Tormax Automatic Smart Drive 1101 User manual

Installation On Site

for Automatic Swing Doors SWINGDOOR

Smart Drive 1101

T-1132 e 3.03

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 3

First edition: 9.02 provisional for 0-Series

Update: 3.03

We print on environment-friendly paper bleached without chlorine.

The enterprises Landert Motoren AG and Landert GmbH are certified according to ISO 9001.

Contents

1 Introduction 4

2 Safety 5

2.1 General Safety and Accident Prevention

Regulations 5

2.2 Safeguarding Danger Points 6

2.3 Organizational Measures 7

3Basic Functions 8

4 Installation 10

4.1 Lintel Mounting Standard Linkage 11

4.2 Door Leaf Mounting Standard Linkage 12

4.3 Sliding Lever u 13

4.4 Panic Fitting u 14

5Mechanical Adjustments 15

6Electrical Connections 16

7Commissioning of the Automatic System 19

7.1 Commissioning with “Teach-In General” 19

7.2 Programming Procedure 19

7.3 Programming Examples 20

7.4.1 Programmable Functions 22

7.4.2 Effect of Homing in Speed and Angle for Homing in Speed Closing 23

7.5 Low Energy Applications 24

8Trouble Shooting 25

9Check List 26

Fold-out page

4Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

Addressee/Status

Area of Application

1Introduction

These instructions are addressed at qualified installation personnel and contain all

required information for the installation on site.

This document is applicable to automatic TORMAX doors of type SWINGDOOR Smart

Drive 1101.

Non-compliance endangers the safety of the installation personnel, the system operator

or the user.

Warning of electrical voltage.

Passages with text on grey background must be absolutely observed for reliable

performance of the system! Neglect can cause material damages.

This symbol marks optional components, which are not installed in all units.

These instructions are available in different languages. Please ask your TORMAX

dealer.

For installation and commissioning of this system, the following instructions and data

sheets are useful; get hold of these documents before beginning the assembly work!

•Operating instructions T-1134 e

•Wiring diagram lintel mounting T-1135 e

• Wiring diagram door leaf mounting T-1154 e

•Drilling template T-1138

•Dimensional drawings standard linkage lintel mounting T3-386-40

•Dimensional drawings standard linkage door leaf mounting T3-386-41

•Dimensional drawings sliding lever lintel mounting T3-386-42

•System test book International: T-895 e

Explanation of Symbols

◆

!

SWINGDOOR

Smart Drive 1101

Languages

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 5

2Safety

2.1 General Safety and Accident Prevention

Regulations

Prior to installation or commissioning, read and follow this information that is being

described on this page—especially the following notes relating to safety—and adhere to

them at all times! Damage to the unit and personal injury may result if these instructions

were not carefully followed.

Pay particular attention to the specially marked notes in this manual (for an explanation

of the symbols please refer to chapter 1)!

TheseproductsareUnderwritersLaboratories,Inc.(UL)listedandcULcertifiedfor

the Canadian marketplace, and therefore comply with the requirements of the

National Electrical Code (NEC) and the Canadian Electrical Code (CEC). Installa-

tionsintendedtomeetULandcULrequirementsmustbefollowedasdescribedin

the instruction provided herein. These are minimum standard requirements.

Where local codes exceed these requirements, they must be followed as well.

Preventing General Hazards and Possible Damage to This Equipment

• Keep fingers away from all moving parts.

•Verify that the power selection switch is set to the correct voltage before start-up.

•The power supply cable (flexible cord) should be entered at the end side that is close

to the input power supply plug. It should not be routed through doorways, window

openings, walls, ceilings, floors, etc. The power supply cable (flexible cord) should not

be attached or otherwise secured to the building structure. It should not also be

concealed behind walls, etc.

•Never allow the power supply cable (flexible cord) to become entrapped in moving

parts of the operator, door, or system.

•The power receptacle must be of the grounding-type. It is very important that the unit

will be properly grounded.

•To reduce the risk of electrical shock, this equipment has a grounding-type plug that

has a third grounding pin. This plug will only fit into a grounding-type outlet. If the plug

does not fit into the outlet, contact a qualified electrician to install the proper outlet. Do

not change the plug in any way.

Warnings of Dangerous Electrical Voltages or Current

•Be sure the electrical power is disconnected and locked-out when working on the

operator unit.

•Install the electrical cables and power only after the mechanical installation to the unit

is done.

•Turn on the power to the operator unit only after all internal cables are connected. Do

not connect cables while the unit is powered.

•Always use appropriate tools for installation and repair.

Prior to commissioning or performing any work on the door system, the operating

instructions for the TORMAX operator and the following safety directions should be

studied with great care and must be observed!

