Torklift central X7910 User manual

Page 1

Parts Inventory

Image

Description

Item #

Qty.

Cross Tube

X7910-W1

1

License Plate

Bracket

X7910-W2

1

Side Plate

X7910-P1

2

Hole Alignment

Plate

X7910-P8

1

Side Plate

Spacer

X7910-P10

2

M16-1.50 x

100mm Class

10.9 Hex Bolt

13790

4

5/8”-11 x 2”

Grade 8 Hex

Bolt

9846

8

5/8”-11 x 4”

Grade 8 Hex

Bolt

13794

4

5/8” SAE Flat

Washer

9717

12

Page 2

5/8” Split Lock

Washer

6023

8

5/8” Star Washer

11357

8

5/8”-11 Grade 8

Hex Nut

9842

8

1/2”-13 x 1-1/2”

Grade 8 Hex

Bolt

9960

10

1/2” SAE Flat

Washer

7465

10

1/2” Split Lock

Washer

9302

10

1/2”-13 Grade 8

Hex Nut

1751

10

M12-1.75 x

100mm Class

10.9 Hex Bolt

13789

2

M12 Flat

Washer

20003

2

1/4”-20 x 3/4”

Button Head

Bolt

15031

2

1/4”-20 x 1/2”

Button Head

Bolt

11981

4

Page 3

1/4” SAE Flat

Washer

10275

10

1/4”-20 Nylock

Hex Nuts

9891

6

5/8”-11 Bolt

Fisher

13696

2

3/8” Hole Plug

12067

2

5/8” Hitch Pin

and Clip

3703

1

Page 4

Step 1:

•Place the transmission in park and chock the rear tires to prevent

the truck from rolling.

•Raise the front of the vehicle and place the front axle on jack

stands.

•If equipped, remove the license plate, then the factory license

plate bracket. The bracket is held in with four self-tapping

screws.

Step 2:

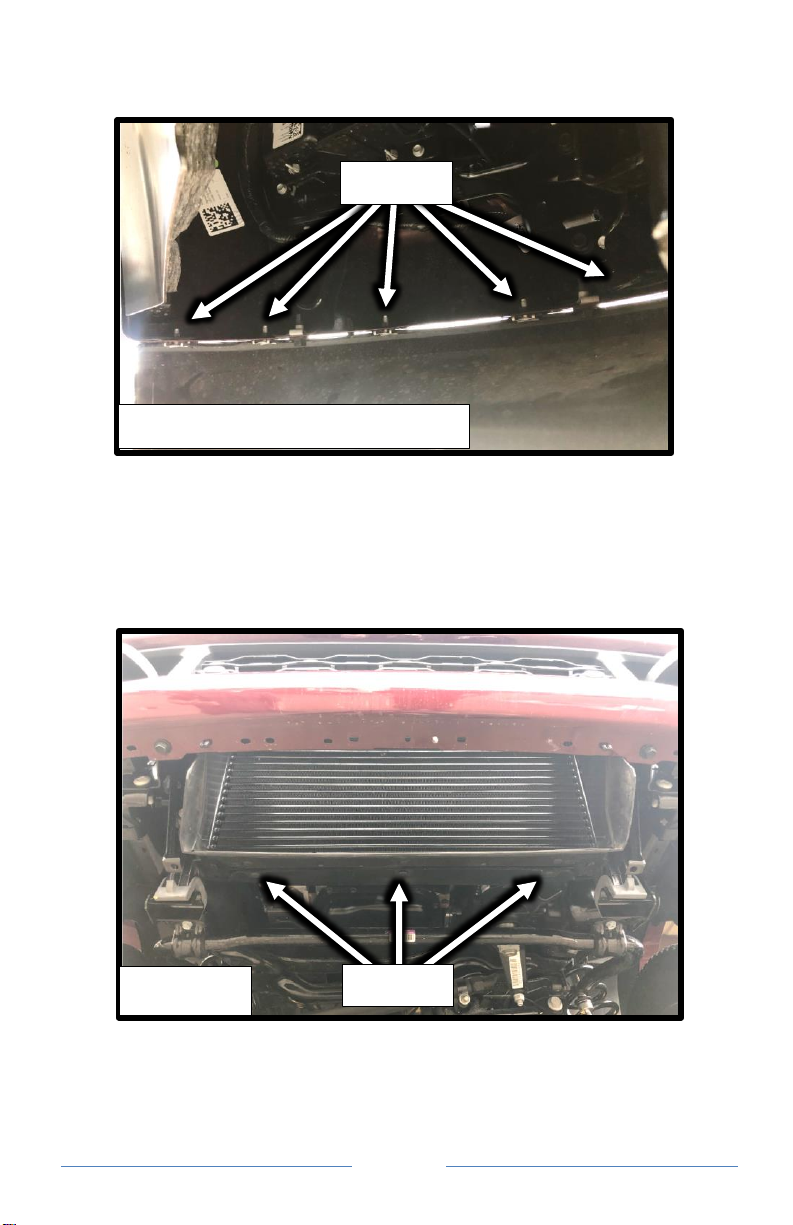

•Remove the 14 nuts attaching the lower air dam to the front

bumper. See Figure 2.1. The middle four nuts can be accessed

through the front opening in the air dam.

•Using a screwdriver, carefully disconnect the two push clips in the

bottom of the air dam.

•Using a screwdriver, carefully disconnect the two remaining clips

holding the air dam to the bumper.

•Set the air dam aside.

Page 5

Step 2 Cont.

