of equipment, as well as

for loading and unloading goods. It is specially advantageous for lifting work in open air grounds and places

where no power supply is available. The chain block can be attached to a trolley of any type as a traveling

chain block. It is suitable to monorail overhead conveying system, hand travelling crane and jid crane.

2

Model Capacity

(Ton)

Lift Height

(m)

Headroom

(Hook to Hook)

(mm)

Chainpull

to Lift

Full Load

No.of Load

Chain

TR9010 1 2.5 300 330N 1

TR9020 2 2.5 380 330N 2

TR9030 3 3 470 390N 2

TR9050 5 3 600 420N 4

GENERAL SAFETY RULES

GENERAL SAFETY RULES

IMPORTANT SAFETY CONSIDERATIONS

WARNING: Read and understand all instructions. Failure to follow all instructions listed below may result

in serious injury.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that could occur. It must be understood by the operator

that common sense and caution are factors that cannot be built into this product, but must be supplied by

the operator.

CAUTION: Do not allow persons to operate or assemble this jack until they have read this manual and

have developed a thorough understanding of how the jack works.

INSPECTION

DO NOT PULL THE HAND CHAIN IN A POSITION OBLIQUE TO THE PLANE OF THE HAND WHEEL TO

PREVENT TANGLING OF THE HAND CHAIN AND TURING OF THE BLOCK.

5. For the sake of safety passing or working under a lifting load is strictly forbidden.

6. While lifting or lowering a load, the hand chain should be pulled steadily so as to prevent it from breaking or

tangling.

7. Stop operation immediately in case that the hand chain cannot be pulled any further and proceed to inspect

as following:

a) Check for any tangles with the load.

b) Check for any troubles with the parts of the block.

c) Check that the load weight is not over the rated capacity of the block.

1. Judge the weight of the load to be lifted and make sure the weight does not over rate de capacity of the

chain block. Never overload the block in any circumstance.

2. Careful inspection should be made to the parts, such as hooks, load chain and braking device. The chain

block can only be used if it’s found to be in perfect conditions.

3. Before lifting, inspect the hooks to make sure they are securely attached. For a better performance of the

block, the load chain should be kept vertically straight without any twist to prevent it from tangling.

4. During operation, the operator should stand in the plane of the hand wheel (9). To lift the load, pull the

hand chain (15) to rotate the hand wheel in clockwise direction. When pulling the hand chain in the reverse

direction, the hand wheel will be separated from the brake seat (10), the ratchet disc (14) checked by pawl

(17) will be released, and the load will be lowered down smoothly.

SAFETY MARKINGS

1. Clean off the dirt on the chain block after use and store it in a dry place to keep it from getting rusty and

corrosiveness.

2. Clean the parts with kerosene and smear the gears and bearings with grease once a year by a skilled

person.

3. Align the “0” marks of the two gears (8) while assembling.

4. The rollers (12) of the chain sprocket bearing may be stuck with grease to the journal of the chain sprocket (4)

before tting them into the outer race of the bearing (13) on the side plate.

5. While assembling the break mechanism, care should be taken to mesh the slanting teeth of the ratchet disc

and the pawl. Make sure that the pawl is controlled by the spring sensitively and reliably. Then turn the

hand wheel clock-wise after screwing it onto the driving shaft, and it must press the disc and the plates on

the brake seat. Turning it counterclockwise, there should be clearances between the disc and the plates.

6. Transition t is applied to the stay (3) and the right side plate (2). Don’t dismantle them, or they will get

loose.

7. Never allow any layman to disassemble the blocks.

8. After cleaning and repairing the block should be subjected to no-load test and heavy load test. A chain

block can be put into operation after it has been tested and found in good condition.

9. Keep clean the friction surfaces of the brake while lubricating or operating the block. Brake mechanism

should be inspected regularly for prevention of faulty braking and falling of the load.

WARNING!

3

4

IMPORTANT SAFETY INFORMATION

Basic Safety Information

Installation Specic Safety Information

Inspection, Testing, and Maintenance Specic Safety Information

Operation Specic Safety Information

SAVE THESE INSTRUCTIONS.

1. Do not lift more than rated load. Be aware of dynamic loading! Sudden load movement may briey create

excess load causing product failure.

2. Do not operate hoist with twisted, kinked, or damaged chain. Inspect chain carefully before every use.

3. Do not operate a damaged or malfunctioning hoist. Inspect hoist carefully and test operation before every

use.

4. Do not lift people or lift loads over people. Falling loads can injure or kill people.

5. Do not operate hoist with anything other than manual power (by hand).

6. Do not remove or cover warning labels and/or tags. These carry important safety information. If unreadable

or missing, contact Customer Service for a replacement.

7. The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible

conditions and situations that may occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be supplied by the operator.