In any case, please pay attention to the specially marked notes within this document (see

chapter 1 for an explanation of symbols).

General safety Instructions

!

6Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

The TORMAX operator is designed according to the current state of technology as well

as the recognized safety-relevant regulations and is intended exclusively for the

deployment in conjunction with automatic interior and exterior doors (without wind loads)

used by people e.g. in hospitals, homes for the elderly, shopping centres, office buildings

and large-scale enterprises. The operator corresponds to protective class IP 22. Without

additional safety precautions, it may only be installed within, i.e. at the inside, of buildings.

Any other use or any use exceeding this aim is determined to be not for its intended

purpose and may lead to personal injury to the user or a third party. Furthermore, the

system or other material assets can be damaged. The manufacturer will not be

responsible for any damage resulting from this; the risk is carried entirely by the operator

of the door system.

The operating, service and maintenance conditions specified by the manufacturer are to

be maintained. The persons entrusted with the service and maintenance must be

acquainted with the matter and informed about any possible danger.

To ensure a reliable function of the door the moment of friction may not exceed 10 Nm.

In addition to the operating instructions, the legal and other obligatory regulations for

accident prevention and environmental protection, in the respective country where the

door system is operated, shall be applicable. The special directives for automatic doors

(e.g. of the European committee for standardization CEN) must be adhered to. Further-

more, the operational/national regulations apply.

Arbitrary changes to the system will exempt the manufacturer from any liability for

damages resulting from this.

2.2 Safeguarding Danger Points

General

Automatic door systems are to constructed in such a manner that on opening and closing

motions endangerments through jamming, shearing and drawing-in are avoided or

safeguarded against, for example through:

–Safety separations

– Limitation of the door-leaf forces

–Monitored safety facilities

–Separating protective facilities

Sufficiently dimensioned minimum safety distances to prevent crushing are:

–for fingers or hand 25 mm

–for the head 200 mm

–for the body 500 mm

Fingers are unlikely to penetrategaps ≤8 mm in powered pedestrian door installations.

The safety measures may be used in combination.

Use for Intended Purpose

!

prEN 12650-2:2002

Maximum Door Leaf Weights

0

50

100

150

200

250

300

350

400

450

0.6 0.8 1 1.2 1.4 1.6

Leaf width

Door leaf weight

kg

m

T1132/40e

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 7

Automatic Swing Doors

Door leaves may not open directly into areas in which other transit traffic takes place. If

door leaves open into an area in which there might be people, safety precaution are to

be taken if this is judged as necessary by the risk evaluation.

Danger points in the range of the opening motion are considered as safeguarded if:

–There is an adequate safety separation regarding the endangered parts of the human

body between the secondary closing edge and adjacent parts of the environment,

or

–The forces of the door leaves are limited to safe values,

or

–Monitored protective facilities will be installed between the secondary closing edge and

adjacent parts of the environment,

or

–The area of the secondary closing edge is protected with separating protective

facilities.

Danger positions during the closing motion are secured – depending on application – if

–The motion travel of a door leaf is continuously supervised through (error-proof and

monitored) presence sensors,

or

–Monitored protective facilities are installed at the main and/or secondary closing edge,

or

–The motion travel of a door leaf is secured with switching mats.

The leaves must be manufactured from materials that will not lead to a potential danger

of injury when breaking (e.g. toughened safety glass, compound safety glass etc. when

using glass).

2.3 Organizational Measures

The installation on site may be carried out only by qualified personnel who have sufficient

knowledge in the area of the power-operated doors due to vocational training and

experience and are acquainted with the relevant national workers protection rules,

accident prevention regulations, directives and generally recognized rules of the

technology to such an extent that they can judge the safe-for-working status of power-

operated doors.

Experience/vocational training in metal construction and in fastening techniques is a

requirement.

If necessary, qualified employees of the contract partner can make use of the training

offered by TORMAX (training courses).

Depending upon leaf weight, an assistant must be available for the installation.

•Use the system only in a technically sound state. Eliminate faults immediately that may

impair safety.

•Keep fingers away from any mobile parts. Special caution is required in the area of the

drive lever, the linkage and the secondary closing edges of the hinges.

•Use exclusively tools that are suitable for the respective work procedure. Pay attention

to good condition of the tools.

•Electric voltage/current: The operator is to be disconnected from electrical mains

before any work is performed on electrical parts.

Install cabling only after the installation is complete.

Plug in the power plug only after all internal cables are connected.

!