Step 3:

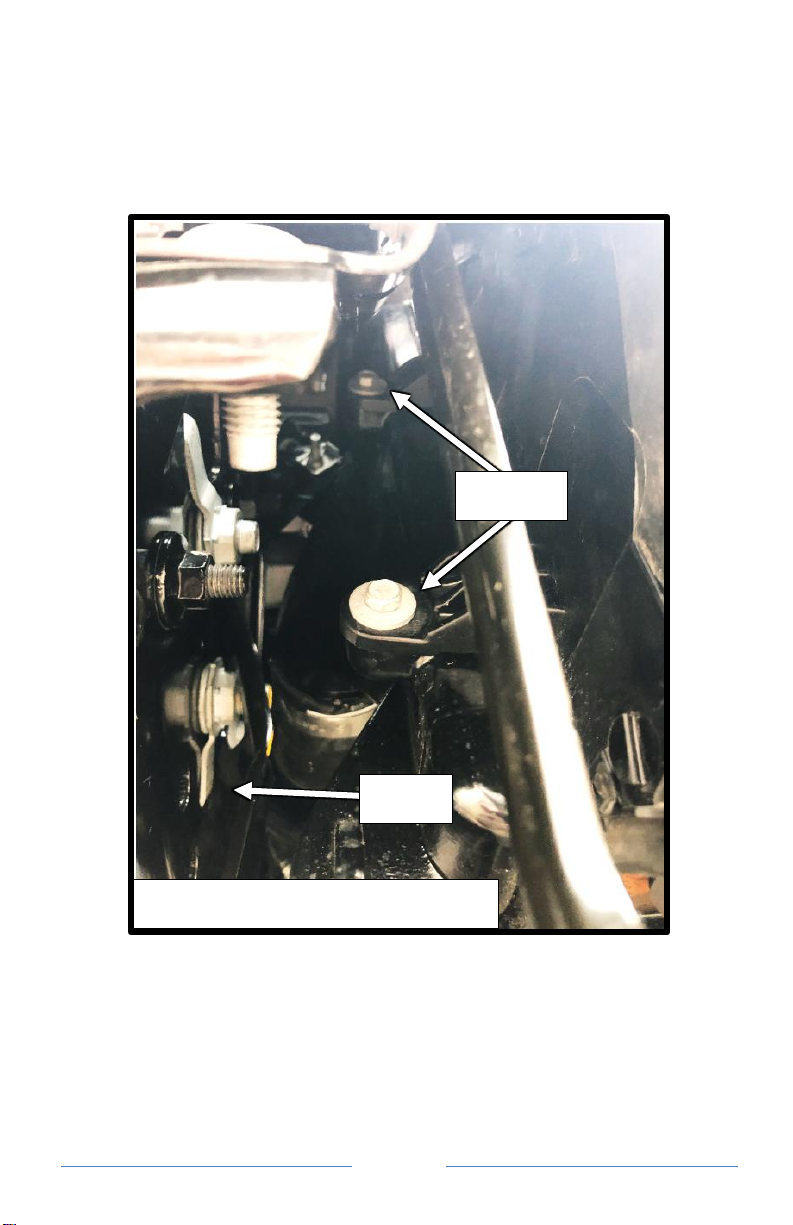

•Remove the three plastic push clips on the bottom of the

intercooler shroud. See Figure 3.1

Figure 2.1 –Driver Side Shown

Remove

Figure 3.1

Remove

Page 6

Step 3: Cont.

•Remove the four bolts (two per side) holding the intercooler

shroud to the front of the intercooler. See Figure 3.2

•Remove the charge air cooler shroud. Be careful not to damage

the charge air cooler fins.

Figure 3.2 –Passenger side shown

Remove

Frame

Page 7

Step 4:

•Using a reciprocating body saw, or other method, trim the center

of the intercooler shroud as shown in figure 4.1.

•Using a reciprocating body saw, or other method, trim the center

of the air dam as shown in figure 4.2.

3-1/4”

2-3/4”

Figure 4.1

Figure 4.2

cut even with top of openings

7-1/2”

2-5/8”

Page 8

Step 5:

