21

Tech. Support Menu ( + + ) (I)

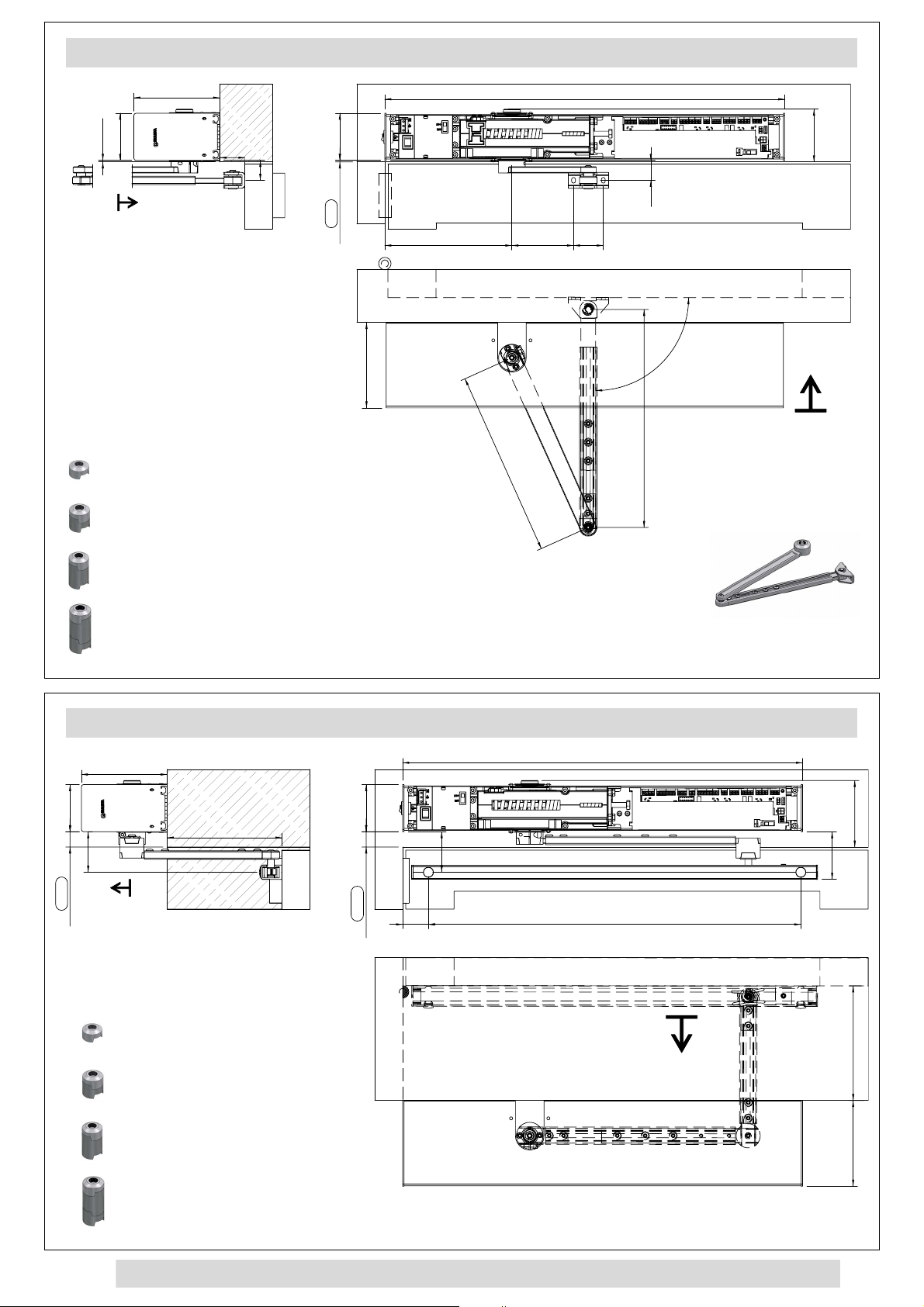

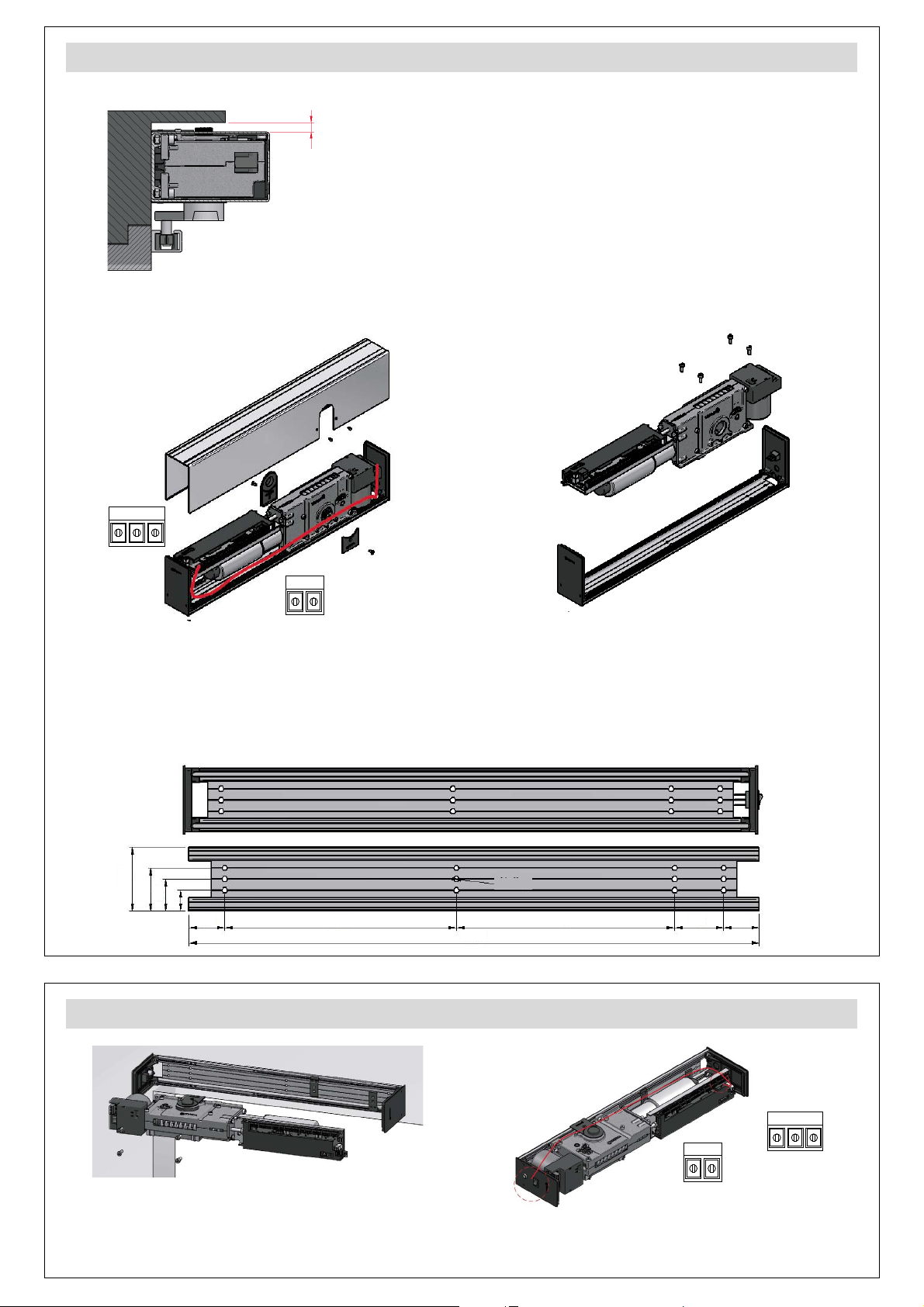

Door Handling *

Door Handling is determined by

standing your back to the

hinges. The side to which the

door normally opens (right or

left) is the opening sense.

1.1.- Setup Menu

1.1.1.- Door Learn Mode

1.1.2.- Factory Reset Restore default parameters

1.1.3- Setup Wizard Guided door configuration

1.2.- Basic Functions

1.2.1- Select Model

• Low Energy Speeds and forces limited according to

Standard EN 16005

•FullEnergy No speed and force limitations. Safety

sensors (EN 16005)

-Standard Standard swing door configuration

-Fire door Comply with fire regulations (EN

14637)

1.2.2.-Type Of Arm Define the type of arm installed

• Articulated - Push Arm

• Slide - Pull Arm

• Slide - Push Arm

1.2.3.-

Direction Of Travel Define the direction of travel

• Inwards

•Outwards

1.2.4.-

Opener Fixed To Define the operator's location

•Lintel

•Door

1.2.5.-

Door Handling* Define opening direction

• Right

•Left

1.2.6.- Door Details Define weight and width (Obligatory

for LOW ENERGY)