Requirements for Installa-

tion Personnel

Fundamental Safety Meas-

ures – Appropriate Behav-

iour

8Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

3Basic Functions

Motion Control – General

The door opens motor-driven in accordance with the adjusted speed against the installed

spring. Ahead of the open position, the motor torque is reduced and the door is braked

down by the spring. The door is held in the open position by a reduced motor torque. The

closing action is performed through spring force only. Thereby, the motor adjusts the

speed. At the completion of the closing motion, deceleration occurs with adjustable

homing in speed over an adjustable angle (see section 7.4.2). The motor is switched off

when the door is closed.

Functionality of the unit

Opens the door in operating mode AUTO and in operating mode OFF in accordance

with “Teach-In General”.

Opens the door in operating mode AUTOin accordance with “Teach-InGeneral”, or with

“Teach-In Key Switch” if this was performed after “Teach-In General”.

This prevents the door from opening. It stops the door during opening.

If both, the safety device in opening direction and the safety device in closing

direction, respond at the same time during a motion, the door stops in place. Through

“Teach-In General”, the safety sensor is disabled automatically over a predetermined

door swing range. If this function is not used, a jumper is inserted between 14–15.

Standard function:

Safety device in closing direction (safety sensor riding along in closing direction).

The door remains open. A commenced closing motion is reversed.

If both, the safety device in opening direction and the safety device in closing

direction, respond at the same time during a motion, the door stops in place.

Optional functions:

Safety device for the swing area

The door remains open or closed. A commenced motion is completed.

The safetydeviceinopeningdirectionhas a higher priority than the safetydevicefor

the swing area.

Safety Device Bodyguard

This function is only in use with the safety device “Bodyguard” of BEA.

The door remains open or closed. A commenced motion is completed. The safety

deviceinopeningdirectionhas a higher priority than the safetydevice“Bodyguard”.

Using this function automatically changes the settings of FeedbackDoorStateto “door

opening or door open”.This feature is compulsory for the function “Bodyguard”

(See Feedback Door State)

If these safety functions are not used, a jumper is inserted between 18–19.

Output for active testing of the safety device in opening direction and safety device

in closing direction (e.g. for Eye-Tech of BEA).

An opening can only be initiated through the key switch.

An opening can be initiated by an activator, a key switch and also by “Push and Go”

depending upon configuration.

Activator

Key Switch

Safety device in closing

direction/safety device for

the swing area/

Safety Device Bodyguard

Safety device in opening

direction

Test of safety devices

Operating Mode OFF

Operating Mode AUTO

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 9

Feedback Door State

The door opens and stops in open position. It opens according to the settings of “Teach-

In General”.

Unlocks on each opening command. On completion of the openingtimedelay, the door

starts opening. When the door has moved somewhat in opening direction, the door lock

drops off again. The door lock is activated only in proximity of the “door closed” position.

The feedback “door closed” (or “door open” if reconfigured) between 11–12 is only valid

as long as mains supply is available. This message is established as soon as the

processor considers the driving function as complete. Connection for 24 VDC relay or

signal light. Transistor output short circuit proof in relation to internal supply voltage

24 VDC / 0.75 A.

If a second opening width has been configured (Teach-In SS) the feedback “door open”

is as follows:

Triggering of opening Feedback defined by

Activator Teach-In General

Key-switch Teach-In key-switch

Push-and-Go Teach-In General

Manual operation the smaller of both opening widths

Using this function automatically changes the settings of FeedbackDoorStateto “door

opening or door open”.The other feed back types can be chosen, but have no effect

whatsoever. (See: Safety device Bodyguard).

The control system Smart Drive 1101 provides a power supply of 24 VDC for sensors,

doorlockand signalling. The power supply may be continuously loaded with maximally

0.75 A. With loads >0.75 A, the point LED on the display goes out. On overload, the unit

switches itself off automatically. In this condition, manual operation of the door is possible

with controlled spring closing action.

If the door hits a firm obstacle during opening, the motor driven opening procedure is

terminated immediately. If the door hits a firm obstacle during closing, the weak spring

closing force remains in existence. The next opening command opens the door again as

usual.

The door opens when an impulse is received, remains in the valid open position during

the valid hold-open time, and closes thereafter again.

The door opens when an impulse is received (from the key switch or an activator) and

remains in the open position. The door closes immediately after the next impulse. The

motional sequence depends on the settings of the respective “Teach-In”.

The motor is switched off immediately when the door is blocked.

Motor and transformer contain thermal relays that interrupt the current supply to the

control system at 110 °C. The system operates as during a power failure until the

temperature drops to 85 °C.

The door can be manually opened if the doorlockcan be unlocked with the door handle.

The door closes through spring force. The motor, which is controlled short-circuited,

controls the closing action with constant braking power. After return of power, the system

is immediately ready for use again.