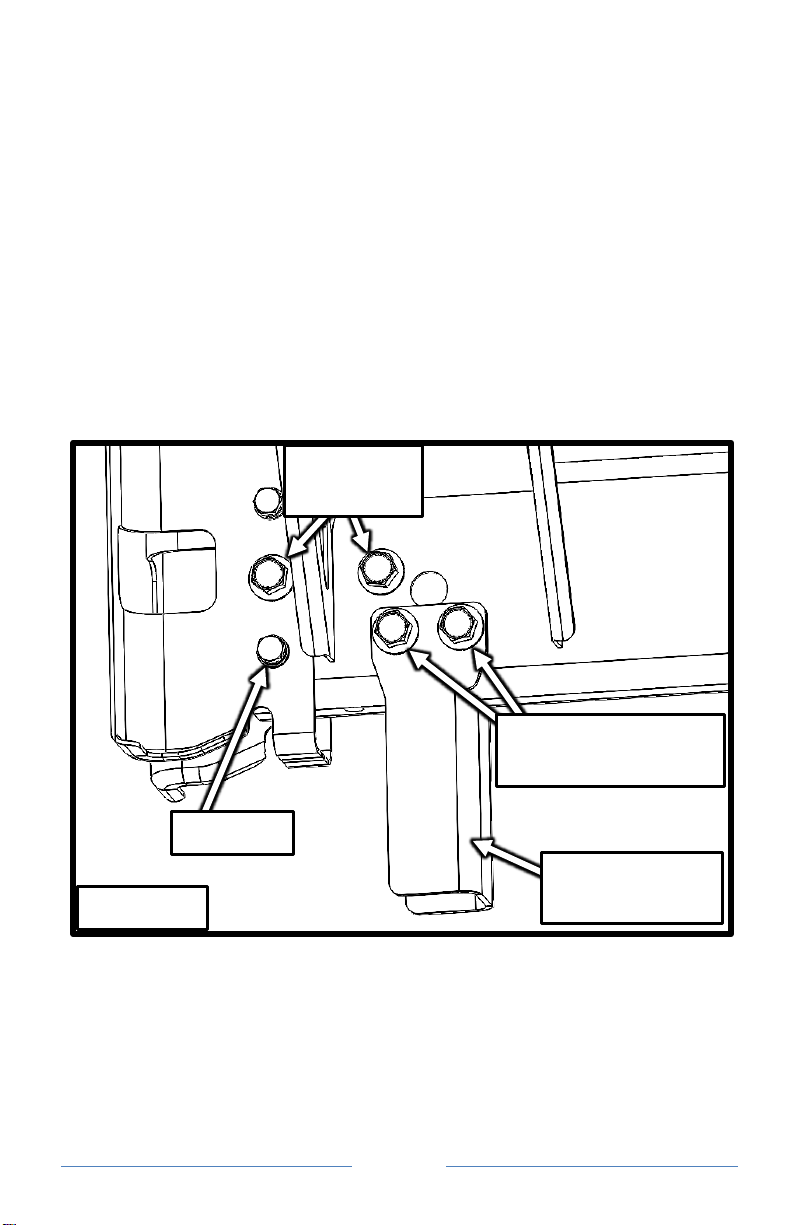

•Starting on the driver side, remove the M12 bolt just forward and

below of the front body mount. See Figure 5.1.

•Remove both M16 tow hook bolts if equipped. Take note of the

factory nut and tab orientations on the opposite side of the frame

before removal.

•Remove both M16 vertical frame bracket bolts and the vertical

frame bracket if equipped.

•If equipped, slide the tow hook out from the bumper and set it

aside.

•Repeat the removal process for the Passenger side of the vehicle.

Proceed to Step 6.

M16 Tow

Hook Bolts

M12 Bolt

Figure 5.1

M16 Vertical Frame

Bracket Bolts

Vertical Frame

Bracket

Page 9

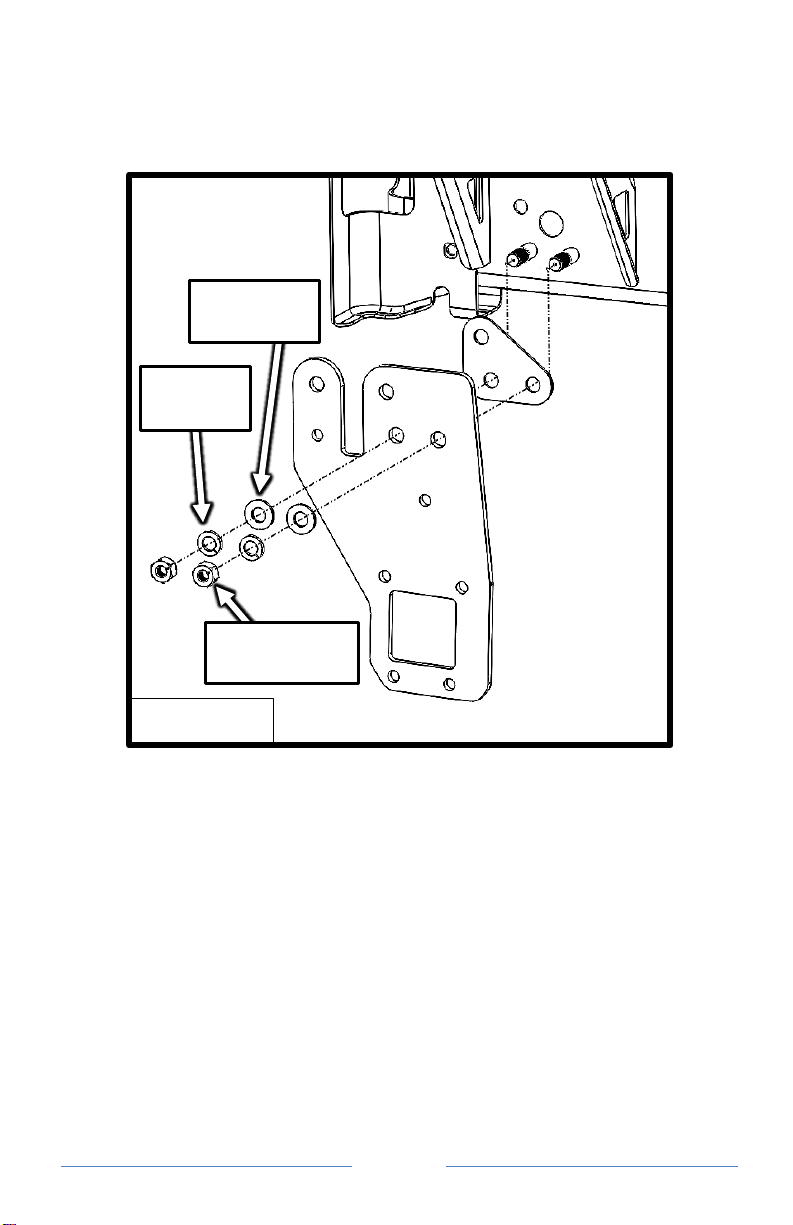

Step 6A: Vehicles equipped with vertical frame brackets.