1. The supporting structure the hoist is mounted to (including trolley, monorail, or crane) must be designed to

withstand the loads and forces imposed by the hoist for the rated load.

2. Install in location that allows the operator to move and stay clear of the load.

3. Where the slack chain hanging from the hoist may create a hazard, use an appropriate chain container (not

provided) to contain the excess chain.

4. Inspect the hoist as explained in Frequent Inspection on page 8 after installation but before use.

1. Perform a “Frequent Inspection” daily.

2. Perform a “Periodic Inspection” every 3 Months.

3. More frequent inspections are needed for hoists that are used heavily.

4. Raise test loads only to the minimum extent needed and stay well clear of load at all times during testing.

1. Wear ANSI-approved safety goggles, ANSI-approved hard hat, and steel-toed work boots during setup and

use.

2. This product is not a toy. Do not allow children to play with or near this item.

3. Use as intended only. Do not use to handle molten material. Do not use for aircraft purposes.

INSTALLATION INSTRUCTIONS

Read the ALL SAFETY INFORMATION in this manual including all text under subheadings

therein before set up or use of this product.

Note: For additional information regarding the parts listed in the following pages, refer to Parts List and

Diagram .

1. The supporting structure the hoist is mounted to (including trolley, monorail, or crane) must be designed to

withstand the loads and forces imposed by the hoist for the rated load.

2. Properly seat the suspension hook on the supporting structure at its intended load bearing point

(see the left side diagram of Figure A).

• Do not allow the hook hitch to support any part of the load.

• Do not apply the load to the point of the hook (shown in Figure A on the right side diagram).

Figure A:— Correct and incorrect

suspension hook attachment

5

OPERATION INSTRUCTIONS

Read the ALL SAFETY INFORMATION in this manual including all text under subheadings

therein before set up or use of this product.

TO PREVENT SERIOUS INJURY: Operation of a vertical hoist involves more than pulling the hand chain

of a hand chain operated hoist. The use of vertical hoists is subject to certain hazards that cannot be met

by mechanical means, but only by the exercise of intelligence, care, common sense, and experience in

anticipating the motions that will occur as a result of operating the controls.

Before Operating Hoist

Operating Controls

1. Familiarize yourself with all operating controls of the hoist and with the operation(s) to be performed.

Instructions include, the warnings on the hoist, and the safety and operating instructions portion of this

manual.

2. WARNING! TO PREVENT SERIOUS INJURY FROM HOIST FAILURE: Do not use damaged

equipment. If adjustments or repairs are necessary, or any defects are known, have the problem

corrected before further use.

3. Do not operate a hoist with an out-of-order sign.

4. Only a qualied technician should perform maintenance to the hoist.

5. Do not use the chain or rope as a ground for welding.

6. Do not touch a welding electrode to the chain or rope.

7. Only operate hand chain operated hoists with hand power, with no more than one operator per hand chain.

8. Designate a work area that is clean and well-lit. The work area must not allow access by children or pets to

prevent distraction and injury.

9. There must not be objects, such as utility lines, nearby that will present a hazard while working.

10. Inspect the hoist as explained in Frequent Inspection on page 8 after installation but before use.

6

Applying the Load

Moving the Load

Locking (Parking) the Load

1. Do not wrap the hoist rope or chain around the load.

2. Attach the load to the load hook securely by properly rated, suitable means, such as chains, shackles,

hooks, lifting slings, etc. Load must be attached to prevent accidental disconnection.

3. Properly seat the sling or other device in the base (bowl or saddle) of the hook (see the left side diagram on

Figure D). Do not allow the hook hitch to support any part of the load.

4. Do not apply the load to the point of the hook (shown in Figure D on the right side diagram).

5. Before moving the load, make sure chains or wire rope are not kinked or twisted or that multiple part chains

or ropes are not twisted around each other.

6. Do not operate the hoist unless rope or chain is seated properly on the drum, sheaves, or sprockets.

7. Do not operate the hoist unless the hoist unit is centered over the load.

8. Do not pick up a load in excess of the rated load appearing on the hoist or load block, except during

properly authorized tests.

9. Do not use a hoist overload limiting device to measure the maximum load to be lifted.

10. Give specic attention to load balancing and hitching or slinging to prevent load slipping.

1. Do not engage in any activity which will divert the operator’s attention while operating the hoist.

2. Respond to signals from a designated person only. However, always obey a stop signal, no matter who

gives it.

3. Do not lift or lower a load with the hoist until the operator and all other personnel are clear of the load.

4. Make sure the load and hoist will clear all obstacles before moving or rotating the load.

5. Do not lift a load more than a few inches until it is well balanced in the sling or lifting device.

6. Each time a load approaching rated capacity is handled, check hoist brake action by lifting the load just

clear of supports and continuing only after verifying that the brake system is operating properly.