Power Supply 24 VDC

Reversing Motion

Time Control

Step Control

Internal Protective Device

Power Failure

Door Lock

Operating Mode OPEN

10 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

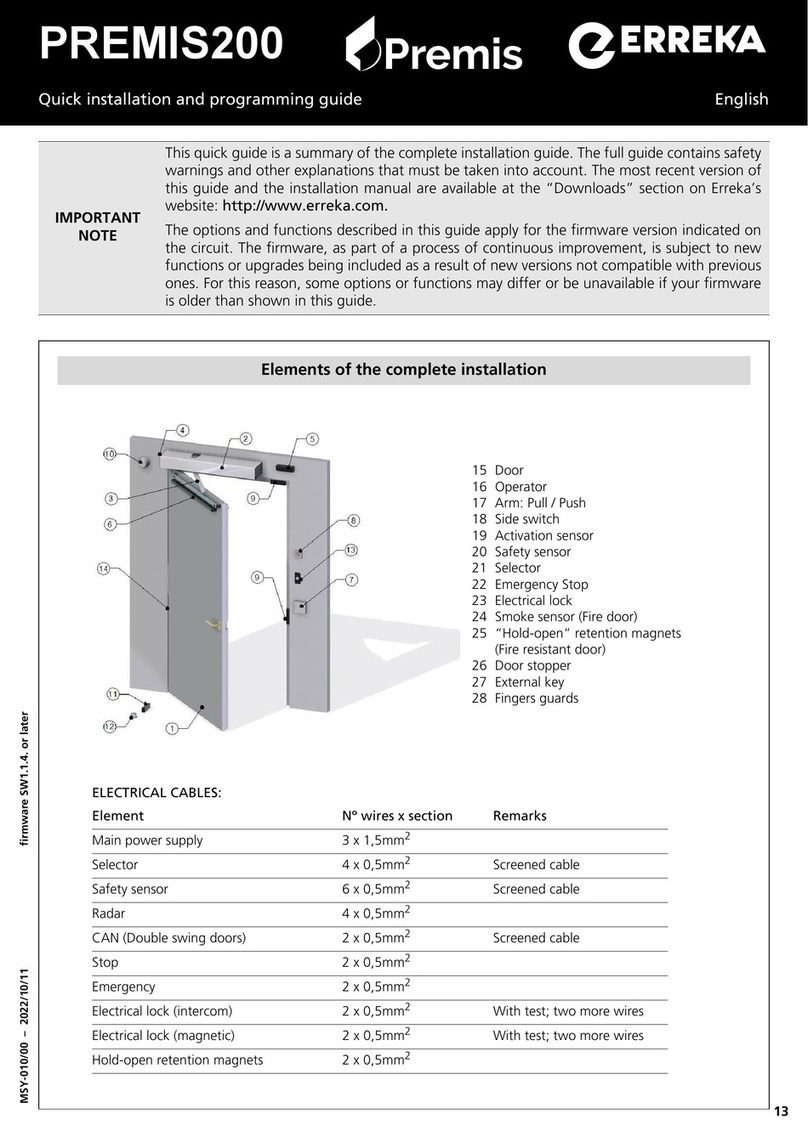

4Installation

T1132/9

T1132/10

T1132/11

T1132/13

T1132/16

T1132/14

T1132/15

T1132/17

T1132/18

T1132/19

T1132/20

T1132/21

see 4.1

see 4.2

see 4.3

see 4.4

Overview of mounting methods

T1132/24

T1132/22

T1132/45

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 11

4.1 Lintel Mounting Standard Linkage

T1132/10

T1132/28

L

A

B

45

C

E

F

D

310

540

50

I

90°

M

H

G

80

K

M

T1132/25

8

23

80 310

290

540

20

50

2x Ø7

4x Ø7

30

580

290

20

Z

Y

45

20

X70.5

116

85

YZ

0 – 10 33

X

–40…+107 +105…+252

0 – 70 93 –40…+107 +105…+252

A) Glue on template

B) Drill holes

C) Attach cone, length according Y, surfaces parallel to side

plates

D) Tighten hexagon-socket screw

E) Fasten operator

F) Fasten bearing trestle according to dimensional specifi-

cations on door leaf

G) Attach connecting part at right-angle to the operator to

cone (length in accordance with Y)