(For vehicles not equipped with Vertical Frame Brackets, proceed

to Step 6B)

•Insert one 5/8”-11 x 4” Grade 8 hex bolt with one 5/8” SAE flat

washer into each of the two lower rear holes in a Side Plate.

•Place a side plate spacer over the threaded ends of the bolts, then

guide the bolts into the frame. See figure 6A.1.

•Secure each bolt with one 5/8” SAE flat washer, one 5/8” split

lock washer, and a 5/8”-11 grade 8 hex nut. Leave the hardware

as loose as possible. Repeat for the opposite side of the frame.

Proceed to Step 7.

Figure 6A.1 –Driver side shown

5/8” SAE

Flat Washer

5/8”-11 x 4”

Grade 8 Hex Bolt

5/8” SAE

Flat Washer

5/8” Lock

Washer

5/8”-11 Grade

8 Hex Nut

Page

10

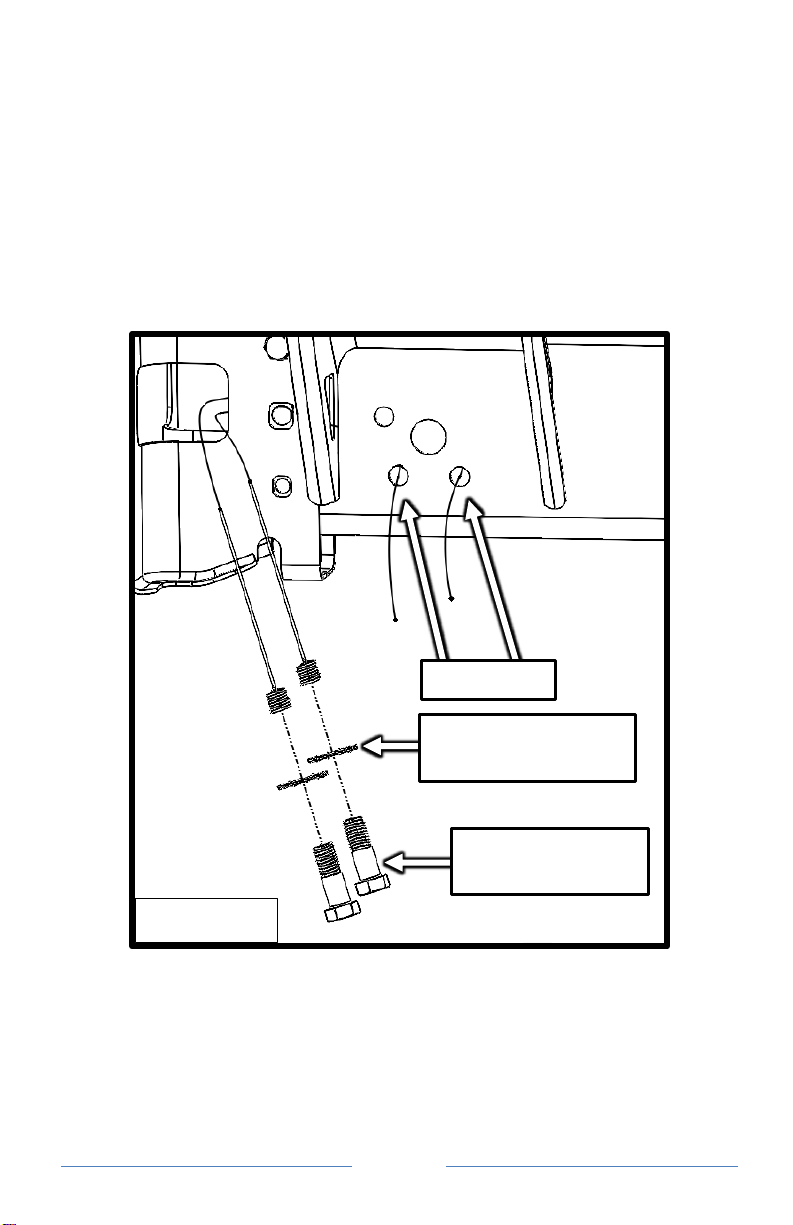

Step 6B: Vehicles not equipped with vertical frame brackets.

•Guide the coiled end of a 5/8” bolt fisher into each of the two

lower rear holes, and out the front end of the frame. See Figure

6B.1.

•Attach one 5/8” internal/external tooth lock washer, and one 5/8”-

11 x 2” grade 8 hex bolt to each bolt fisher.

•Pull on the straight end of each bolt fisher until the threads of both

bolts are protruding from the two lower rear holes. Keep the bolt

fishers attached.

Figure 6B.1

Lower Holes

5/8” internal/external

tooth lock washer

5/8”-11 x 2” grade 8

hex bolt

Page

11

•String the bolt fishers through a side plate spacer, and then

through the lower rear mounting holes in a side plate. See Figure

6B.2

•Place the side plate spacer and side plate up against the frame.

•Carefully remove one of the bolt fishers, then secure the bolt with

one 5/8” SAE flat washer, one 5/8” split lock washer, and a 5/8”-

11 grade 8 hex nut. Keep the hardware as loose as possible.

Repeat for the other bolt.

•Repeat step 6B for the opposite side of the frame, then proceed to

Step 7.