7. WARNING! Do not carry any load over any person.

8. WARNING! Do not carry personnel on the hook or the load.

9. Avoid swinging the load or load hook when traveling the hoist.

10. On trolley mounted hoists, avoid contact between trolleys and between trolleys and stops.

11. Do not use the upper (or lower, if provided) limit devices as a normal means of stopping the hoist. These

are emergency devices only.

1. Do not leave a suspended load unattended unless specic precautions have been instituted and are in

place.

2. Position the load block above head level for storage when the hoist is not in use.

3. Exercise care when removing a sling from under a landed and blocked load.

Figure D:— Correct and incorrect

load hook attachment

7

INSPECTION, TESTING, AND MAINTENANCE

Procedures not specically explained in this manual must be performed only by a qualied

technician.

Daily Inspection

Perform the procedures in this section BEFORE INITIAL USE and DAILY. Inspection is needed more often for

heavily used hoists.

1. Check operating mechanisms for proper operation, proper adjustment, and unusual sounds.

2. Frequent Braking System Inspection The braking system must automatically stop and hold up to the rated

load if the hand chain is released.

3. Frequent Hook Inspection

a. distortion, such as bending, twisting, or increased throat opening

b. wear

c. cracks, nicks, or gouges

d. latch engagement (if equipped)

e. damaged or malfunctioning latch (if provided)

f. hook attachment and securing means.

4. Frequent Hoist Load Chain Inspection:

a. Test the hoist under load in lifting and lowering directions and observe the operation of the chain and

sprockets. The chain should feed smoothly into and away from the sprockets.

b. If the chain binds, jumps, or is noisy, rst see that it is clean and properly lubricated. If the trouble persists,

inspect the chain and mating parts for wear, distortion, or other damage.

c. Examine visually for gouges, nicks, weld spatter, corrosion, and distorted links. Slacken the chain and move

the adjacent links to one side to inspect for wear at the contact points. If wear is observed or if stretching is

suspected, the chain should be measured as follows:

I) Select an unworn, un-stretched length of the chain (e.g., at the slack end).

II) Suspend the chain vertically under tension and, using a caliper-type gauge, carefully measure the outside

length of any convenient number of links approximately 12" to 24" overall.

III) Carefully measure the same number of links in the used sections and calculate the percentage increase in

length.

IV) If the used chain is 2.5% longer than the unused chain, replace the chain.

5. Check rope or load chain reeving.

WARNING! TO PREVENT SERIOUS INJURY FROM HOIST FAILURE: Do not use damaged

equipment. If any defect or damage is noted, repair the problem before further use.

8

3 Month Inspection

Storage Inspection

A qualied technician should perform the procedures in this section AT LEAST EVERY 3 Months. Inspection

is needed more often for heavily used hoists. Remove or open access covers to allow inspection of

components.

1. First, follow all Frequent Inspection procedures. Additionally:

2. Check fasteners for evidence of loosening.

3. Check load blocks, suspension housings, hand chain wheels, chain attachments, clevises, yokes,

suspension bolts, shafts, gears, bearings, pins, rollers, and locking and clamping devices for evidence of

wear, corrosion, cracks, and distortion.

4. Check hook retaining nuts or collars, and pins, welds, or rivets used to secure the retaining members for

evidence of damage.

5. Check load sprockets, idler sprockets, drums, and sheaves for evidence of damage and wear.

6. Check the brake mechanism for evidence of worn, glazed, or oil contaminated friction disks; worn pawls,

cams, or ratchets; and corroded, stretched, or broken pawl springs.

7. Check supporting structure or trolley, if used, for evidence of damage.

8. Check warning label for legibility and replacement.

9. Check end connections of wire ropes or load chains for evidence of wear, corrosion, cracks, damage, and

distortion.

10. Check the hoist and hoist mounting or evidence of missing parts.

1. Store in a dry location, recommended indoors.

2. A hoist that is used in infrequent service, which has been idle for a period of a month or more, but

less than a year, must be inspected before being placed in service according to the Frequent Inspection

requirements.

3. A hoist that is used in infrequent service, which has been idle for a period of a year or more, must be

inspected before being placed in service according to the Periodic Inspection requirements.

4. Equipment should be stored in an area where they will not be subjected to damage.

5. If extreme temperatures or chemically active or abrasive environments are involved, the guidance provided

in shall be followed.

6. Temperature - When equipment are to be used at temperatures above 140"F (60"C) or below -20"F (-29"C),

the equipment manufacturer or a qualied person should be consulted.

7. Chemically Active Environments -The strength and operation of equipment can be affected by chemically

active environments such as caustic or acid substances or fumes. The equipment manufacturer or a

qualied person should be consulted before equipment are used in chemically active environments.

8. Other Environments - The internal workings of equipment can be affected by high moisture, gravel or

sand, silt, grit, or other dust-laden air. Equipment subject to these environments should have their inner

components frequently cleaned, inspected, and lubricated.