H) Interconnect bearing trestle and adjustment member

I) Adjust adjustment member at right-angle to the lintel and

tighten screws

K) Interconnect connecting part and adjustment member

L) Fasten covers

M) Snap in side plates

12 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

T1132/10

4.2 Door Leaf Mounting Standard Linkage

310

540

B

C

D

E

G

M

L

T1132/29

45

A

50

I

80

K

F

H

M

T1132/26

540

20

50

2x Ø7

4x Ø7

30

8

23 580

290

Z

Y

45

20

X70.5

116

85

20

80 310

290

YZ

0 – 10 33

X

–40…+107 +105…+252

0 – 70 93 –40…+107 +105…+252

A) Glue on template

B) Drill holes

C) Attach cone, length according Y, surfaces parallel to side

plates

D) Tighten hexagon-socket screw

E) Fasten operator

F) Fasten bearing trestle according to dimensional specifi-

cations on lintel

G) Attach connecting part at right-angle to the operator to

cone (length in accordance with Y)

H) Interconnect bearing trestle and adjustment member

I) Adjust adjustment member at right-angle to the lintel and

tighten screws

K) Interconnect connecting part and adjustment member

L) Fasten covers

M) Snap in side plates

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 13

4.3 Sliding Lever ◆

T1132/11

A) Glue on template

B) Drill holes

C) Attach cone (length according Y)

D) Tighten hexagon-socket screw in a way that the

cone can be turned by hand

E) Fasten operator

F) Fasten sliding rail according to dimensional

specifications on door leaf

G) Insert cover profile

H) insert bearing trestle into sliding rail

I) Mount side covers of sliding rail

Connect to mains,

Trigger factory reset, (see paragraph 7.3 programmimg table)

Choose operating mode OPEN (with operating mode switch ◆or by connecting terminals no 2 and 3)

axis will turn 20°

K) Slide connecting part over cone and push up to the operator

insert other end completely into bearing threstle, tighten cone Konus (hexagon-socket screw) and connecting part

L) Fasten covers

M) Snap in side plates

C

D

E

GK

A

B

450

250

45

F

H

I

I

T1132/38

M

M

T1132/39

UW

0 – 20 59 ±3

X

0…+150

0 – 80 119 ±3 0…+150

540

20

4x Ø5

4x Ø7

30

160 + x/2

290

20

23

32

250

40

140

140

350

X

20

70.5

116

W

U

3±3

85

580

8

140

45

49

500

14 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

4.4 Panic Fitting ◆

T1132/11

C

D

G

K

A

B

540

250

45

F

H

I

T1132/23

E

400

100 ... 300

L

N

M

M

UW

0 – 20 59 ±3

X

0…+150

0 – 80 119 ±3 0…+150

X

20

70.5

116

W

U

3±3

85

45

49

540

20

4x Ø5

4x Ø7

30

290

20

23

32

250

580

8

4x Ø5

34

19

160 + X/2

350

130

130 130 110

700

T1132/44

A) Glue on template

B) Drill holes

C) Attach cone (length according Y)

D) Tighten hexagon-socket screw in a way that the

cone can be turned by hand

E) Fasten operator

F) Fasten hinge of panic fitting and holding plate

according to dimensional specifications on door

leaf

G) Adjust the desired holding force of the magnet by

sliding it in the rail.

H) insert bearing trestle into sliding rail

I) Mount side covers of sliding rail

Connect to mains,

Trigger factory reset, (see paragraph 7.3 programmimg table)

Choose operating mode OPEN (only with operating mode switch ◆or by connecting terminals no 2 and 3)

axis will turn 20°

K) Slide connecting part over cone and push up to the operator

insert other end completely into bearing threstle, tighten cone (hexagon-socket screw) and connecting part

L) Fasten cover

M) Snap in side plates

N) Fasten rubber stop on the lintel, so that the connecting part will rest on it, when triggering the panic fitting.

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 15

5Mechanical Adjustments

The internal OPEN end-stop is only to be used as a safety device (e.g. wind load, manual

operation). In automatic operation it must not be hit!

•Open the door to the greatest possible opening width and secure it.

• Adjust the OPEN end-stop.

The door should only be opened so far that the standard linkage cannot tip over and the

sliding lever does not leave the rail.

Door in open position at the end stop (internal

OPEN end-stop or door stopper).

T1132/30

!

!

max. 170 °

T1132/35

16 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

6Electrical Connections

Observe wiring diagram T-1135 e for lintel mounting and T-1154 e for door-leaf mounting!

A system switch must be mounted on site.

Before beginning the work described here check that the mains supply is switched off.

If possible, route the mains connection along the side of the power supply to the operator.

The connecting cables must be of the type “PVC cable H05VV-F” or “rubber hose cable

H05RR-F”.

Round the edges and remove burrs from all conduits used for the mains connection.

•Remove mains supply cover (1).

•Connect the mains cable to terminal (11) in

accordance with figure.