Figure 6B.2

5/8” Lock

Washer

5/8” SAE

Flat Washer

5/8”-11 Grade

8 Hex Nut

Page

12

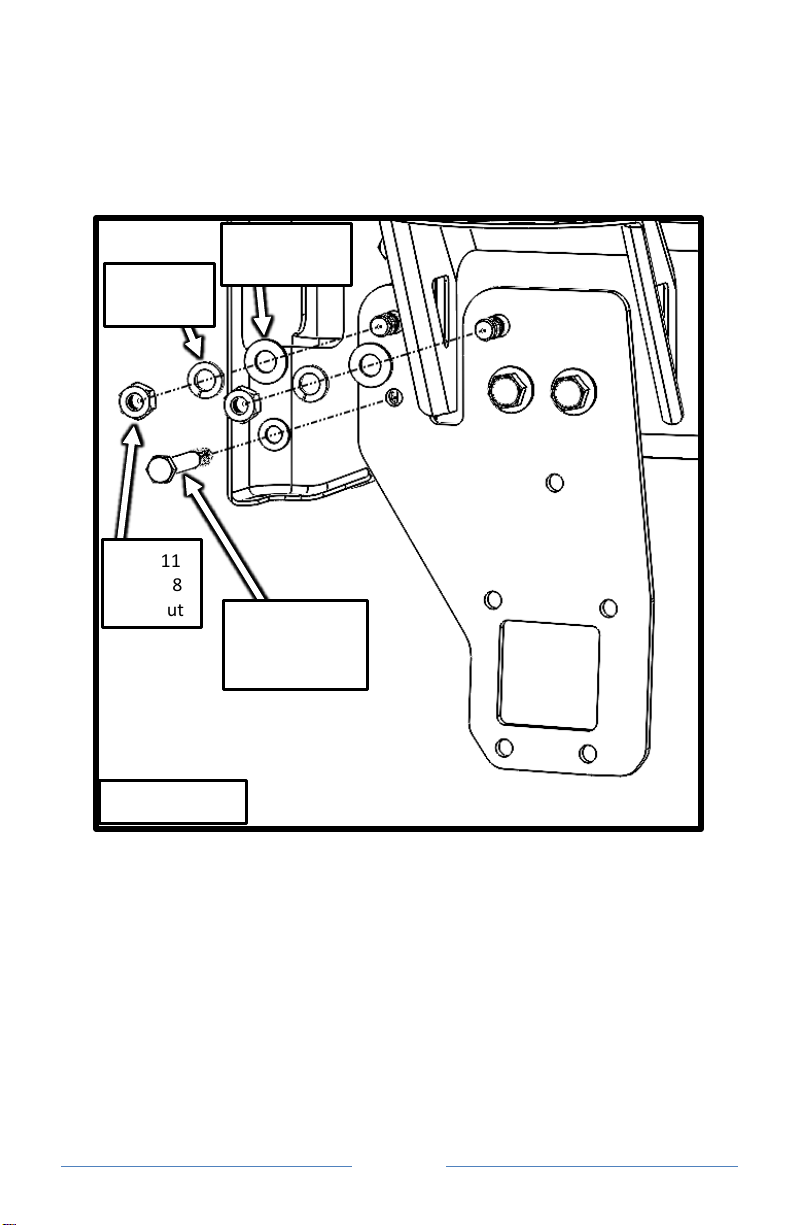

Step 7A: Vehicles equipped with tow hooks.

(For vehicles not equipped with tow hooks, proceed to Step 7B)

•Slide the tow hook back through the bumper and into the frame.

•Install one M16-2.00 x 100mm class 10.9 hex bolt with one 5/8”

SAE flat washer into each of the two upper holes in the side plate

and through the tow hook. Loosely thread each of the bolts into

the factory nuts.

•Install one M12-1.75 x 100mm class 10.9 hex bolt with one M12

flat washer into the remaining hole. Loosely secure the bolt with

the factory nut. See Figure 7A.1.

•Repeat Step 7A for the passenger side of the truck, then proceed

to Step 8

Figure 7A.1

M12-1.75 x

100mm class

10.9 hex bolt

M12 SAE

flat washer

M16 SAE

flat washer

M16-2.00

x 100mm

class 10.9

hex bolt

Page

13

Step 7B: Vehicles not equipped with tow hooks.

•Guide the coiled end of a 5/8” bolt fisher into each of the two

upper holes, and out the front end of the frame. See Figure 7B.1.

•Attach one 5/8” internal/external tooth lock washer, and one 5/8”-

11 x 2” grade 8 hex bolt to each bolt fisher.

•Pull on the straight end of each bolt fisher until the threads of both

bolts are protruding from the two upper holes. Keep the bolt

fishers attached.

Figure 7B.1

5/8”-11 x 2” grade 8

hex bolt

5/8”

internal/

external

tooth

lock

washer

Page

14

•Carefully remove one of the bolt fishers, then secure the bolt with

one 5/8” SAE flat washer, one 5/8” split lock washer, and a 5/8”-

11 grade 8 hex nut. See Figure 7B.2. Keep the hardware as loose

as possible. Repeat for the other bolt.

•Install one M12-1.75 x 100mm class 10.9 hex bolt with one M12

flat washer into the remaining hole. Loosely secure the bolt with

the factory nut.

•Repeat step 7B for the passenger side of the frame, then proceed

to Step 8.

Figure 7B.2

5/8” SAE

Flat Washer

5/8” Lock

Washer

5/8”-11

Grade 8

Hex Nut

M12-1.75 x

100mm class

10.9 hex bolt

Page

15

Step 8

•Reattach the intercooler shroud and air dam in the reverse

order of removal. Be careful! Do not allow the studs in the air

dam to scratch the paint.

•Install the cross tube into the side plates, one side at a time. It

is easiest to angle the cross tube into position with one side

farther towards the rear of the truck. You will need to flex the

air dam downwards until the hitch receiver aligns with the

cutout.