Note: If the equipment is stored outdoors, be sure to lubricate all parts before and after use to ensure the

equipment stays in good working condition.

WARNING! TO PREVENT SERIOUS INJURY FROM HOIST FAILURE: Do not use damaged

equipment. If any defect or damage is noted, repair the problem before further use.

9

MAINTENANCE INSTRUCTIONS

• Maintain your equipment. It is recommended that the general condition of any equipment be examined

before it is used. Keep your equipment in good repair by adopting a program of conscientious repair and

maintenance. Have necessary repairs made by qualied service personnel.

• Follow the maintenance instructions carefully to keep your equipment in good working condition. Never

perform any maintenance on the equipment while it is under a load.

a. All moving parts of the equipment should be regularly cleaned.

b. Lubricate parts as required by the manufacturer’s specications. The type of lubricant should be as

specied by the manufacturer or a qualied person. Lubrication systems should be checked to verify proper

operation.

c. If additional maintenance is required, it should be completed in accordance with the instructions of the

manufacturer or qualied person.

Inspection

You should inspect the product for damage, wear, broken or missing parts (e.g.: pins) and that all

components function before each use. Follow lubrication and storage instructions for optimum product

performance. Check the climbing pins to make sure that they are not worn or damaged. Check that

everything is good working condition and that nothing is blocking the holes. Do not use the equipment

unless it is in good working condition.

Binding

If the product binds while under a load, use equipment with equal or a larger load capacity to lower the load

safely to the ground. After unbinding; clean, lubricate and test that equipment is working properly. Rusty

components, dirt, or worn parts can be causes of binding. Clean and lubricate the equipment as indicated in

the lubrication section. Test the equipment by lifting without a load. If the binding continues contact Customer

Service.

IF YOUR EQUIPMENT BINDS

As your equipment becomes older, the threads may start binding. This will prevent the equipment

from operating properly and safely. Rusty threads, dirty threads, or a worn threads can cause binding.

Clean and lubricate the equipment. Test the equipment without a load. If the binding continues, refer to

the after sale parts and service. If your equipment binds while under a load, use equipment with equal or

larger load capacity to lower the load safely to the ground.

Cleaning

If the moving parts of the equipment are obstructed, use cleaning solvent or another good degreaser to clean

the equipment. Remove any existing rust, with a penetrating lubricant.

Do not use motor oil to lubricate the equipment

Rust Prevention:

-Check daily for any signs of rust or corrosion.

Without a load check for signs of rust that are visible and clean as needed.

1. Quarterly (every 3 months), clean off load chain, then lubricate load chain links with lithium grease. Apply

grease to inner surfaces of load chain, where the links rub against each other.

2. Repair or replacement of hoist components must be performed only by a qualied technician using

only identical replacement parts with the same rating.

10

11

ASSEMBLY DIAGRAM

12

PARTS LIST

Ref. Description Qty

1 Hand wheel cover 1

2 Self-locking nut 5

3 Hand wheel 1

4 Hand-chain 1

5 Friction plate 2

6 Ratchet disc 1

7 Baake seat 1

8 Pawl 1

9 Pawl spring 1

10 Pawl pin 1

11 Nut 3

12 Spring washer 3

13 Bearing race 1

14 Hook assembly 2

15 Bolt 3

16 Snap ring 1

17 Right side plate 1

18 Pinion shaft 2

19 Splined gear 1

20 Nut 1

21 Disk gear 2

22 Driving shaft 1

23 Bent plate 1

24 Sheet cover 1

25 Guide roller 1

26 Cotter pin 2

27 Chain shaft 1

28 Stripper assembly 1

29 Screw 1

30 Load chain 1

31 Ldle sheave 1

32 Hook holder 1

33 Snap ring 4

34 Shaft 1

35 Suspension plate assembly 1

36 Self-locking nut 1

37 Chain sprocket assembly 1v

Safe Operating Temperature is between 40°F – 105°F (4°C - 41°C)

13

This equipment is covered under a 1-year limited warranty when used as recommended. Only those

items listed with a Part # are available for purchase. For assistance with the operation or the availability of

replacement parts, contact our Parts and Warranty Department at 1-888-44-TORIN (1-888-448-6746). Please

have available a copy of your receipt, the model number of the product, serial number, and specic details

regarding your question.

Not all equipment components are available for replacement; illustrations provided are a convenient reference

of location and position in the assembly sequence.

The manufacturer reserves the rights to make design changes and or improvements to product lines

and manuals without notice.

WARRANTY NOTICE

We want to know If you have any concerns with our products. If so, please call toll-free for Immediate

assistance. For additional web customer support help inquiries visit the Customer Service section at:

http://www.torin-usa.com.