•Route the mains cable either through the

prepared holes of the side cover or through

the slots in the mounting plate.

•Use only cable bushings made from syn-

thetic materials. Metallic bushings are to be

earthed.

•Check correct adjustment of the voltage

selector (12) and reinstall the mains supply

cover (1).

•Secure mains cable with a cable strap at the

plastic nub (17) and at the supporting metal

sheet.

•Mount the emergency-off switch in accordance with the contract order and route the

mains connection via emergency-off switch.

•Mount in accordance with contract order

•Connect in accordance with connection diagram and the manufacturer’s specification

•Adjust the detection field/sensitivity and action radius according to the requirements

and the surroundings of the system.

10AT

L1 3mm

N

230/115V~

50/60 Hz

T1132/1

!

Mains Connection

Emergency-off Switch ◆

T1132/34

L1

N

12

11

1

Activator and Safety

Facilities ◆

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 17

Terminal Connections

Legend:

*programmable

+24 V 24 VDC (21 … 24 VDC)

IN Input 24 VDC / 3 mA

OUT Output NPN integrated protective diode

T1132/3e

1 2 3 4 5 6 7 8 9 10 11 12

IN

GND

IN

GND

IN

+24 V

GND

IN

OUT

+24 V

OUT

+24 V

Activator

Status indication

door closed/*open

OFF

AUTO

OPEN

Key switch

Door lock 24 VDC

locked currentless

* unlocked currentless

–

+

No protective

circuit necessary

T1132/6e

Safety devices without

monitoring

13 14 15 16 17 18 19 20

–

+

GND

IN

OUT

24 V

GND

IN

OUT

24 V

+

+

–

+

Safety device

in opening direction

Safety device in

closing direction /

*Swing area

Safety devices with

monitoring

Safety device

in opening direction

13 14 15 16 17 18 19 20

Safety device in

closing direction

BEA

Eye-

tech

–

+

BEA

Eye-

tech

–

+

1

7

6

5

2

8

7

6

5

2

8

GND

IN

OUT

24 V

GND

IN

OUT

24 V

+

+

1

18 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

Safety Device

BEA Bodyguard

T1032/7

8

!

Do not connect safety devices with monitoring and without monitoring in combination.

Overall, the 24 V power supply may be loaded with max. 0.75 A, on overload the point

LED goes out.

GND

+24 V

OUT

IN

GND

+24 V

OUT

IN

T1132/41

BEA

LO-21 BEA

Bodyguard

6orange

4weiss

8rot-weiss

9braun

6

7

5

3

1

13 14 15 16 17 18 19 20

2

Sicherheit

öffnen

910 11 12

+24 V

OUT

21

schwarz

rot

Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e 19

7Commissioning of the

Automatic System

•The sensors, safety facilities and operating devices are professionally installed,

connected and preset.

•The operator is mounted professionally and the linkage is attached.

•The linkage and the internal end stop are adjusted and coordinated.

•The mains cable is expertly laid and connected.

•The system is switched on and is in operating mode AUTO.

•The point LED at the digital display is illuminated.

7.1 Commissioning with “Teach-In General”

During commissioning and in particular during “Teach-In” no people or items may be

present in the swing area of the door!

1. Push simultuaneosly the yellow and the blue key ➞ programming mode is active. (No

number is visible on the digital display yet).

2. Press yellow key once ➞display 0 is illuminated for max. 5 s.

(function “Teach-In” is now selected)

3. Press blue key once ➞display 0 flashes

(“Teach-In General”is now ready for execution)

4. Open the door by hand with the desired speed, keep it open as long as desired and

close it with the desired speed (the speeds are limited upward by the motor and the

spring force).

5. Open the door by way of the activator ➞the operator now opens the door and

reproduces the manually performed operational sequence for opening and displays

the sequence with the numbers 1 to 3 on the digital display.

During this sample opening sequence, the safety device in opening direction is

disabled automatically starting from the door position from where it responds. The

detection of the wall is thereby ignored for all following door openings.

“Teach In” is finished on completion of this test run. The learned values are now

stored. The function is departed automatically.

6. Check the safety facilities in opening and closing direction to find out whether they

react to a test object in the given swing area (see operating instructions T-1134

section 4.2).

Attention: Changing the position of the linkage requires a new Teach-In.

7.2 Programming Procedure

(See table in section 7.4)

Smart Drive 1101 possesses many useful features and parameters. These can be

programmed through 2 keys and a digital display as follows:

•Push simultuaneosly the yellow and the blue key ➞programming mode is active. (No

number is visible on the digital display yet).

•Select the desired function (1st number) with the yellow key.

•Press the blue key for confirmation of your choice.