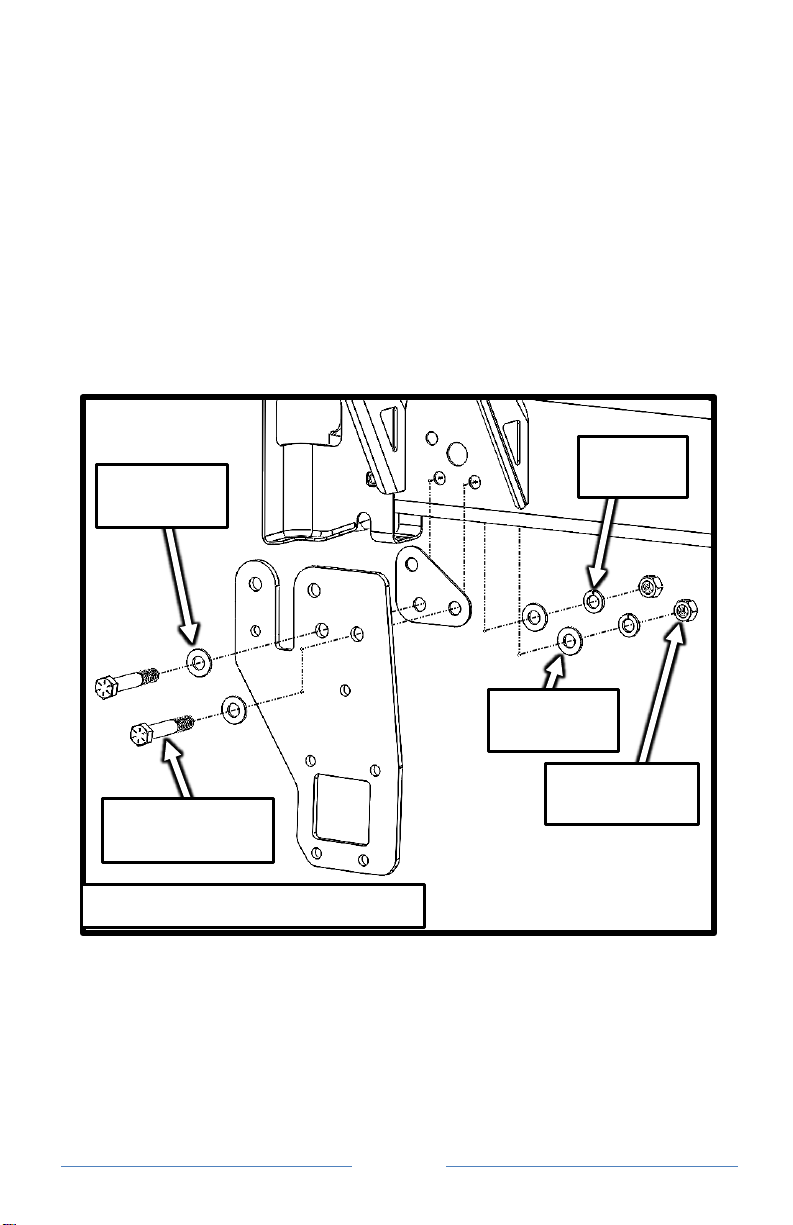

•Attach both side plates to the cross tube by installing one 1/2”-

13 x 1-1/2” grade 8 hex bolt with one 1/2” SAE flat washer

into each of the five holes per side plate. Secure each bolt with

one 1/2 split lock washer and one 1/2”-13 grade 8 hex nut.

See figure 8.1

Figure 8.1

1/2”-13 x 1-1/2”

grade 8 hex bolts

1/2”-13 grade

8 hex nuts

1/2” lock

washers

1/2” SAE

flat washers

Page

16

Step 9

Torque the hardware in the following order.

•Torque the M16 bolts to 200 ft-lbs (some installations will not

use any M16 bolts)

•Torque the 5/8” bolts to 200 ft-lbs

•Torque the M12 bolts to 80 ft-lbs

•Torque the 1/2” bolts to 80 ft-lbs

Step 10

•Hold the hole alignment plate up against the bottom of the air

dam and align it with one of the two tabs on the receiver. Use

a felt tipped pen to mark the hole location. Repeat for the

opposite side of the receiver. See Figure 10.1.

•Drill a 1/4” hole in the two marked locations.

Figure 10.1

Page

17

•Install one 1/4”-20 x 3/4” button head bolt up into each hole

the air dam and through the tab on the side of the receiver.

•Secure each bolt with one 1/4” SAE flat washer and one 1/4”-

20 thin nylock nut. Tighten until snug. Do not over tighten as

it may deform the plastic.