WARRANTY INFORMATION

14

TORIN ONE YEAR LIMITED WARRANTY

Torin Inc.® has been producing quality automotive repair and maintenance products since 1968. All products

sold are felt to be of the highest quality and are covered by the following warranty:

With proof of purchase for a period of one year from the date of that purchase, the manufacturer will repair or

replace, at its discretion, without charge, any of its products or parts thereof which fail due to a defect in

material or workmanship. This warranty does not cover damage or defects caused by improper use, careless

use or abuse of the equipment. This warranty does not cover parts normally considered to wear out or be

consumed in the normal operation of the equipment. Except where such limitations and exclusions are

specically prohibited by applicable law, (1) the CONSUMERS SOLE AND EXCLUSIVE REMEDY SHALL BE

THE REPAIR OR REPLACEMENT OF DEFECTIVE PRODUCTS AS DESCRIBED

ABOVE, and (2) THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGE OR LOSS WHATSOEVER, and (3) THE DURATION OF ANY AND ALL

EXPRESSED AND IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, ANY WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IS LIMITED TO A PERIOD OF ONE

YEAR FROM DATE OF PURCHASE. Product alteration in any manner by anyone other than us, with the sole

exception of alterations made pursuant to product instructions and in a workman like manner. You

acknowledge and agree that any use of the product for any purpose other than the specied use(s) stated in

the product instructions is at Your own risk.

Always check for damaged or worn out parts before using any product. Broken parts will affect the equipment

operation. Replace or repair damaged or worn parts immediately. Do not modify the product in any way.

Unauthorized modication may impair the function and/or safety and could affect the life of the equipment.

There are specic applications for which products are designed and tested during production. Manufacturer

provided warranted items are not authorized to be repaired by anyone other than the manufacturer or

manufacture approved repair person. Distributor does not have authorization to amend these statements. You

acknowledge and agree that any modication of the product for any purpose other than manufacturer

completed repairs is at your own risk. Before using this product, read the owner's manual completely and

familiarize yourself thoroughly with the product and the hazards associated with its improper use.

IMPORTANT: BEFORE FIRST USE on any Lift verify that a daily inspection has been completed and that all

components are in the proper working order.

This limited warranty gives you specic legal rights, and you also may have other rights, which vary from

state to state. Some states do not allow limitations or exclusions on implied warranties or incidental or

consequential damages, so the above limitations may not apply to You. This limited warranty is governed by

the laws of the State of California, without regard to rules pertaining to conicts of law. The state courts

located in San Bernardino County, California shall have exclusive jurisdiction for any disputes relating to this

warranty.

Manufacturer reserves the rights to make design changes and or improvements to this product lines and

manual without notice. We at Torin have taken every effort to ensure complete and accurate instructions have

been included in this manual. However, possible product updates, revisions and or changes may have

occurred since this printing. Torin Inc. reserves the right to change specications without incurring any

obligation for equipment previously or subsequently sold. Not responsible for typographical errors.

Alternately Customer Service can be reached through www.torin-usa.com or via email at

Not all equipment components are available for replacement, but are illustrated as a convenient reference of

location and position in the assembly sequence. Contact Customer Service for equivalent component. When

you contact us, please have your Product’s Model number, Serial Number and Description ready so that we

may help you efciently. This information can be found on a sticker on the product.

For any warranty support or if your Torin® equipment is not functioning properly contact

Torin® Customer Service directly by telephone at 1-888-44-TORIN (1-888-448-6746)

8:00am – 5:00pm Pacic Time, Monday – Friday

www.torin-usa.com Made in China

MANUEL DU PROPRIÉTAIRE

PALAN À CHAÎNE

Article No.:TR9010 TR9020 TR9030 TR9050

ENREGISTREZ

VOTRE PRODUIT

http://www.torin-usa.com/

customer-support/

register-a-product.html

SCANNEZ LE CODE

Questions, problèmes, pièces manquantes? Avant de retourner voir votre fournisseur, appelez notre service à

la clientèle au 1-888-44-TORIN (1-888-448-6746) entre 8 heures et 17 heures, HNP, du lundi au vendredi.

Lisez attentivement et comprenez toutes les DIRECTIVES DE MONTAGE ET DE FONCTIONNEMENT avant

l’utilisation. Vous pouvez subir des blessures graves si vous ne vous conformez pas à ces règles et autres

précautions de sécurité.

AVERTISSEMENT!

UTILISATION PRÉVUE

SPÉCIFICATIONS TECHNIQUES

Le PALAN À CHAÎNE est un dispositif de levage portatif qui peut être actionné facilement par une chaîne à

main. Approprié pour être utilisé dans des usines, des mines, des granges, des chantiers de construction,

des quais, des docks et des entrepôts pour installer de l'équipement, ainsi que pour charger et décharger

des produits. Il est spécialement utile pour le travail de levage dans des terrains en plein air et des endroits

sans alimentation électrique. Le palan à chaîne peut être attaché à toute sorte de chariot en tant que palan à

chaîne mobile. Apte pour système de transport aérien par monorail, grue mobile manuelle et grue à èche.