➞2nd number (parameter) flashes.

•Modify the parameter with the yellow key as desired.

•For storage of the adjusted parameter, press the blue key again.

The procedure is thus complete and the 1st number (function) is displayed again.

Prerequisite

!

T1032/7

8

20 Installation On Site SWINGDOOR Smart Drive 1101 T-1132 e

If no action takes place for 5 s during programming, the procedure is aborted without

effect. (Return to functions or leaving programming mode). Exceptions are the Teach-

In functions (0), which can be cancelled by prssing the blue key, as long as the door

has not been moved.

The input and outputs are inactive as long as the control system is in the programming

mode.

7.3 Programming Examples

Program the desired functions now in sequence in accordance with the programming

table. The individual functions are described in section 7.4.

Check the programming options immediately after they are set!

Changing the opening time delay to 1.2 s.

•Read values from the programming table.

•Push simultuaneosly the yellow and the blue key ➞programming mode is active. (No

number is visible on the digital display yet).

•Press the yellow key several times until the number 3 appears on the display

➞Number 3 is lit (function)

•Press the blue key once for confirmation of the choice

➞Number 0, or the value programmed last, flashes (parameter)

•Press the yellow key several times until the number 3 appears

➞Number 3 flashes (parameter)

•Press the blue key once for storage of the adjusted value

➞Number 3 is lit (function)

Examination of the last programmed value of the release angle for the function

“Push and Go”.

•Push simultuaneosly the yellow and the blue key ➞programming mode is active. (No

number is visible on the digital display yet).

•Press the yellow key several times until the number 1 appears on the display

➞Number 1 is lit (function)

•Press the blue key once for confirmation of the choice

➞The last programmed value is now displayed and is flashing

The value associated with the displayed number can be inferred from the programming

table.

•Wait 5 s

➞The LED shows no 1 lit

•Wait 5 s

➞The point LED is lit

(programming was aborted automatically without any changes)

Factory reset

•Push simultuaneosly the yellow and the blue key ➞programming mode is active. (No

number is visible on the digital display yet).

•Press the yellow key several times until the number 9 appears on the display

➞Number 9 is lit (function)

•Press the blue key once for confirmation of the choice

➞Number 0 flashes (parameter)

•Press the yellow key once

➞Number 1 flashes (parameter)