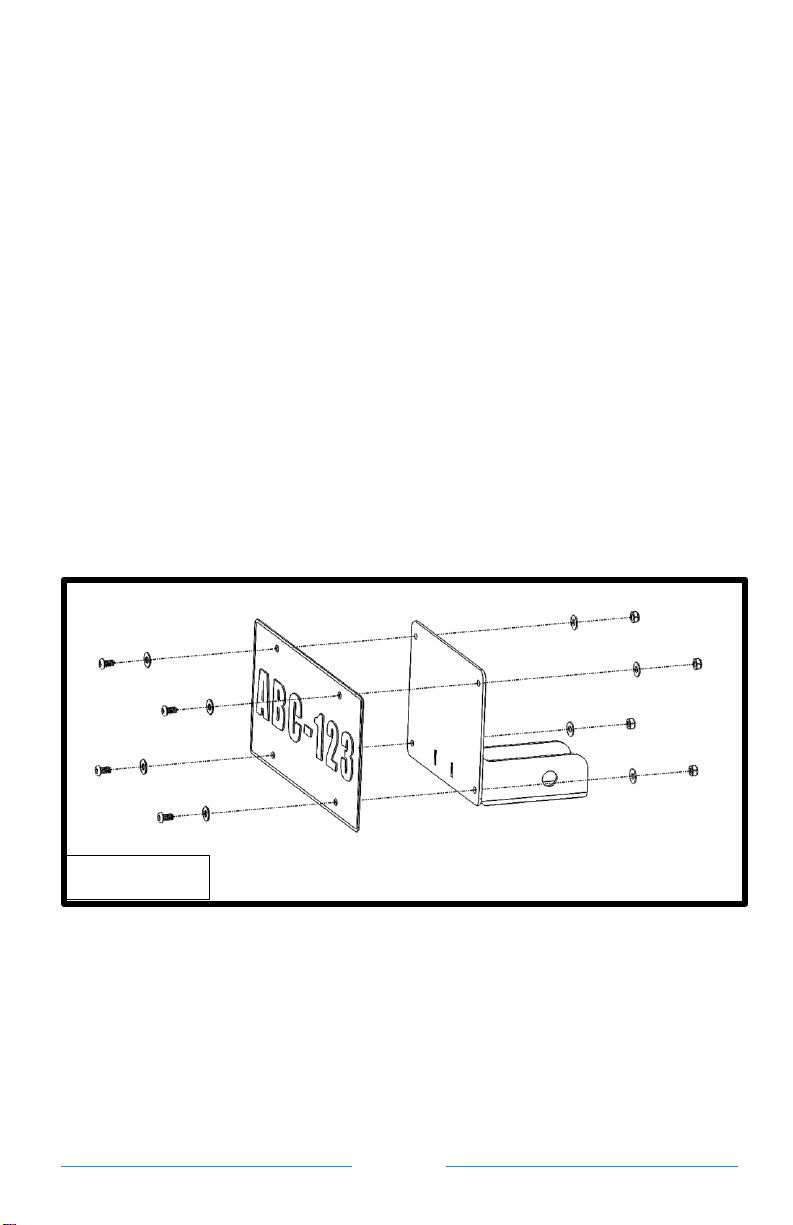

Step 10

•Install one 3/8” hole plug into the holes left in the bumper by

the original license plate bracket.

•Install one 1/4”-20 x 1/2” button head bolt with one 1/4” SAE

flat washer into each hole in the license plate and through the

license plate bracket. Secure each bolt with one 1/4” SAE flat

washer and one 1/4”-20 thin nylock nut. See Figure 10.1.

•Slide the license plate bracket into the hitch receiver and pin it

in place using the supplied 5/8” hitch pin and clip.

Installation is complete.

Figure 10.1

Page

18

WARRANTY/DISCLAIMER

INFORMATION

Torklift Central requires proof of purchase for warranty claim

registration, with pictures of any defective product before issuing a

replacement. Torklift will not accept claims on any product without

proof of purchase, which can be faxed, scanned, emailed or mailed to

the information provided below. Torklift Central warrants its hitches,

custom hitch receivers and accessories (excluding electrical wire

harnesses which carry a warranty from their specified manufacturer)

from date of purchase against defects in material and workmanship

under normal use and service for the ownership life of the original

consumer purchaser. Torklift Central will replace free of charge any

part that proves defective in material or workmanship when presented

to Torklift Central, transportation charges prepaid by purchaser, at the

address below.

This warranty is limited to defective parts

replacement only. Labor charges and/or damage

incurred in installation or replacement, as well as

incidental and consequential damages connected

therewith are excluded.

This warranty does not include normal wear and tear or the

finish and paint. Rusting, cracking or peeling of the finish is also

excluded. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or

exclusion may not apply to you. Any damage to Torklift Central

products as a result of misuse, abuse, neglect, accident, improper

installation or any use violative of instructions furnished by Torklift

Central will void the warranty. This warranty gives you specific legal

rights and you may also have rights, which vary from state to state.

With warranty service, you may be able to go to a small claims court,

a state court or a federal district court.

Page

19

Although Torklift Central trailer hitches are both tested and rated for

towing within the specific capacity label found on each trailer hitch.

Torklift Central assumes no liability for vehicle manufacturers

warranty due to the use of a Torklift Central trailer hitch being used

for towing behind any vehicle or using the trailer hitch in a manner

that it was not designed for. Although this specific trailer hitch has a

load rating, which includes trailer tongue weight, and a trailer weight

carrying capacity, Torklift Central is not responsible for the voiding

of any warranty on any vehicle due to factory towing limitations. All

vehicle warranties are the sole property and responsibility of the

owner of the vehicle that the Torklift Central trailer hitch is installed

upon. Torklift Central does not endorse towing behind any vehicle if

the vehicles manufacturer states that towing is not recommended.

Check your vehicle’s owner’s manual for the proper tow rating of

your vehicle.

ADDRESS: 315 Central Ave N. Kent, WA 98032

*WARNING* Your vehicle may have a lower tow rating than this

trailer hitch. If your vehicle’s tow rating is less than the rated towing

capacity on your Torklift Central trailer hitch, your trailer hitch

capacity is limited to your vehicle’s factory rated towing capacity.