16

Modèle Capacité

(tonnes)

Hauteur de levage

(mm)

Hauteur libre (de

crochet à crochet)

(mm)

Poussée de chaîne

pour soulever

charge complète

Quantité de

chaînes de

levage

TR9010 1 2.5 300 330N 1

TR9020 2 2.5 380 330N 2

TR9030 3 3 470 390N 2

TR9050 5 3 600 420N 4

IMPORTANT

RESPONSABILITÉ DU PROPRIÉTAIRE OU DE L’UTILISATEUR

Avant de commencer, enregistrez ce produit.

Pour référence future, enregistrez le nom de modèle, le numéro, la date de fabrication et la date d’achat du

produit. Vous pouvez trouver ces renseignements sur le produit.

Nom de modèle _______________________

Numéro de modèle _______________________

Date de fabrication _______________________

Date d’achat _______________________

NE PAS UTILISER OU RÉPARER CE PRODUIT SANS AVOIR LU LE PRÉSENT MANUEL.

Lisez et suivez les directives de sécurité. Conservez ces directives à la disponibilité des opérateurs. Assu-

rez-vous que tous les opérateurs sont bien formés et savent comment utiliser le produit correctement et en

toute sécurité. En continuant, vous convenez que vous comprenez complètement le contenu du présent ma-

nuel. Le produit peut causer des blessures ou provoquer la mort si vous n’utilisez pas le produit dans le but

pour lequel il a été conçu. Le fabricant n’est pas responsable des dommages ou blessures provoquées par

une utilisation inappropriée ou par négligence. Ne faites fonctionner le produit que si toutes les pièces sont en

place et fonctionnent de manière sécuritaire. N’utilisez que des pièces de rechange authentiques. Effectuez

l’entretien de ce produit uniquement avec des pièces de rechange autorisées ou approuvées; la négligence

rendra l’utilisation du produit dangereuse et annulera la garantie. Inspectez régulièrement et avec soin le pro-

duit et effectuez tout l’entretien nécessaire. Conservez ces directives dans un endroit protégé sec. Conservez

propres et visibles tous les autocollants sur le produit. Ne modiez pas ou n’utilisez pas le produit pour une

application autre que celle pour laquelle il a été conçu. Pour toute question relative à une application particu-

lière, N’utilisez PAS le produit avant d’avoir communiqué avec le distributeur ou le fabricant an de déterminer

si cela peut se faire.

Pour toutes questions d’ordre technique, appelez au 1-888-448-6746.

INSPECTION

NE TIREZ PAS DE LA CHAÎNE À MAIN DANS UNE POSITION OBLIQUE AU NIVEAU DU VOLANT DU

MANOEUVRE AFIN D’ÉVITER LES ENCHEVÊTREMENTS DE LA CHAÎNE À MAIN ET DE TOURNER

LE PALAN.

5. Pour assurer la sécurité, il est strictement interdit de passer ou de travailler sous une charge qui est en

train d’être soulevée.

6. Lors du levage ou de l'abaissement d’une charge, la chaîne à main doit être tirée de façon continue an

d'éviter qu’elle se casse ou qu’elle s'enchevêtre.

7. Cessez immédiatement le fonctionnement si la chaîne à main ne peut être tirée plus et examinez le

suivant:

a) Vériez qu’il n’y ait pas d'enchevêtrements avec la charge.

b) Vériez qu’il n’y ait pas de problèmes avec les parties du palan.

c) Vériez que le poids de la charge ne surpasse pas la capacité prévue du palan.

1. Déterminez le poids de la charge à soulever et assurez-vous que le poids ne surpasse pas la capacité du

palan à chaîne. Ne surchargez jamais le palan en aucun cas.

2. Les parties, telles les crochets, la chaîne de levage et le système de freinage doivent être examinées

soigneusement. Le palan à chaîne ne peut être utilisé que s’il est en bon état.

3. Avant le levage, examinez les crochets afin de vous assurer qu’ils sont bien fixés. Pour une meilleure

performance du palan, la chaîne de levage doit être verticalement en ligne droite sans aucune torsion an

d’éviter les enchevêtrements.

4. Pendant son fonctionnement, l’opérateur doit être au niveau du volant du manœuvre (9) Pour soulever

la charge, tirez de la chaîne à main (15) afin de faire tourner le volant du manœuvre dans le sens

des aiguilles d’une montre. Lorsque vous tirez de la chaîne à main dans le sens inverse, le volant du

manœuvre sera séparé du siège du frein (10), la roue à rochet (14) arrêtée par le cliquet (17) sera

relâchée, et la charge sera abaissée sans problèmes.