• Press the blue key once to execute the factory reset

➞The point LED is lit

Example 2

Example 3

Example 1

Table of contents

Other Tormax Automatic Door Opening System manuals

Tormax Automatic

Tormax Automatic TORMAX 2201 User manual

Tormax Automatic

Tormax Automatic 2101 User manual

Tormax Automatic

Tormax Automatic iMotion 2202 User manual

Tormax Automatic

Tormax Automatic iMotion 1302.KI User manual

Tormax Automatic

Tormax Automatic Win Drive 2201 User manual

Tormax Automatic

Tormax Automatic T-1165 Operating instructions

Popular Door Opening System manuals by other brands

Label

Label NEXT 120s installation manual

Entrematic

Entrematic Ditec SPRINTSET installation manual

Label

Label NEXT 75 user manual

Entrematic

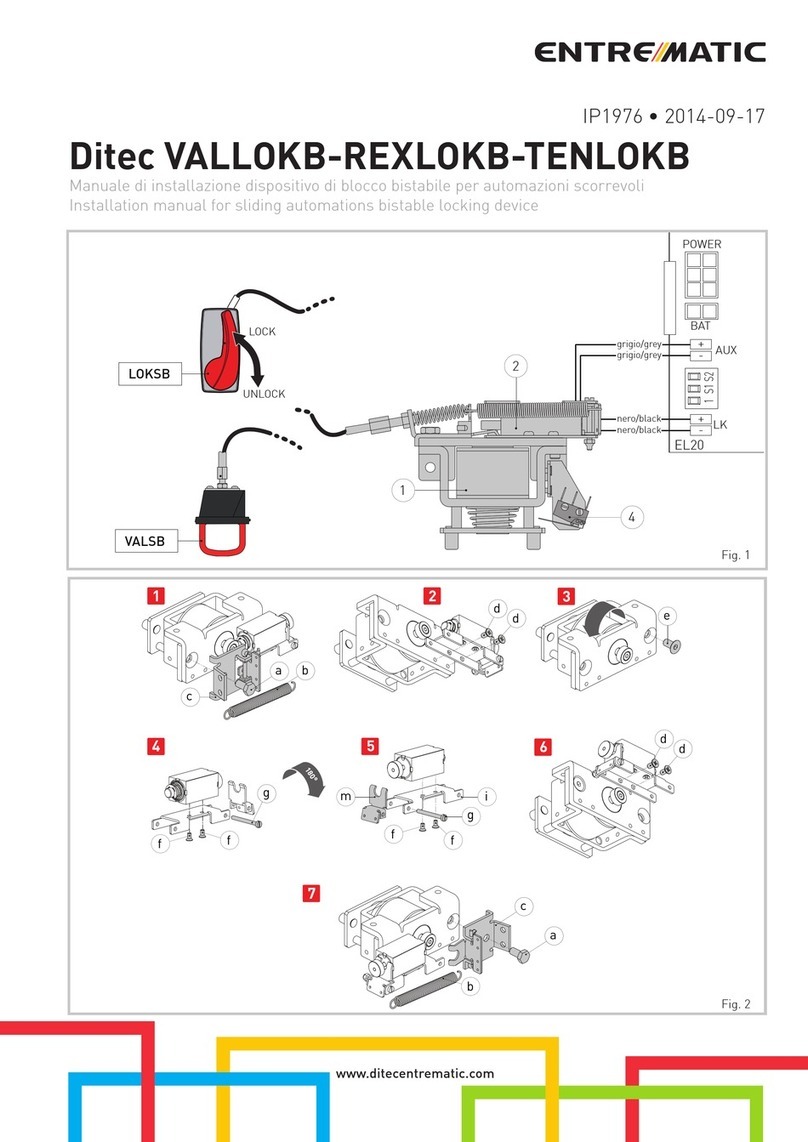

Entrematic Ditec VALLOKB installation manual

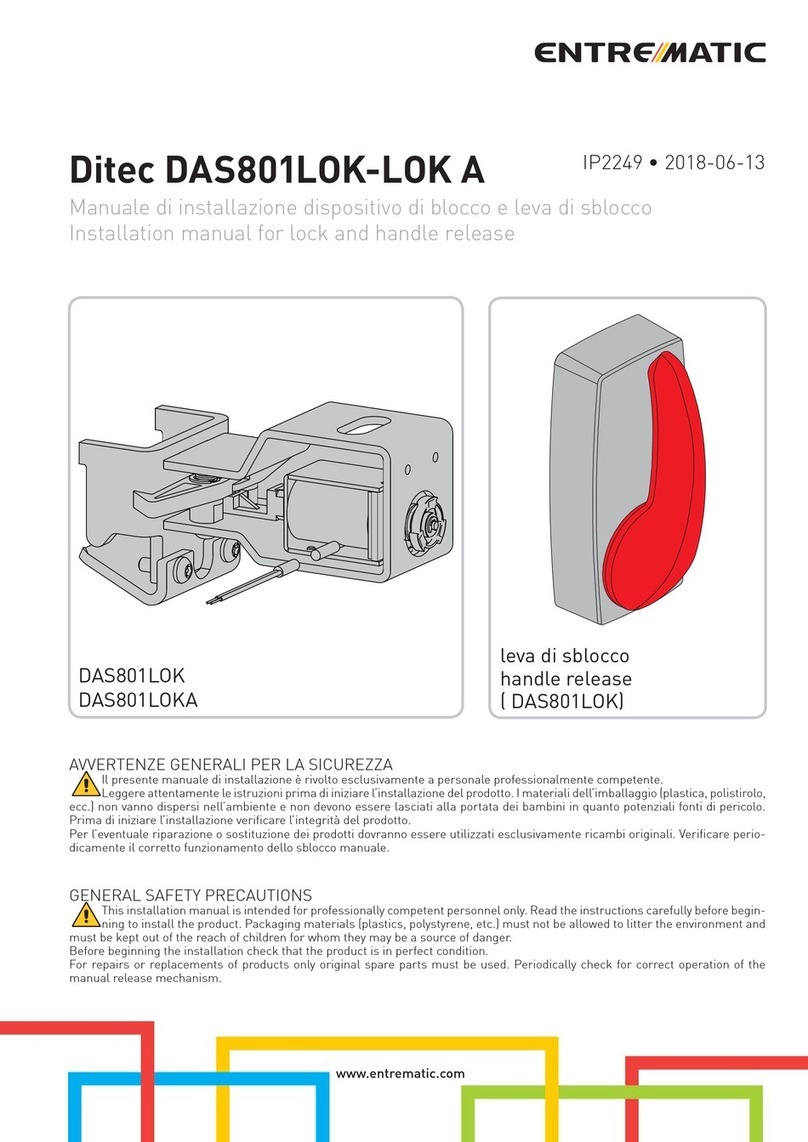

Entrematic

Entrematic Ditec DAS801LOK installation manual

Keyautomation

Keyautomation TURBO Instructions and warnings for installation and use