• Door Weight (kg) 50 to 250 kg, def. 50 Kg

• Door Width (mm) 700 to 1.400 mm, def. 700 mm

1.2.7.- Electric Lock

• Type Define if it has electro lock or not

-Electric Strike

-Maglock

-Disabled Door with no electro lock

• Voltage Define the power supply voltage

-12V

-24V

• Opening Delay 0 to 10.000 msec, def. 0 msec

• Opening Force 0 to 5, def. 0

• Test Define if the electro lock has a test

signal

-NO

-NC

-Disabled No test

RIGHT

LEFT

LEFT

RIGHT

1.3.- Advanced Functions

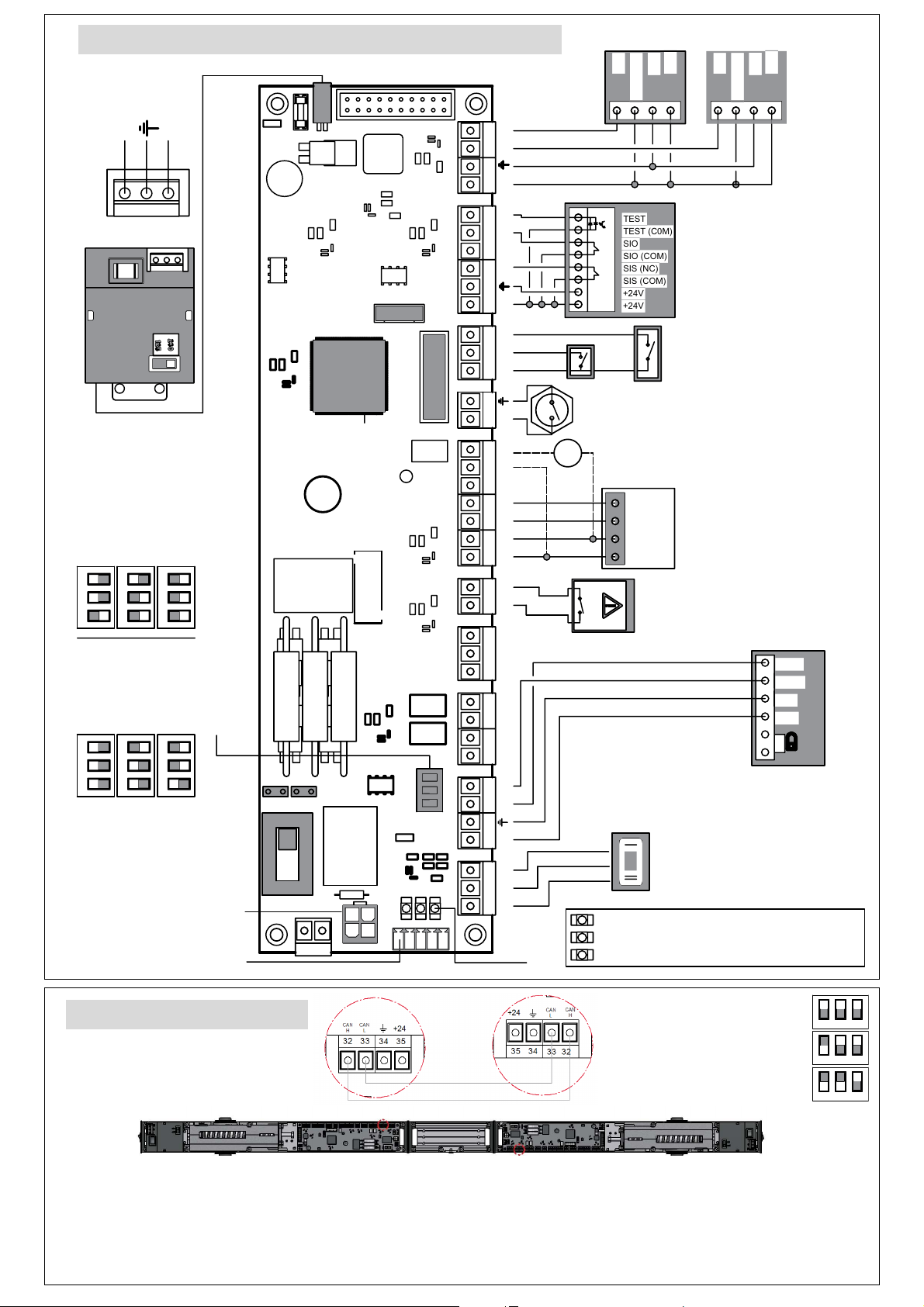

1.3.1.- Door Sync

• Select Door Define who leads the movements

-M1 Master (Leader) 1

-S1 Slave 1

•DoorSync

-Enable

·Disabled

· Enabled

-Sync Distance 0 to 45º, def. 0º

• Interlock Define interlock operation

-Enable

·Disabled

· Enabled

-Type

·Standard See “SAT Menu” in the “Installation

Guide”.

· Smart See “SAT Menu” in the “Installation

Guide”.

-Interlock Time 0 to 300 seg, def. 0 seg

1.3.2.- Automatic Mode Define operation in automatic mode

• Configuration Default configuration

-Normal Mode See “SAT Menu” in the “Installation

Guide”.

-Semi Auto Mode See “SAT Menu” in the “Installation

Guide”.

-Accessible toilets See “SAT Menu” in the “Installation

Guide”.

• Closing Device

-Motor Closing Closing with motor according to

parameters configured from selector

-Spring Closing Closing with spring. Engine released

and with passive brake

• Push&Go mode

See “SAT Menu” in the “Installation

Guide”. Def. Disabled. Degrees: 0 to

45º, def.: 0º

• Push&Close mode See “SAT Menu” in the “Installation

Guide”. Def. Disabled.

1.3.3.- Manual mode

• Normal mode

• Servo Assist mode 0 to 5, def.: 0

1.3.4.- Entrapment

• Sensitivity Level

1 to 10, def.: 5

(1 very sensitive, and 10 not very

sensitive)

• Sensitivity mode

-Standard See “SAT Menu” in the “Installation

Guide”.

-Extra Safe See “SAT Menu” in the “Installation

Guide”.

• Spring Closing

-Enabled

-Disabled

(...)