MARQUAGE DE SÉCURITÉ

1. Nettoyez le palan à chaîne après chaque utilisation et rangez-le dans un site sec pour éviter la rouille et la

corrosivité.

2. Une personne qualiée doit nettoyer les parties avec du kérosène et graisser les roues dentées et les

roulements une fois par an.

3. Alignez les marques “0” des deux roues dentées (8) lors de l’assemblage.

4. Les galets (12) du roulement de la roue de chaîne peuvent être coincés avec de la graisse à la portée de

la roue de chaîne (4) avant de rentrer dans la piste extérieure de la roue (13) sur la plaque latérale.

5. Lors de l'assemblage du mécanisme de freinage, soyez soigneux an d’engrener les dents inclinées de

la roue à rochet et le cliquet. Assurez-vous que le cliquet soit contrôlé par le ressort soigneusement et de

manière able. Puis tournez le volant du manœuvre dans le sens des aiguilles d’une montre après l'avoir

vissé sur l’arbre de commande, et il doit appuyer la roue et les plateaux sur le siège du frein. Tournez-le

dans le sens contraire des aiguilles d’une montre; il devrait avoir un espace entre la roue et les plateaux.

6. Il doit avoir un ajustement incertain dans l’arrêt (3) et dans la plaque droite (2). Ne les démontez pas, sinon

ils deviendront mal xés.

7. Ne permettez jamais que quelqu'un d’inexpert démonte les palans.

8. Après le nettoyage et la réparation, le palan doit être soumis à un essai à vide et à un essai pour charge

lourde. Le palan à chaîne peut commencer à fonctionner après les essais qui prouvent son bon état.

9. Gardez les surfaces de friction du frein propres lors du graissage ou du fonctionnement du palan. Le

mécanisme de freinage doit être examiné régulièrement an d’éviter un freinage défectueux et la chute de

la charge.

AVERTISSEMENT !

17

RÈGLES GÉNÉRALES DE SÉCURITÉ

AVERTISSEMENT : Lisez et comprenez toutes les instructions. Si vous ne suivez pas les instructions

mentionnées ci-dessous, il peut en résulter des blessures graves.

AVERTISSEMENT : Les avertissements, mises en garde et directives mentionnés dans le présent

manuel d’instruction ne peuvent pas couvrir toutes les conditions ou situations qui peuvent se

produire. L’opérateur doit bien comprendre que le bon sens et la prudence sont des facteurs qui ne

peuvent pas être incorporés dans ce produit, mais doivent être fournis par l’opérateur.

MISE EN GARDE : Ne permettez à personne d’utiliser ou d’assembler ce cric avant d’avoir lu le

manuel et d’avoir bien compris le fonctionnement du cric.

CONSIGNES GÉNÉRALES DE SÉCURITÉ

FACTEURS DE SÉCURITÉ IMPORTANTS

18

CONSIGNES DE SÉCURITÉ IMPORTANTES

Consignes de sécurité de base

Consignes de Sécurité pour l’Installation

Consignes de Sécurité pour Inspection, Essais et Entretien

Consignes de Sécurité Spéciques pour le Fonctionnement

CONSERVEZ CES INSTRUCTIONS

1. Ne soulevez plus que la capacité prévue. Soyez conscient de la charge dynamique! Les mouvements

brusques de la charge peuvent créer brièvement une surcharge provoquant la panne du produit.

2. N’utilisez pas le palan si sa chaîne est tordue, pliée, ou endommagée. Examinez la chaîne soigneusement

avant chaque usage.

3. N’utilisez pas le palan s’il est endommagé ou avec un mauvais fonctionnement. Examinez le palan

soigneusement et testez son fonctionnement avant chaque usage.

4. Ne soulevez pas des personnes ou des charges par-dessus des personnes. Les charges qui tombent

peuvent blesser ou tuer des personnes.

5. Faites fonctionner le palan seulement manuellement (à la main)

6. N’enlevez ni ne couvrez les étiquettes d'avertissement. Elles ont des consignes de sécurité importantes. Si

elles sont illisibles ou manquantes, contactez le Service à la Clientèle et demandez-les des remplacements.

7. Les avertissements, les précautions et les instructions dans ce manuel d’instructions ne peuvent pas

couvrir toutes les conditions ou situations possibles qui pourraient survenir. L’opérateur doit comprendre

que le bon sens et la prudence sont des facteurs qui ne peuvent pas être incorporés dans ce produit, mais

que c'est le rôle de l’opérateur d’en faire preuve.

1. La structure de support sur laquelle est montée le palan (y compris chariot, monorail ou grue) doit être

conçue pour résister les charges et les forces imposées par le palan pour la capacité prévue.

2. Installez-le dans un endroit qui permet à l’opérateur de se déplacer et de s’éloigner de la charge.

3. Si les mous dans la chaîne qui est suspendue du palan peuvent entraîner des risques, utilisez une gaine

pour chaîne convenable (non fournie) an de contenir la chaîne en excès.