*DANGER* Never exceed your vehicle's manufacturer's

recommended towing capacity which may be a lower rating than this

trailer hitch

Table of contents

Other Torklift central Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

EUFAB

EUFAB JAMO manual

Prorack

Prorack K384 Fitting Instructions for Basic Carrier

NORTHMAN

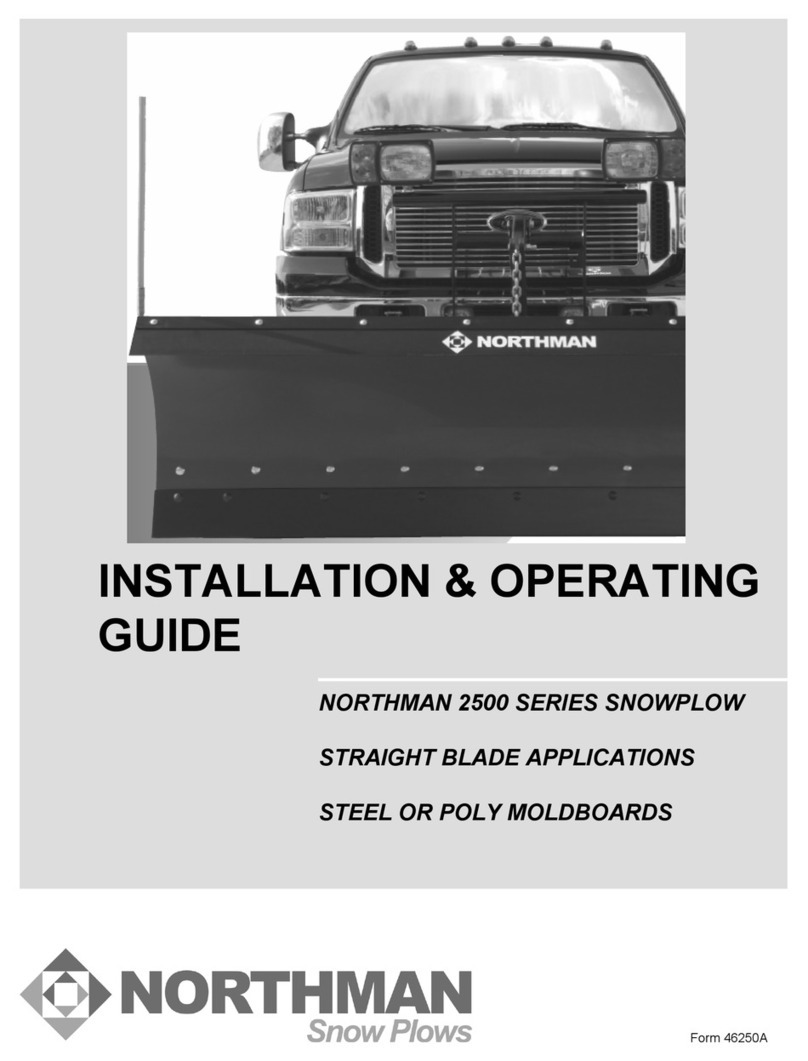

NORTHMAN 2500 Series Installation & operating guide

Steinhof

Steinhof P-045 FITTING AND OPERATION MANUAL

Firstech

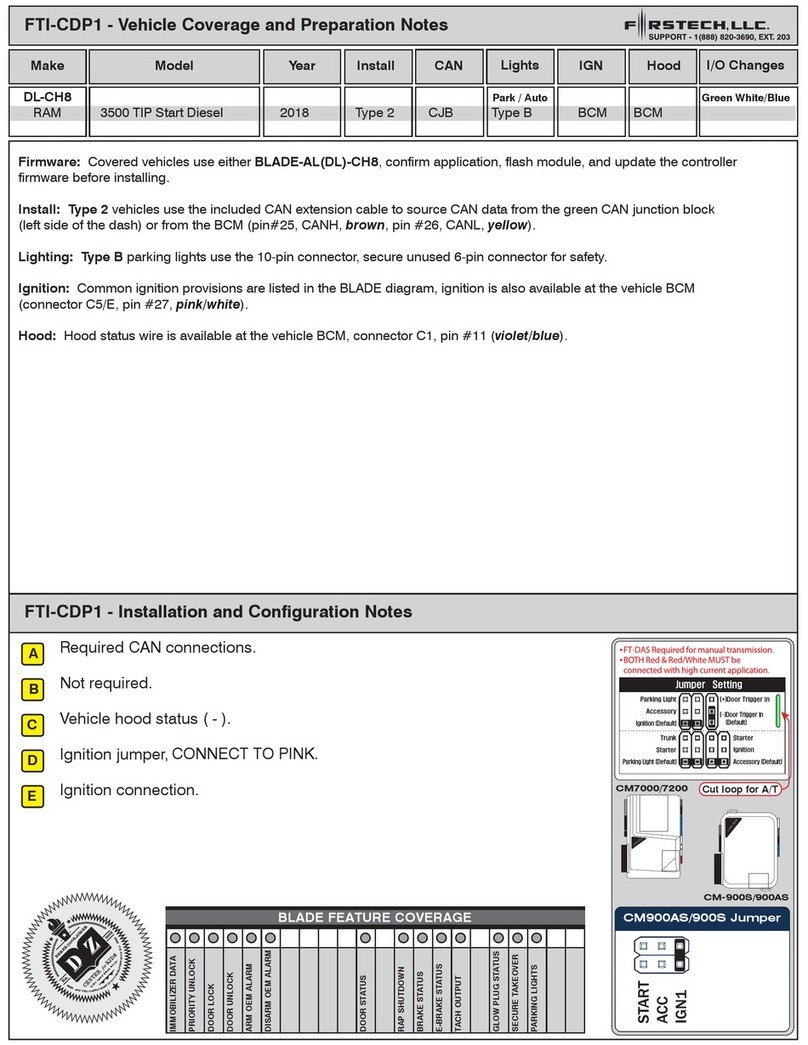

Firstech BLADE Series install guide

Metra Electronics

Metra Electronics CHTO-013 installation instructions