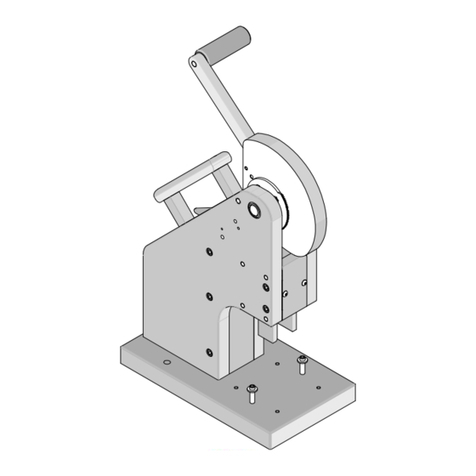

TM42 Termination Press

Order No: TM-690025099 Release Date: 08-08-02 UNCONTROLLED COPY Page 4 of 49

Re ision: H Re ision Date: 01-15-13

Table of Contents

Contents

Tm42 Termination Press ............................................................................................................................................... 1

Order No.69002-5099 .................................................................................................................................................... 1

Safety Warnings and Information .................................................................................................................................. 2

Table of Contents .......................................................................................................................................................... 4

Section 1 ................................................................................................................................................................... 6

General Description .............................................................................................................................................. 6

1.1 Description................................................................................................................................................. 7

1.2 Features .................................................................................................................................................... 7

1.3 Technical Specifications ............................................................................................................................ 7

1.4 Deli ery Check .......................................................................................................................................... 7

1.5 Tools .......................................................................................................................................................... 8

Section 2 ................................................................................................................................................................... 9

Installation............................................................................................................................................................. 9

2.1 Lifting/Mounting ....................................................................................................................................... 10

2.2 Reel Support Assembly ........................................................................................................................... 11

2.3 Foot Pedal and Power Connection .......................................................................................................... 11

2.4 Hand Rest................................................................................................................................................ 11

2.5 Safety and Work Area Check .................................................................................................................. 11

2.6 Bolster Shim Installation and Remo al .................................................................................................... 12

Section 3 ................................................................................................................................................................. 14

Setup and Operation ........................................................................................................................................... 14

3.1 Termination Die Set Installation and Remo al ......................................................................................... 15

3.2 Loading the Terminal Strip....................................................................................................................... 16

3.3 Punch and An il Alignment ...................................................................................................................... 18

3.4 Feed Finger Adjustment .......................................................................................................................... 18

3.5 Forward Feed Adjustment ....................................................................................................................... 18

3.6 Back Stroke Feed Adjustment ................................................................................................................. 19

3.7 Manually Cycling the Press ..................................................................................................................... 19

3.8 Conductor Crimp Punch Adjustment ....................................................................................................... 20

3.9 Insulation Crimp Punch Adjustment ......................................................................................................... 20

3.10 Operation ................................................................................................................................................. 21

Section 4 ................................................................................................................................................................. 22

Maintenance and Clutch Unit Ser ice ................................................................................................................. 22

4.1 Cleaning .................................................................................................................................................. 23

4.2 Lubrication ............................................................................................................................................... 23

4.3 Perishable Orders .................................................................................................................................... 24

4.4 Spare Orders ........................................................................................................................................... 24

4.5 Clutch Unit Ser ice Adjust/Repair ............................................................................................................ 24

4.6 Oiler ......................................................................................................................................................... 27

Section 5 ................................................................................................................................................................. 29

5.1 Parts List ................................................................................................................................................. 30

5.2 Assembly Drawings ................................................................................................................................. 33

5.3 Electrcal Parts List ................................................................................................................................... 37

5.3 Electrcal Schematic ................................................................................................................................. 38

5.4 Troubleshooting ....................................................................................................................................... 39

Appendix A .............................................................................................................................................................. 41

A.1 Conductor Brush and Terminal Position .................................................................................................. 42