4. Examinez le palan suivant les explications fournies dans Inspection Fréquente à la page 8 après l’installation

mais avant l’utilisation.

1. Effectuez une « Inspection Fréquente » tous les jours.

2. Effectuez une « Inspection Périodique » tous les 3 mois.

3. Les palans qui sont beaucoup utilisés doivent être inspectez plus fréquemment.

4. Augmentez les charges d’épreuve seulement jusqu'au minimum nécessaire et éloignez-vous bien de la

charge à tout moment pendant les essais.

1. Mettez des lunettes de sécurité approuvées par ANSI, casque de sécurité approuvé par ANSI et bottes de

travail à embout d'acier pendant le réglage et l’utilisation.

2. Ce produit n'est pas un jouet. Ne laissez pas que les enfants jouent avec ou près du produit.

3. À être utilisé exclusivement aux ns prévues. Ne l’utilisez pas pour manipuler des matières en fusion. Ne

l’utilisez pas avec des aéronefs.

AVERTISSEMENT !

NOTICE DE MONTAGE

Lisez TOUTE L’INFORMATION DE SÉCURITÉ dans ce manuel y compris tous les textes sous

les sous-titres avant de régler ou d’utiliser ce produit.

Remarque: Pour plus d’information sur les parties énumérées dans les pages suivantes, consultez la Liste

des Pièces et la Vue Éclatée.

1.La structure de support sur laquelle est montée le palan (y compris chariot, monorail ou grue) doit être

conçue pour résister les charges et les forces imposées par le palan pour la capacité prévue.

2.Placez correctement le crochet de suspension sur la structure de support dans le point d’appui de la charge

(voir le schéma gauche de la Figure A).

•Ne permettez pas que l'attache de levage du crochet supporte aucune partie de la charge.

•N’appliquez pas la charge à la pointe du crochet (montré dans la Figure A dans la partie droite du schéma).

Figure A: — Attache correcte et incorrecte du

crochet de suspension

19

INSTRUCTIONS D’UTILISATION

Lisez TOUTE L’INFORMATION DE SÉCURITÉ dans ce manuel y compris tous les textes sous

les sous-titres avant de régler ou d’utiliser ce produit.

POUR ÉVITER DES BLESSURES GRAVES L’utilisation d’un palan vertical exige plus que de tirer la chaîne à

main d’un palan actionné par une chaîne à main. L’emploi des palans verticaux est soumis à certains dangers

qui ne peuvent pas être affrontés par des moyens mécaniques, mais uniquement en faisant usage de bonne

intelligence, de prudence, de bon sens et de l’expérience prévoyant les mouvements qui auront lieu en raison

du fonctionnement des commandes.

Avant l’utilisation du palan

Commandes de fonctionnement

1. Familiarisez-vous avec toutes les commandes de fonctionnement du palan et avec le(s) opération(s) à

effectuer. Les instructions comprennent les avertissements sur le palan et les Consignes de Sécurité et

d'utilisation dans ce manuel.

2. AVERTISSEMENT ! POUR ÉVITER DES BLESSURES GRAVES À CAUSE D’UNE DÉFAILLANCE

DU PALAN: N’utilisez pas l’équipement s’il est endommagé. Si c’est nécessaire de faire des

réglages ou des réparations, ou s’il y a quelque défaut, corrigez le problème avant de continuer à

l’utiliser.

3. Ne faites pas fonctionner un palan qui a un écriteau qui dit « hors service ».

4. L’entretien du palan doit être fait seulement par un technicien qualié.

5. N’utilisez pas la chaîne ou le câble comme terre pour soudage.

6. Ne laissez pas que la chaîne ou le câble soient touchés par une électrode de soudage.

7. Ne faites fonctionner les palans actionnés par une chaîne à main que manuellement, avec seulement un

opérateur par chaîne à main.

8. Choisissez une aire de travail propre et bien illuminée. L’accès des enfants ou des animaux domestiques à

l’aire de travail doit être interdit an d’éviter des distractions et des blessures.

9. Aucun objet qui puisse présenter un danger pendant le travail, tel des câbles de service public, ne devront

pas être dans les environs.

10.Examinez le palan suivant les explications fournies dans Inspection Fréquente à la page 8 après

l’installation mais avant l’utilisation.

20

AVERTISSEMENT !

Loquet du

crochet

Structure de

support

Crochet de

suspension

Chaîne à

main

Chaîne à

main

Pour

abaisser

la charge,

tirez de ce

côté vers

le bas

Pour

soulever

la charge,

tirez de ce

côté vers

le bas.

Chaîne de

levage

Crochet de

levage

Figure B : Pour soulever la charge Figure C : pour abaisser la charge

This manual suits for next models

3

Table of contents

Languages:

Other Torin BIG RED Construction Equipment manuals